Fiber Fixing Fixtures for Inclined Surfaces

A technology for fixing cards and optical fibers, applied in the field of optical fiber communication, can solve the problems of easy falling of feeders, unreliable fixing, etc., and achieve the effects of not easy to fall off, reliable fixing, and flexible position adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

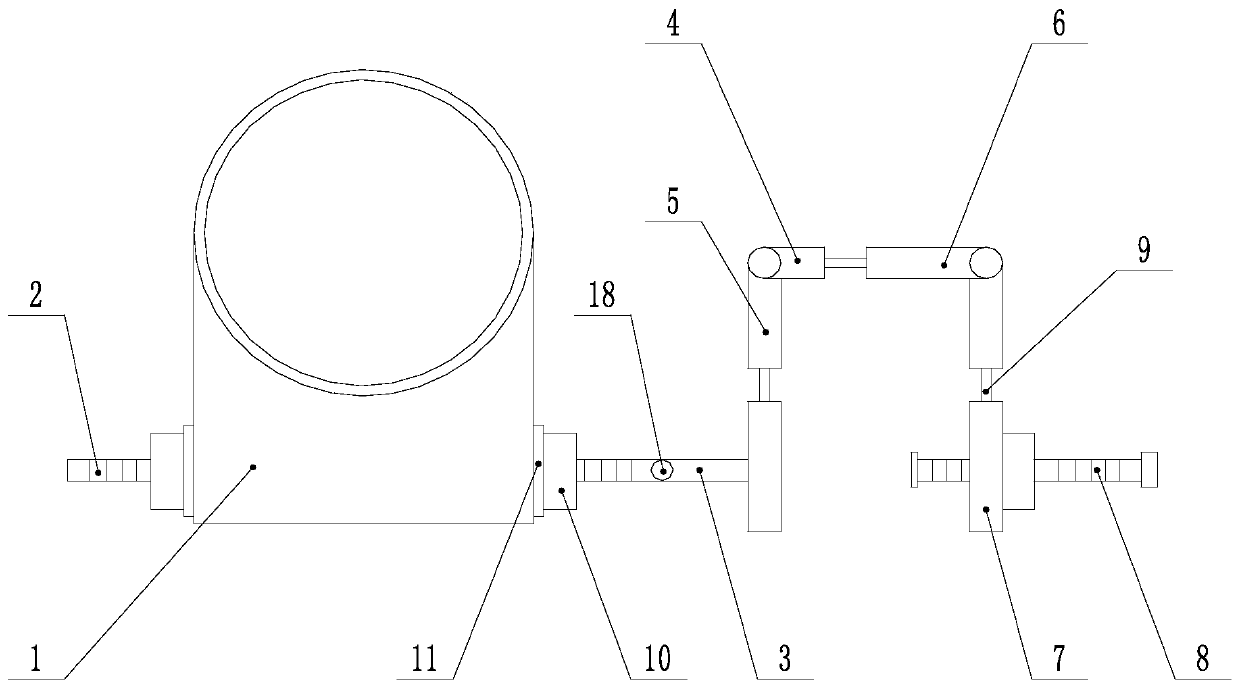

[0027] Such as figure 1 As shown, the optical fiber fixing jig suitable for fixing on an inclined plane includes an optical fiber sheath 1, and a screw 2 is installed through the optical fiber sheath 1, and the optical fiber sheath 1 and the screw 2 are screwed together, and the optical fiber sheath 1 can move along the screw 2 , one end of the screw rod 2 is hinged with a connecting rod 3, and the hinge can be fixed by a threaded fastener, and the end of the connecting rod 3 away from the screw rod 2 is provided with a C-shaped mount 4; the C-shaped mount 4 includes a mounting plate-5, installation Plate 2 6, mounting plate 3 7, the two ends of mounting plate 6 are respectively hinged with mounting plate 1 5 and mounting plate 3 7, and the hinges can be fixed by threaded fasteners, mounting plate 1 5 is far away from connecting rod 3 One end of the screw rod 2 is connected, the mounting plate 3 7 is penetrated with a compression screw 8, the compression screw 8 is screwed wit...

