Accurate guiding and positioning equipment

A technology for guiding and positioning and equipment, applied in lighting and heating equipment, conveyor objects, furnaces, etc., can solve the problems of large transmission error, complex structural electronic system, increase production line cost budget, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

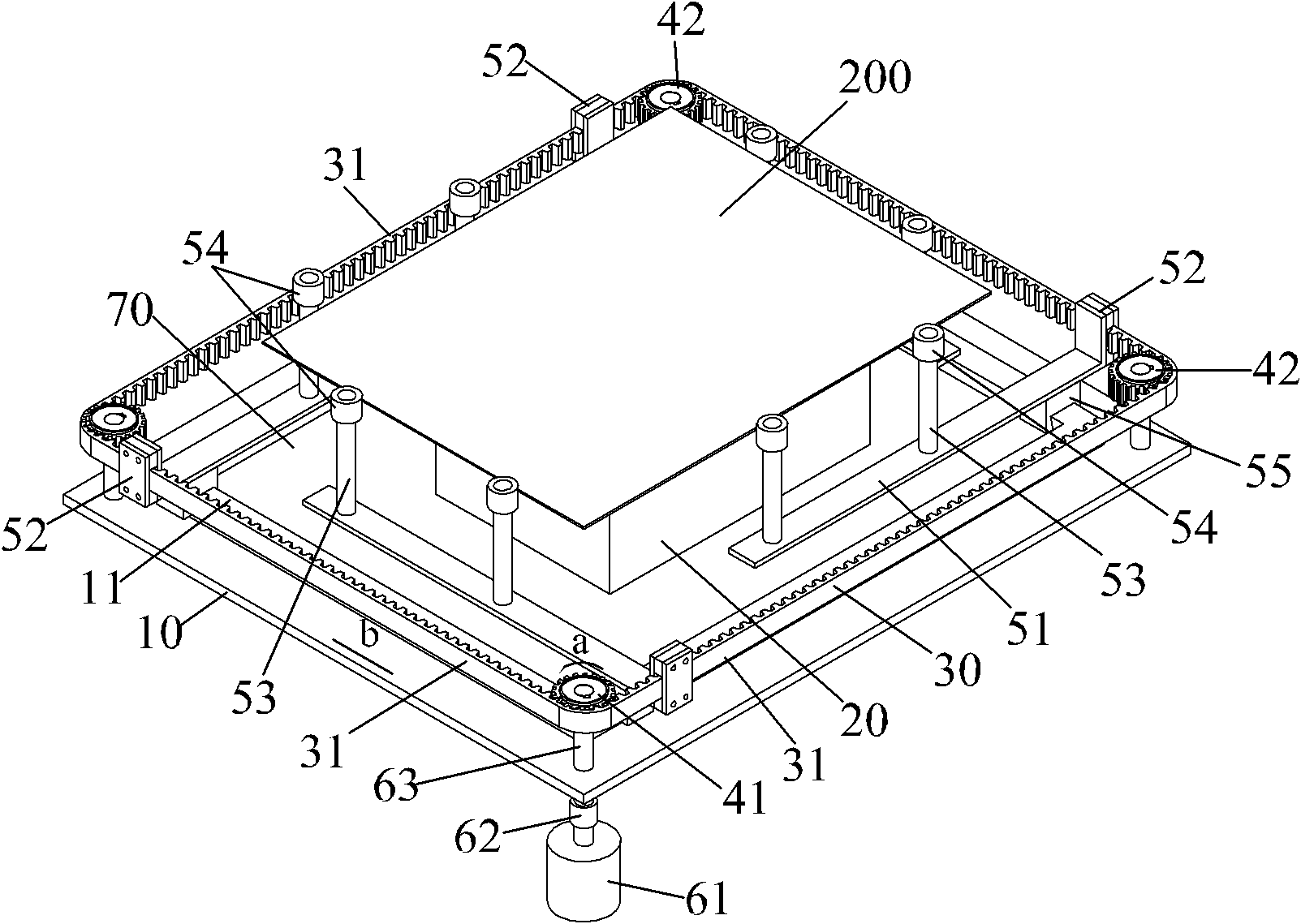

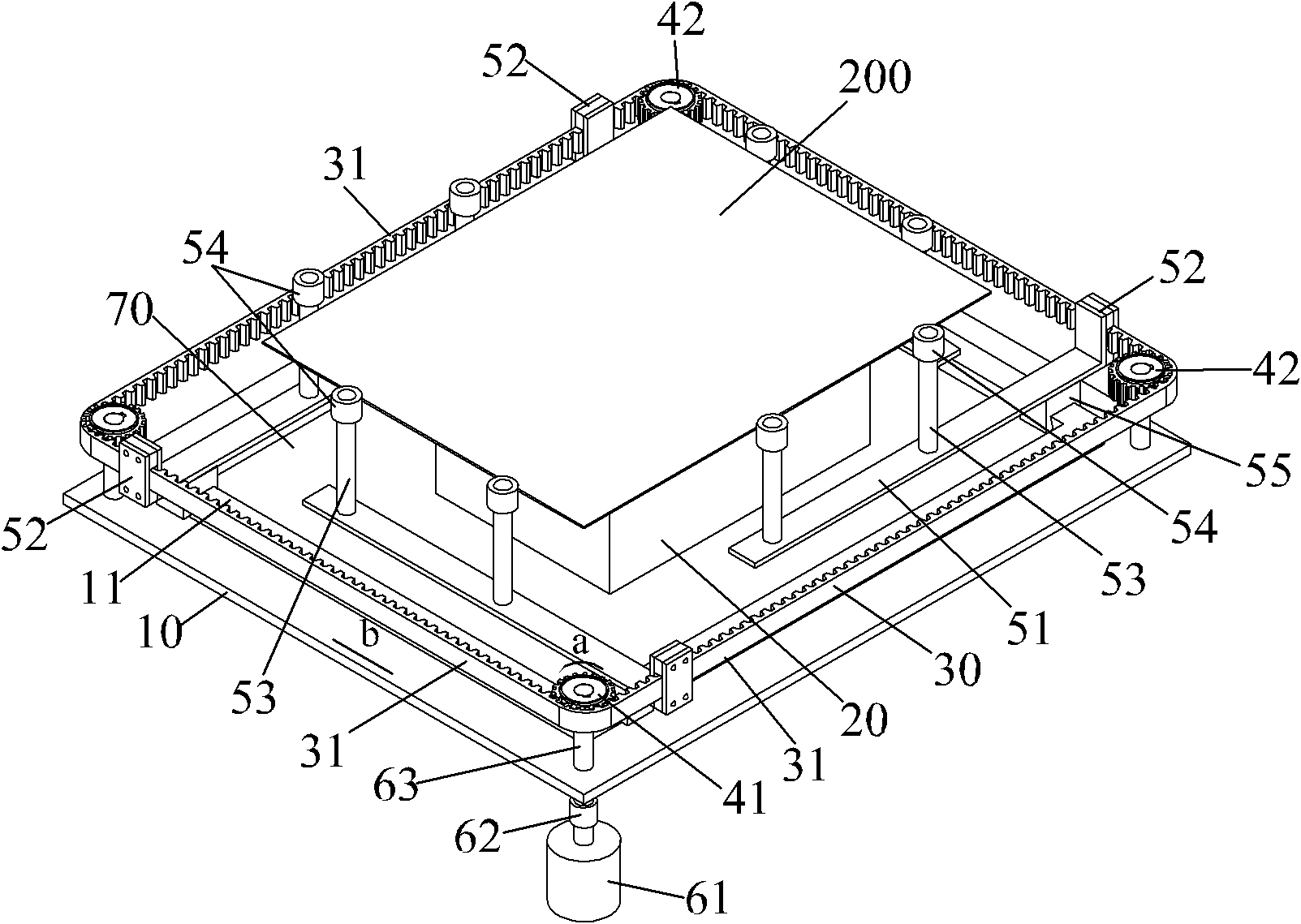

[0015] Such as figure 1 As shown, the precision guiding and positioning device of the present invention includes a base plate 10, a flat plate fixing seat 20, a transmission member 30, a transmission wheel, four positioning components and a power mechanism. In this embodiment, the transmission member 30 is a transmission chain.

[0016] The substrate 10 is square. The transmission wheel includes a driving wheel 41 and three driven wheels 42 , and the driving wheel 41 and the driven wheels 42 are respectively mounted on four corners of the upper surface of the base plate 10 . The transmission member 30 is wound on the driving wheel 41 and the driven wheel 42, and the transmission member 30 forms a sub-transmission section 31 between corresponding two adjacent transmission wheels, and the directions of the two opposite transmission sub-sections 31 are opposite to each other. parallel. The inner side of the transport element 30 forms a processing area 70 . The plate fixing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com