Patents

Literature

35results about How to "Increase or decrease spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

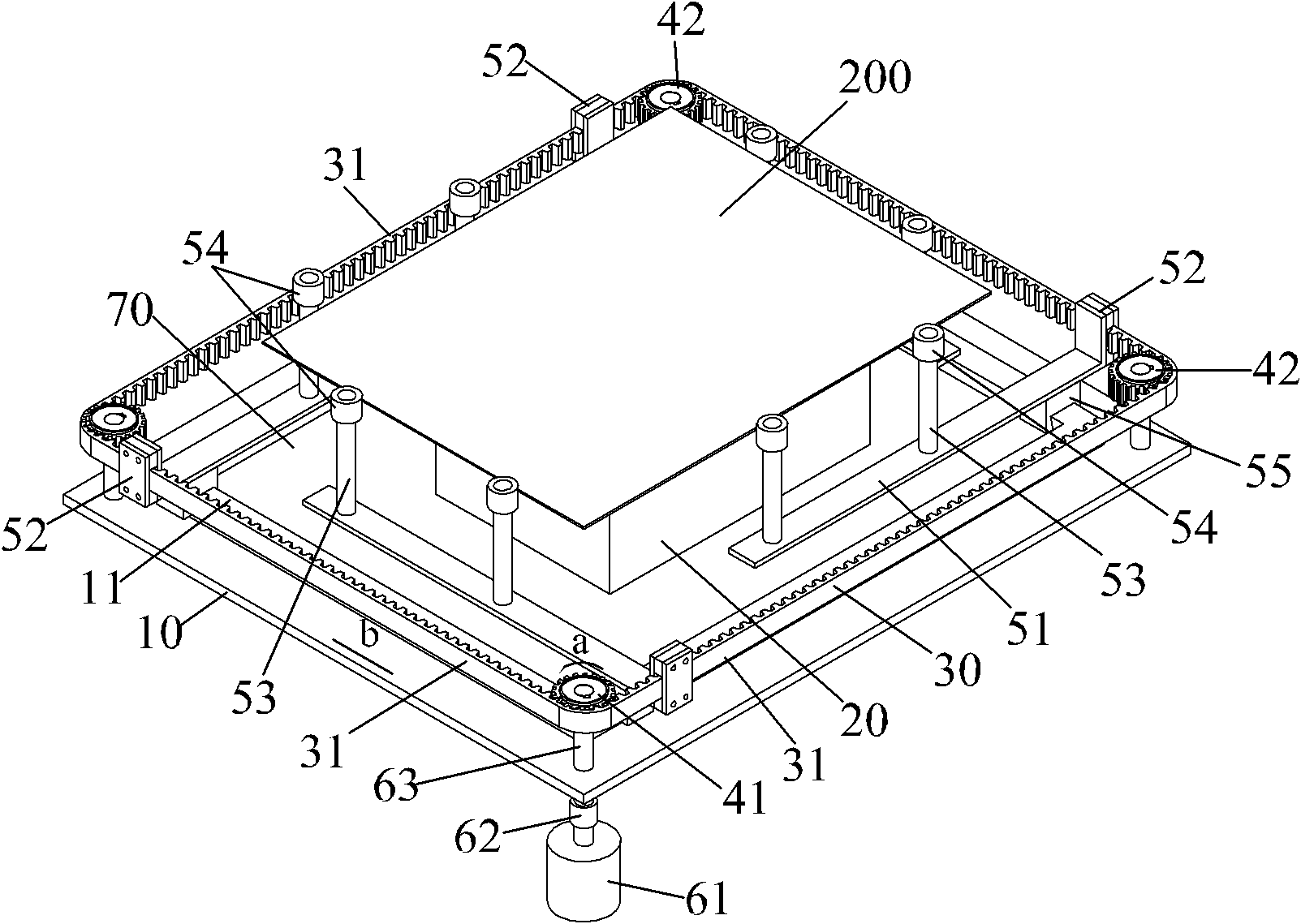

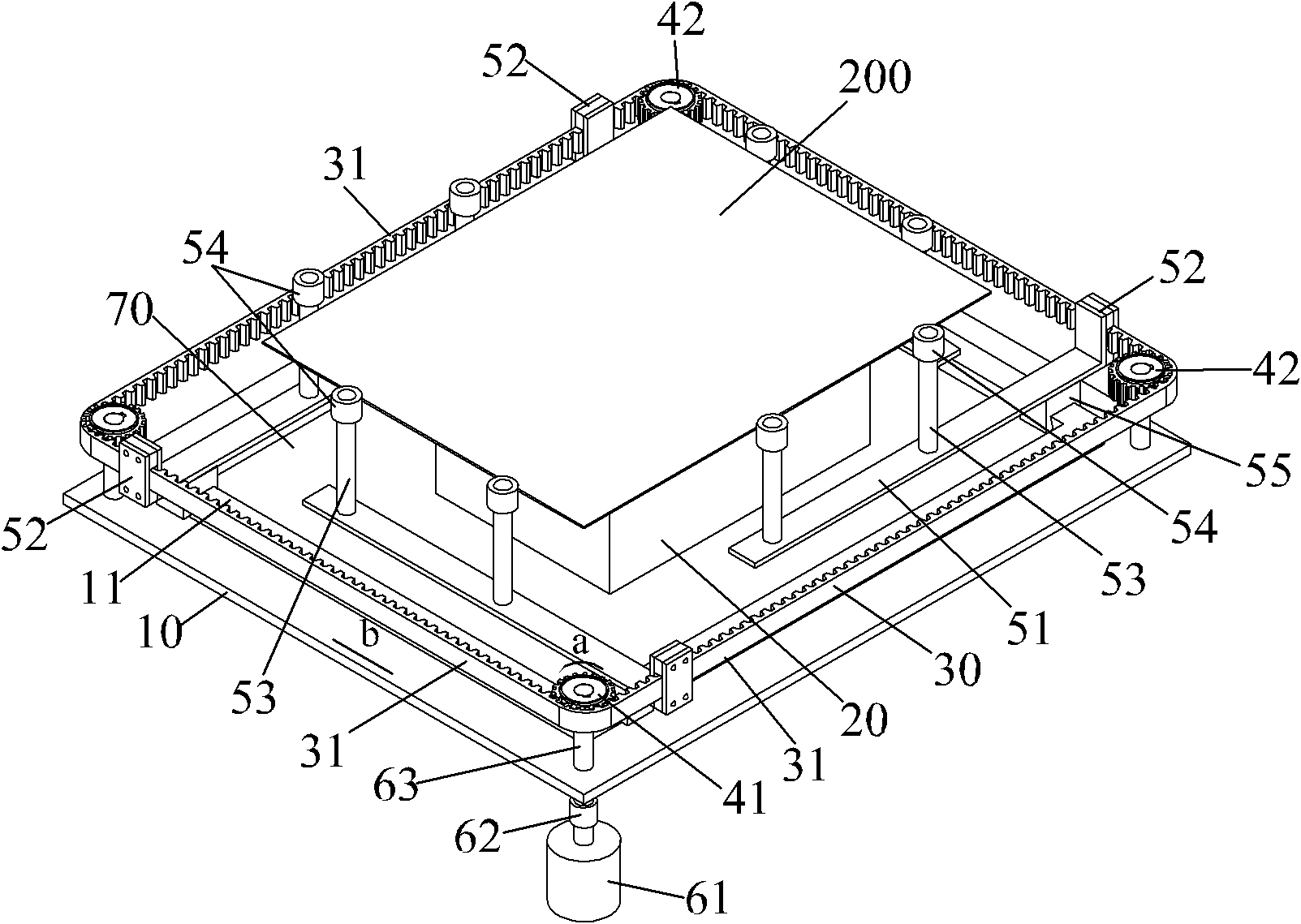

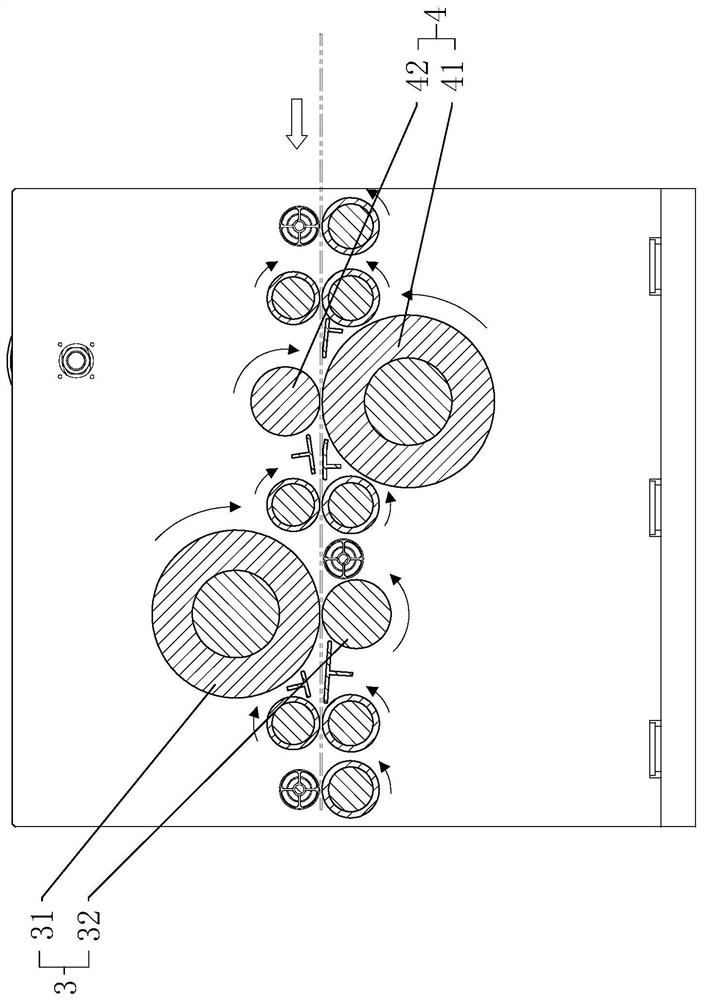

Accurate guiding and positioning equipment

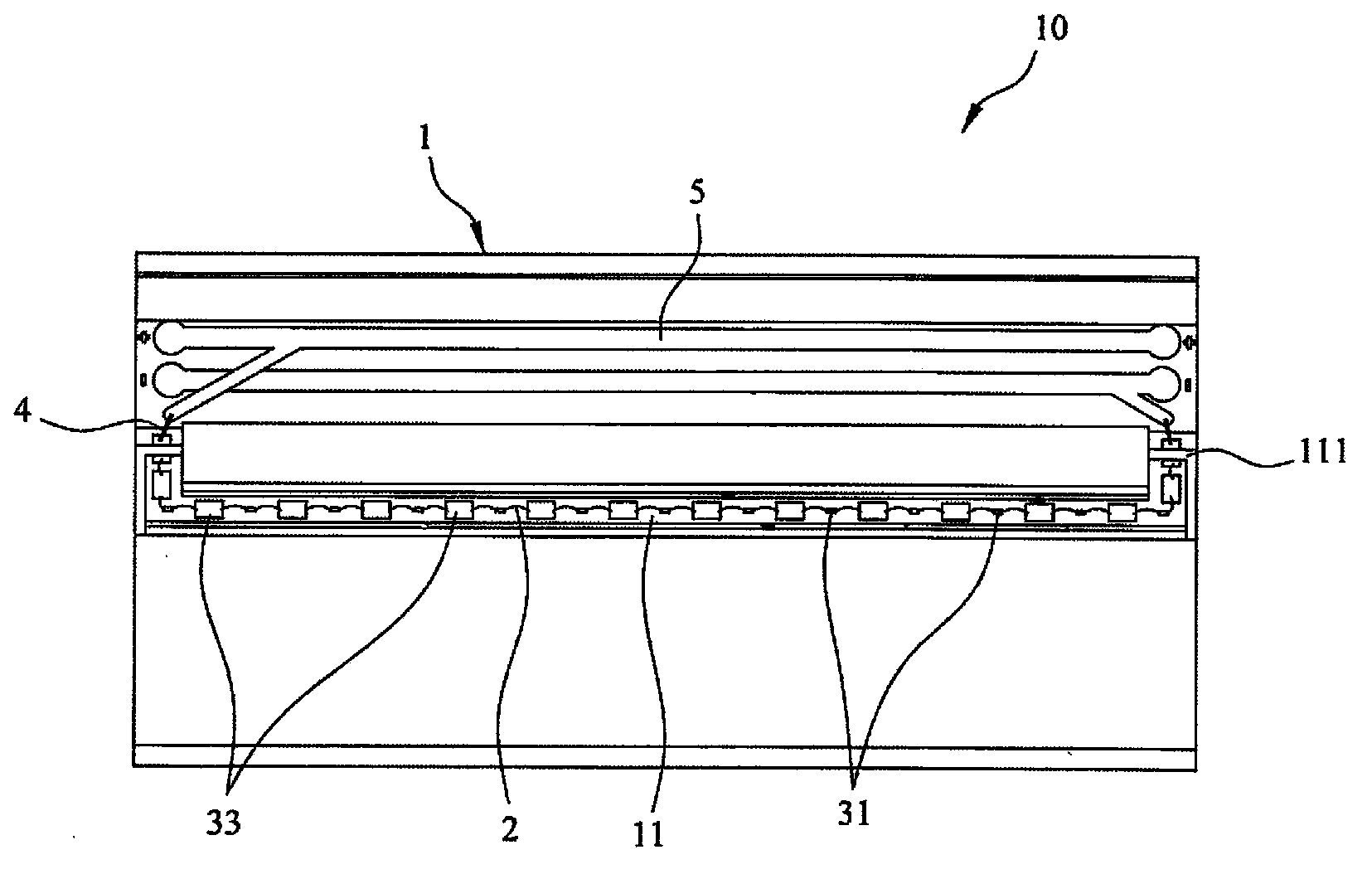

InactiveCN102180348AAchieve positioningAchieve alignmentCharge manipulationConveyor partsFlat glassEngineering

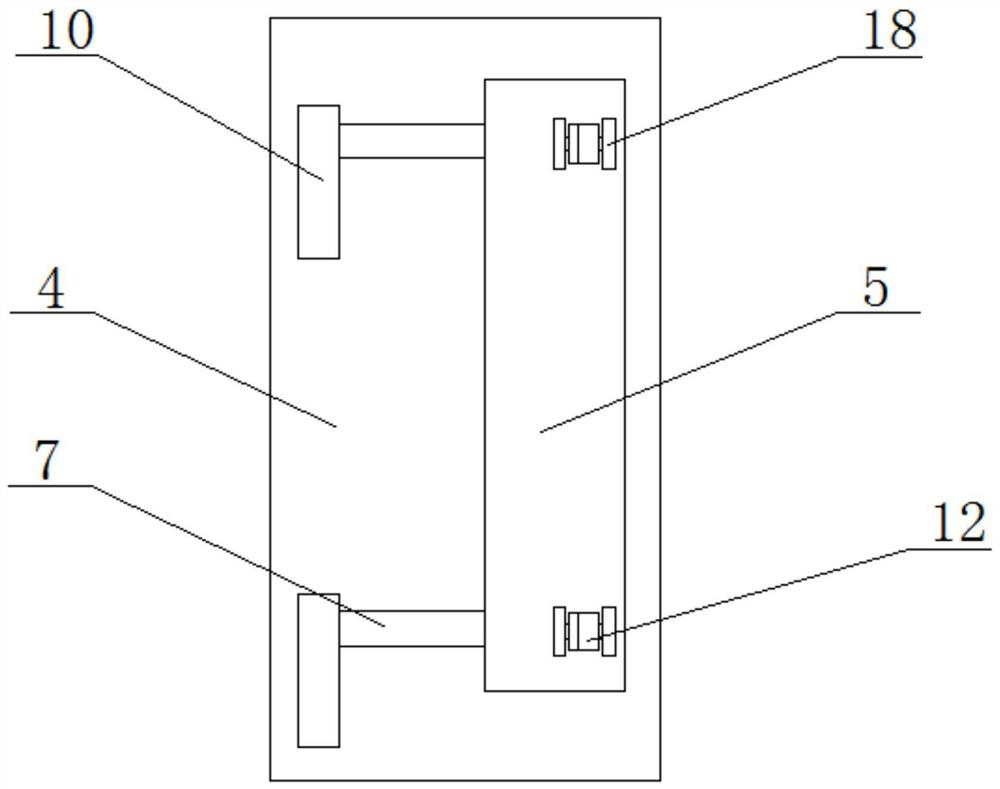

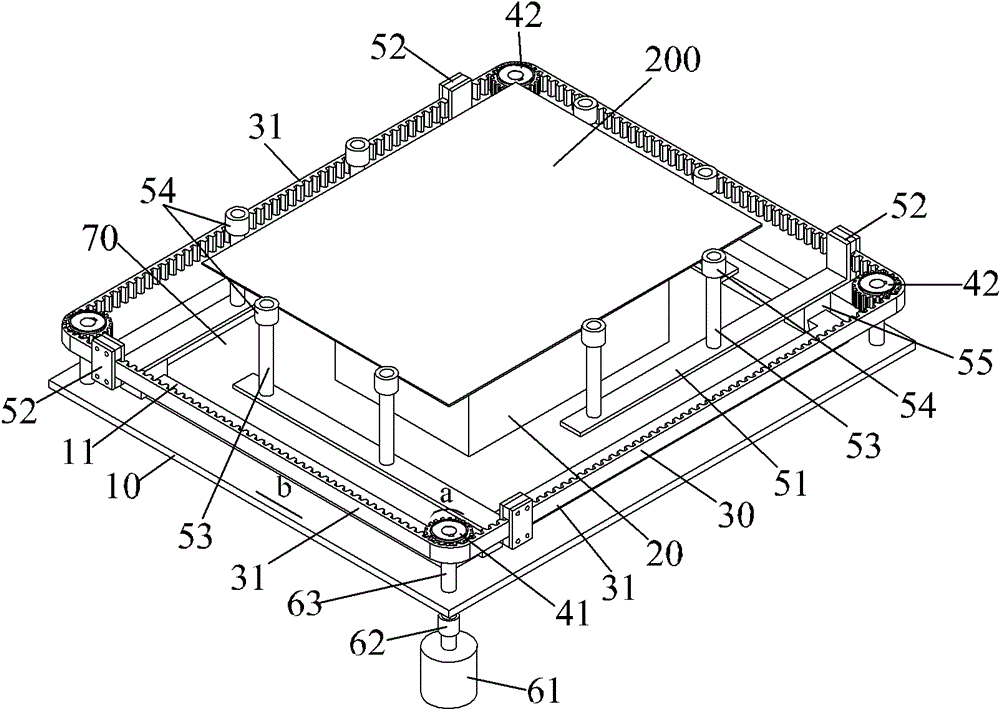

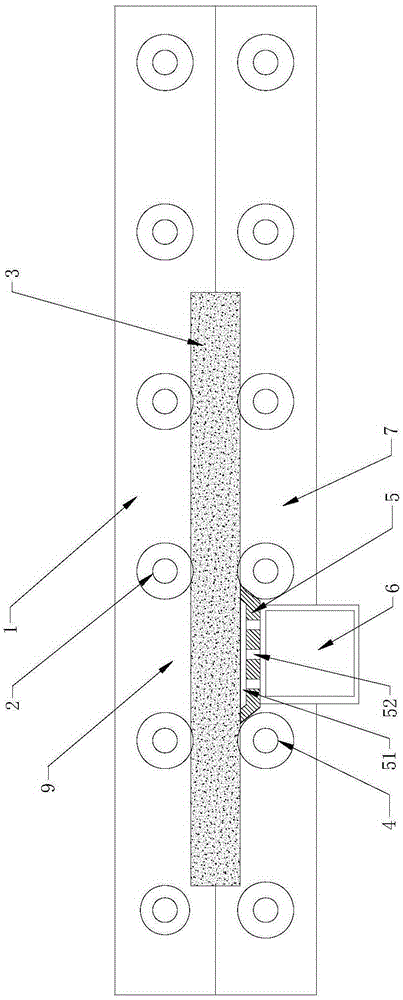

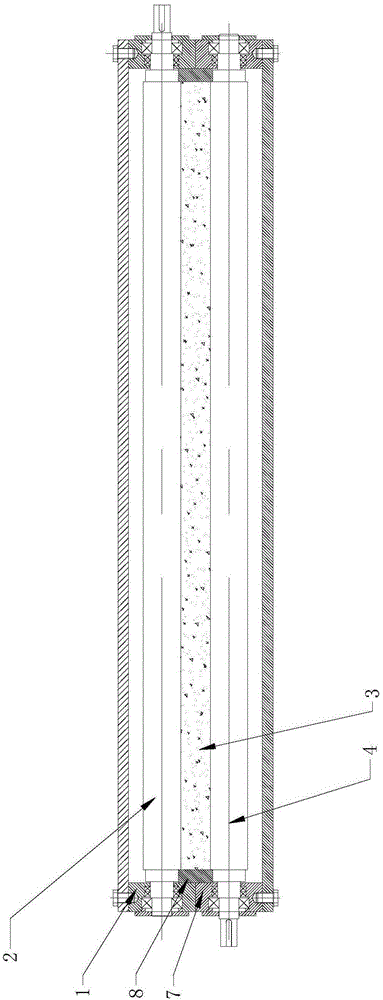

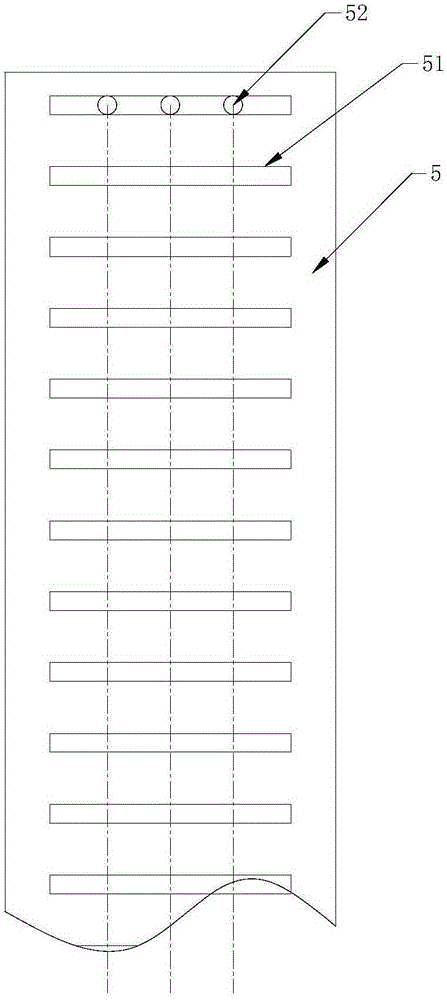

The invention discloses accurate guiding and positioning equipment which comprises a base plate, a power mechanism, a flat plate fixing base, a transmission piece, a plurality of transmission wheels and a plurality of positioning components. The transmission wheels are fixed on the periphery of the base plate; the transmission piece is wound on the transmission wheels; a machining region is formed on the inner side of the transmission piece; the power mechanism is connected with one transmission wheel; a sub transmission region is formed between two adjacent transmission wheels corresponding to the transmission piece; the positioning components are fixed on the input side of the sub transmission region; each positioning component comprises a guide wheel rod seat, a guide wheel fixed rod seat, a guide wheel fixed rod, a guide rod and a guide rail sliding block; the guide wheel fixed rod seat is fixed on a corresponding sub transmission region; one end of the guide wheel rod seat is fixedly connected on the guide wheel fixed rod seat, and the other end of the guide wheel rod seat extends into the machining region; the guide wheel fixed rod is fixed on the upper surface of the guide wheel rod seat; and the guide wheel is fixed at the upper end of the guide wheel fixed rod. The transmission piece drives the positioning components to move at the same time, so that a flat glass plate is positioned.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

