Patents

Literature

35results about How to "Increase or decrease in pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

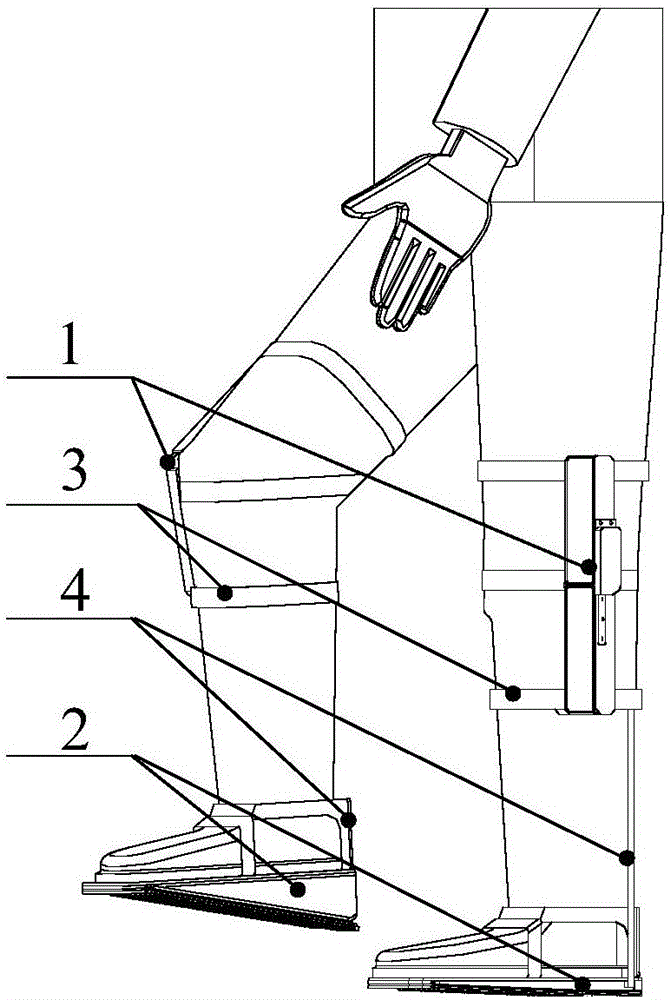

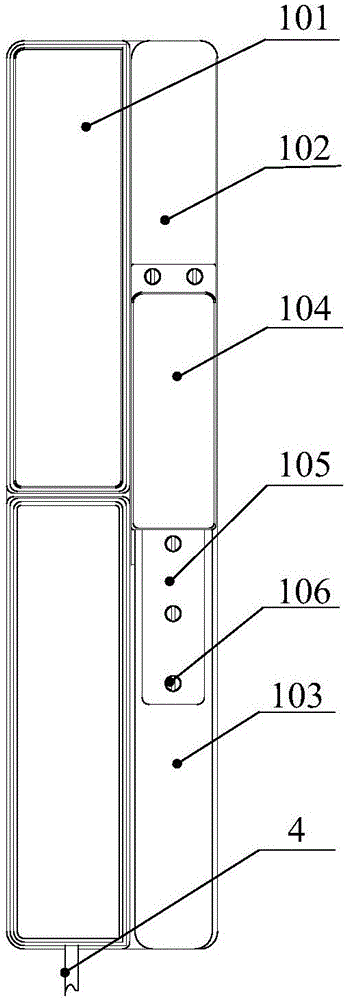

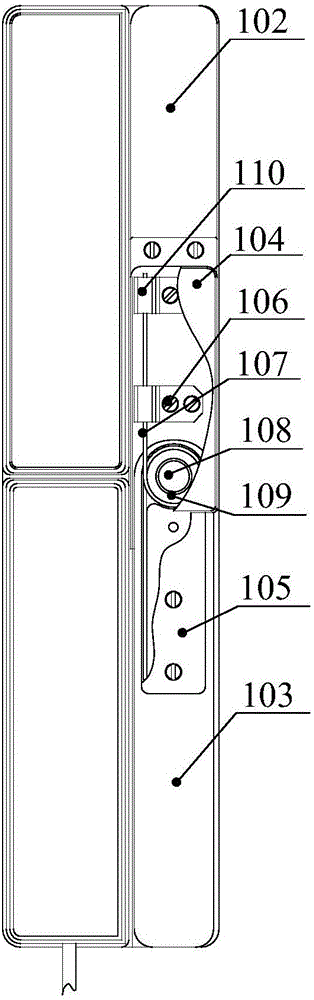

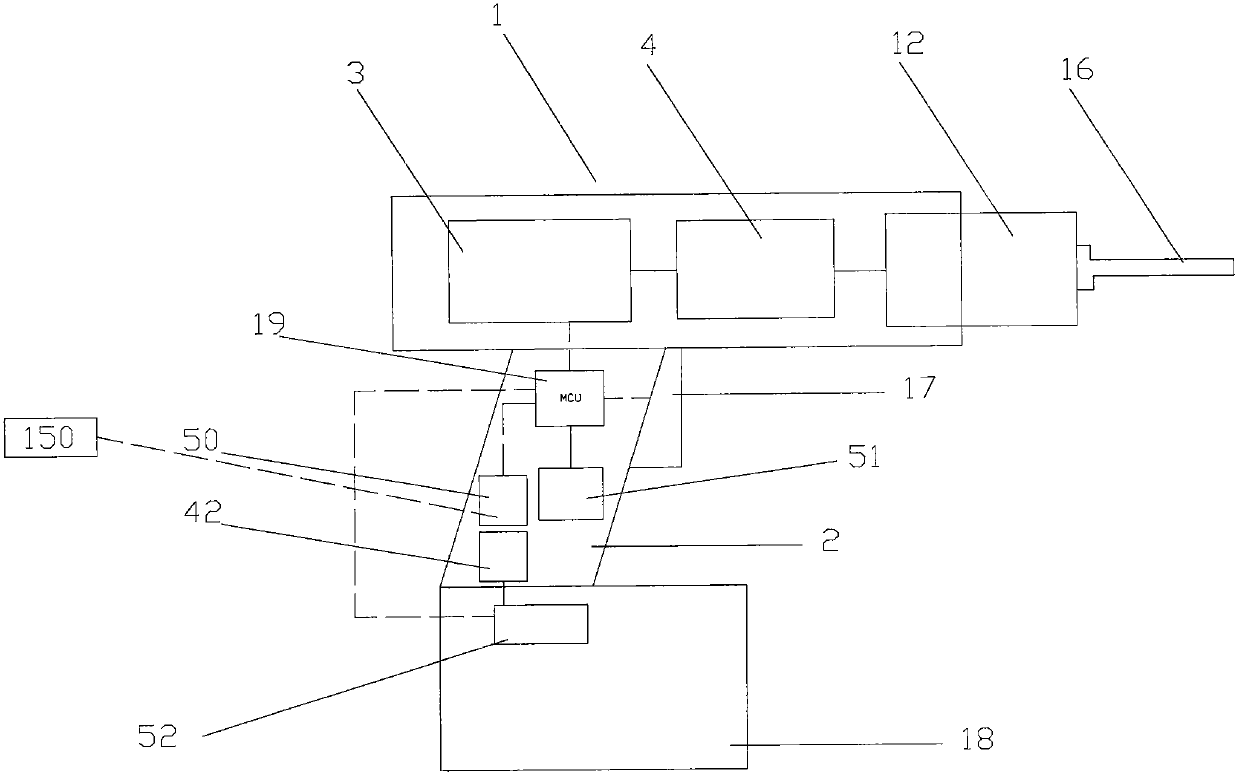