Embodiment 2

[0030] This embodiment is based on Embodiment 1 to further illustrate the present invention.

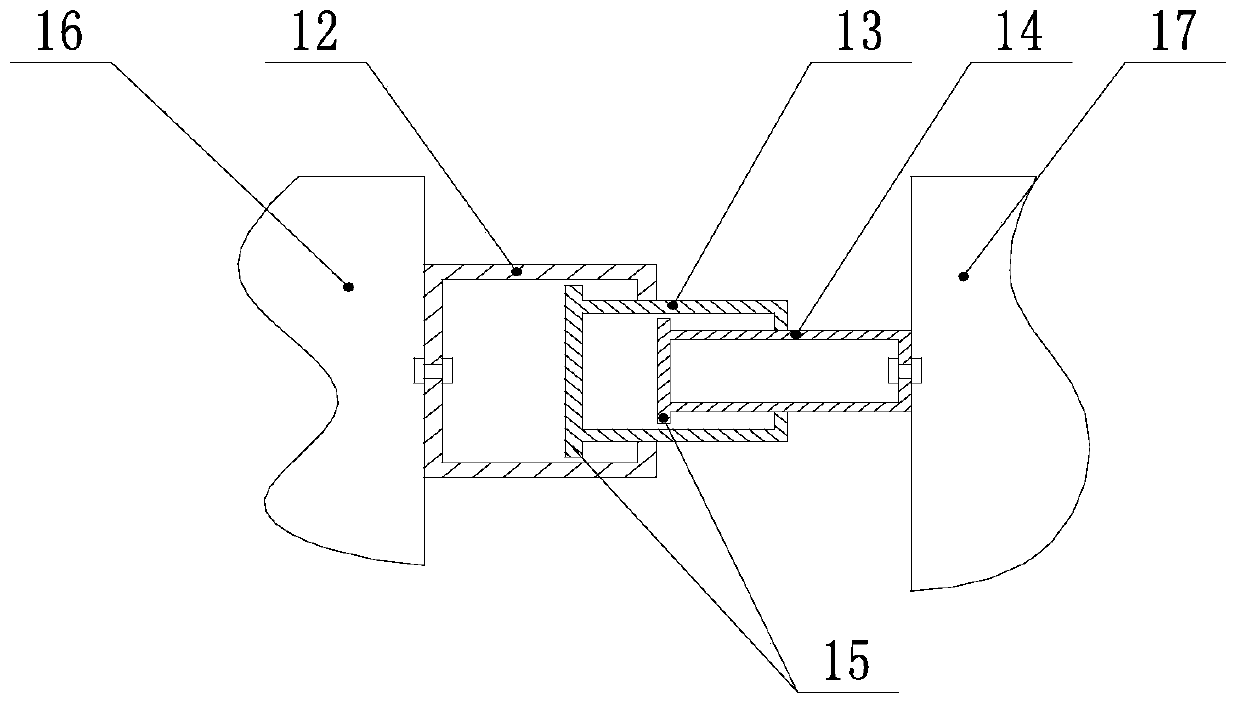

[0031] Such as figure 2As shown, the optical fiber fixing jig suitable for fixing on an inclined plane, the telescopic rod 9 includes a large cavity 12, a middle cavity 13 and a small cavity 14, and the length thereof increases successively, and one end of the large cavity 12 is connected to the flat plate 16, The other end is provided with an opening, the middle cavity 13 is located in the large cavity 12, and can move along the opening of the large cavity 12; the end of the middle cavity 12 located in the large cavity 12 is provided with a limiter 15, and the other end is provided with a Opening; the small cavity 14 is located in the middle cavity 13, and can move along the opening of the middle cavity 13; the end of the small cavity 14 located in the middle cavity 13 is also provided with a limiter 15, and the other end is connected to the flat plate 2 17 Above, the lengths of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com