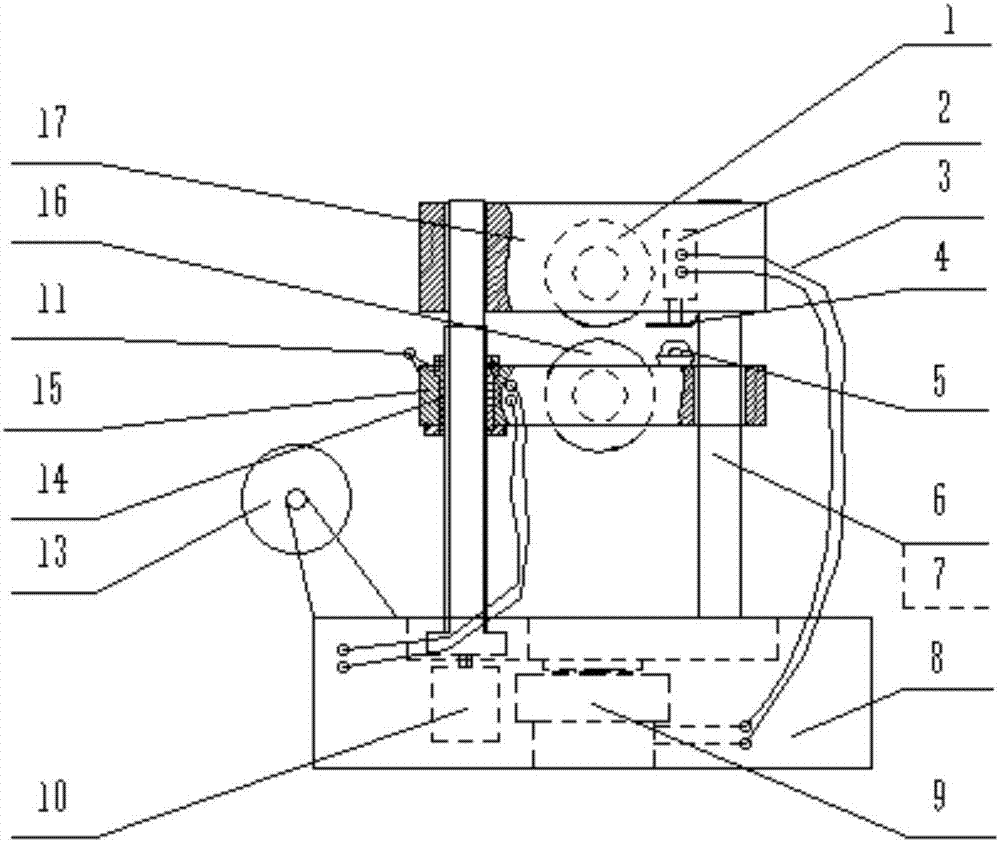

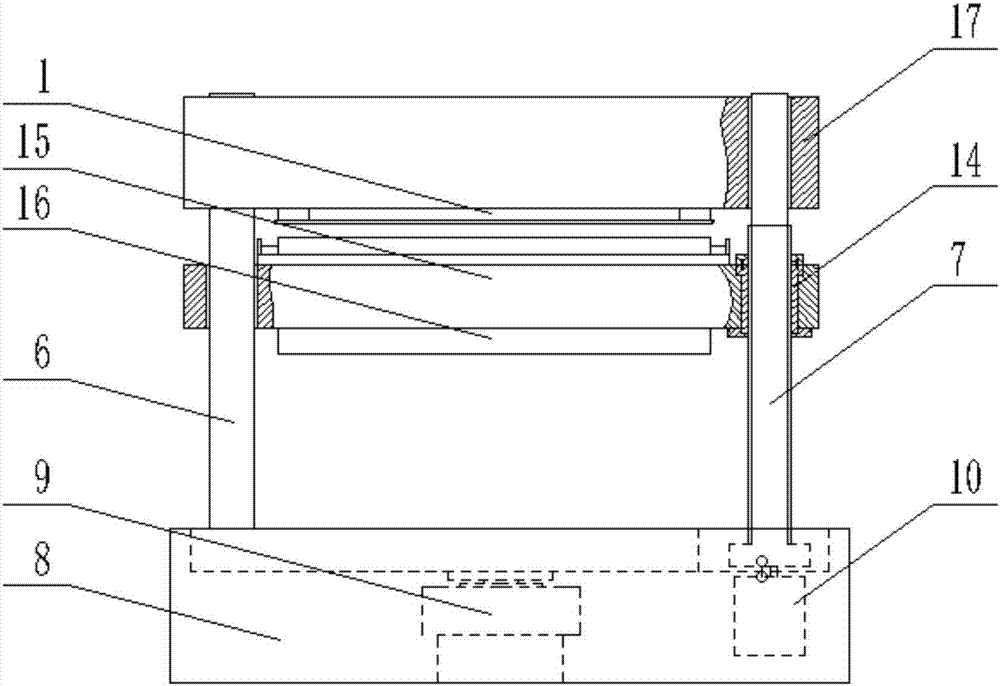

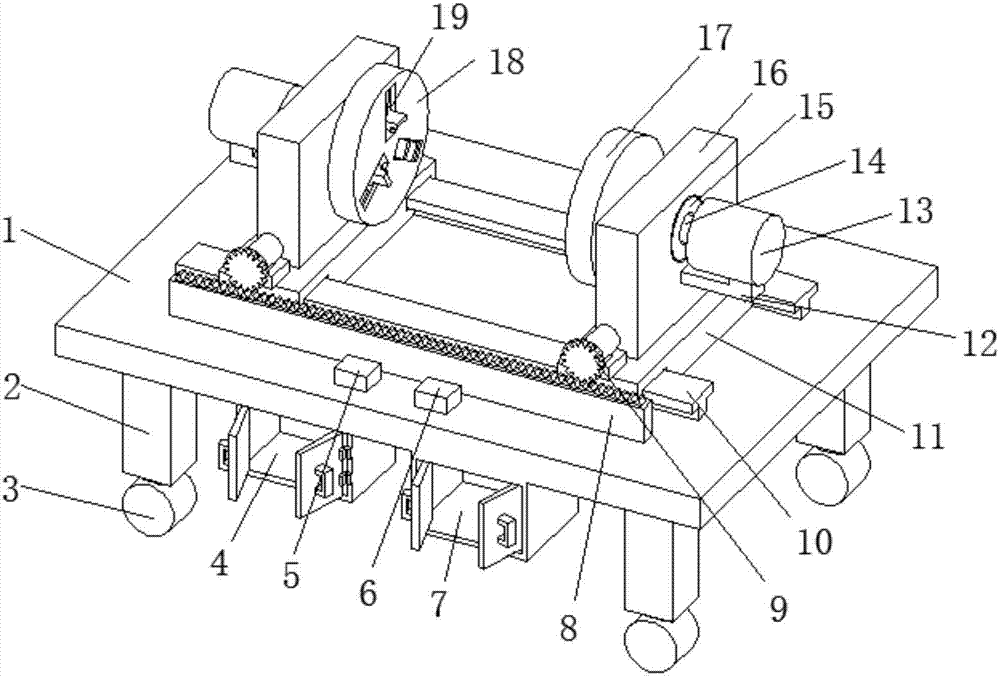

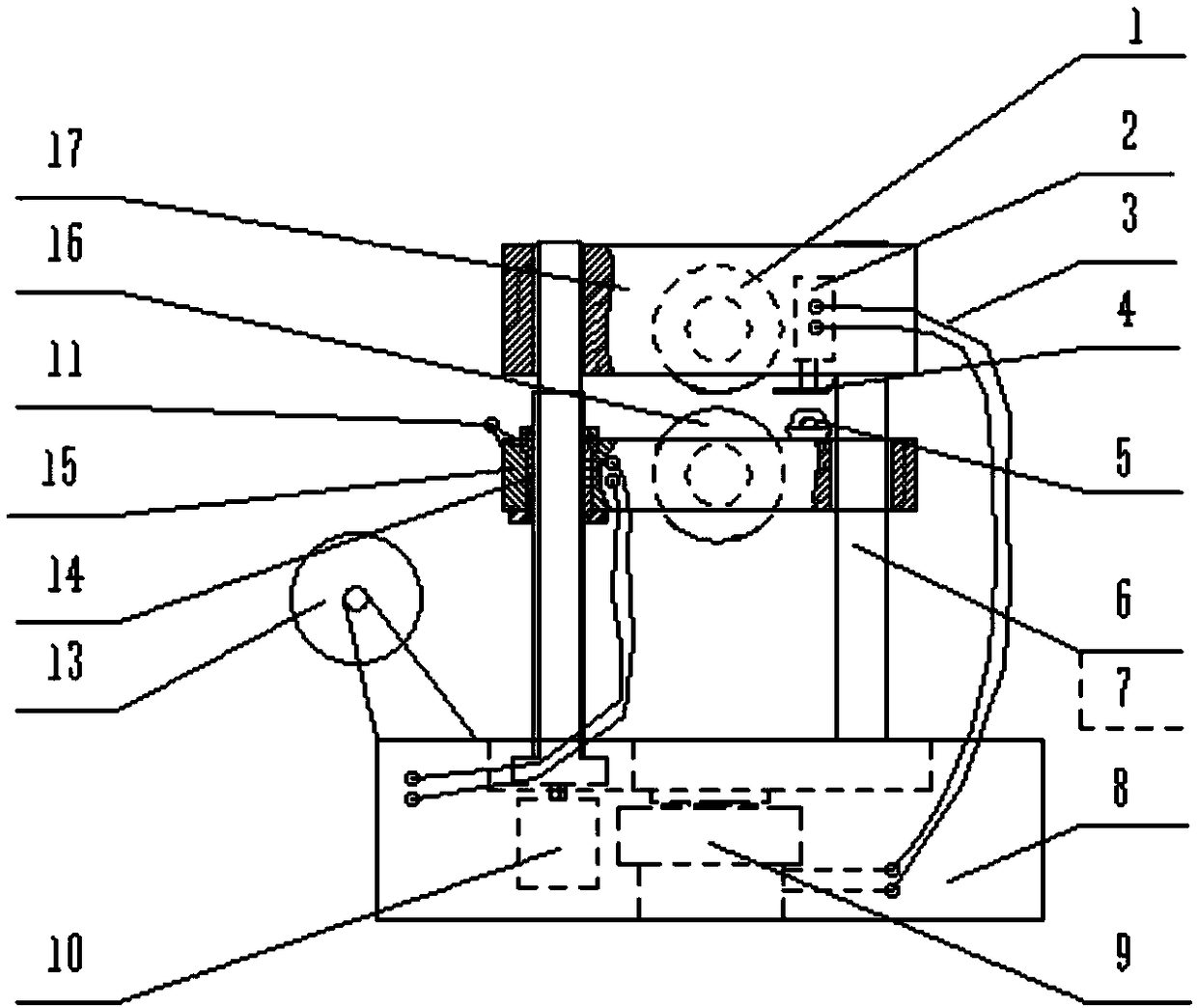

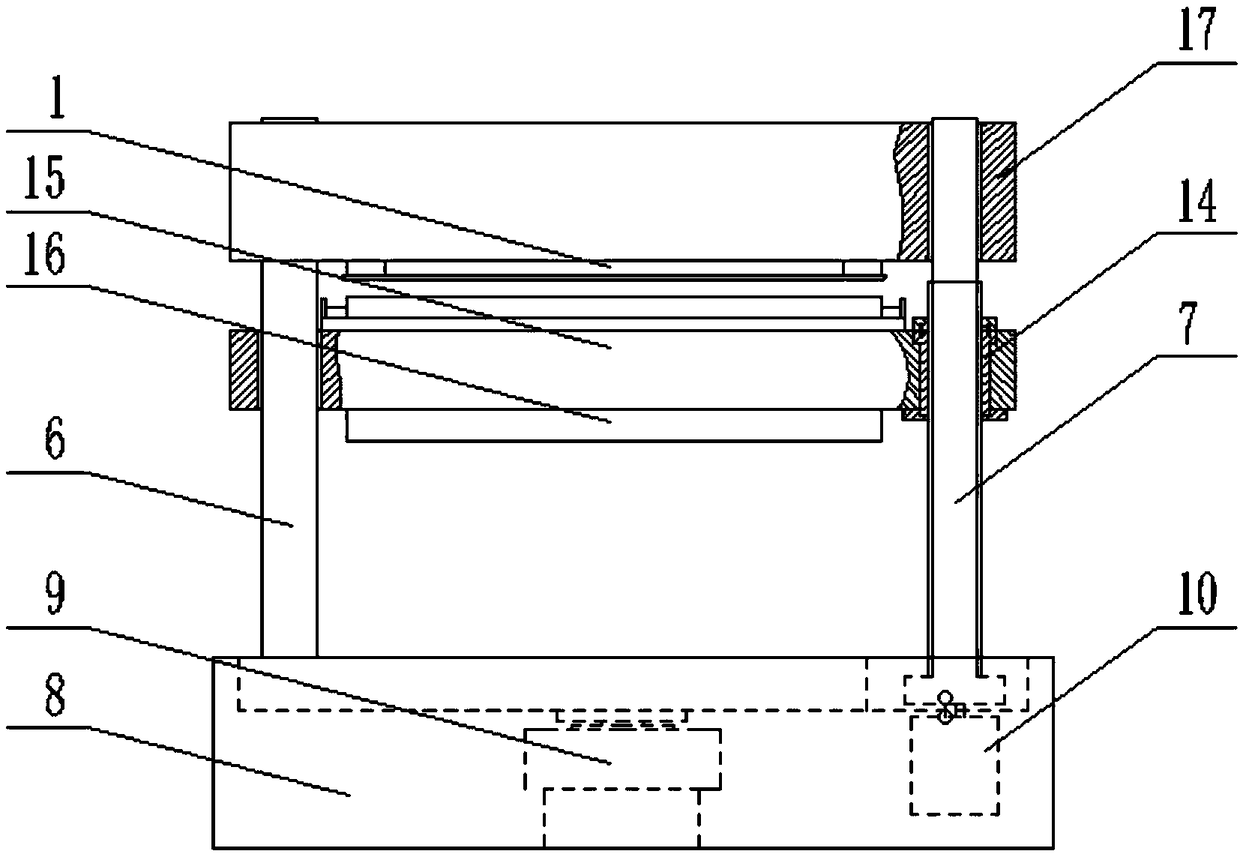

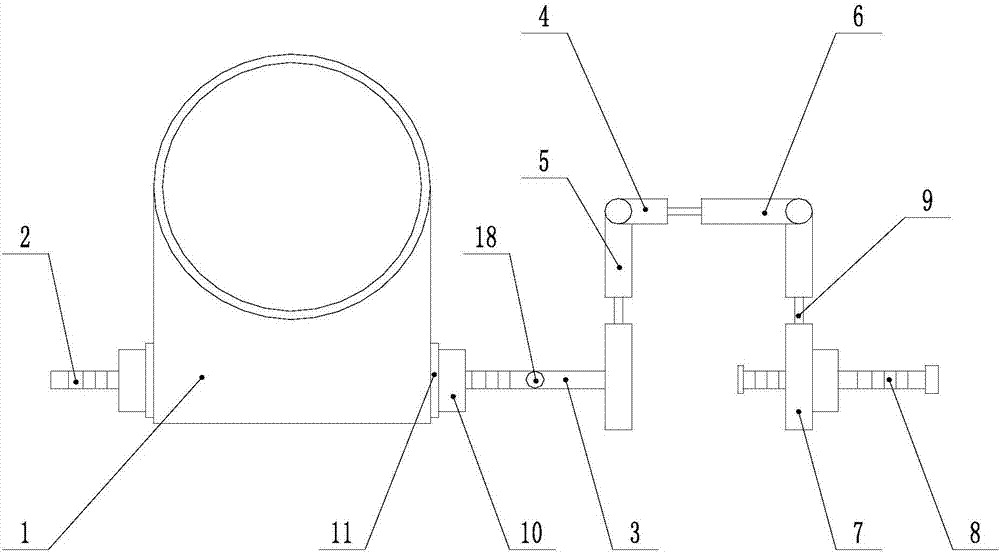

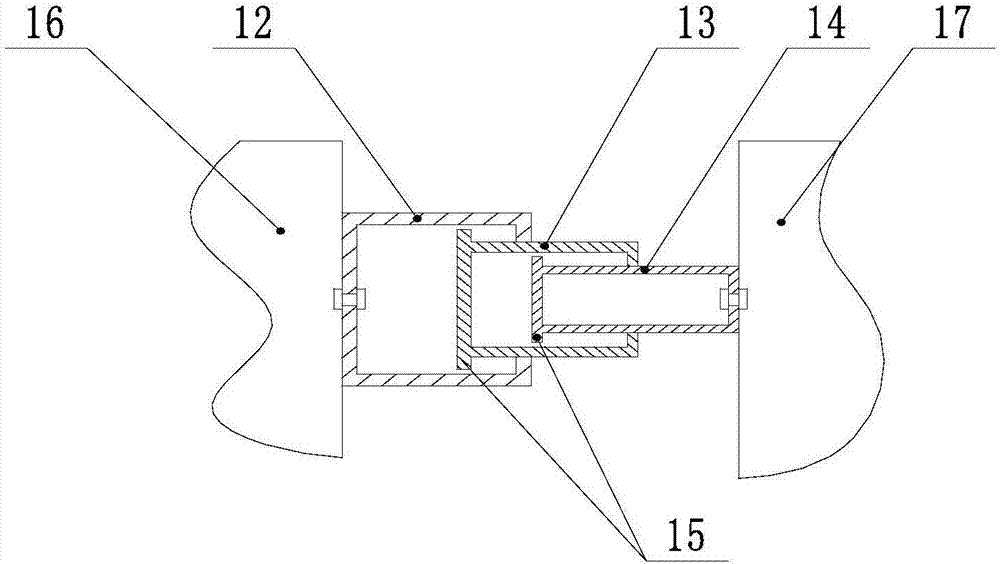

Roller printing machine

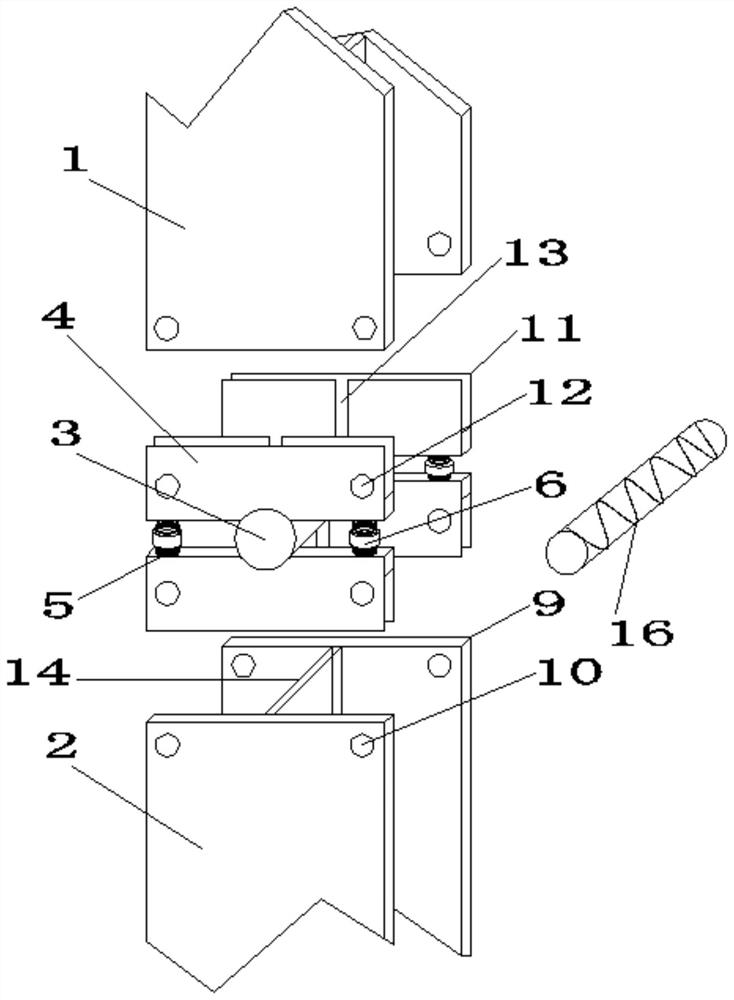

ActiveCN107323069AImprove printing and dyeing layeringAvoid printing uneven colorRotary intaglio printing pressApparatus for force/torque/work measurementSelf adaptiveDyeing

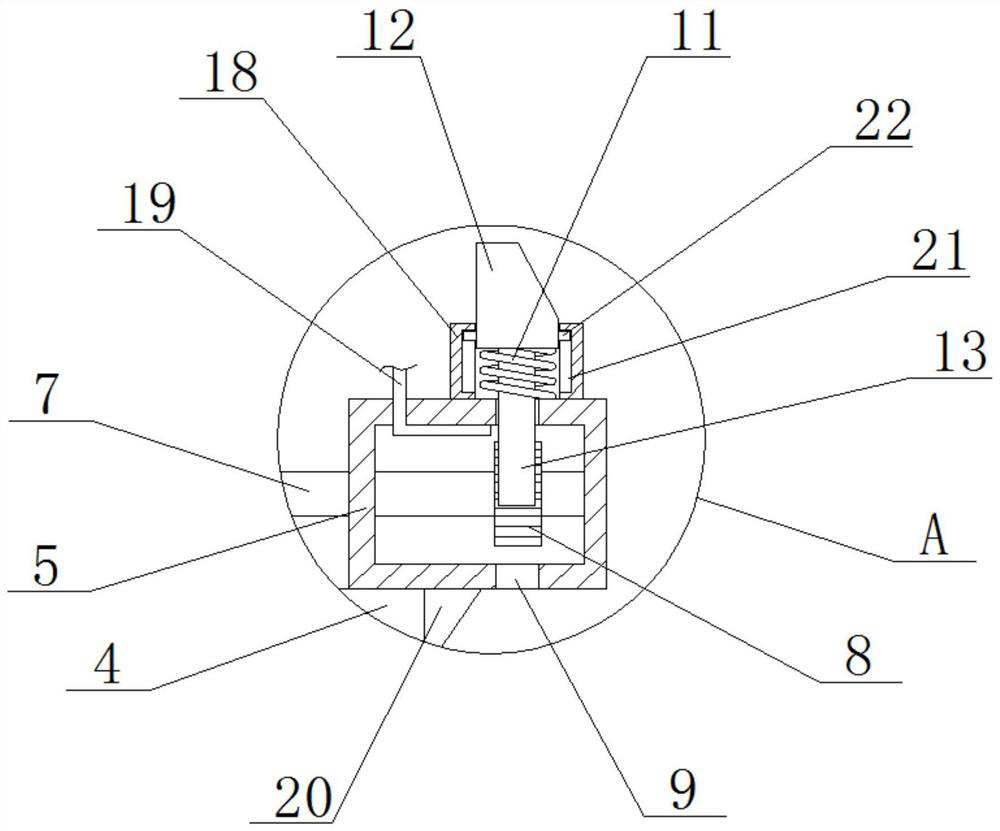

The invention discloses a roller printing machine, belonging to the technical field of printing and dyeing. The roller printing machine comprises a printing machine base, a lead screw, a feed rod, a driving nut, a lower crossbeam, a lower printing roller, an upper crossbeam, an upper printing roller, a motor and a feed rod fine adjustment mechanism, wherein the rapid adjustment and accurate adjustment of the distance between the lower printing roller and the upper printing roller can be realized by the feed rod fine adjustment mechanism through the screw-thread fit between the lead screw and the driving nut; a driven roller is arranged on the lower crossbeam of the roller printing machine of the embodiment; a pressure sensor and a piezoelectric signal converter are arranged on the upper crossbeam; and the distance between a driving roller and the driver roller can be automatically adjusted according to the thickness of raw materials to be processed and the requirements of printing and dyeing pressure, thereby realizing the self-adaptive adjustment of pressure in the printing and dyeing process, improving the poor printing and dyeing layering of the roller printing machine and avoiding the phenomenon of defective goods such as uneven printing colors.

Owner:JIANGSU KUNTAI MACHINERY

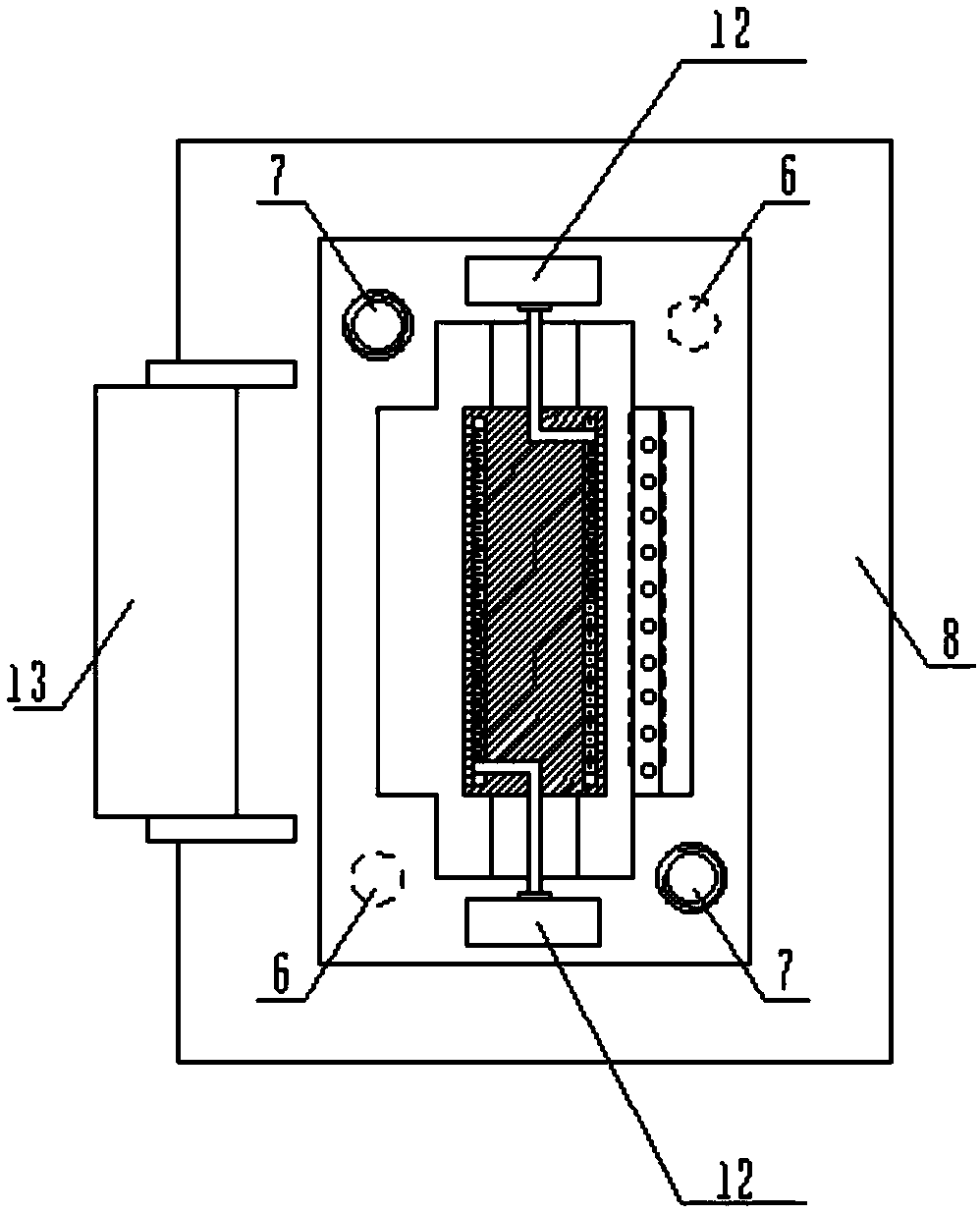

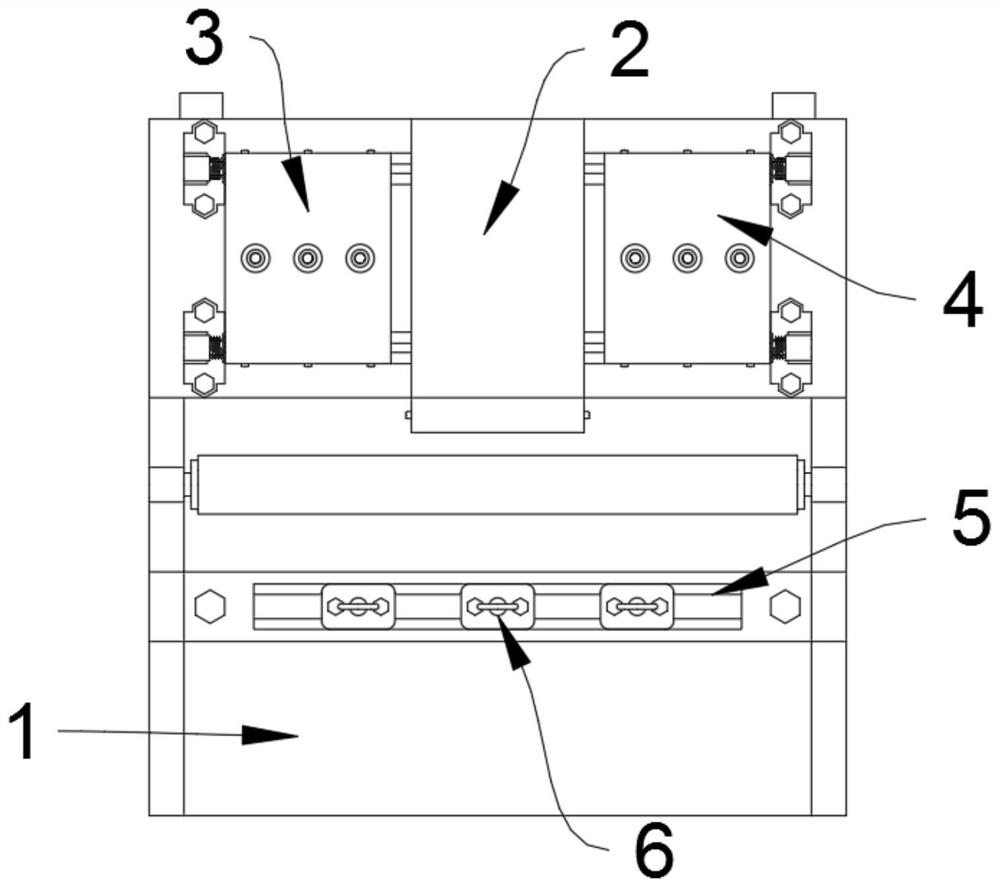

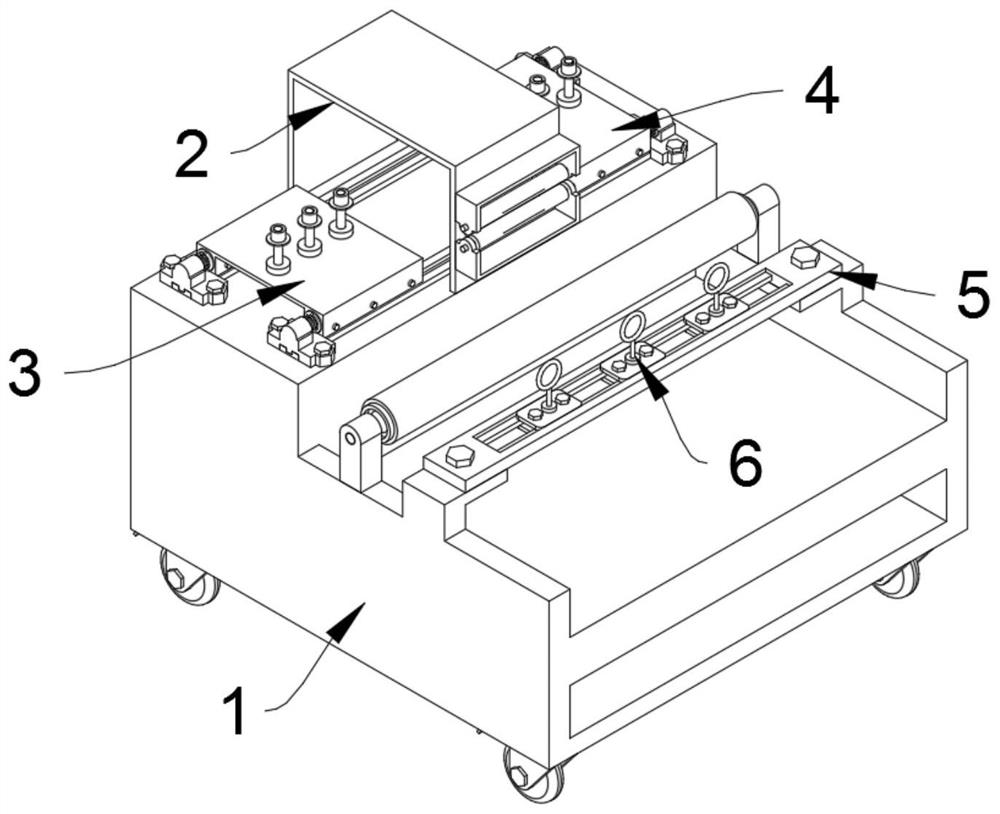

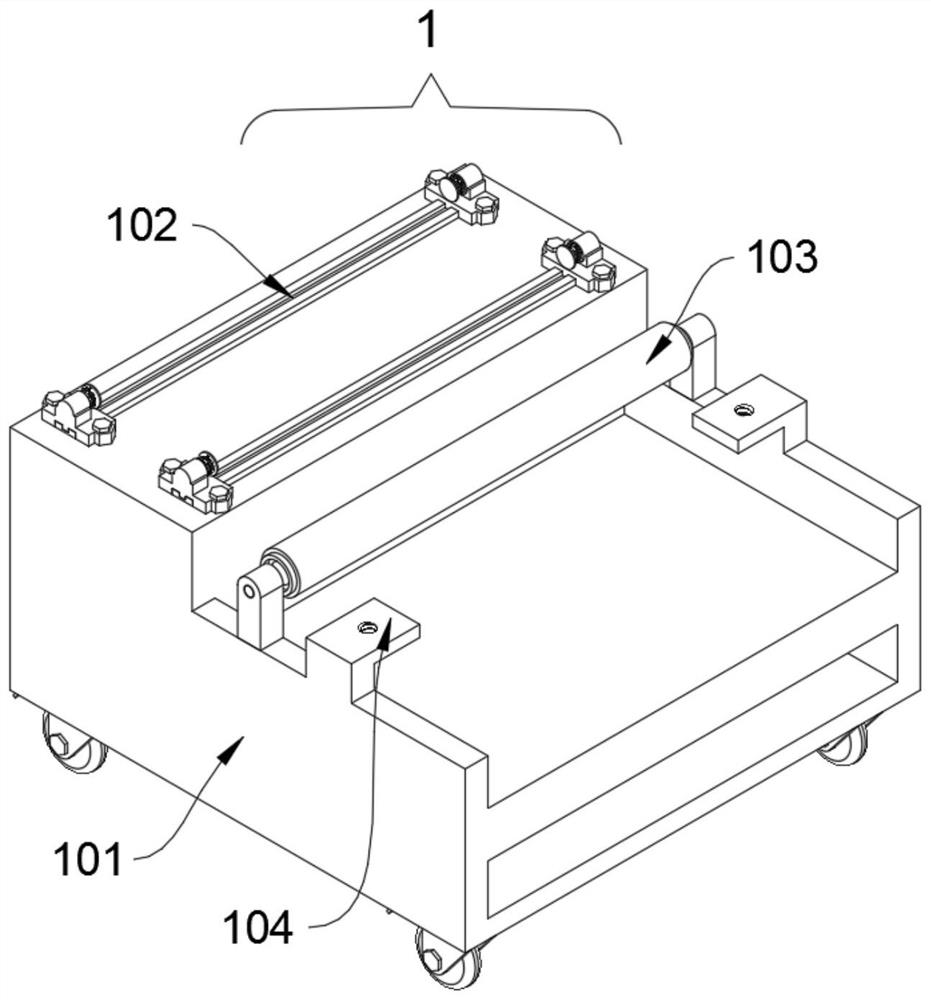

Electronic product magnetic core clamping device

The invention discloses an electronic product magnetic core clamping device. The device comprises a bottom plate, a first control switch and a second control switch are arranged on one side of the upper surface of the bottom plate, two sliding rails are arranged on the upper surface of the bottom plate at equal intervals, sliding plates are clamped at the left ends and the right ends of the two sliding rails in a sliding mode respectively, support plates are arranged on the upper surfaces of the sliding plates, bearings are clamped in through grooves inside the support plates, a first motor isfixed to one side of one support plate through a first motor fixing base, an input end of the first motor is electrically connected with an output end of the first control switch, an output shaft ofthe first motor is connected with a first rotating shaft through a coupling, and the first rotating shaft penetrates through an inner rings of the bearings. According to the electronic product magnetic core clamping device, use is convenient, magnetic cores of different lengths can be clamped, the two ends are fixed and clamped simultaneously, automatic clamping is achieved, the magnetic cores ofdifferent diameters can be clamped, the device is uses widely, subsequent winding work is facilitated, and the working efficiency is improved.