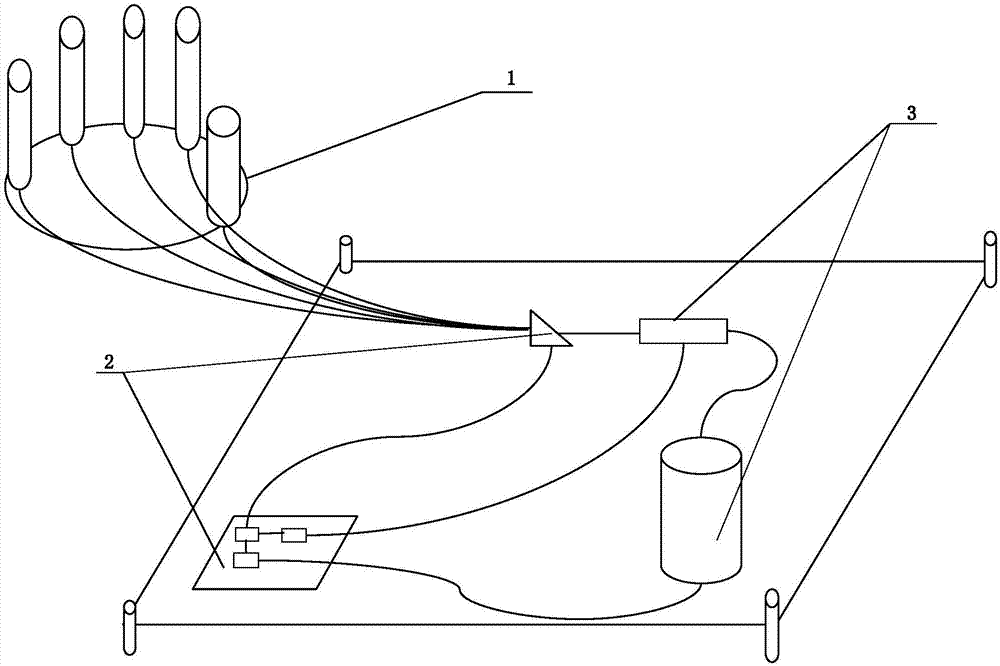

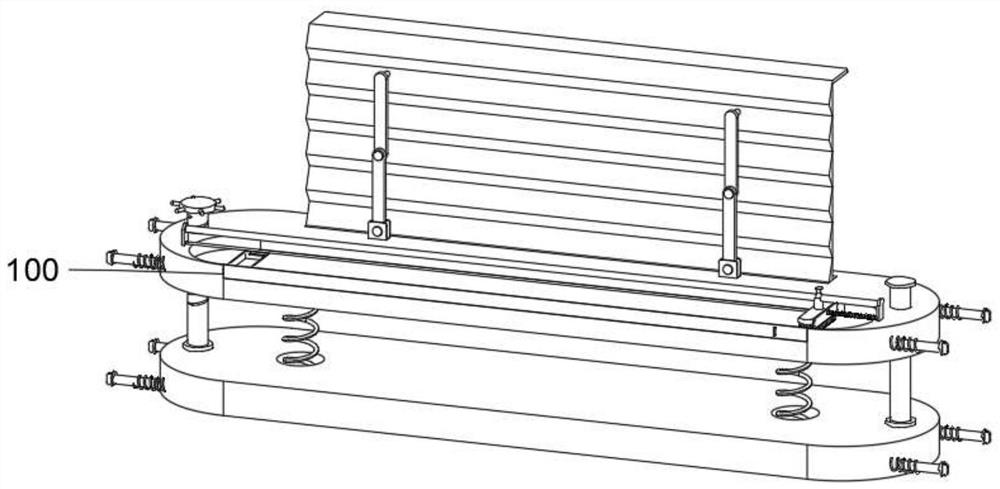

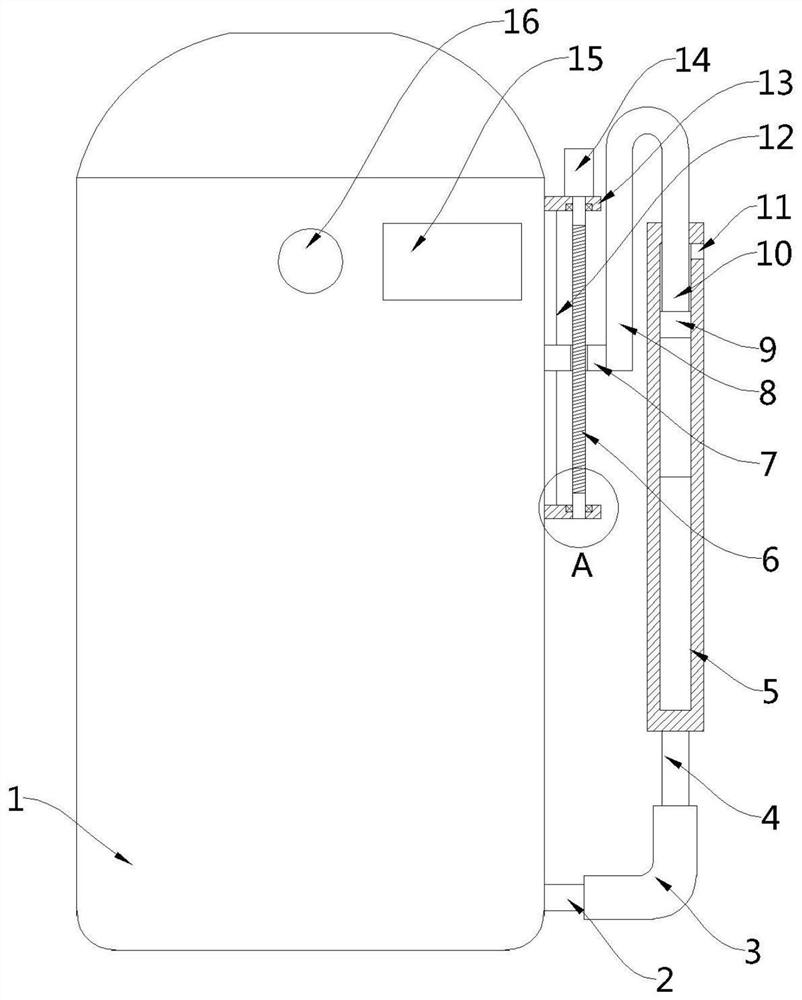

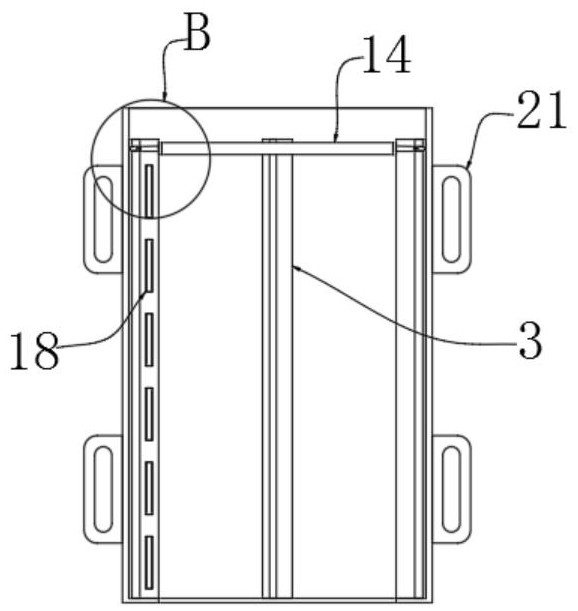

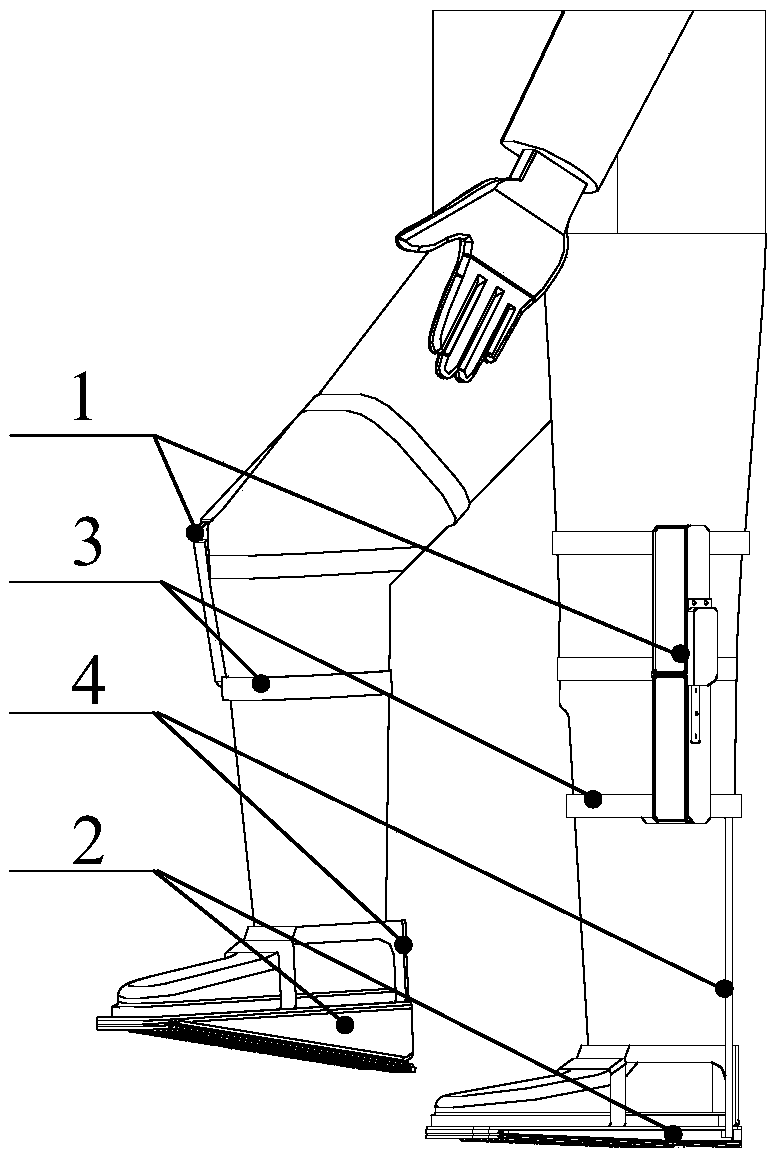

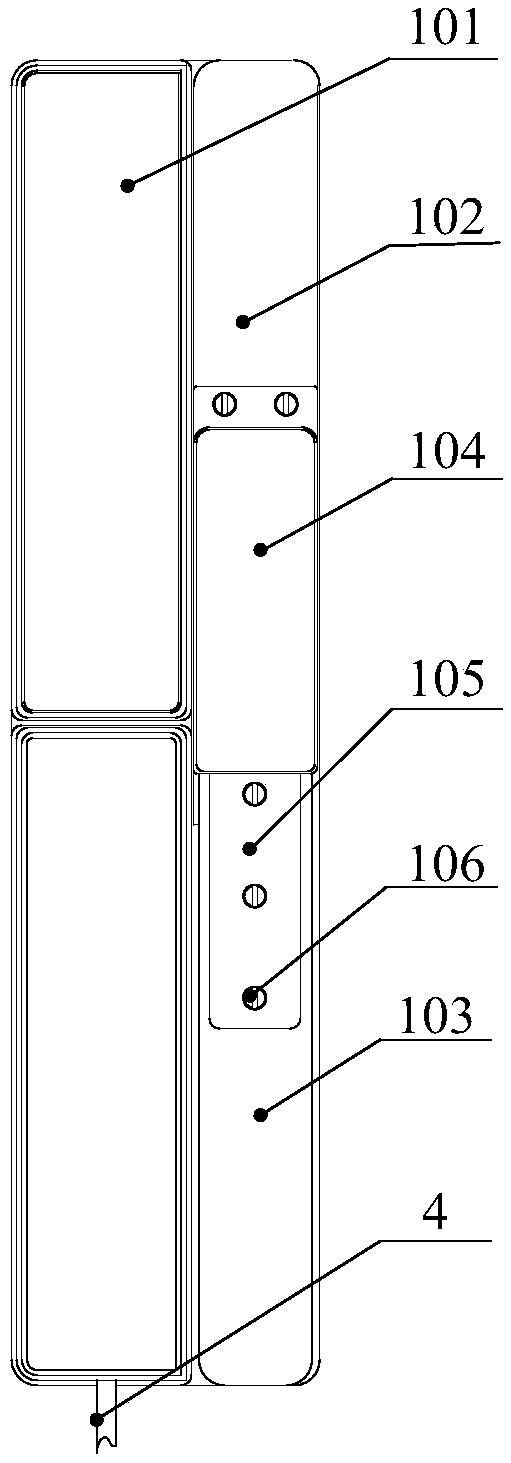

