Integration multi-layer type LED lamp tube with bridging unit

A LED tube, multi-layer technology, applied to the components of lighting devices, lighting devices, light sources, etc., to achieve the effects of shortening production time, simplifying the manufacturing process, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following describes the embodiments of the present invention in more detail in conjunction with the drawings and component symbols, so that those skilled in the art can refer to the text of the description to implement them.

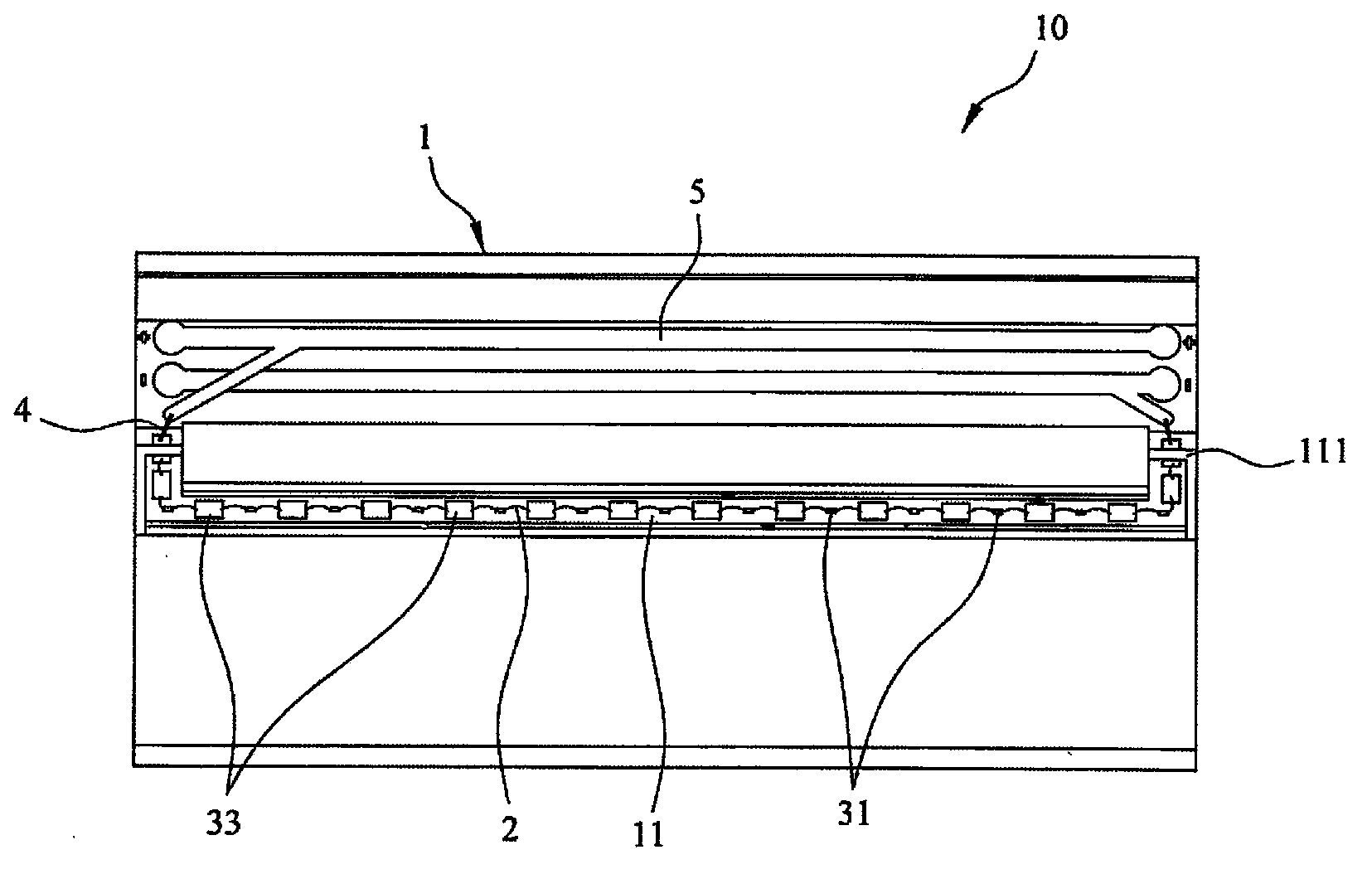

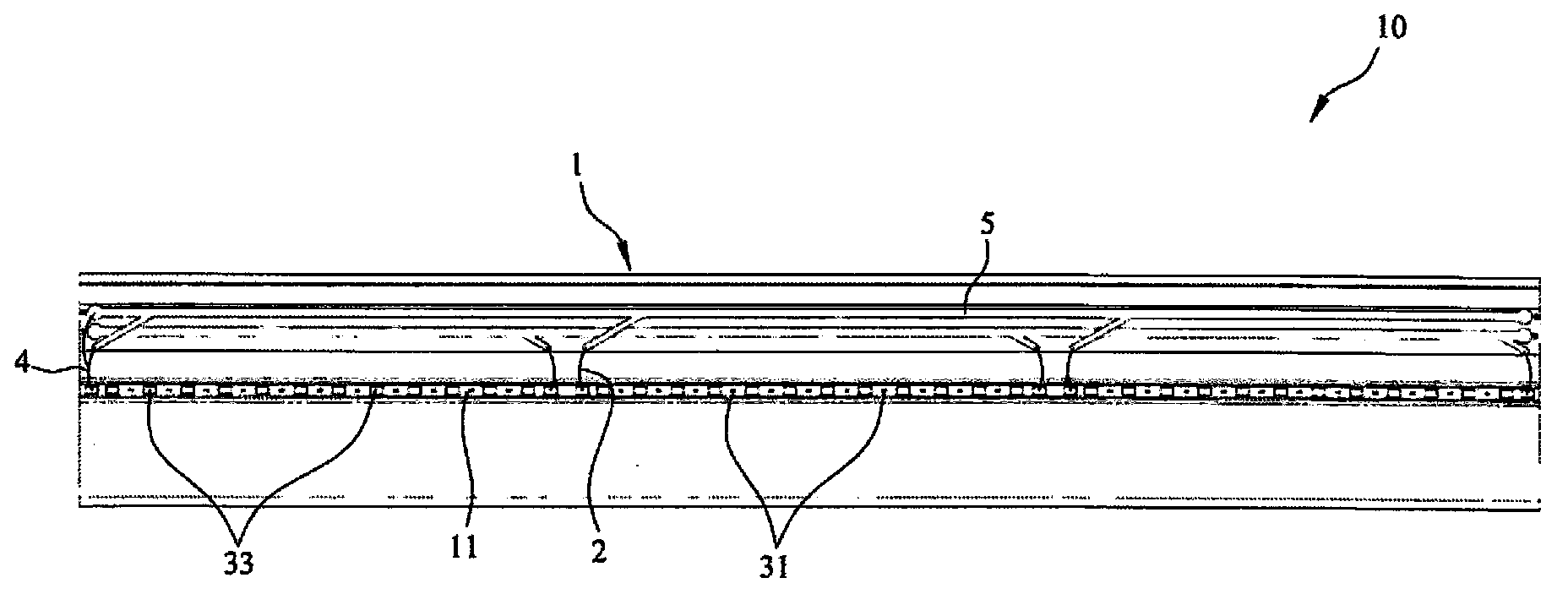

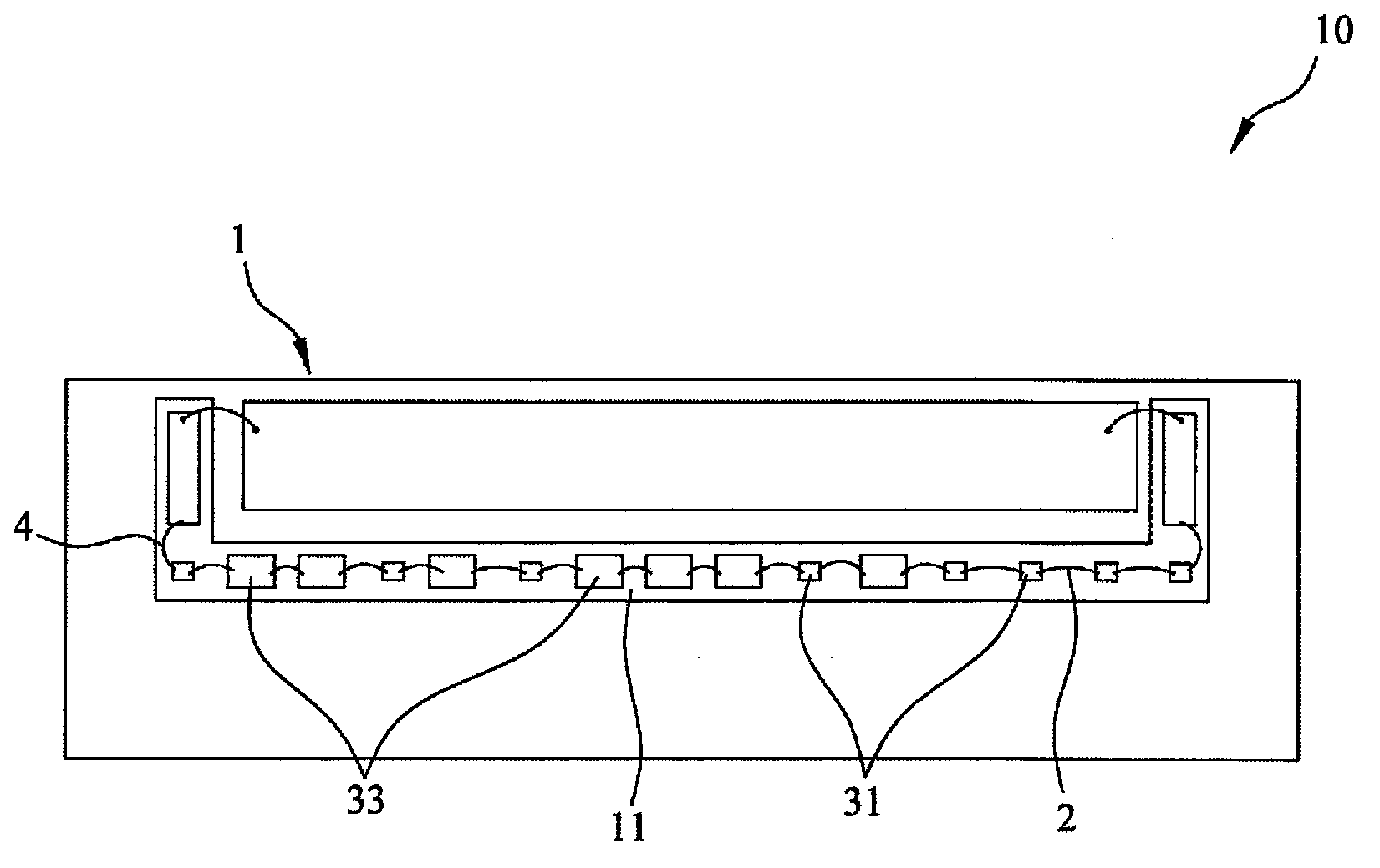

[0048] Refer to figure 1 , figure 1 This is the top view of the integrated multi-layer LED tube with bridge unit of the present invention, see figure 2 , figure 2 It is a cross-sectional view of an integrated multi-layer LED tube with a bridge unit according to the present invention. Such as figure 1 As shown, the integrated multi-layer LED tube 10 with bridge unit of the present invention includes a heat dissipation base 1, at least one lighting unit, and at least one bridge unit. The heat dissipation base 1 has a light exit side ES, a groove 11 is formed on the light exit side ES, the at least one lighting unit is disposed on the bottom surface of the groove 11, and the two side walls of the groove 11 are non-vertical On the other hand, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com