Owner:珠海美源智科技有限公司

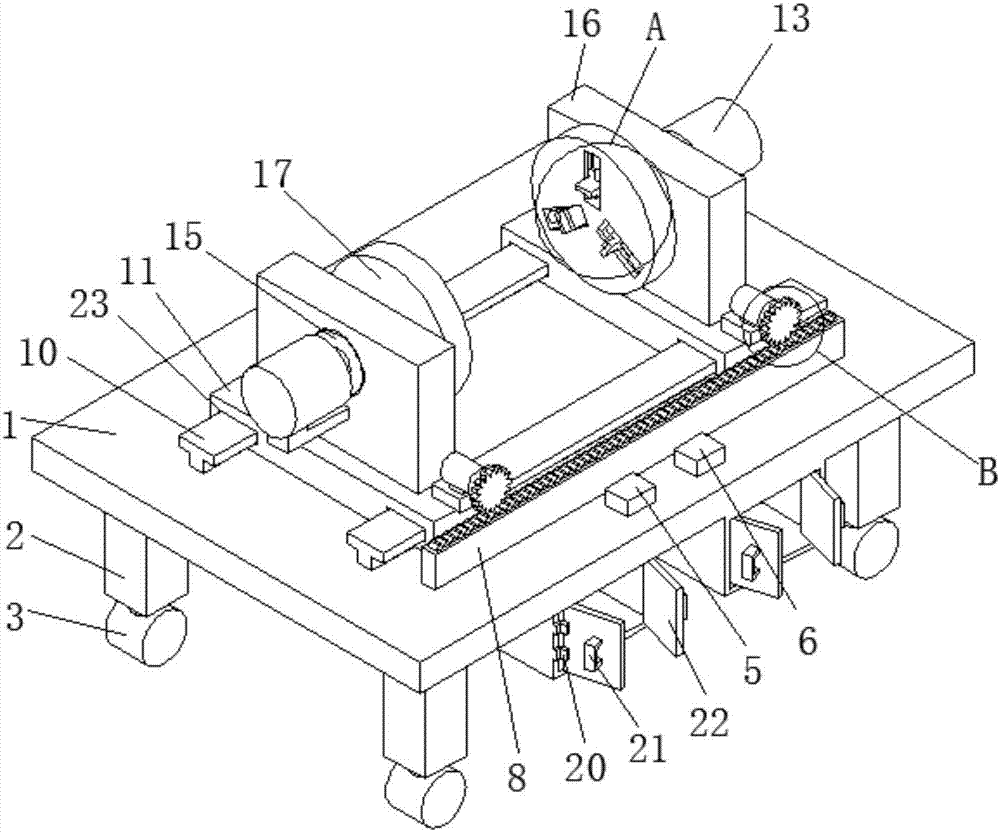

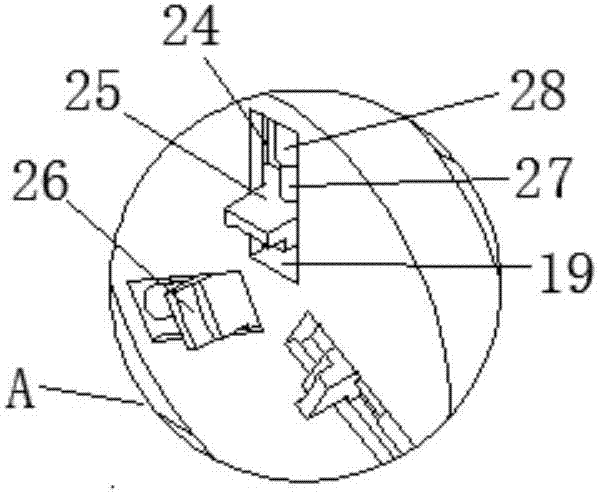

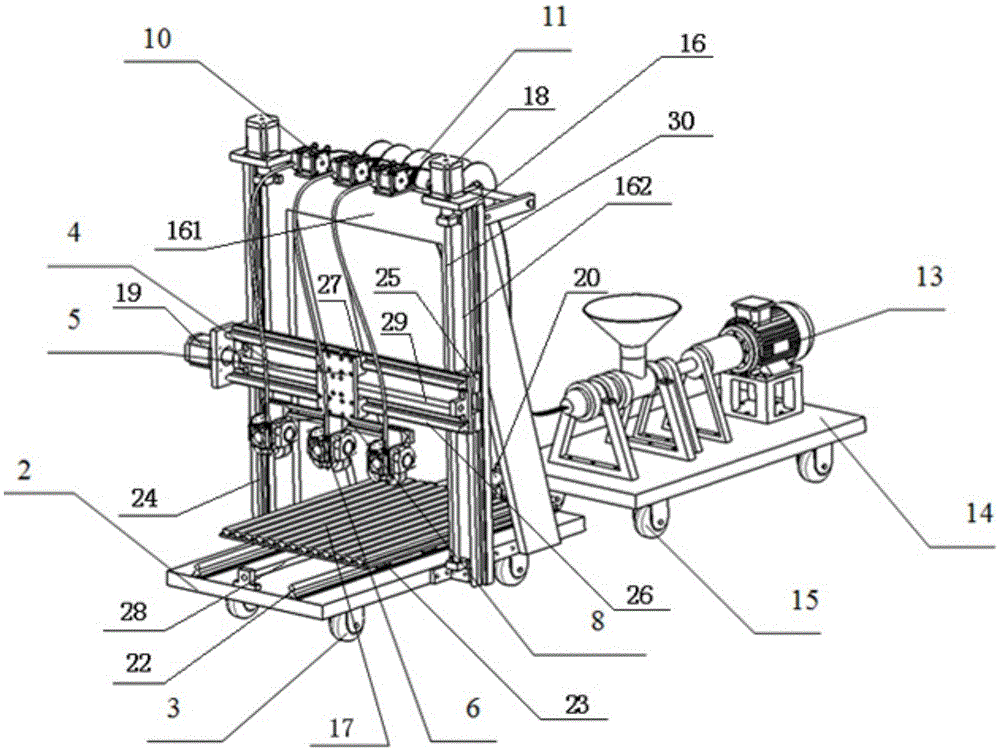

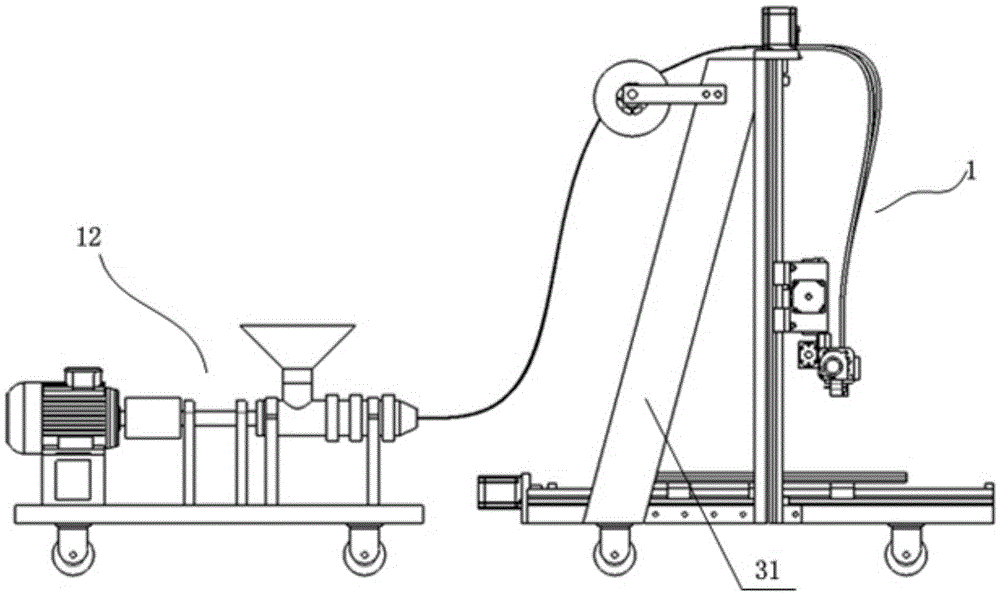

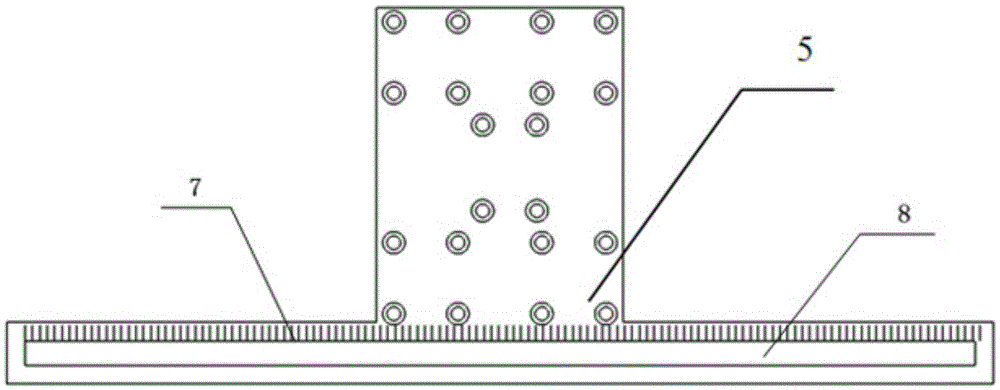

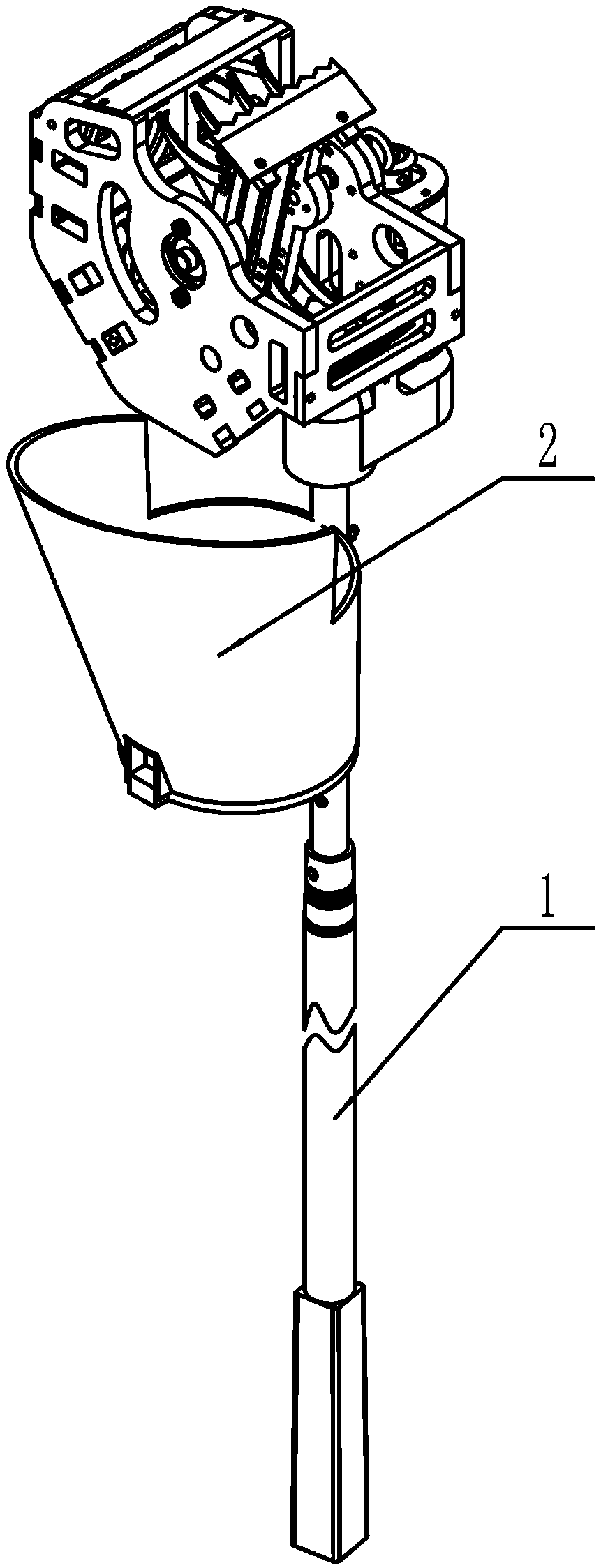

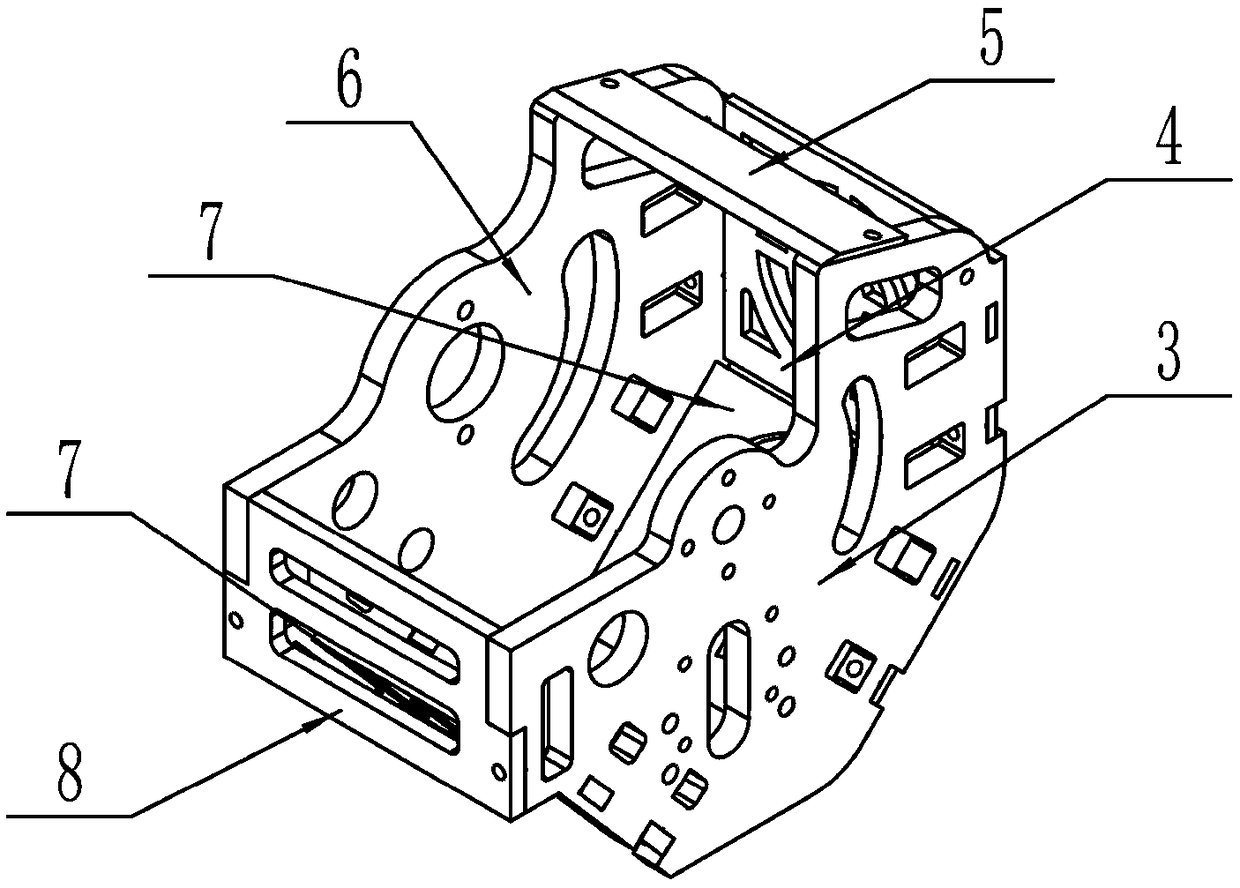

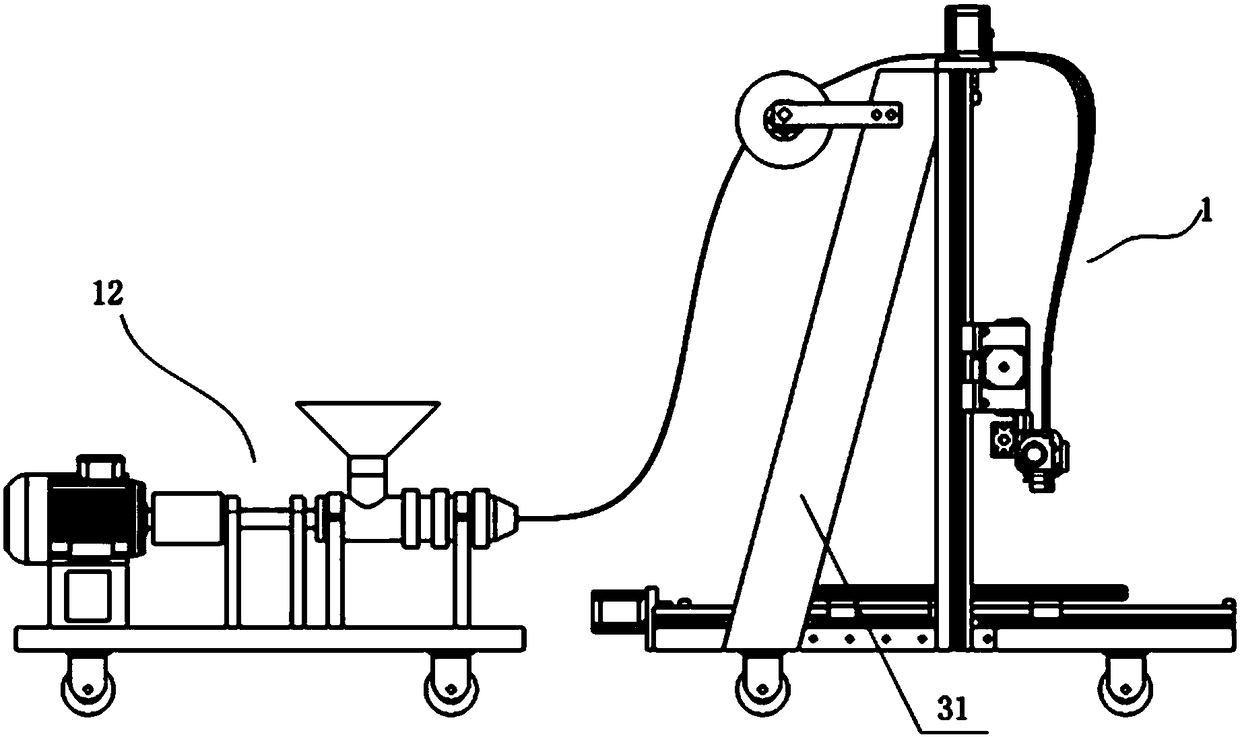

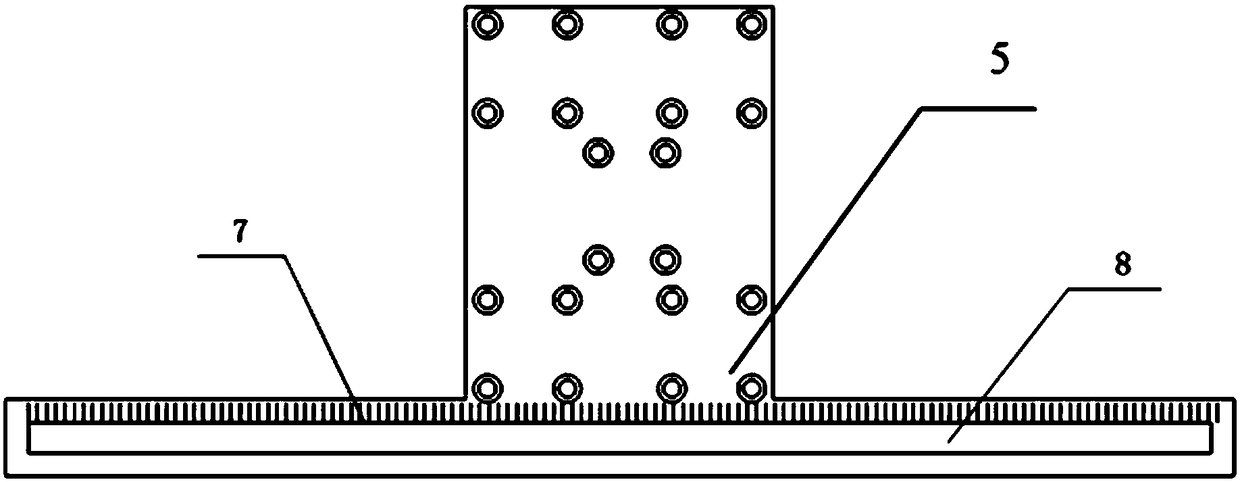

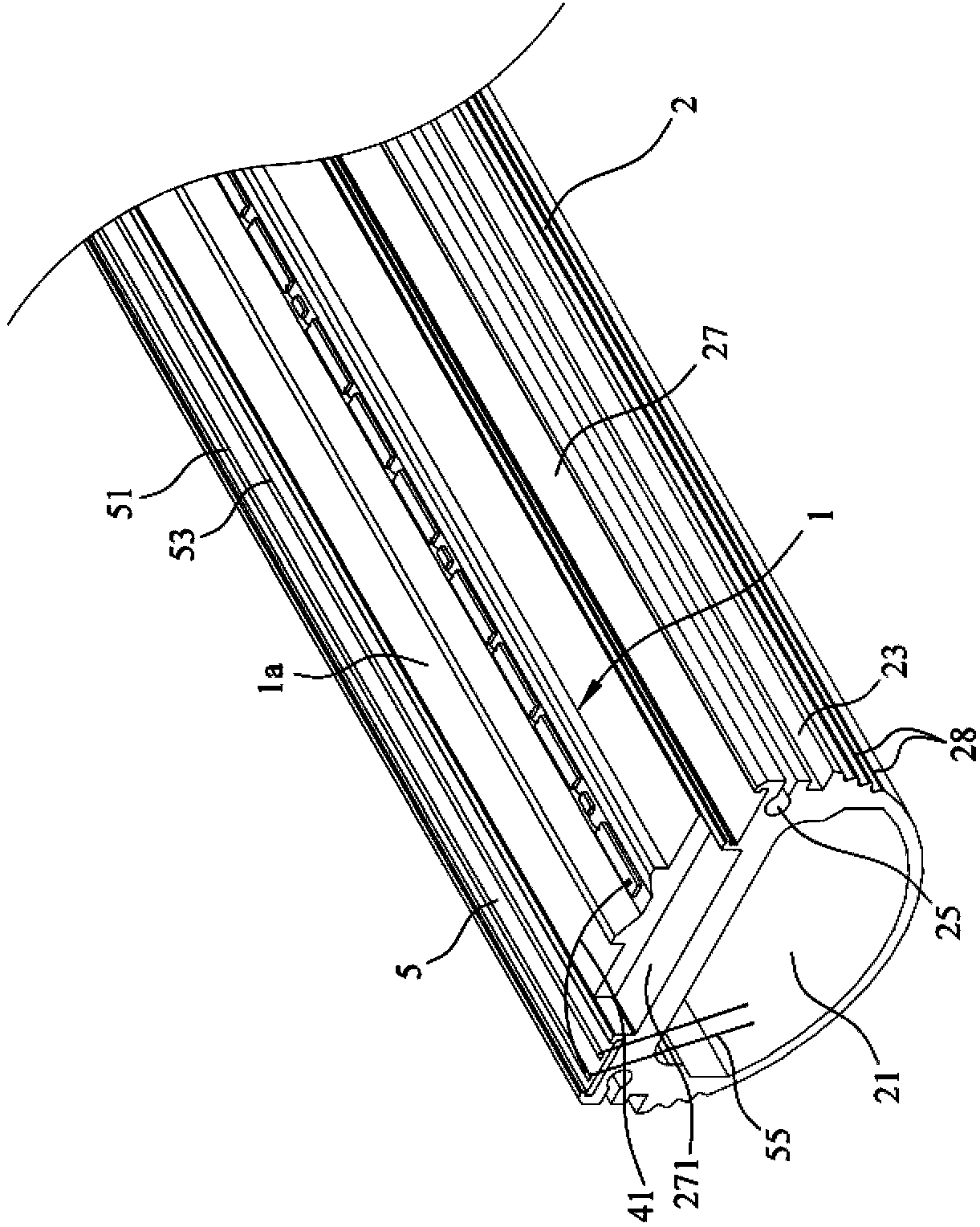

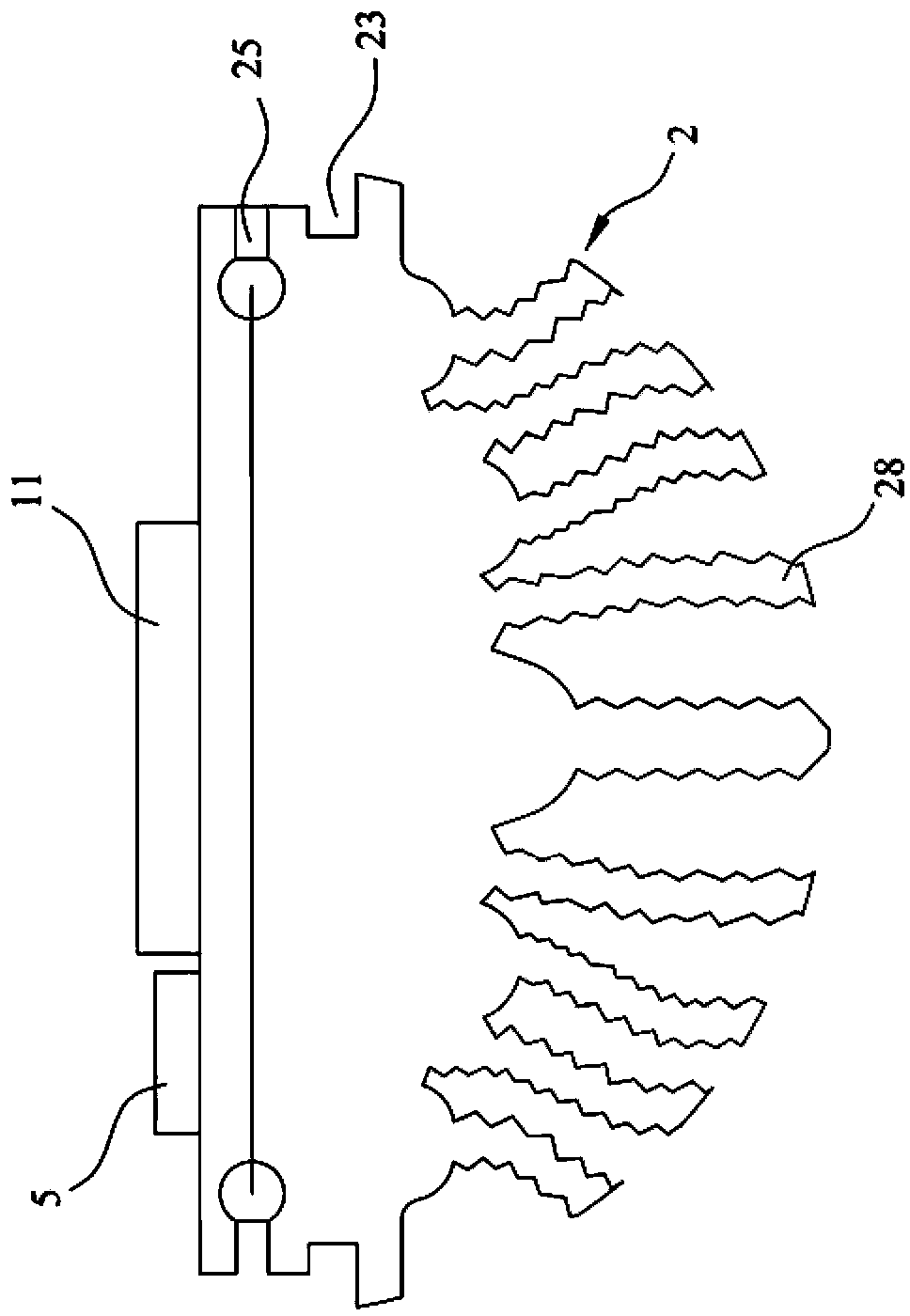

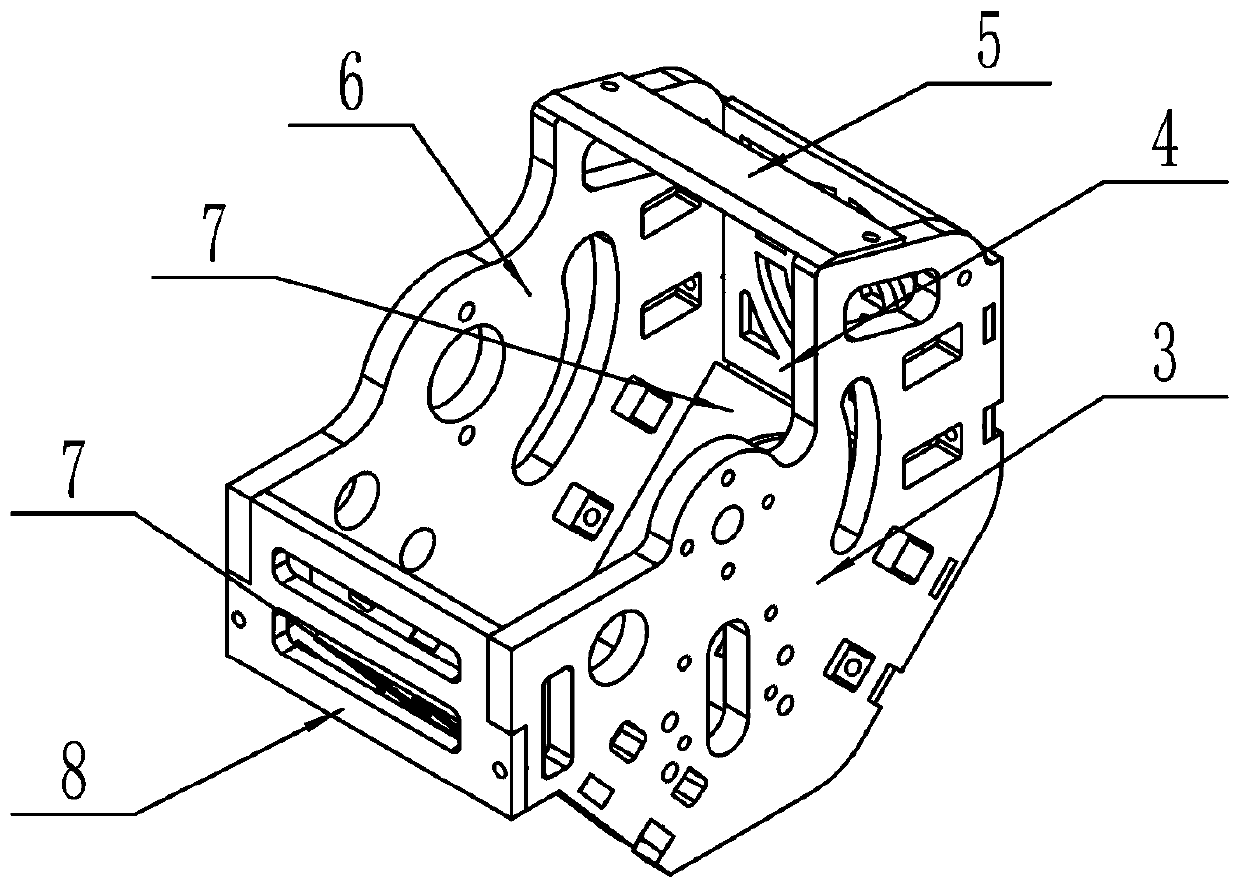

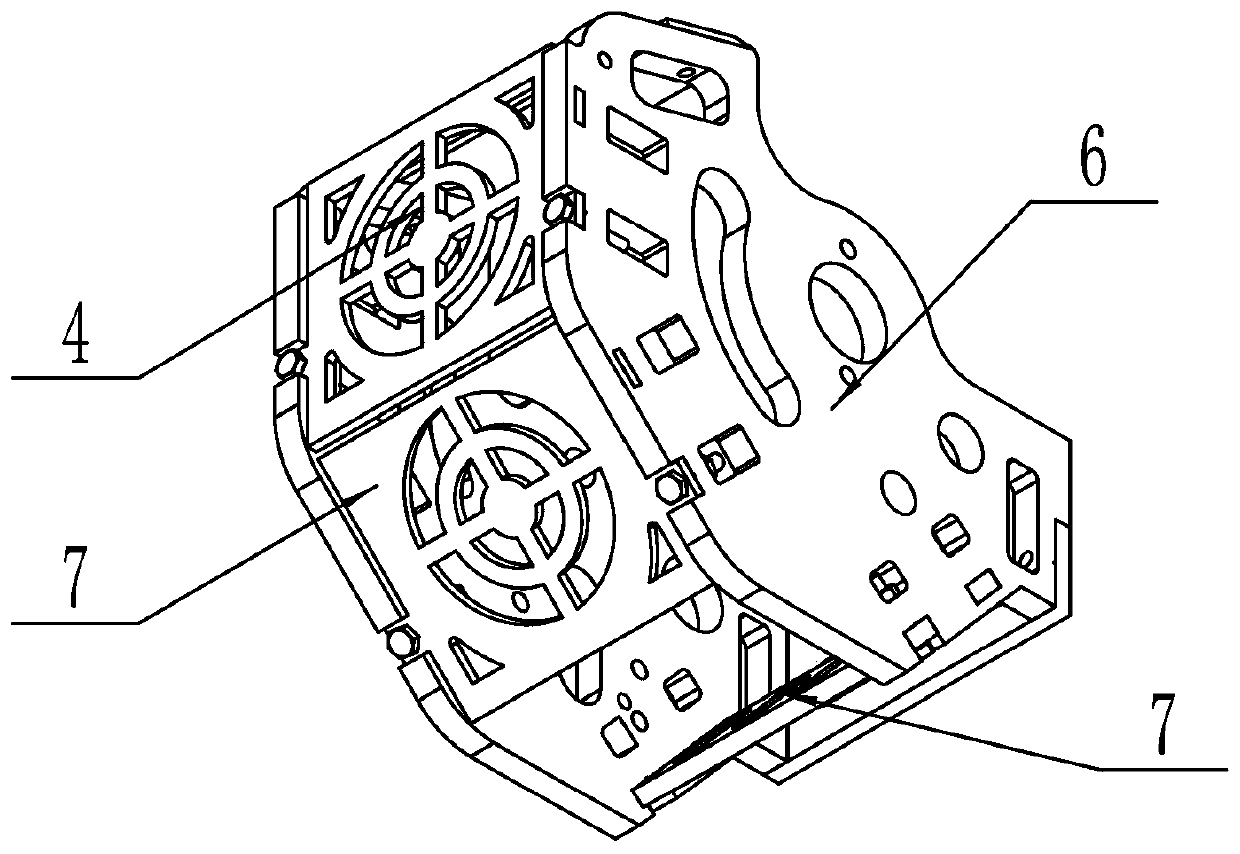

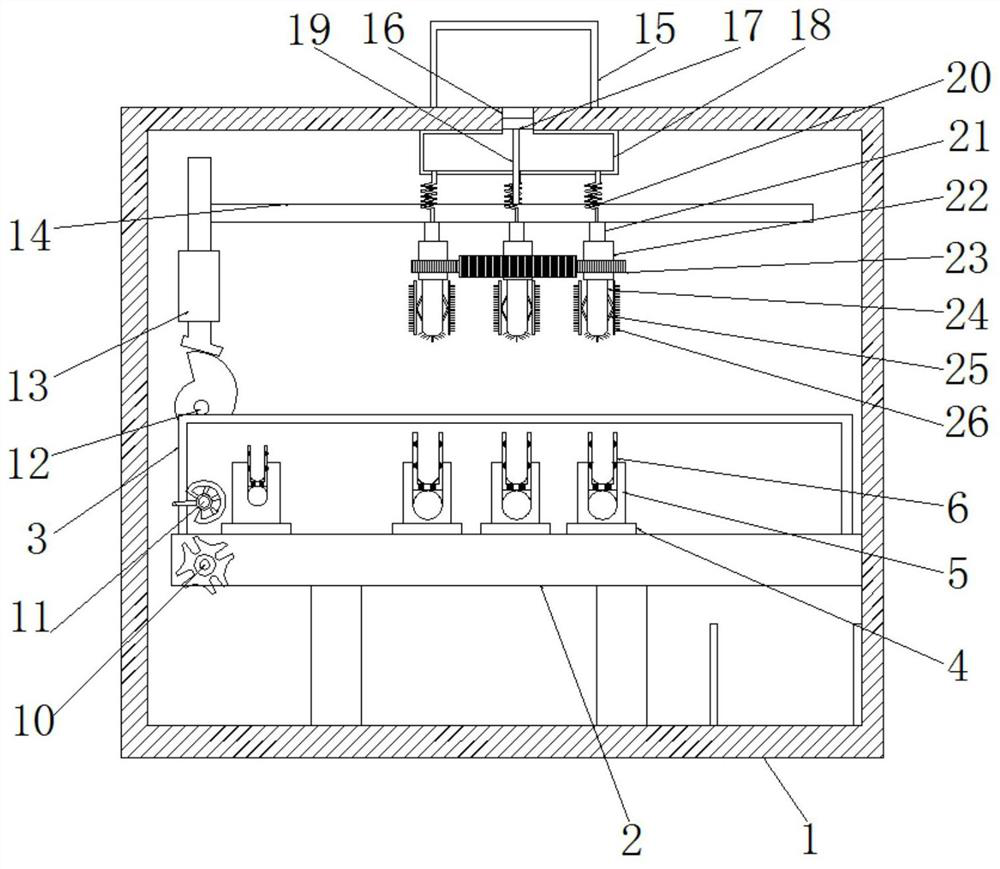

Automatic-feeding multi-head melting extrusion forming 3D printing equipment

ActiveCN105619820AImprove material utilization and equipment utilizationReduce manufacturing costAdditive manufacturing apparatusEngineeringElectrical and Electronics engineering

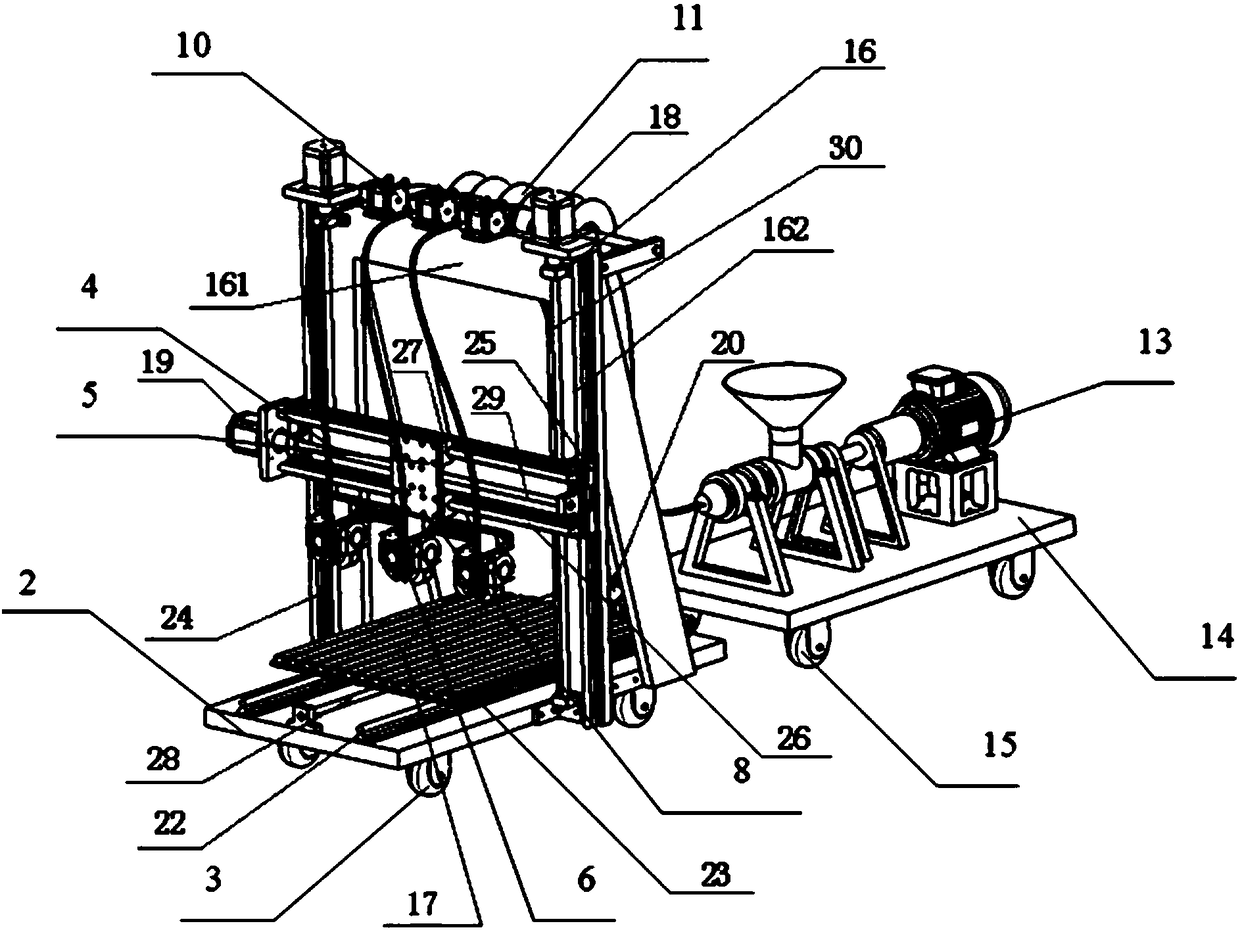

The invention discloses automatic-feeding multi-head melting extrusion forming 3D printing equipment which comprises a 3D printer and an injection molding machine. The 3D printer comprises a 3D printer base, a 3D printer support, an X-axis module, a printing head mounting plate and a printed object supporting platform, wherein the 3D printer support and the X-axis module constitute a vertical moving pair, the X-axis module and the printing head mounting plate constitute a horizontal moving pair, and the 3D printer base and the printed object supporting platform constitute a horizontal moving pair. The printing head mounting plate is perpendicular to the moving direction of the printed object supporting platform and in an inverted-T shape, the vertical part of the printing head mounting plate is mounted on the X-axis module in a sliding mode, and one or more printing heads are detachably mounted on the horizontal part of the printing head mounting plate. The automatic-feeding multi-head melting extrusion forming 3D printing equipment has the beneficial effects that the multiple printing heads which can be conveniently dismounted, added and reduced and are adjustable in distance are arranged for simultaneous printing, the printer and the injection molding machine are combined in a conveniently integrated or split mode, and the automatic feeding process is adopted, so that printing is efficient and rapid, the material utilization rate and the equipment utilization rate are increased, and production cost is reduced.

