Self-floating spatial spiral net-shaped drainage device and working method

A drainage device and self-floating technology, which is applied in the direction of infrastructure engineering, construction, soil protection, etc., can solve the problem of gradual clogging of plastic drainage boards and drainage failure, the decrease of the permeability coefficient of the vacuum filter membrane, and the drainage path of the drainage belt Single and other problems, to achieve fine control of drainage path and treatment range, increase vertical treatment range, and increase the effect of treatment space scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

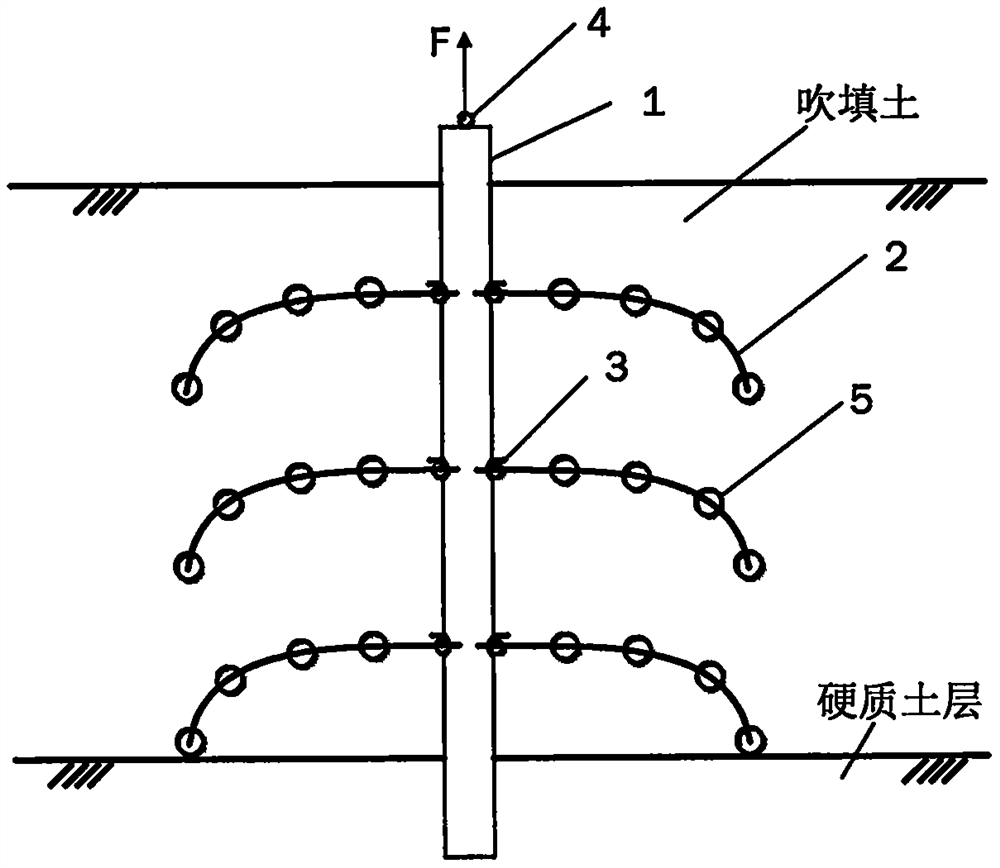

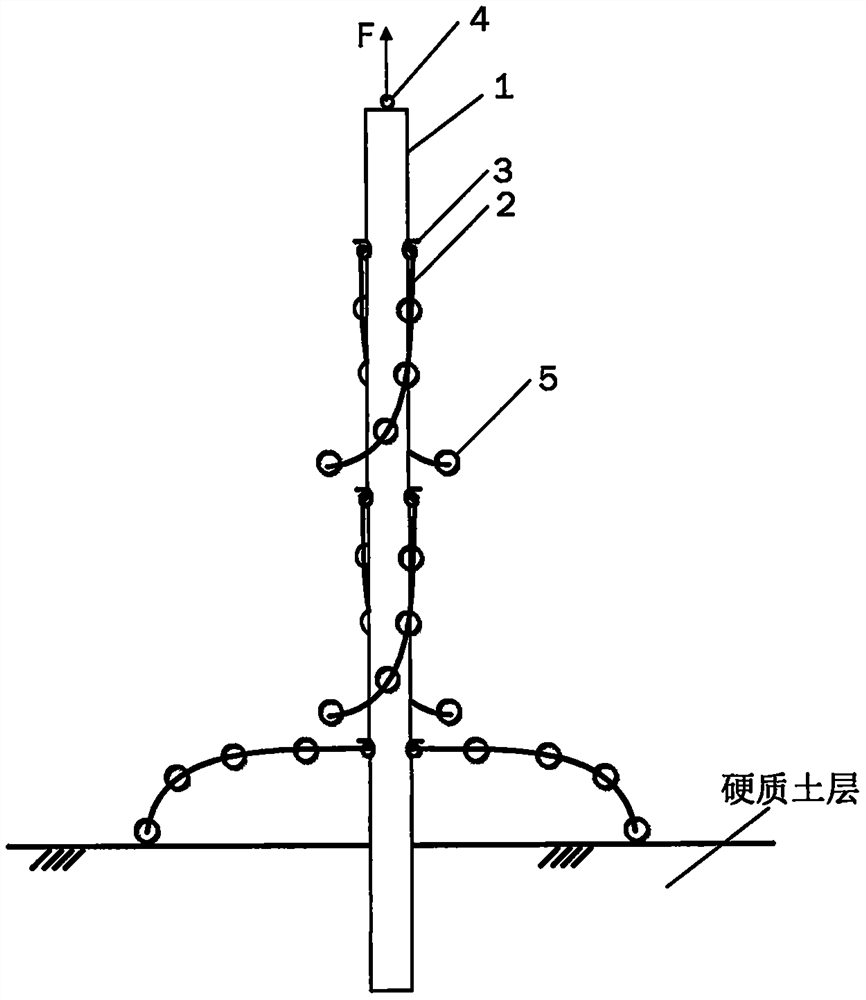

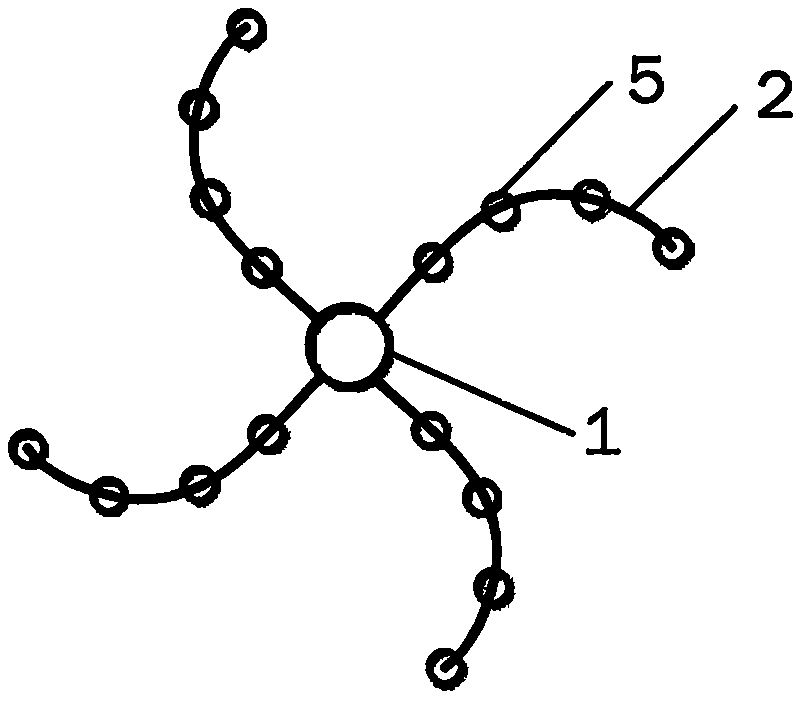

[0033] like Figure 1-Figure 4 As shown, the self-floating spiral mesh drainage device includes a main drainage belt 1, a drainage branch 2, a stopper 3, a hanging hole 4, and a floating ball 5;

[0034] The main drainage belt 1 is a traditional flexible drainage belt, which can transmit the moisture in the soil to the top and discharge; , a multi-layer drainage branch 2 is arranged in the middle, the drainage branch 2 is connected with the internal pores of the main drainage belt 1, and the water in the drainage branch can be discharged through the top of the main drainage belt;

[0035] The drainage branch 2 is an arc-shaped rigid tubular structure, and the surface is covered with geotextile, which is water permeable; 3 to 5 floating balls 5 are attached to each drainage branch, which are equally spaced on the drainage branch, and rely on the filling s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com