Owner:ANHUI SCI & TECH UNIV

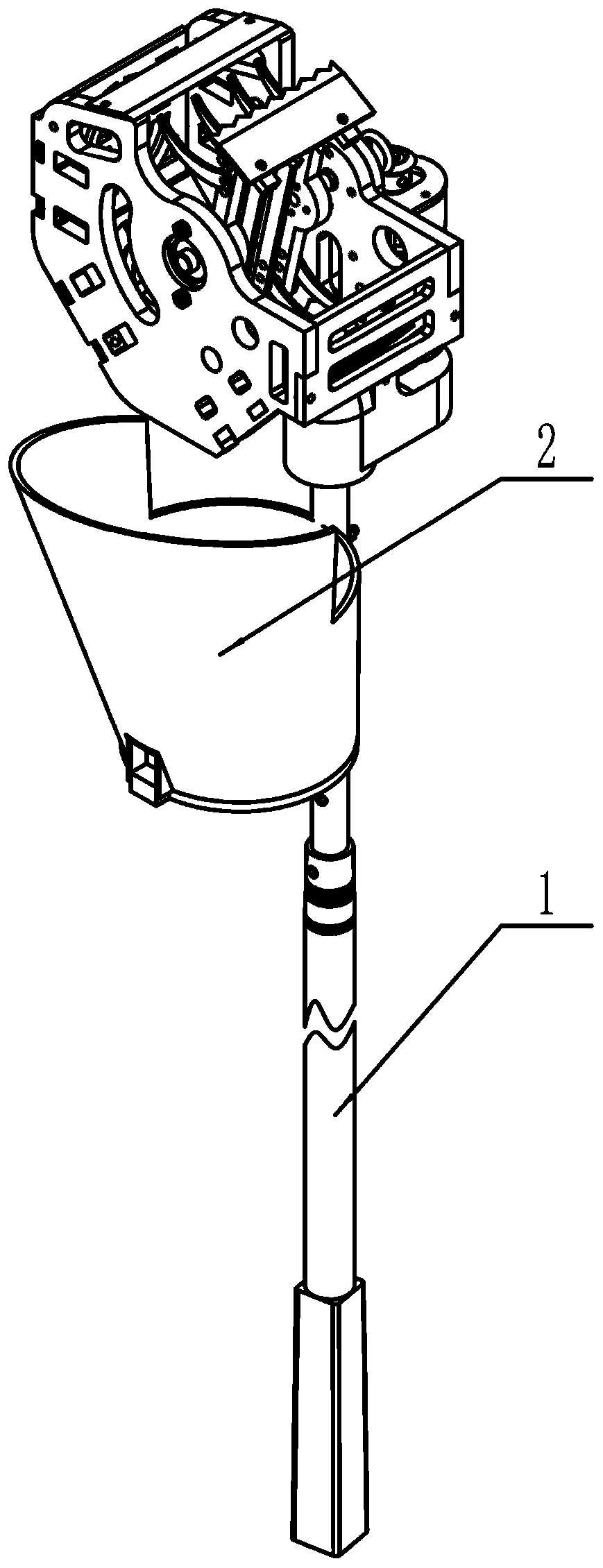

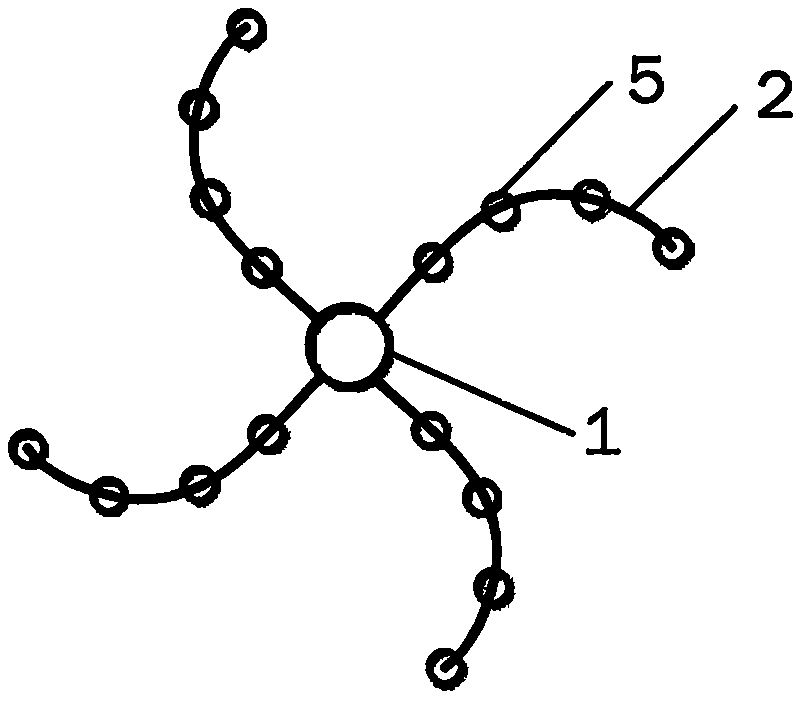

Serrated knife assisted cherry picking device with easy-to-adjust comb structure and picking method thereof

ActiveCN108901358AComb in orderlyIncrease or decrease the numberPicking devicesPull forceEngineering

The invention discloses a serrated knife assisted cherry picking device with an easy-to-adjust comb structure and a picking method thereof. An existing fruit picking machine is not easy to move and ishigh in manufacture cost. The serrated knife assisted cherry picking device consists of a telescopic device, a collecting device and a serrated knife comb picking device, wherein a transmission gearcolumn is driven by a motor; springs are arranged between the transmission gear column and a second intermediate gear column as well as a first intermediate gear column and a support gear column, twonuts connected to a threaded rod are arranged between the first intermediate gear column and the second intermediate gear column, and a spring is arranged between the two nuts; nuts are arranged on the outer sides of the transmission gear column and the support gear column; adjusting gears are fixedly arranged at two ends of each gear column; two ends of a serrated knife are separately fixed withthe support gear column and the transmission gear column. When shearing, the adjusting gears rotating to the top are used to comb cherry roots and provide a pulling force to the cherry roots; when theserrated knife rotating to the top is close to a fixed blade on a shell, the cherry roots are cut off by combined action of the shearing force of the serrated knife and the pulling force of the adjusting gears. The serrated knife assisted cherry picking device is small in size and low in cost.

Owner:浙江知多多网络科技有限公司

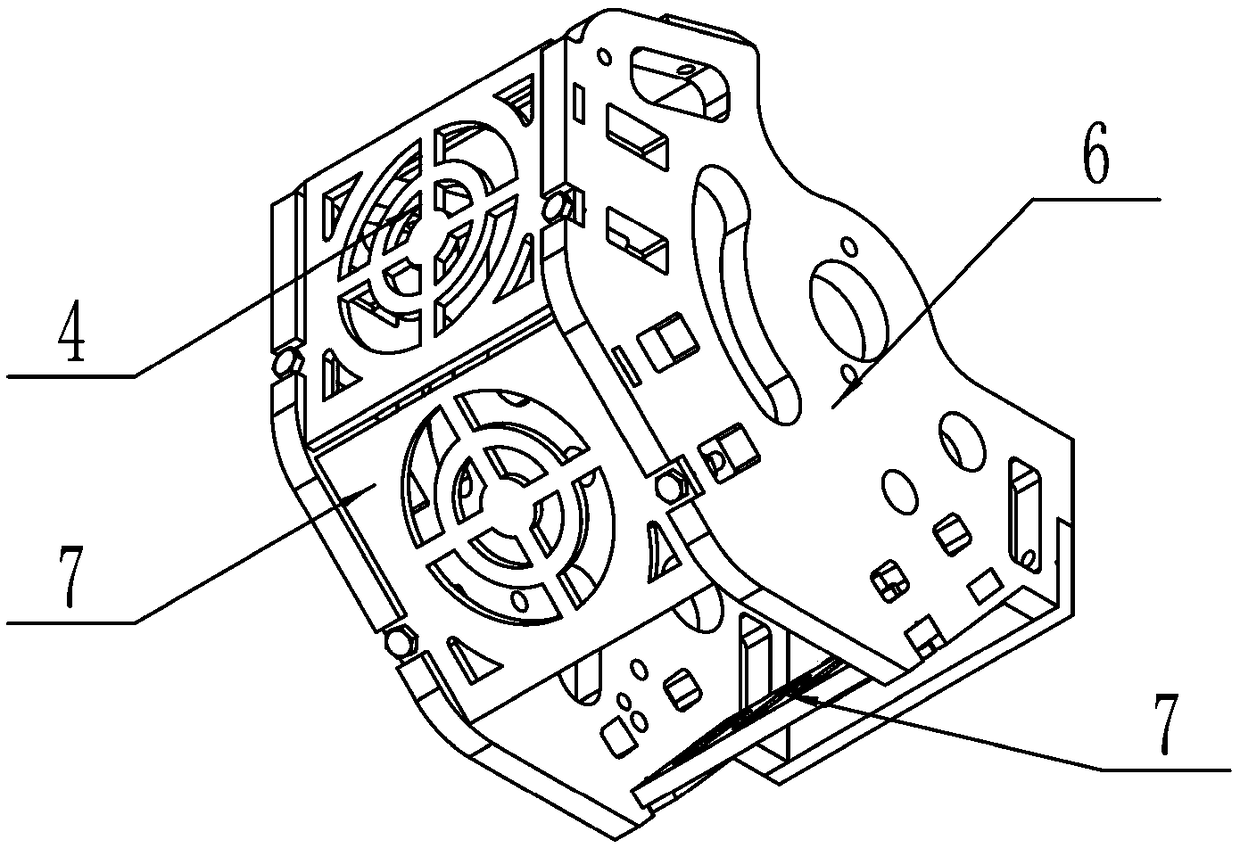

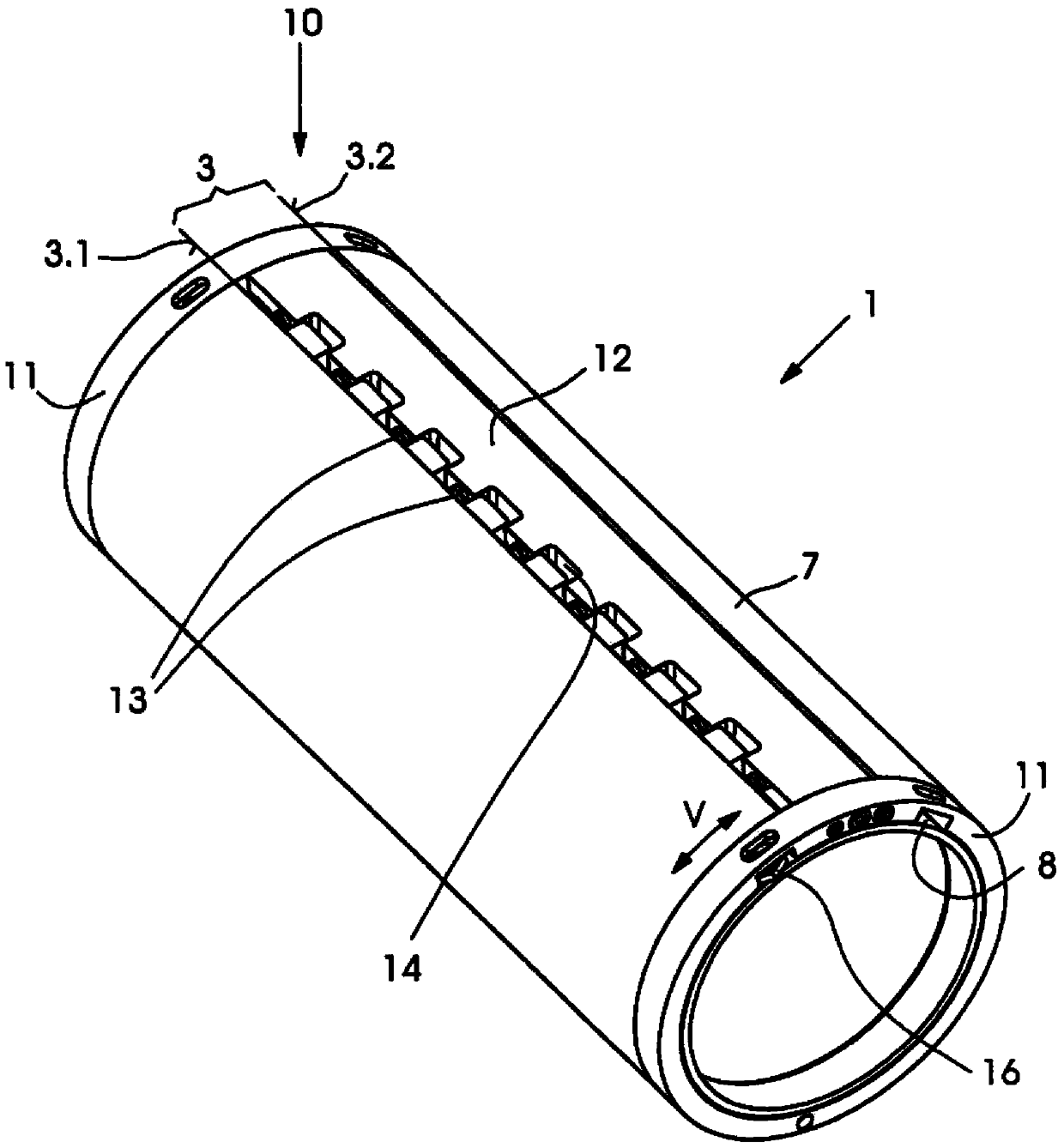

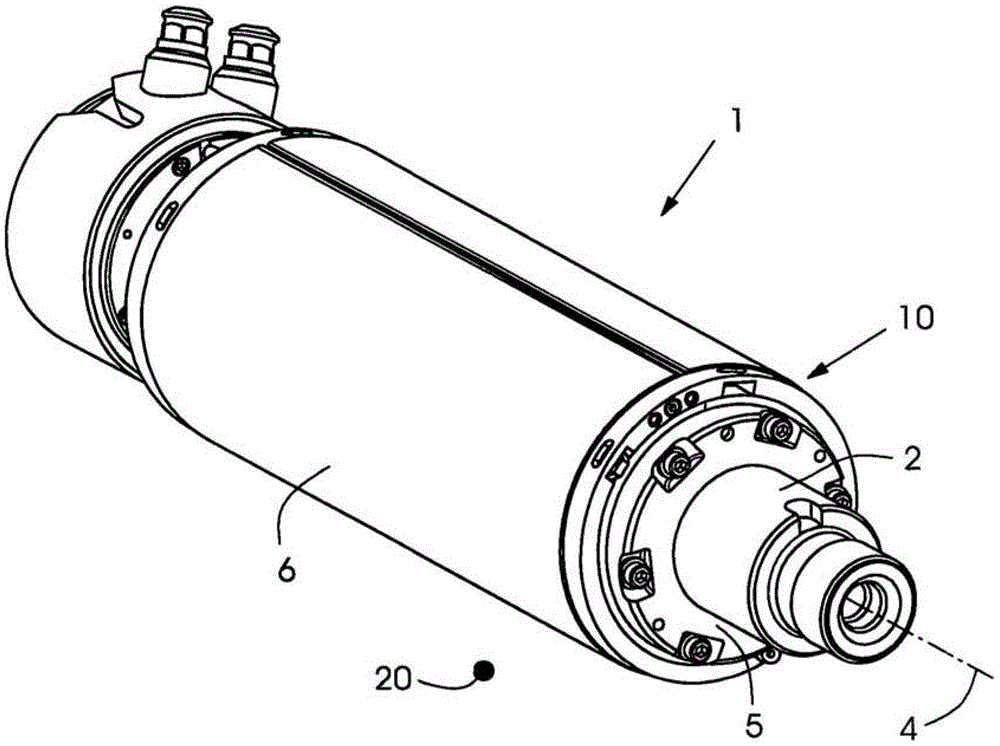

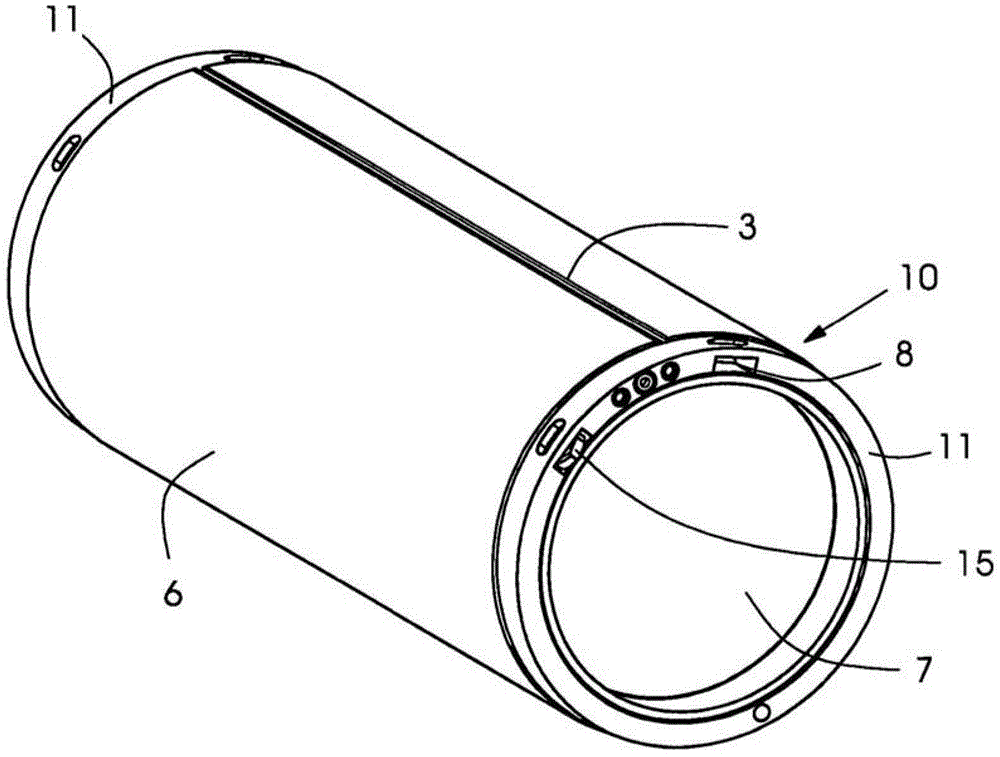

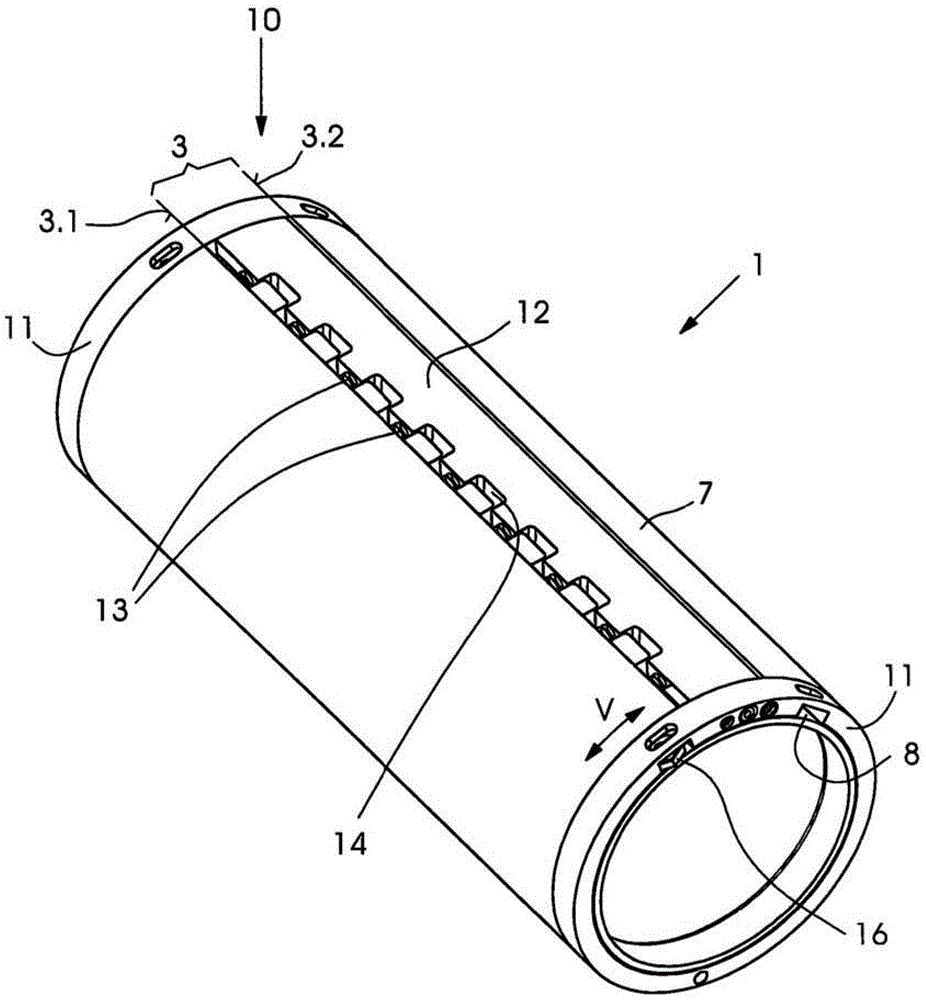

Embossing cylinder and embossing system having such an embossing cylinder

ActiveCN103722867ASimple but sure supportLarge bearing surfaceRotary pressesEmbossing decorationsSpring forceThermal expansion

An embossing cylinder for receiving a sleeve-shaped embossing mold has a hollow cylindrical body having two separating edges oriented in longitudinal direction of the body, such that a lateral surface broken by a gap is formed. The embossing cylinder is provided with a clamping system for expanding the hollow cylindrical body. The clamping system has two rotatable rings respectively supported on the axial end side of the body. The rings are connected by a carrier present in the gap. The spring elements are employed at the carrier and at the first separating edge. The spring force of the spring elements mainly act in the circumferential direction of the body. The advantage of the embossing cylinder of the invention is that a sleeve-shaped embossing mold can be mounted easily and rapidly, and the length difference can be compensated in the condition that different materials are applied to the sleeve-shaped embossing mold and the body, wherein the compensation is realized by different coefficients of thermal expansion. The invention also relates to an embossing system for processing belt-shaped or page-shaped elements, which comprises an embossing cylinder, a clamping shaft, a sleeve-shaped embossing mold, and a pressing roller pair.

Owner:GALLUS FERD RUESCH

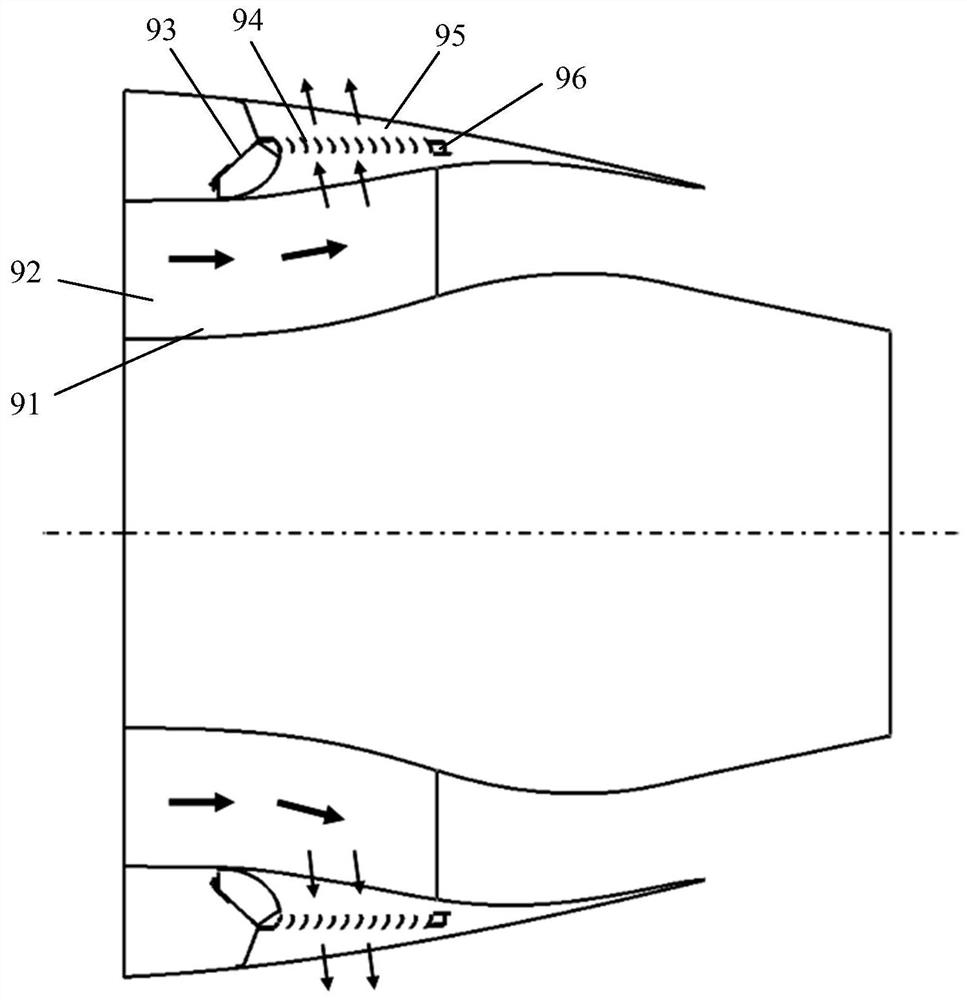

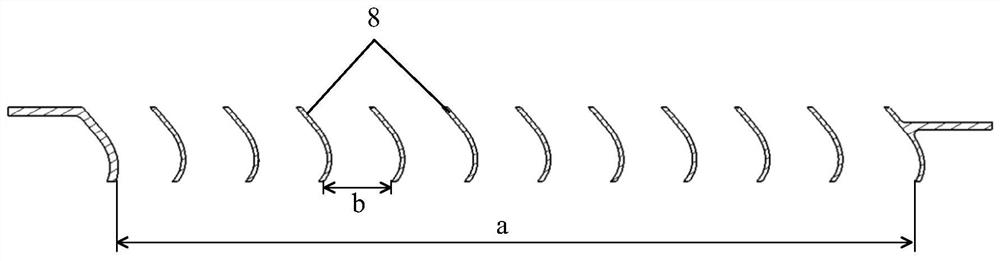

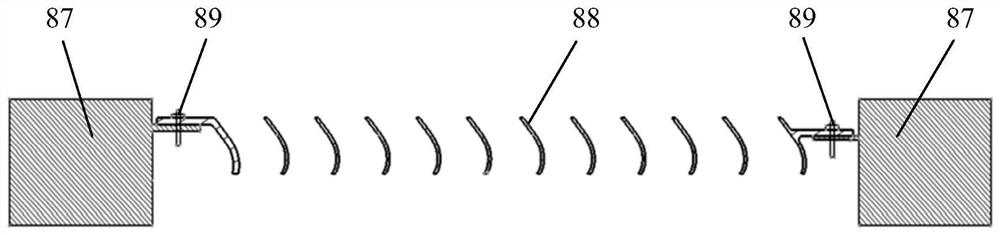

Reverse thrust cascade test system and test reverse thrust cascade thereof

PendingCN113865838AImprove efficiencySimple structureMachine part testingPhysicsMechanical engineering

One purpose of the invention is to provide a test reverse thrust cascade, which provides a basis for rapid test of different cascade exhaust areas. Another purpose of the invention is to provide a reverse thrust cascade test system which comprises the test reverse thrust cascade. In order to achieve the purpose, the test reverse thrust cascade comprises an outer frame, a plurality of blades and a linkage assembly. The outer frame is provided with a first matching part, the plurality of blades are respectively provided with a second matching part, the second matching part is detachably connected with the first matching part, the first matching part allows each blade to move along the first direction of the outer frame, the linkage assembly is respectively connected with each blade, and the linkage assembly is operated to simultaneously adjust the distance between the plurality of blades in the first direction.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

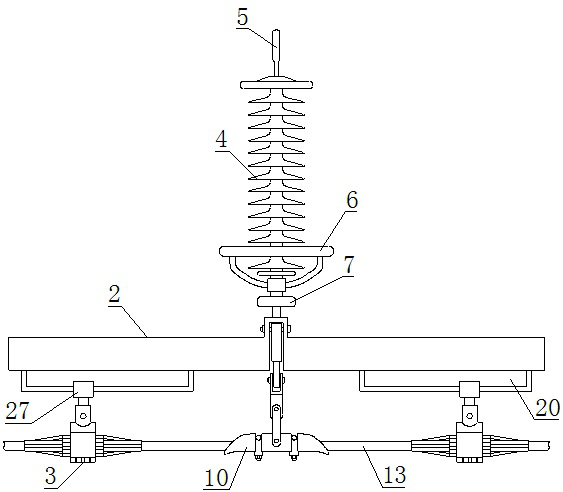

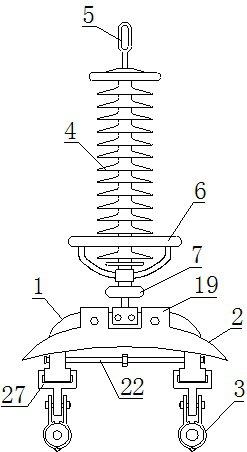

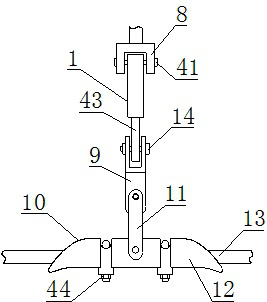

Fixing cover for double-wire clamp

PendingCN112421541AIncrease or decrease spacingPrevent looseningSuspension arrangements for electric cablesRolling chassisCord clamping

The invention relates to a fixing cover for a double-wire clamp, and the cover comprises a chassis, a cover plate and a clamping seat; an insulator string is arranged above the chassis, a traction seat is connected to a leading-out end on the lower side of the chassis, a suspension clamp is arranged on the lower side of the traction seat, a connecting seat is arranged on the outer side of the chassis, the cover plate is arranged on the lower side of the connecting seat, and a sliding rod is arranged below the cover plate; the distance between the sliding rods can be changed by rotating the screw rods, the lower sides of the sliding rods are connected with the clamping seats, and the inner twisted wires, the tightening rings and the outer twisted wires are sequentially wound on the outer sides of the parts, making contact with the clamping seats, of the wires, so large clamping force can be provided for the wires; the positions of the sliding rod and the sliding base are adjusted, the clamping base is fastened to the wire in a buckled mode, and under the combined action of the suspension clamp and the clamping base, accidents caused by wire damage to a power transmission line can beprevented. The clamping device has the advantages of being convenient to install, wide in applicability, good in clamping effect and high in protection capacity.

Owner:XINYANG POWER SUPPLY OF HENAN ELECTRIC POWER CORP

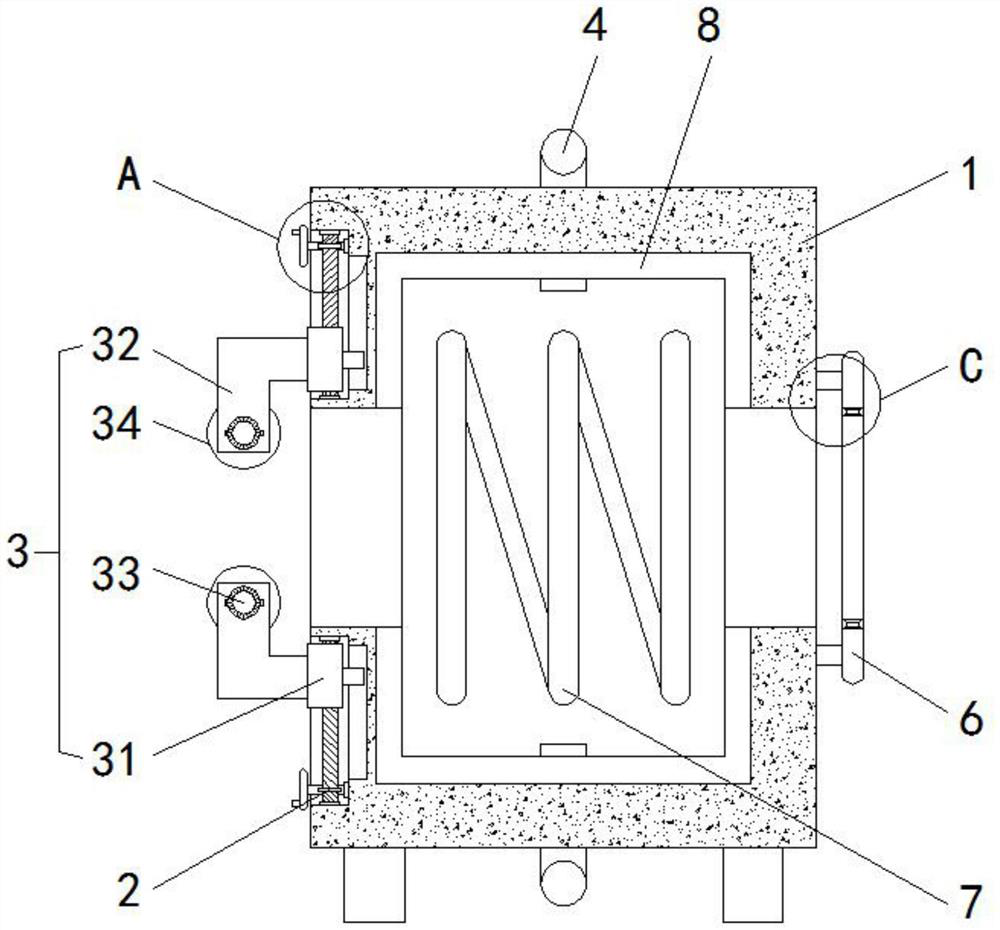

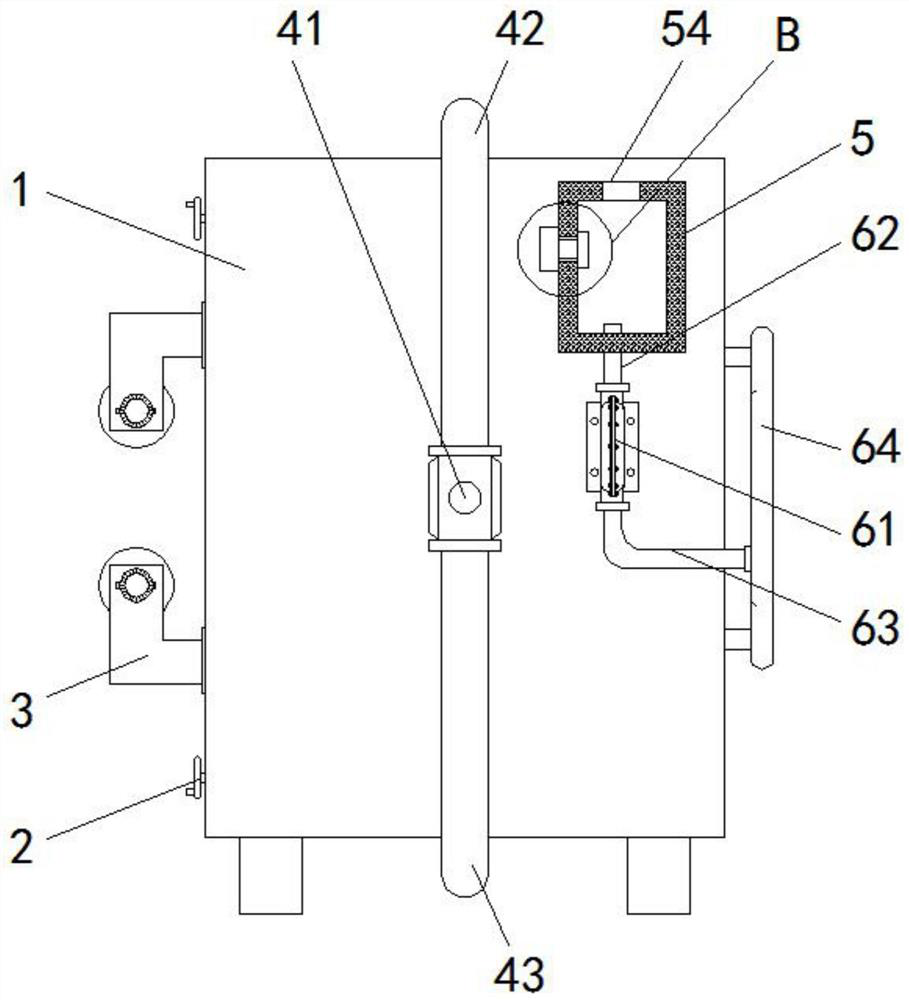

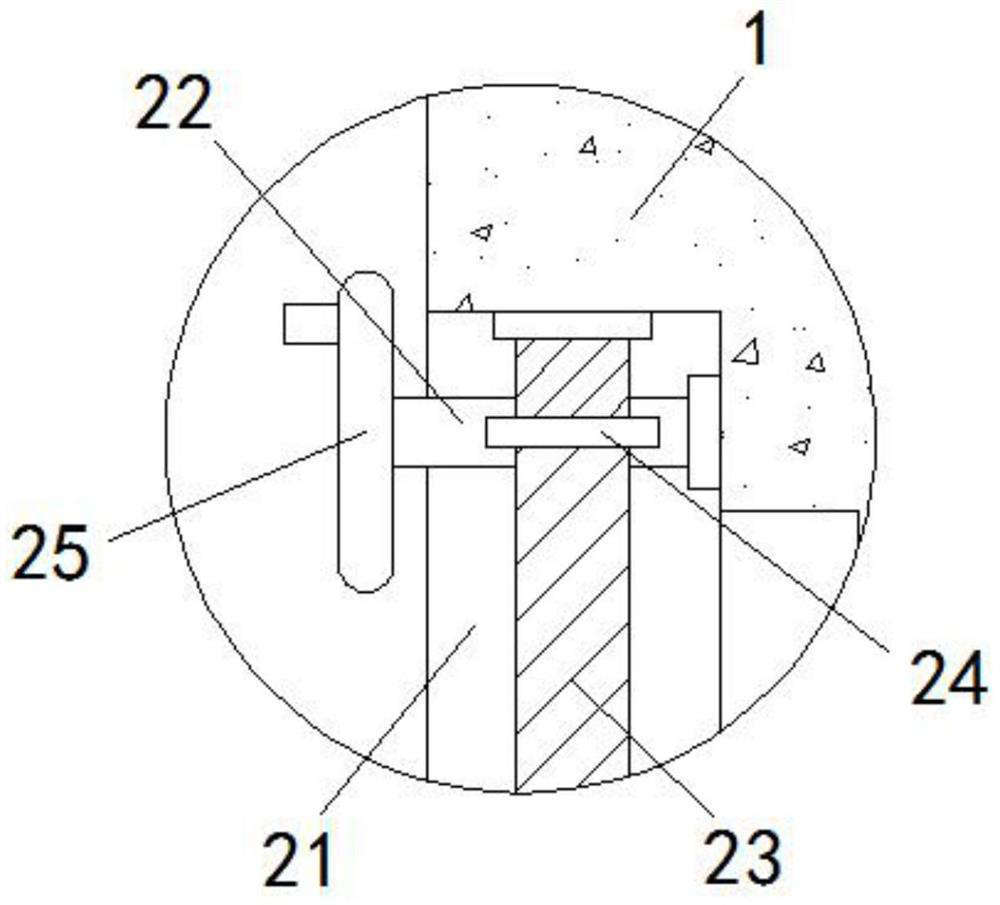

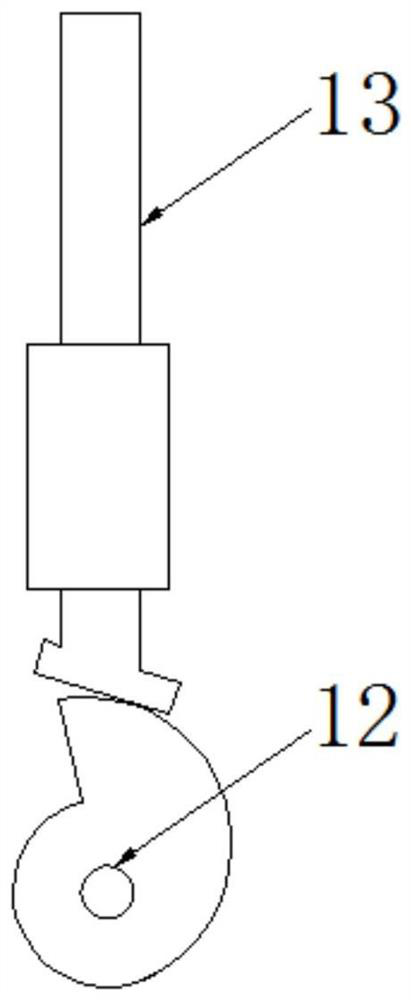

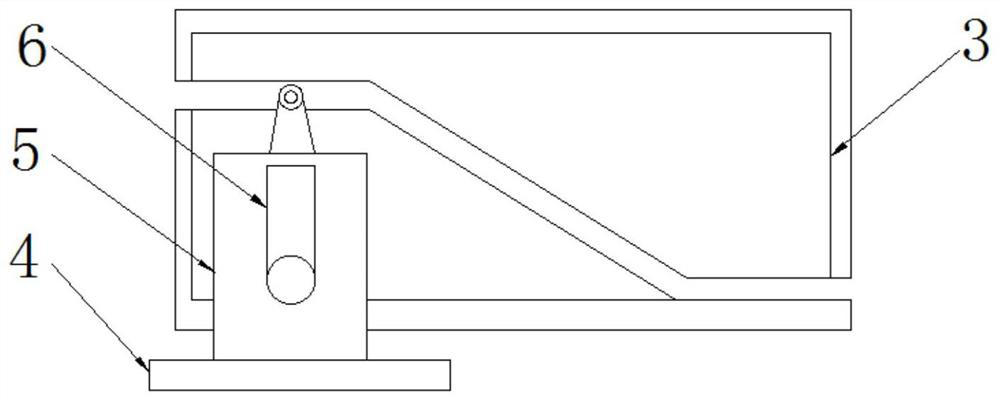

Heat treatment device for stainless steel bar

PendingCN114277237AEasy to processIncrease heating rateFurnace typesHeat treatment furnacesPhysicsWorm drive

The invention relates to a stainless steel bar heat treatment device which comprises a treatment box, a driving mechanism is arranged on the left side of the treatment box, a clamping mechanism is arranged on the driving mechanism, an air blowing mechanism is arranged on the front face of the treatment box, and a refrigeration mechanism is arranged on the front face of the treatment box and located on the right side of the air blowing mechanism. And a pumping mechanism is arranged on the front face of the treatment box and located below the refrigeration mechanism, a heating wire is fixedly installed in the treatment box, and a heat preservation layer is fixedly installed on the inner wall of the treatment box. According to the heat treatment device for the stainless steel bar, the clamping mechanism is arranged, a rotating handle is held to rotate a worm, the worm drives a worm wheel, the worm wheel drives a threaded rod to rotate, the threaded rod rotates to drive a threaded sliding block to ascend and descend, and the threaded sliding block drives an L-shaped plate to ascend and descend, so that the distance between two round rollers is increased or reduced; therefore, heat treatment processing requirements of bars with different apertures can be met, and processing of the bars is facilitated.

Owner:江苏百德特种合金有限公司

A roller printing machine

ActiveCN107323069BAdjustable spacingFine pitch adjustmentRotary intaglio printing pressApparatus for force/torque/work measurementPulp and paper industryScrew thread

The invention discloses a roller printing machine, belonging to the technical field of printing and dyeing. The roller printing machine comprises a printing machine base, a lead screw, a feed rod, a driving nut, a lower crossbeam, a lower printing roller, an upper crossbeam, an upper printing roller, a motor and a feed rod fine adjustment mechanism, wherein the rapid adjustment and accurate adjustment of the distance between the lower printing roller and the upper printing roller can be realized by the feed rod fine adjustment mechanism through the screw-thread fit between the lead screw and the driving nut; a driven roller is arranged on the lower crossbeam of the roller printing machine of the embodiment; a pressure sensor and a piezoelectric signal converter are arranged on the upper crossbeam; and the distance between a driving roller and the driver roller can be automatically adjusted according to the thickness of raw materials to be processed and the requirements of printing and dyeing pressure, thereby realizing the self-adaptive adjustment of pressure in the printing and dyeing process, improving the poor printing and dyeing layering of the roller printing machine and avoiding the phenomenon of defective goods such as uneven printing colors.

Owner:JIANGSU KUNTAI MACHINERY

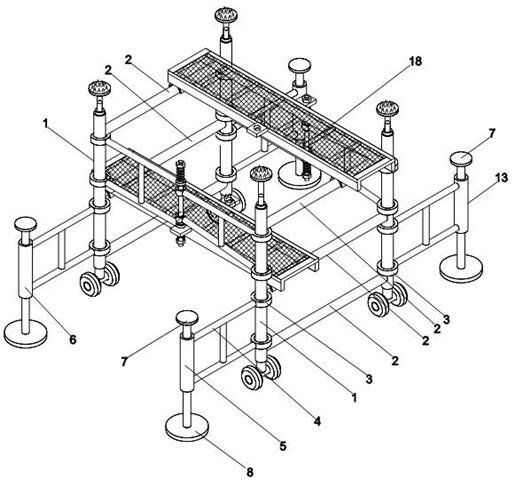

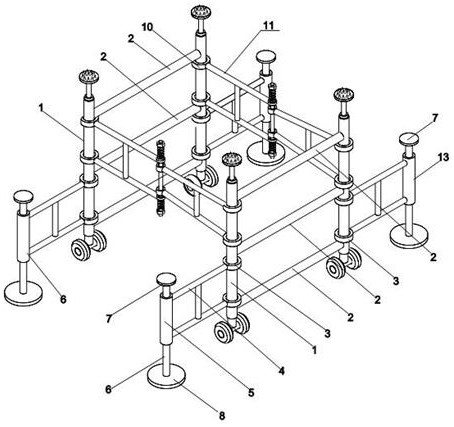

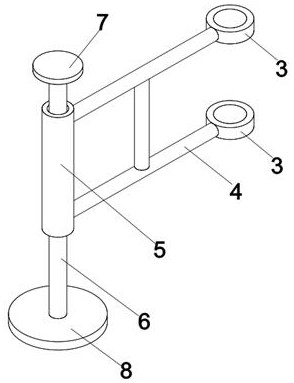

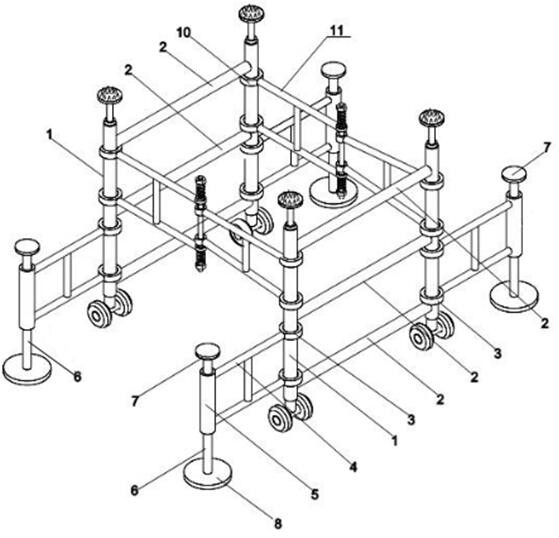

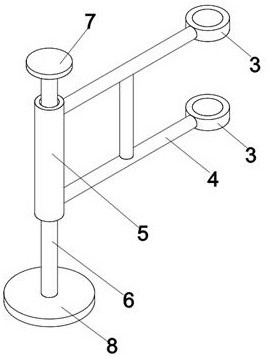

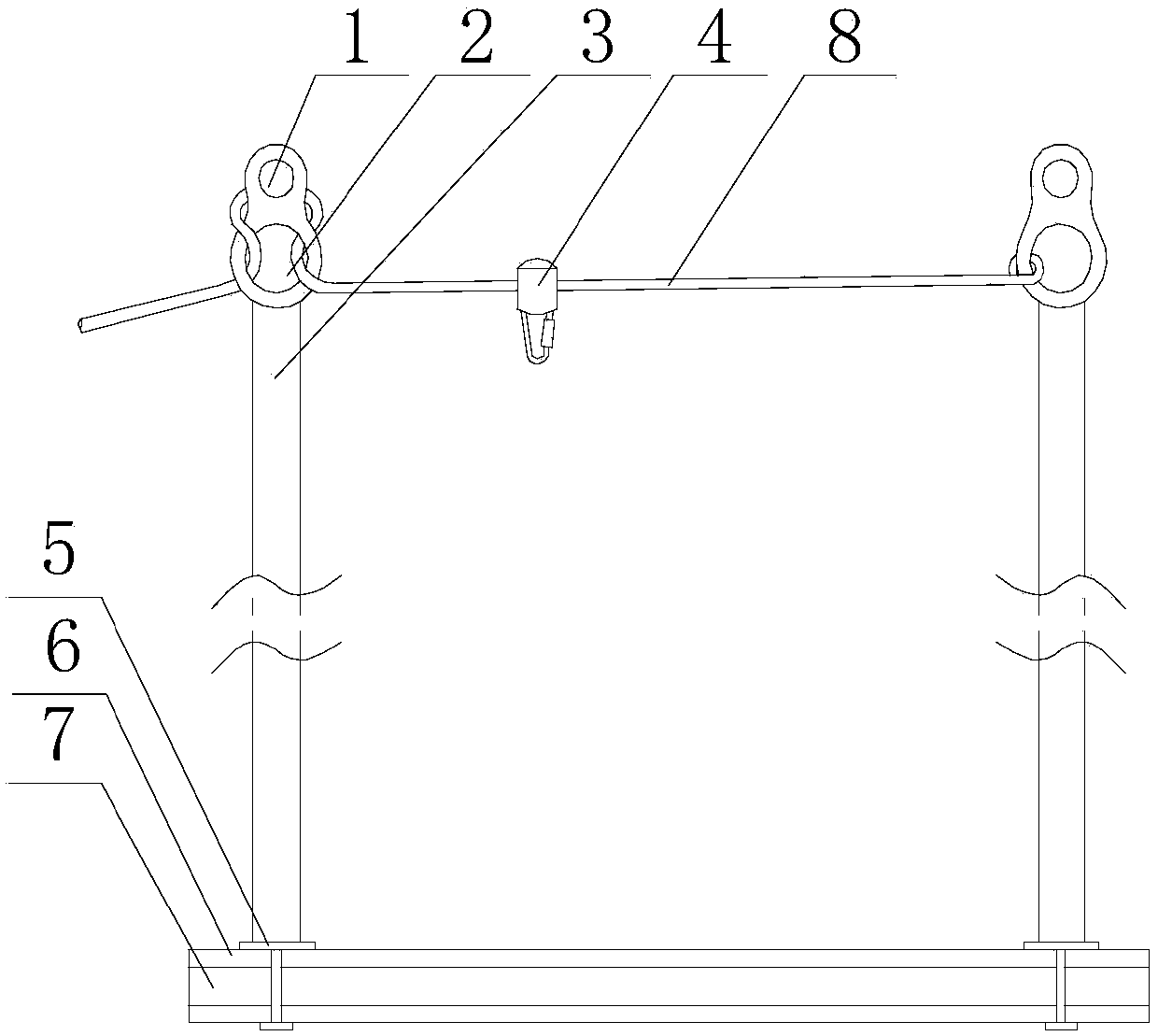

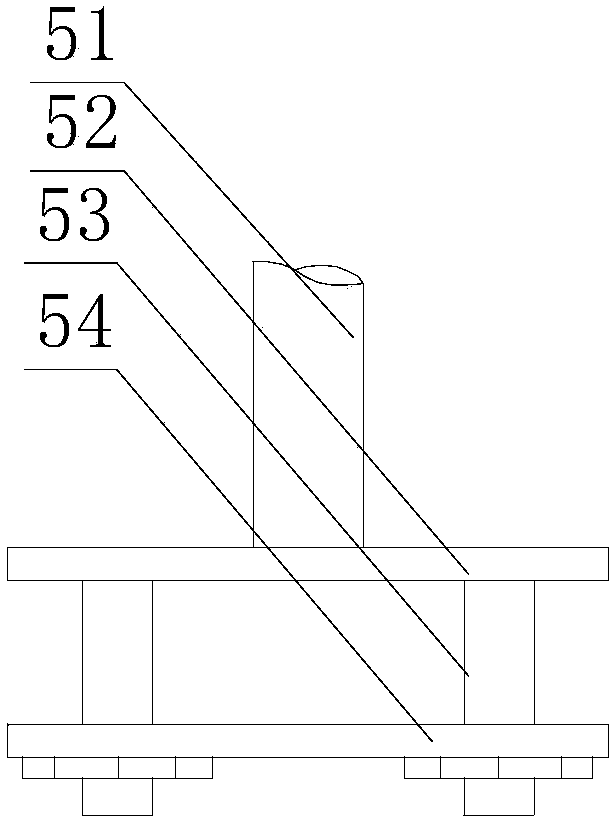

Building near-edge structure column construction protection frame

ActiveCN111622518AIncrease or decrease spacingAdapt to construction needsBuilding material handlingSupport pointScrew thread

The invention discloses a building near-edge structure column construction protection frame which comprises stand columns. Three fixing rods which are parallel and first lantern rings are arranged between the two stand columns on the same side at equal intervals in the horizontal direction. The first lantern rings are connected with threaded sleeves and first screw rods through strengthening rods.The top ends of the first screw rods are fixedly connected with rotary discs used for rotating the first screw rods. Foot plates are arranged at the bottoms of the first screw rods. Connecting devices are arranged between the stand columns. Each connecting device comprises a second lantern ring, a connecting rod and a shaft rod, wherein the shaft rod is provided with an upper fixing nut, a lowerfixing nut, an upper buffering spring and a lower buffering spring. Net frames are arranged between the fixing rods. The net frames are symmetrically fixedly provided with clamping blocks, fixing holes and clamps, and the tops of the clamps are provided with sliding blocks and sliding grooves. By means of the building near-edge structure column construction protection frame, the problems that whena common protection frame is built, the size cannot be adjusted according to the space, when high-layer supporting net frames are used, the motion range is large and use is not safe, the moving position is not convenient, a supporting point is not changed, and time and labor are wasted during demounting and mounting are solved.

Owner:奉节县华东建筑工程有限责任公司

Impression cylinder and imprinting system having such an impression cylinder

ActiveCN103722867BEasy and fast assemblySimple but sure supportRotary pressesEmbossing decorationsSpring forceEngineering

The forming cylinder has a hollow cylindrical body having two separating edges oriented in longitudinal direction of the body, such that a lateral surface broken by a gap is formed. A clamping system (10) is provided for expanding the hollow cylindrical body. The clamping system has two rotatable rings mounted on the hollow cylindrical body. The rings are connected by a carrier present in the gap. The spring elements are employed at the carrier and at the former separating edge. The spring force of the spring elements act in circumferential direction of the hollow cylindrical body.

Owner:GALLUS FERD RUESCH

A construction protection frame for structural columns on the edge of a building

ActiveCN111622518BIncrease or decrease spacingAdapt to construction needsBuilding material handlingArchitectural engineeringSupport point

The invention discloses a construction protection frame for a building's border structure column, which includes a column, and three parallel fixing rods and a first collar are arranged equidistantly in the horizontal direction between the two columns on the same side, and the first set The ring is connected with a threaded sleeve and a first screw through a reinforcing rod, the top of the first screw is fixedly connected with a turntable for rotating the first screw, the bottom of the first screw is provided with a foot plate, and the uprights are provided with A connection device, the connection device includes a second collar, a connecting rod, and a shaft rod, the shaft rod is provided with upper and lower fixing nuts and upper and lower buffer springs, a grid frame is arranged between the fixing rods, and the The network frame is symmetrically fixed with blocks, fixing holes and clamps, and the top of the clamps is provided with a slide block and a chute. This device solves the problems that the commonly used protective frame cannot be adjusted according to the space when it is built, the high-level support grid frame has a large range of activities, is unsafe, it is inconvenient to move the position and cannot change the support point, and it is time-consuming and laborious to disassemble.

Owner:奉节县华东建筑工程有限责任公司

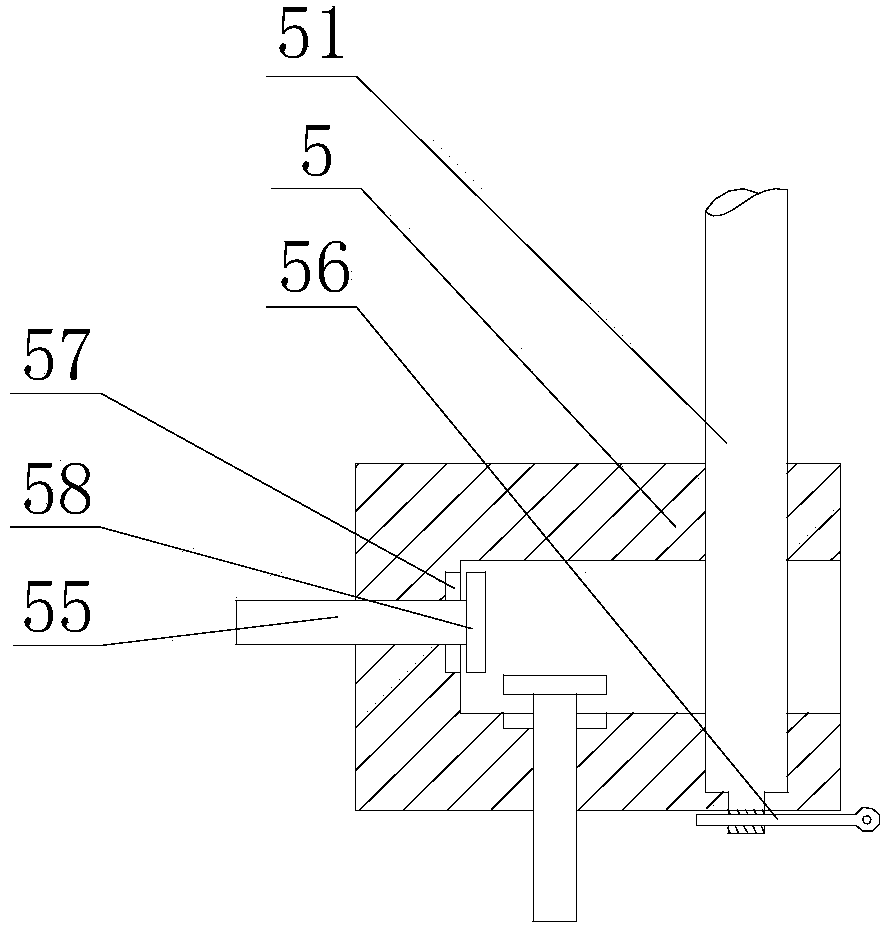

Fiber fixing clamp suitable for fixation of inclined planes

ActiveCN107367815AEasy to fixAdjustable lengthOptical fibre/cable installationFiberThreaded fastener

The invention discloses a fiber fixing clamp suitable for fixation of inclined planes. The clamp comprises a fiber sheath. A screw penetrates through the fiber sheath. The fiber sheath and the screw are screwed together. The fiber sheath is capable of moving along the screw. A connection rod is hinged to one end of the screw. The hinging place can be fixed through a screw fastening piece. One end, away from the screw, of the connection rod is equipped with a C-type fixing rack. The C-type fixing rack comprises an installation plate 1, an installation plate 2 and an installation plate 3. Two ends of the installation plate 2 are hinged to the installation plate 1 and the installation plate 3, and hinging places can be fixed through thread fastening pieces. One end of the installation plate is connected with one end, away from the screw, of the connection rod. A press screw penetrates through the installation plate 3. Each of the installation plate 1, the installation plate 2 and the installation plate 3 comprises a flat plate 1 and a flat plate 3. The flat plates 1 are connected with the flat plates 2 through telescoping rods. According to the invention, the clamp is suitable for fixation on multiple kinds of planes; positions of feed line cards can be quite flexibly adjusted; and feed lines can be fixed and are not liable to fall off.

Owner:锋迈(厦门)半导体科技有限公司

Anti-thread-loose type spinning processing device used for flax textile device

The invention provides an anti-thread-loose type spinning processing device used for a flax textile device, and relates to the technical field of textile devices. The problems that existing textile anti-thread-loose equipment only limits spun threads in a clamping groove, the situation that spun threads are knotted to directly influence normal use of a textile device is caused by large-amplitude movement, the winding positions of spun threads cannot be adjusted, the equipment is not suitable for most textile machines, and time is quite consumed due to the fact that the equipment needs to be suspended for a period of time to replace spun threads when spun threads are added every time are solved. The anti-thread-loose type spinning processing device used for the flax textile device comprisesa frame body mechanism, a limiting mechanism, a first thread table mechanism, a second thread table mechanism, an adjusting mechanism and anti-thread-loose devices. Movable base plates are slidably connected into a platen clamping groove, sliding of the movable base plates is limited through screws connected with the movable base plates and auxiliary mounting plates, and the positions of the three anti-thread-loose devices can be adjusted on an adjusting mechanism.

Owner:章小燕

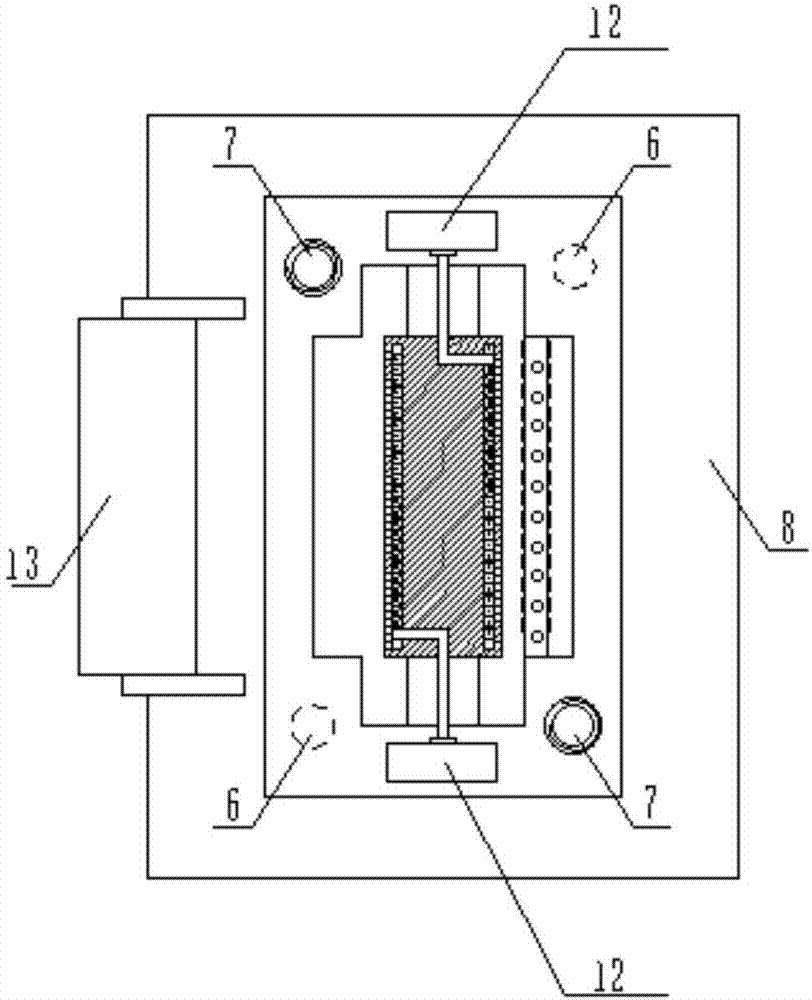

Foaming formwork positioning device on door body foaming line

Owner:CHUZHOU ASPIRE IND TECH

Accurate guiding and positioning equipment

InactiveCN102180348BAchieve positioningAchieve alignmentCharge manipulationConveyor partsFlat glassEngineering

The invention discloses accurate guiding and positioning equipment which comprises a base plate, a power mechanism, a flat plate fixing base, a transmission piece, a plurality of transmission wheels and a plurality of positioning components. The transmission wheels are fixed on the periphery of the base plate; the transmission piece is wound on the transmission wheels; a machining region is formed on the inner side of the transmission piece; the power mechanism is connected with one transmission wheel; a sub transmission region is formed between two adjacent transmission wheels corresponding to the transmission piece; the positioning components are fixed on the input side of the sub transmission region; each positioning component comprises a guide wheel rod seat, a guide wheel fixed rod seat, a guide wheel fixed rod, a guide rod and a guide rail sliding block; the guide wheel fixed rod seat is fixed on a corresponding sub transmission region; one end of the guide wheel rod seat is fixedly connected on the guide wheel fixed rod seat, and the other end of the guide wheel rod seat extends into the machining region; the guide wheel fixed rod is fixed on the upper surface of the guide wheel rod seat; and the guide wheel is fixed at the upper end of the guide wheel fixed rod. The transmission piece drives the positioning components to move at the same time, so that a flat glass plate is positioned.

Owner:DONGGUAN ANWELL DIGITAL MASCH CO LTD

Automatic feeding multi-head melt extrusion forming 3d printing equipment

ActiveCN105619820BIncrease profitImprove equipment utilizationAdditive manufacturing apparatus3D object support structuresEngineeringGlyph

The invention discloses an automatic feeding multi-head melt extrusion forming 3D printing equipment, including a 3D printer and an injection molding machine; the 3D printer includes a 3D printer base, a 3D printer support, an X-axis module that forms a vertical movement pair with the 3D printer support, The print head mounting plate that forms a horizontal movement pair with the X-axis module, and the printing object support platform that forms a horizontal movement pair with the 3D printer base, the print head mounting plate is perpendicular to the direction of movement of the printing object support platform, and the print head mounting plate is inverted T In the shape of a font, the vertical part of the print head mounting plate is slidably installed on the X-axis module, and more than one print head is detachably installed on the horizontal part. The beneficial effects of the present invention are: setting up multi-printing heads that can be easily disassembled, increasing or decreasing, and adjusting spacing to print at the same time; Utilization and equipment utilization, saving production costs.

Owner:ANHUI SCI & TECH UNIV

Insulation operating platform for isolation switch

The invention discloses an insulation operating platform for an isolation switch. The insulation operating platform comprises two bases. A supporting rod is fixed to the upper end of each base, and afixing block is arranged at the upper end of each supporting rod. Small holes and large holes are sequentially formed in the fixed blocks in the axes of the supporting rods from top to bottom. The axes of the small holes are parallel to the axes of the large holes. The initial end of a safety rope is connected to one fixing block; the end of the safety rope passes through the inside of the large holes on the other fixing block, is wound half a turn on the outer side walls of the small holes, and then passes through the large holes again and continues to extend outwards. An operator can adjusthis / her position in time according to the change of an inspection station to solve the inconvenience of fixed-point positioning and maintenance. At the same time, in the event of an accident, the operator can be quickly lowered to the ground by releasing the fastening state at the end of the safety rope to prevent the operator from being left in a suspended state after the occurrence of the danger, the emergency time is shortened and the construction safety of the operator is ensured to the maximum extent.

Owner:PANZHIHUA POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER

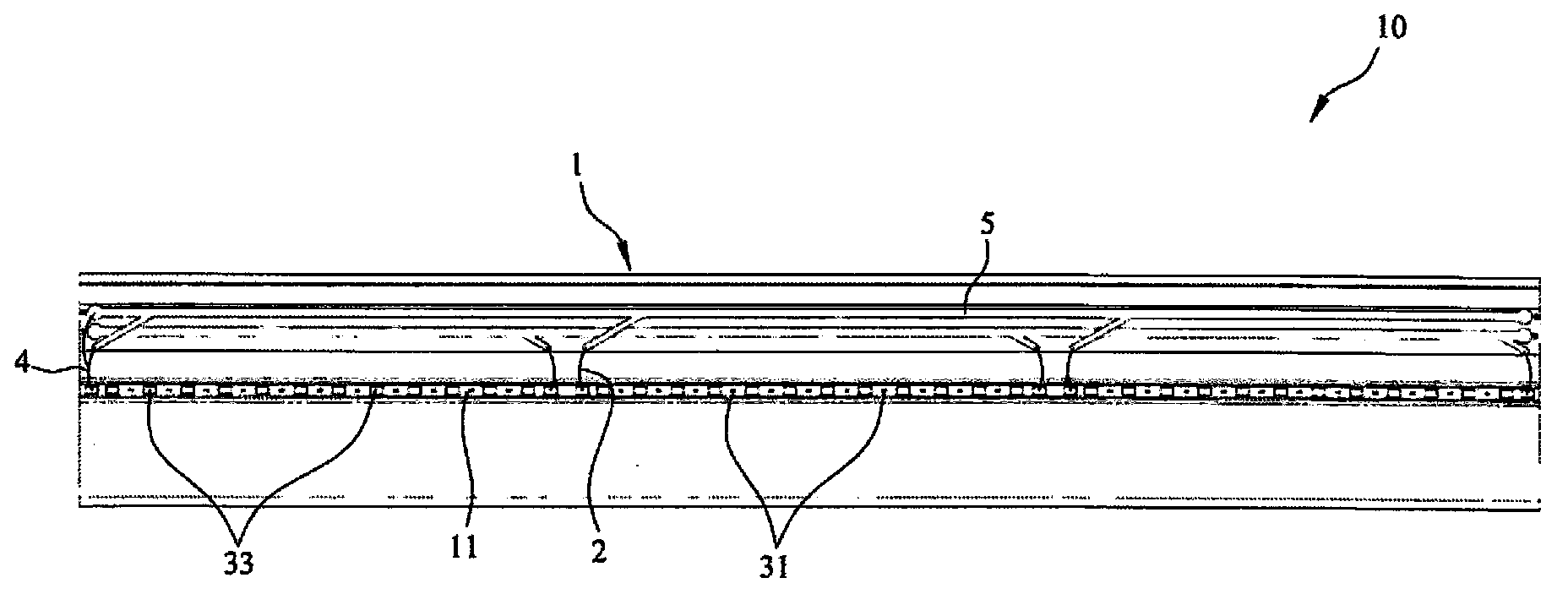

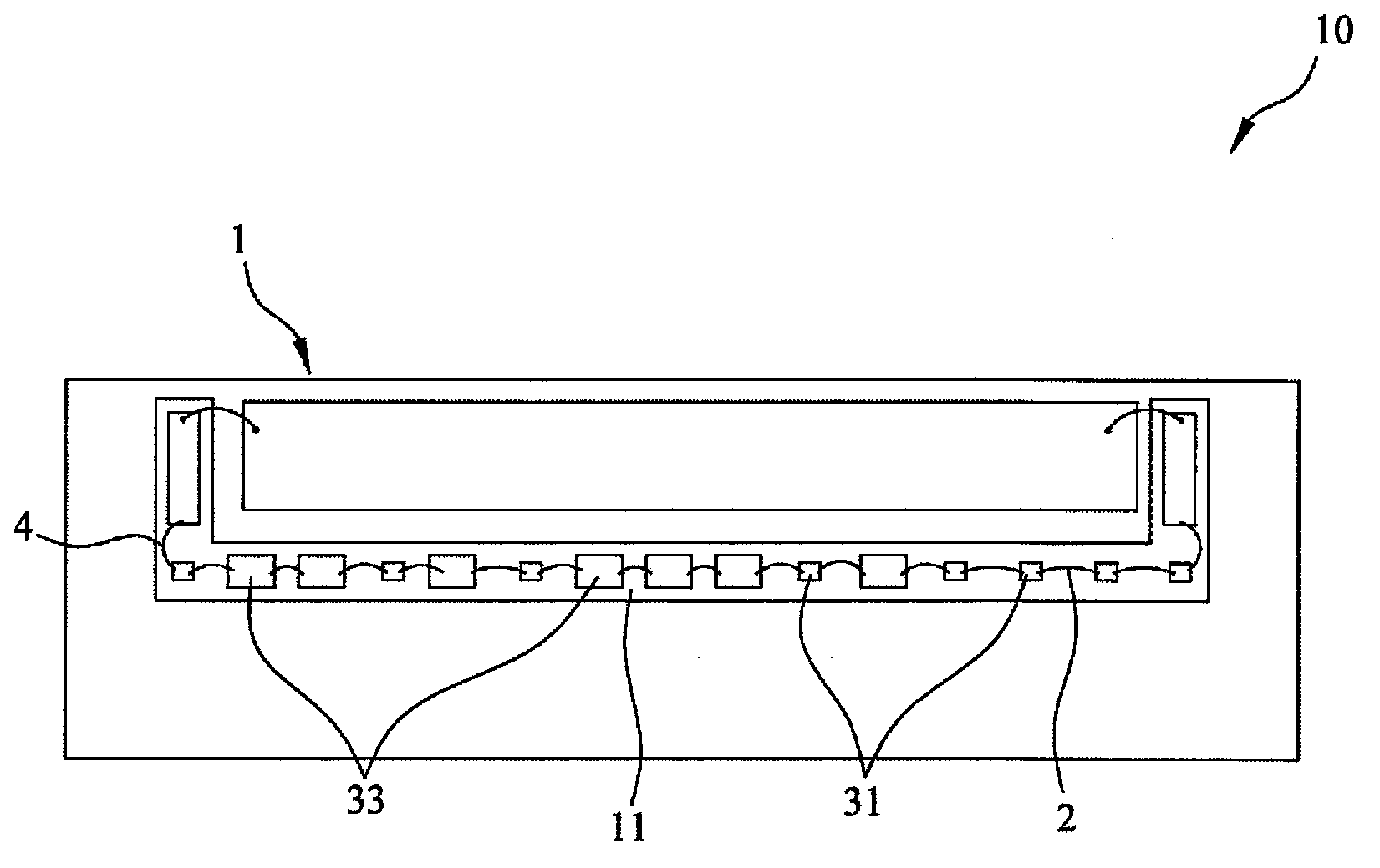

Modular integrated multilayer LED lamp tube

InactiveCN104344244AShorten production timeSimplify the processPoint-like light sourceElongate light sourcesModularityEngineering

A modular integrated multilayer LED lamp tube mainly comprises a modular LED base, a radiating base and a modular lead frame, wherein the modular LED base is formed by integrating a base with a trench structure, a lighting unit and a bridge connection unit, and the radiating base is arranged to be flower-shaped, so that the radiating area thereof is increased substantially and the radiating efficiency thereof is improved substantially. The temperature of the lighting unit is kept within a proper range, so that optimum light-emitting efficacy is maintained. Additionally, the modular lead frame can enable a circuit unit and the bridge connection unit to be connected electrically. The modular integrated multilayer LED lamp tube has the advantages that the modular LED base, the radiating base and the modular lead frame can be prefabricated and can be assembled to form lamp tubes in various specifications according to actual needs at any time, modular assembly is rapid, and accordingly overall fabrication time can be shortened effectively and overall fabrication cost can be reduced effectively.

Owner:盈勝科技股ふん

Flame retardant impregnation device for foamed plastic board

The invention discloses a flame retardant impregnating device of a foam plastic board. The flame retardant impregnating device comprises a rack, an upper conveying roller group, a lower conveying roller group and a vacuum impregnating mechanism, wherein the linear speed of the upper conveying roller group is matched with that of the lower conveying roller group; the vacuum impregnating device comprises a bottom plate arranged between two adjacent conveying rollers; multiple suction grooves are formed in the surface of the bottom plate; a main suction pipe is arranged at the bottom of the bottom plate; each suction groove is communicated with the main suction pipe which is communicated with a vacuum system; when the foam plastic board is conveyed on the bottom plate, the foam plastic board, the upper conveying roller group at two sides of the bottom plates and two side roller frames form a containing space for containing the flame retardant, a vacuum cavity is formed between the foam plastic board and the suction grooves, and the forward conveying force applied on the foam plastic board by the upper and lower conveying roller groups is greater than the friction between the foam plastic board and the bottom plate. According to the flame retardant impregnating device of the foam plastic board, the flame retardant can be uniformly impregnated into the foam plastic board, the structure is simple, the equipment volume is small and the energy consumption and cost are low.

Owner:ZHANGJIAGANG SHUANGCHENG ELECTRICIAN EQUIP CO LTD

An H-shaped steel main girder connection device with adjustable balance

ActiveCN111472445BIncrease spacingIncrease (or decrease spacingBuilding constructionsEngineeringMechanical engineering

Owner:GUIZHOU UNIV

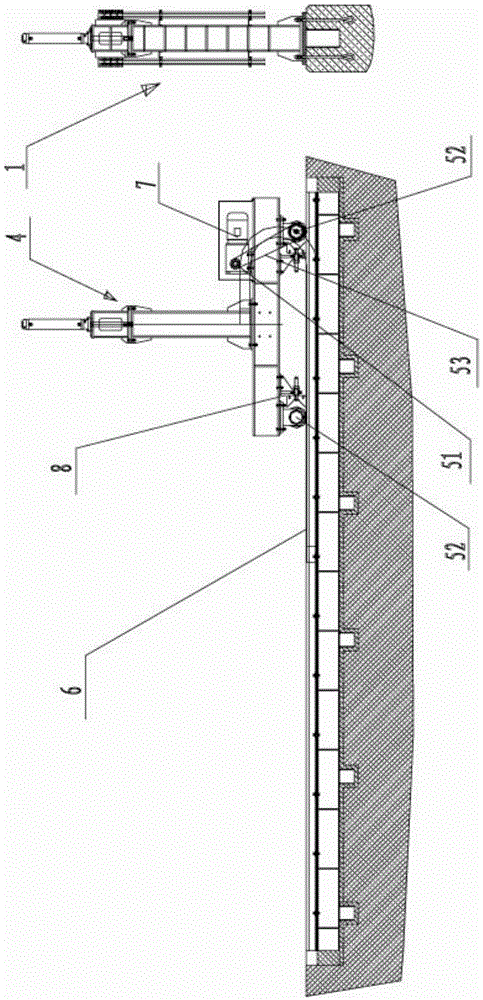

Thin plate grinding machine rolling structure

PendingCN111660198AIncrease or decrease spacingEasy to processEdge grinding machinesGrinding carriagesThin slabStructural engineering

The invention relates to a thin plate grinding machine rolling structure. The thin plate grinding machine rolling structure is fixed between a first side plate and a second side plate which are opposite to each other of a thin plate grinding machine, the thin plate grinding machine comprises a second brush grinding set and a first brush grinding set, the first brush grinding set comprises a firstback pressure wheel and a first roller which correspond to each other up and down, and thin plates passes between the first back pressure wheel and the first roller; one end of the first back pressurewheel is connected with a first lifting mechanism, the other end of the first back pressure wheel is connected with a second lifting mechanism, and the first lifting mechanism and the second liftingmechanism drive the two ends of the first back pressure wheel to move up and down respectively so as to adjust the distance between the bottom end of the first back pressure wheel and the top end of the first roller. According to the thin plate grinding machine rolling structure, by adjusting ascending and descending of the first back pressure wheel, the distance between the first roller and the first back pressure wheel is increased or decreased so as to adapt to thin plates of different thickness specifications, the machining process of the thin plates can be more convenient, and meanwhile the material and labor cost for material replacement is reduced.

Owner:东莞市鸿仁自动化设备科技有限公司

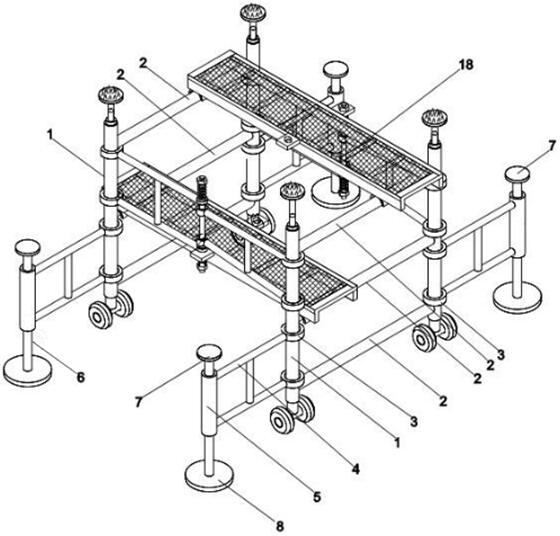

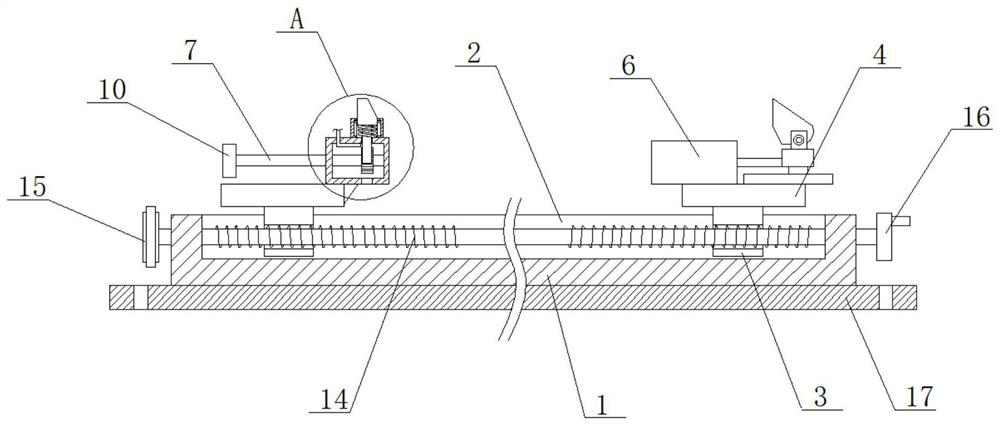

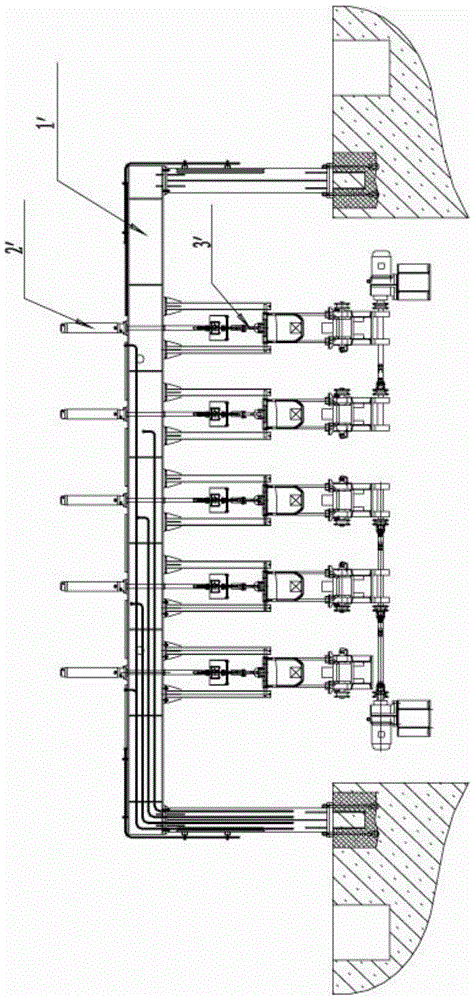

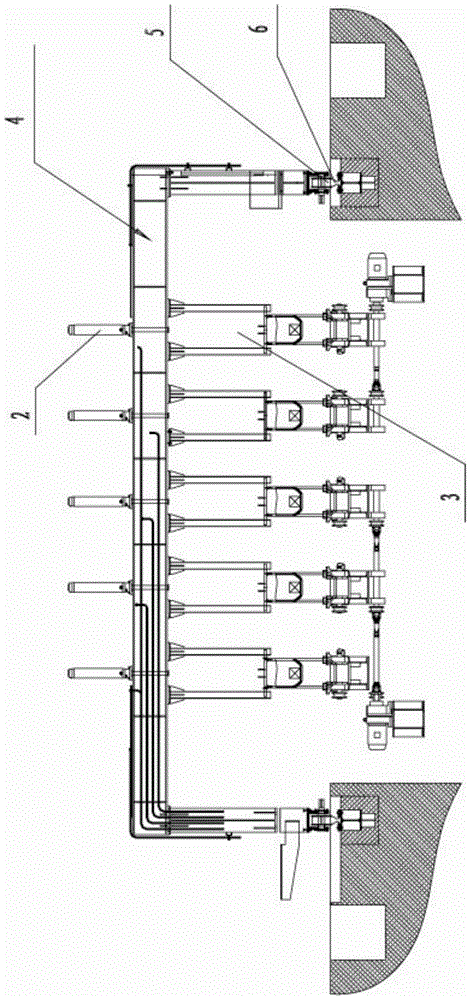

Mobile Weighing and Sizing Platform for Continuous Casting Machine Billets

ActiveCN104289691BConvenient online weighingIncrease or decrease spacingCasting parameters measurement/indication devicesDrive wheelEngineering

Owner:BEIJING ZHONGYUANTONG SCI & TECH

Integration multi-layer type LED lamp tube with bridging unit

InactiveCN104132258AReduce dosageReduce manufacturing costPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention provides an integration multi-layer type LED lamp tube with a bridging unit. The integration multi-layer type LED lamp tube comprises a heat dissipation base, a lighting unit and the bridging unit, a groove is formed in the heat dissipation base, the lighting unit composed of a plurality of LED crystalline grains and the bridging unit composed of a plurality of conducting elements are arranged on the bottom face of the groove, and an optical layer and a protective layer are arranged in the groove. The conducting elements are utilized for being connected with the LED crystalline grains, and therefore according to different use aims, gaps between the LED crystalline grains can be increased or shortened, the set density of the LED crystalline grains has the elasticity, the brightness of the LED lamp tube is optimal, and after the LED crystalline grains are arranged on the groove, and the optical layer and the protective layer are formed on the LED crystalline grains, manufacturing of the LED lamp tube is roughly completed. Therefore, many unnecessary manufacture procedures are removed, and the aims of effectively shortening the manufacturing time and reducing the manufacturing cost are achieved.

Owner:盈勝科技股ふん

Auxiliary device and method for picking cherries with sawtooth knife and easy-to-adjust comb structure

ActiveCN108901358BComb in orderlyIncrease or decrease the numberPicking devicesPull forceElectric machinery

The invention discloses a serrated knife assisted cherry picking device with an easy-to-adjust comb structure and a picking method thereof. An existing fruit picking machine is not easy to move and ishigh in manufacture cost. The serrated knife assisted cherry picking device consists of a telescopic device, a collecting device and a serrated knife comb picking device, wherein a transmission gearcolumn is driven by a motor; springs are arranged between the transmission gear column and a second intermediate gear column as well as a first intermediate gear column and a support gear column, twonuts connected to a threaded rod are arranged between the first intermediate gear column and the second intermediate gear column, and a spring is arranged between the two nuts; nuts are arranged on the outer sides of the transmission gear column and the support gear column; adjusting gears are fixedly arranged at two ends of each gear column; two ends of a serrated knife are separately fixed withthe support gear column and the transmission gear column. When shearing, the adjusting gears rotating to the top are used to comb cherry roots and provide a pulling force to the cherry roots; when theserrated knife rotating to the top is close to a fixed blade on a shell, the cherry roots are cut off by combined action of the shearing force of the serrated knife and the pulling force of the adjusting gears. The serrated knife assisted cherry picking device is small in size and low in cost.

Owner:浙江知多多网络科技有限公司

Fiber Fixing Fixtures for Inclined Surfaces

The invention discloses a fiber fixing clamp suitable for fixation of inclined planes. The clamp comprises a fiber sheath. A screw penetrates through the fiber sheath. The fiber sheath and the screw are screwed together. The fiber sheath is capable of moving along the screw. A connection rod is hinged to one end of the screw. The hinging place can be fixed through a screw fastening piece. One end, away from the screw, of the connection rod is equipped with a C-type fixing rack. The C-type fixing rack comprises an installation plate 1, an installation plate 2 and an installation plate 3. Two ends of the installation plate 2 are hinged to the installation plate 1 and the installation plate 3, and hinging places can be fixed through thread fastening pieces. One end of the installation plate is connected with one end, away from the screw, of the connection rod. A press screw penetrates through the installation plate 3. Each of the installation plate 1, the installation plate 2 and the installation plate 3 comprises a flat plate 1 and a flat plate 3. The flat plates 1 are connected with the flat plates 2 through telescoping rods. According to the invention, the clamp is suitable for fixation on multiple kinds of planes; positions of feed line cards can be quite flexibly adjusted; and feed lines can be fixed and are not liable to fall off.

Owner:锋迈(厦门)半导体科技有限公司

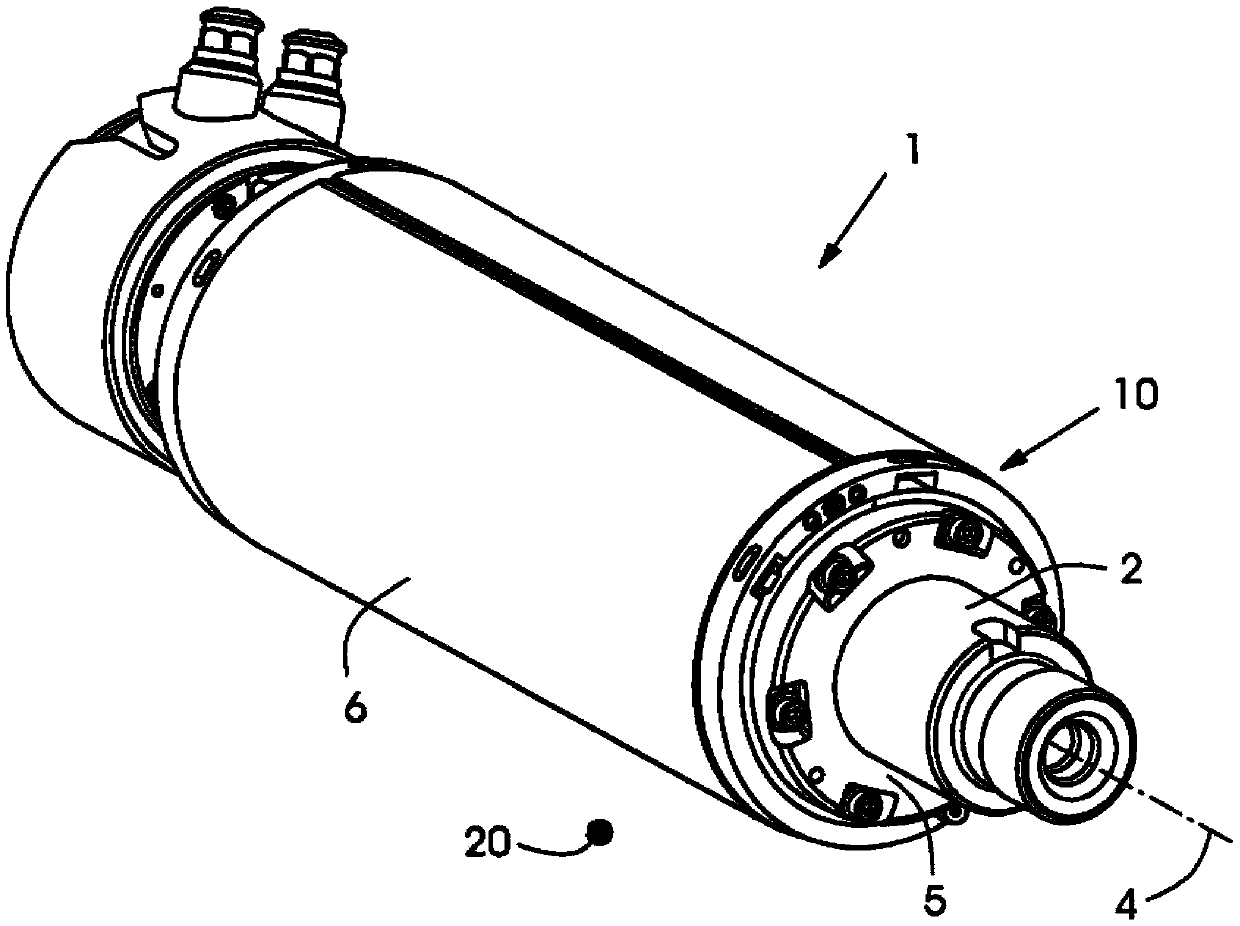

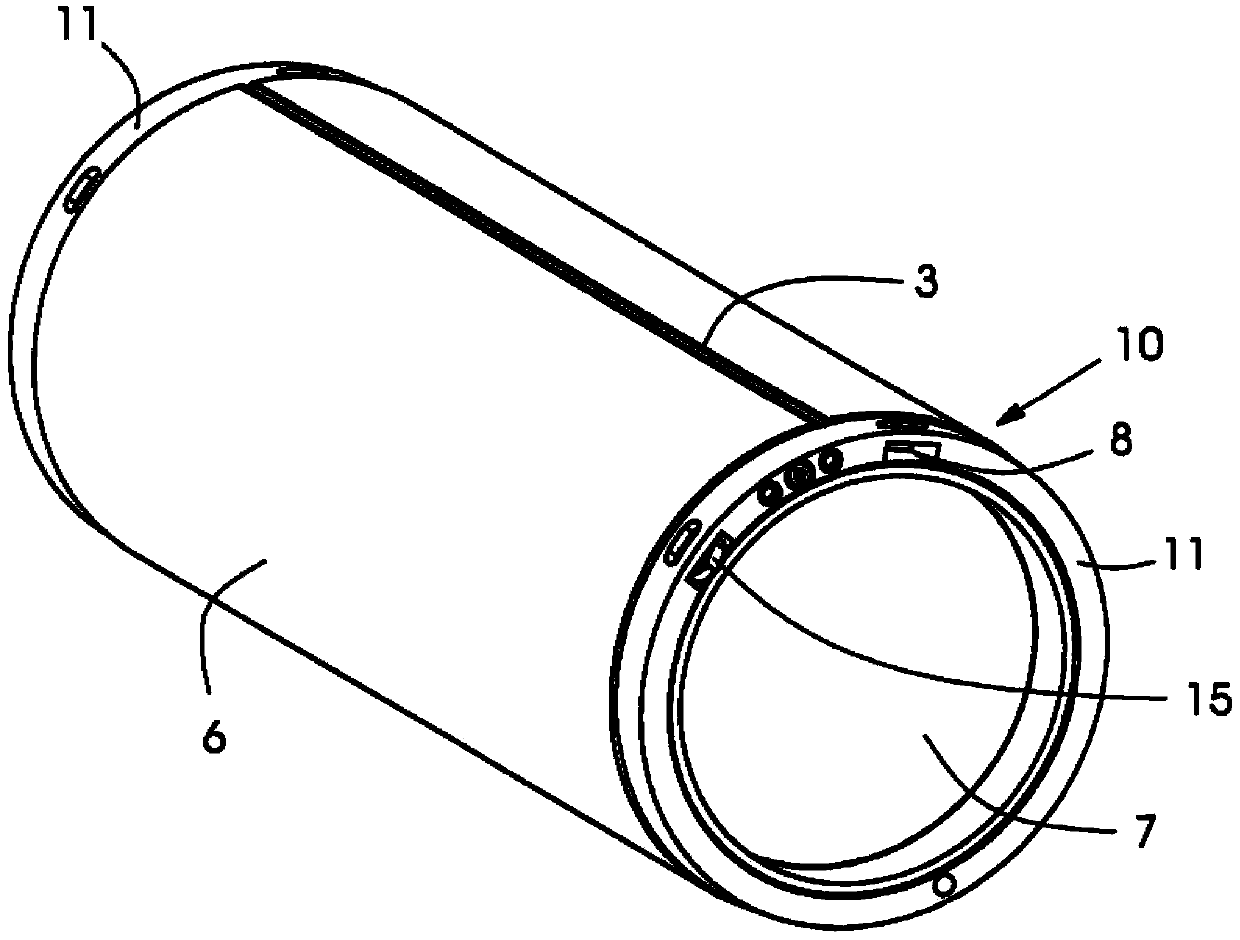

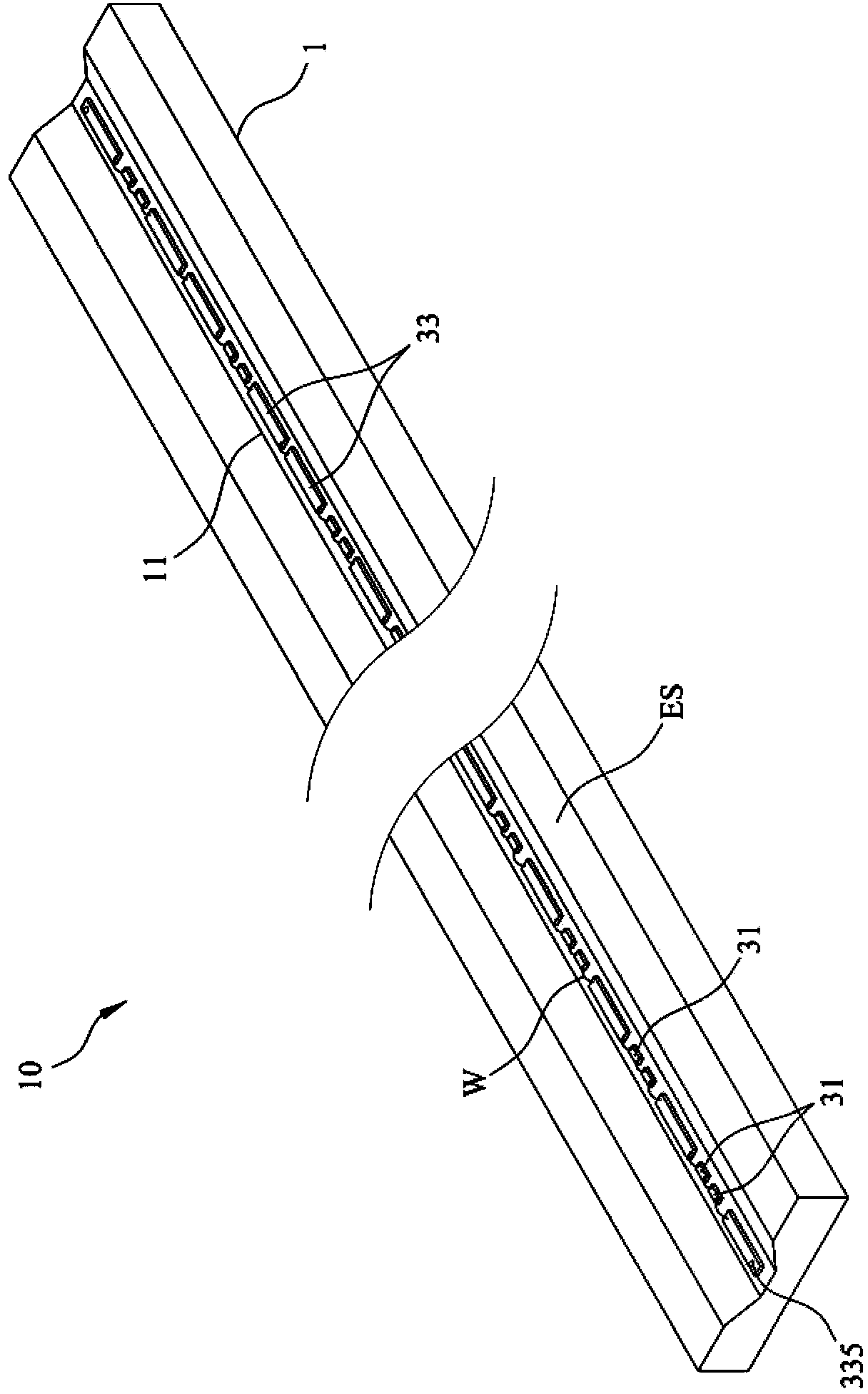

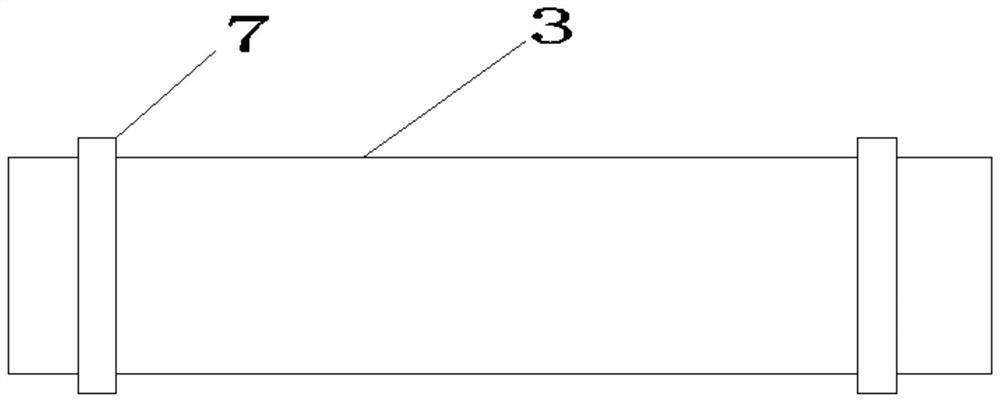

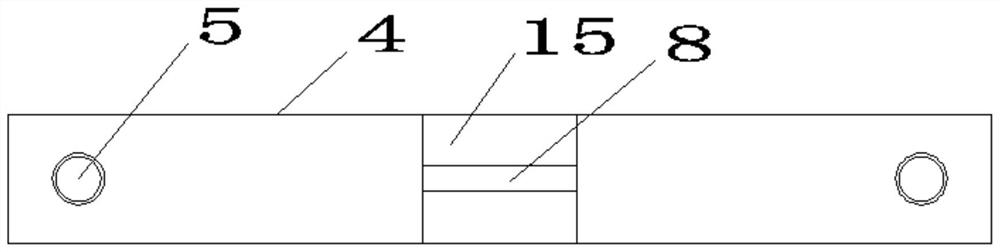

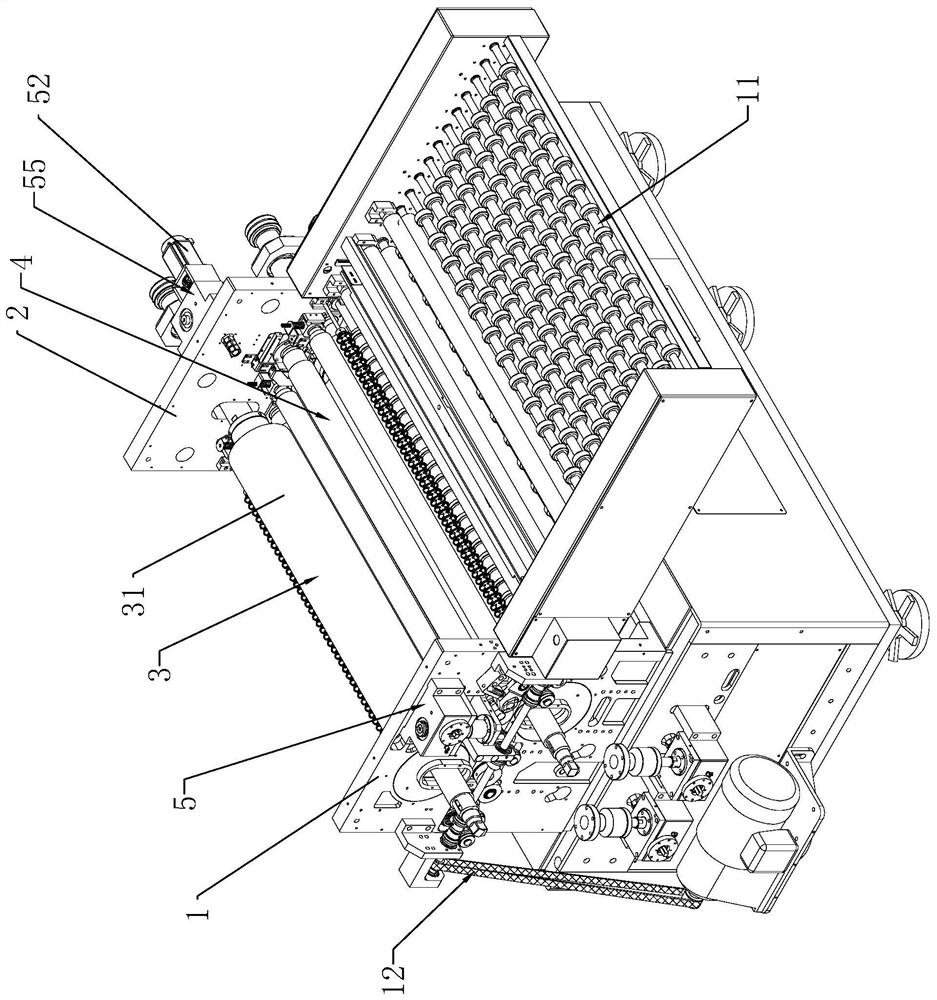

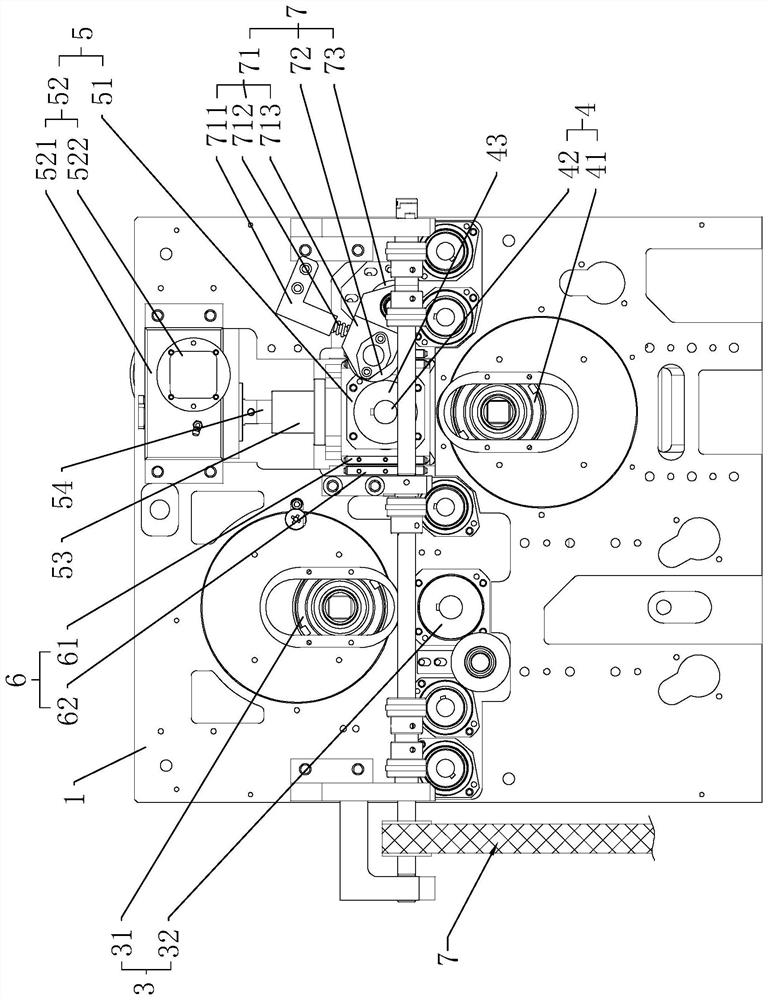

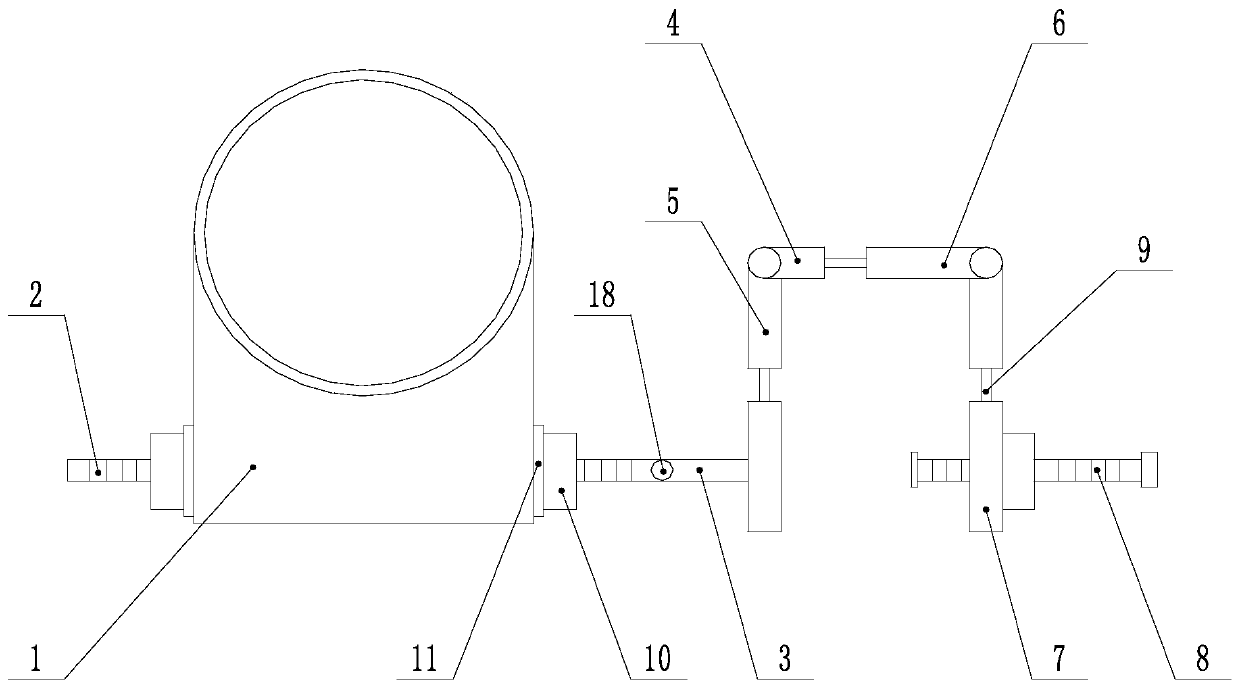

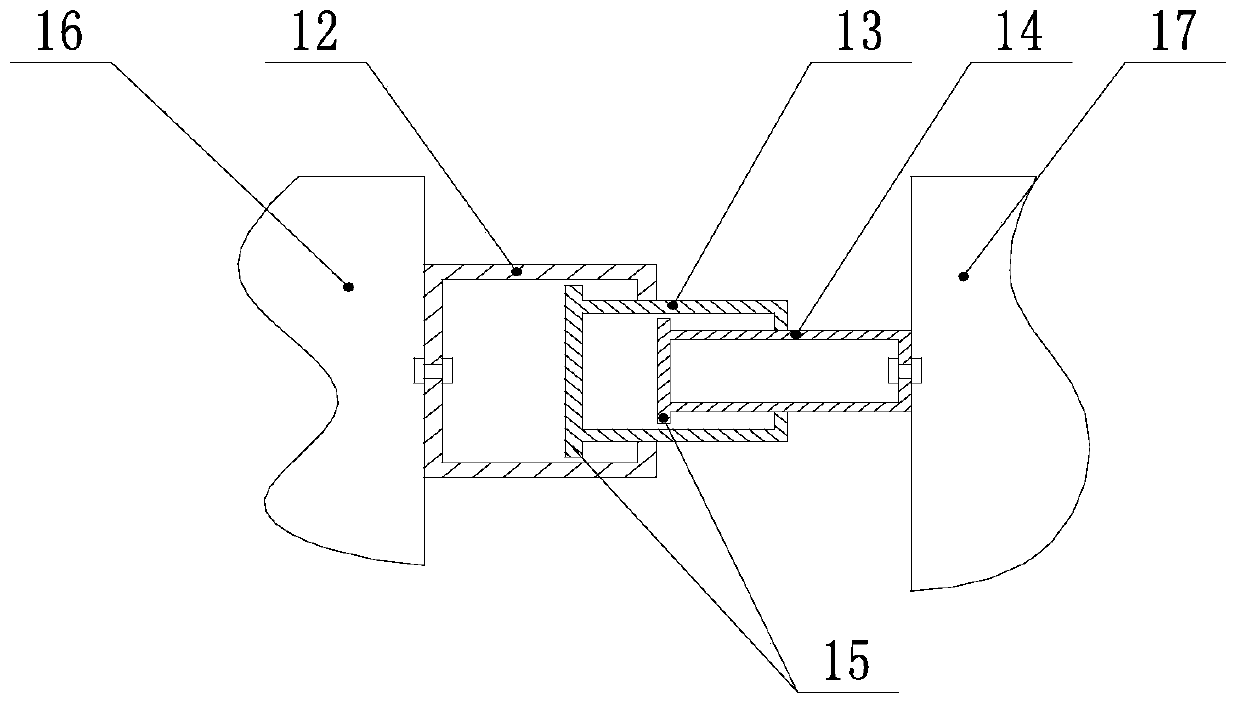

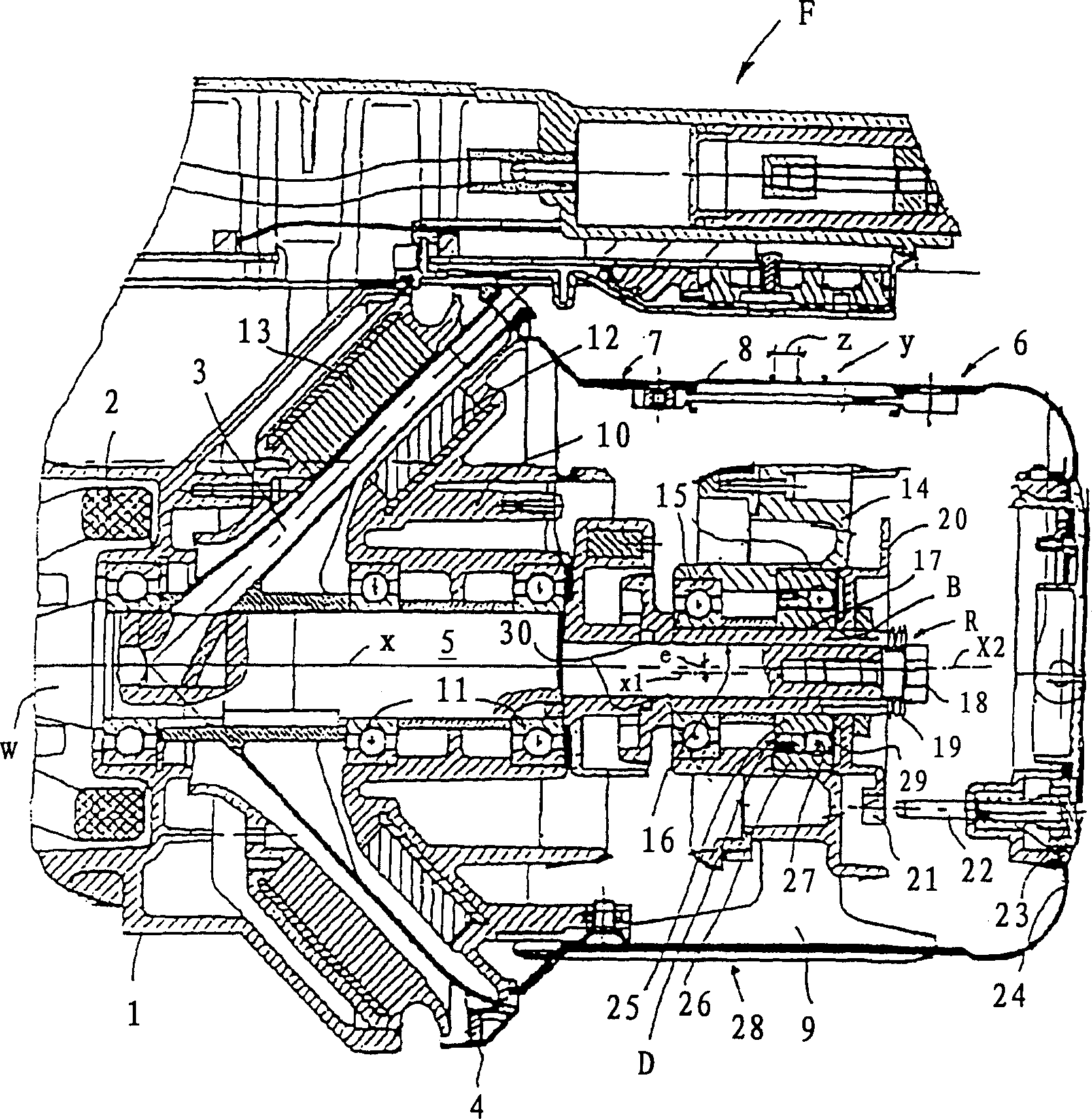

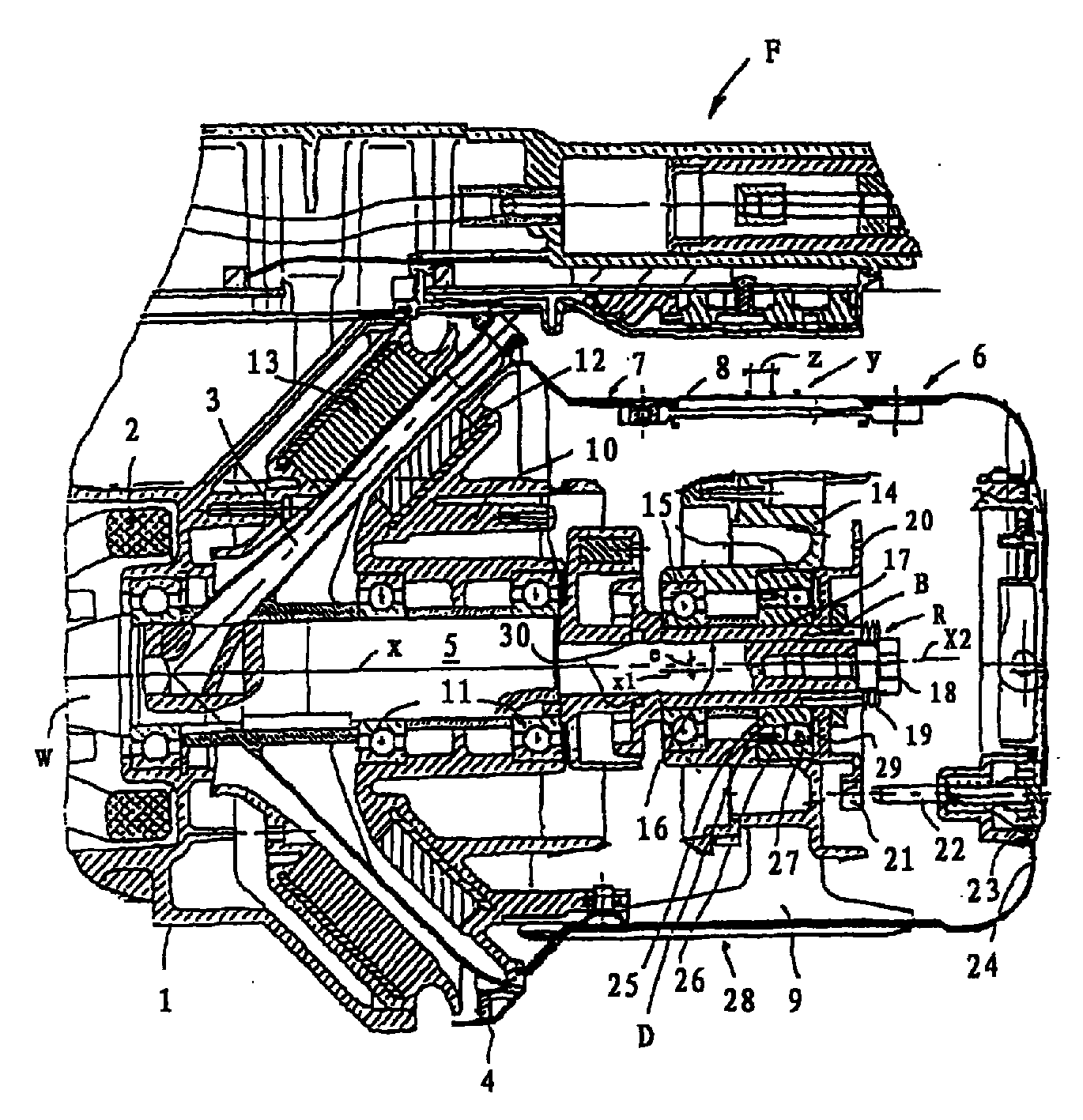

Yarn feeding device

The invention relates to a yarn feeding device (F) with a stationary storage drum and an adjustable yarn pitch. The yarn feeding device comprises a motor housing, a drive shaft of a reeling element (3) and a storage drum (6). Said storage drum consists of meshing finger-shaped cages (7, 8 and 28). The finger-shaped advance cage (28) has an advance bearing (15) that is eccentric and sloped with respect to the drive shaft (W). A recoil break (D) for the take-up element (3) is mounted in said advance cage. Said recoil brake (D) is furthermore interposed between the finger-shaped advance cage (28) and the drive shaft (W).

Owner:IROPA AG (CH)

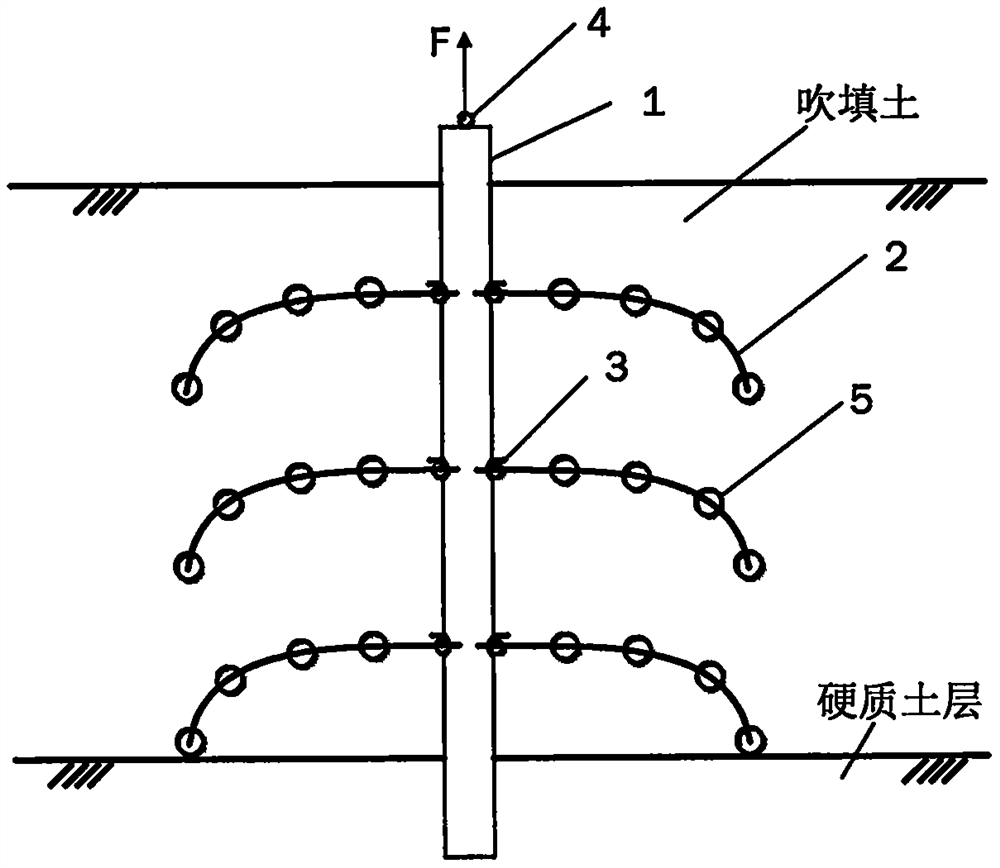

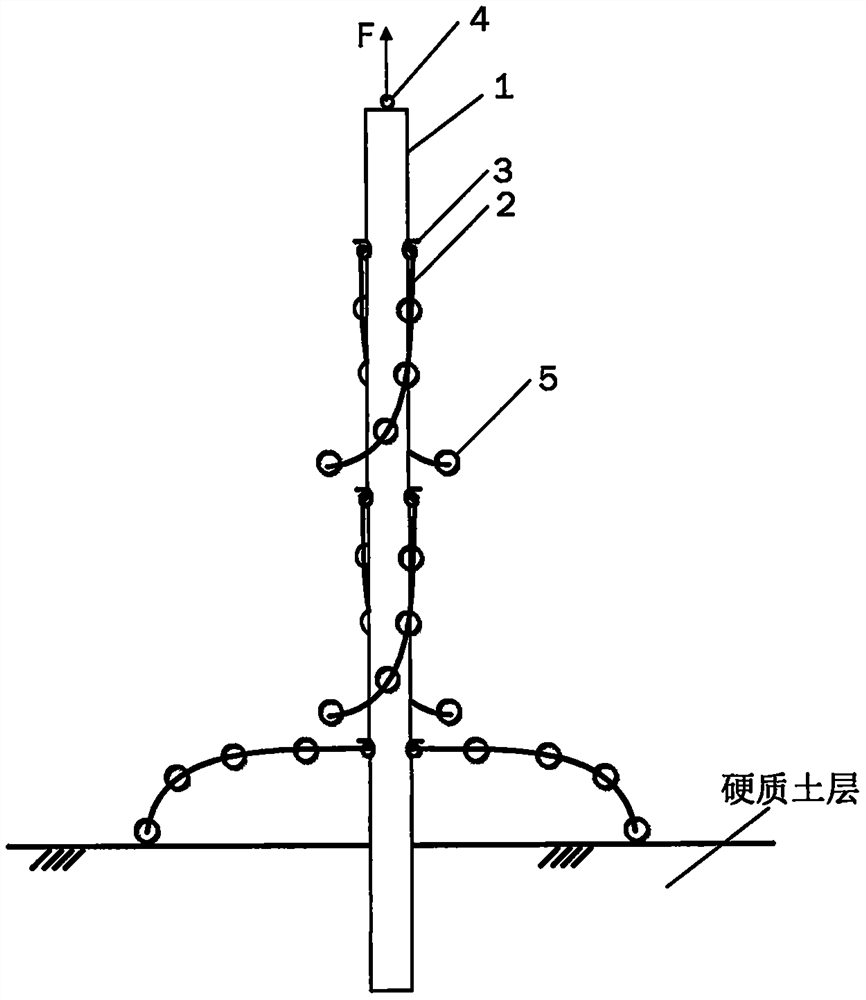

Self-floating spatial spiral net-shaped drainage device and working method

PendingCN114875887AIncrease processing spatial scaleShorten the lengthSoil preservationWhole bodyMechanical engineering

The invention provides a self-floating type spatial spiral net-shaped drainage device and a working method. The device comprises a main drainage belt, drainage branches, limiters, hanging holes and floating balls. The main drainage belt is a traditional flexible drainage belt; the drainage branches are of arc-shaped hard tubular structures, geotechnical cloth wraps the surfaces of the drainage branches, the drainage branches have water permeability, and water in the drainage branches can be drained through the top of the main drainage belt; the floating balls are equidistantly distributed on the drainage branches; in a dredger fill construction site, the lower end of the main drainage belt is pre-buried in a hard soil layer to be fixed, and in the rising process of dredger fill, the floating balls drive the drainage branches to rise by means of buoyancy brought by the dredger fill, so that the whole body is of a spatial spiral net structure; compared with a traditional drainage belt, the device has the advantages that transverse and vertical treatment ranges are increased, the length of a drainage path is effectively reduced, the treatment space scale of the same drainage belt is increased, and the overall treatment range and treatment efficiency of a whole drainage device system are guaranteed.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com