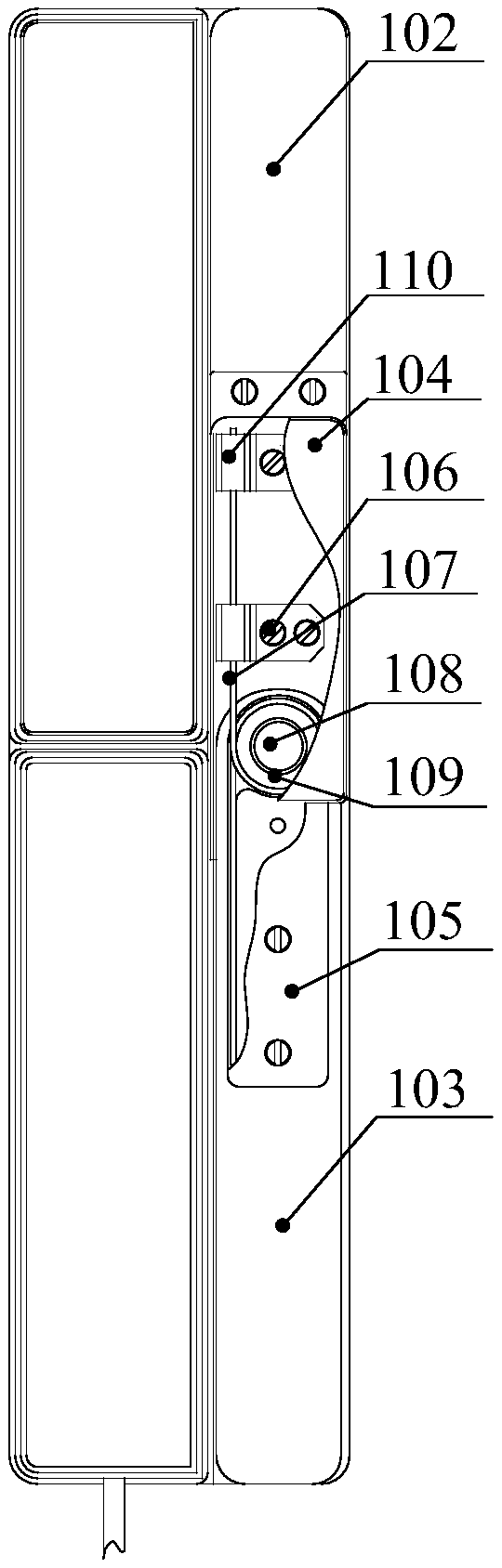

Portable flexible walking assisting equipment

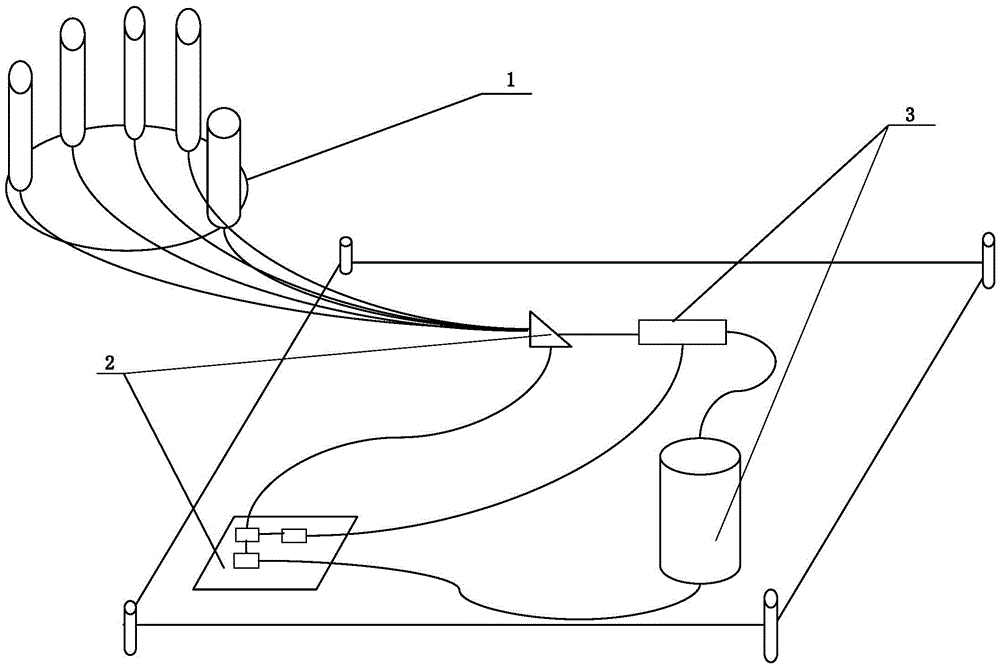

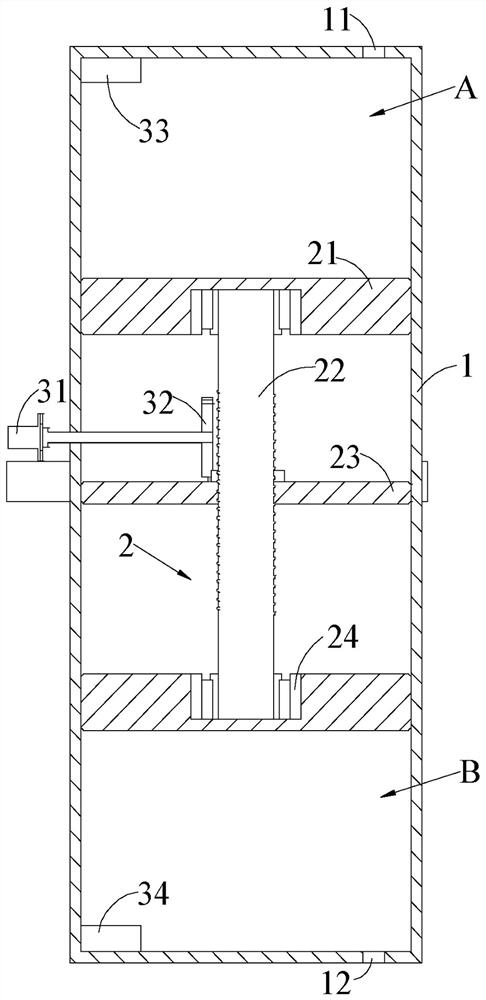

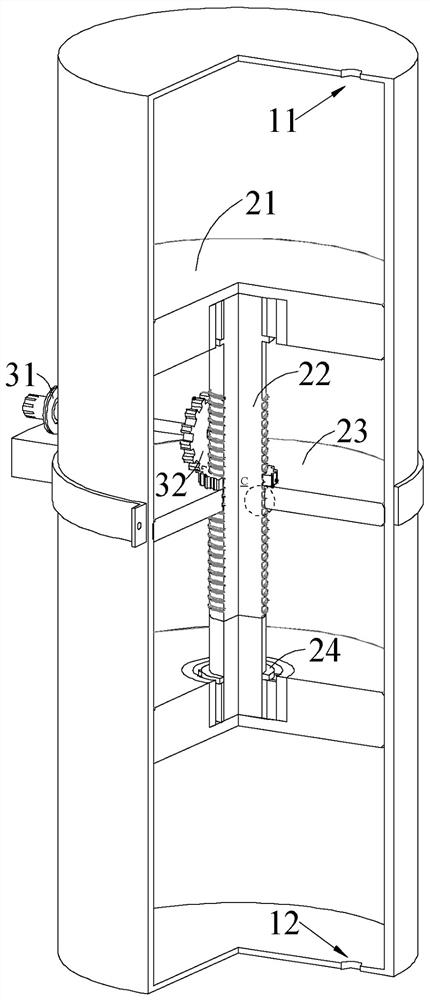

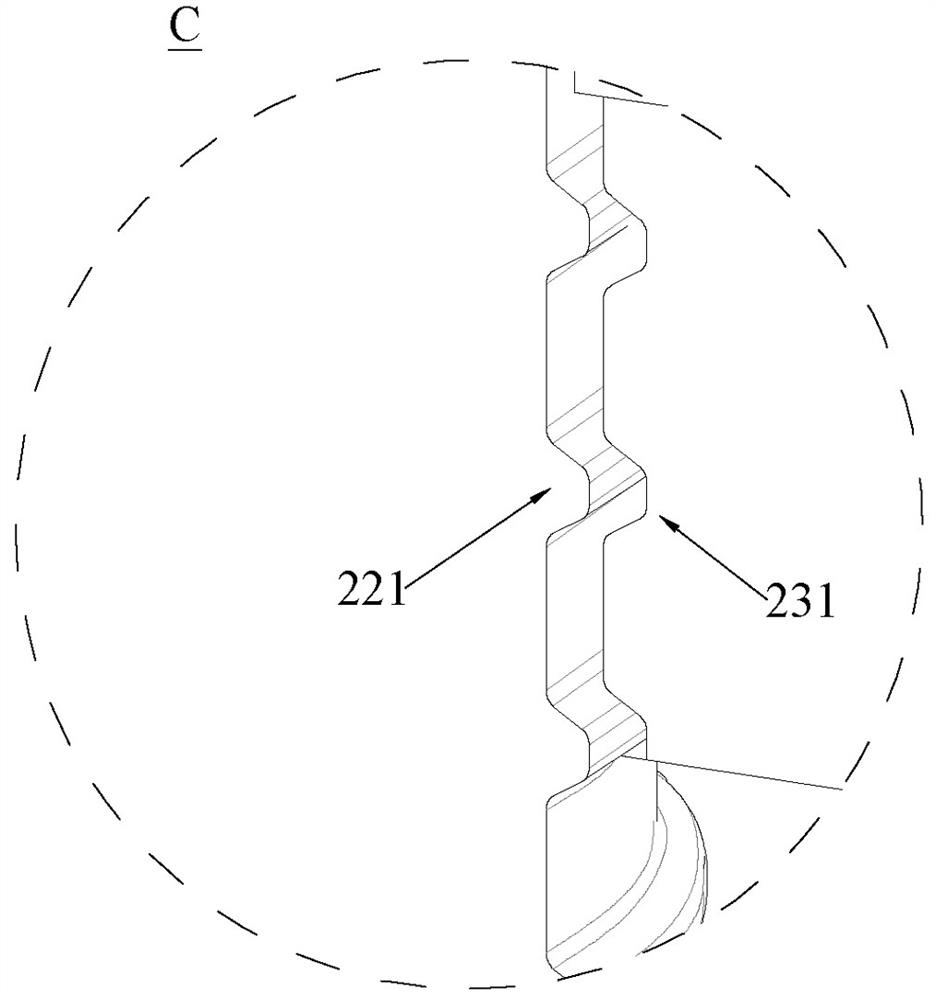

The invention discloses portable flexible walking assisting equipment. The portable flexible walking assisting equipment comprises knee joint flexible actuating mechanisms (1), air pressure forming mechanisms (2), flexible fixing bands (3) and air pipes (4). In the walking process of a person, the air pressure forming mechanisms (2) make the air pressure of air bags of the knee joint flexible actuating mechanisms (1) rapidly increased or decreased, and the knee joint flexible actuating mechanisms (1) generate torque assisting the knees in bending and stretching. The weight of the person is adopted as the driving force of the equipment, and no other additional energy is needed; the flexible driving mode combining the pneumatic driving force of the air bags and the elastic force of torsion springs is adopted for the actuating parts, and the pneumatic driving force and the elastic force compensate for each other in the walking process of the person. By adopting the flexible driving mode combining the pneumatic driving force and the elastic force of the torsion springs, the structural inertia is small, the defects that a rigid mechanism like a common leg assistance device or an exoskeleton robot is large in inertia, likely to injure the knee joints of a person, poor in comfort and the like are overcome, and the safety and comfort of the equipment are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

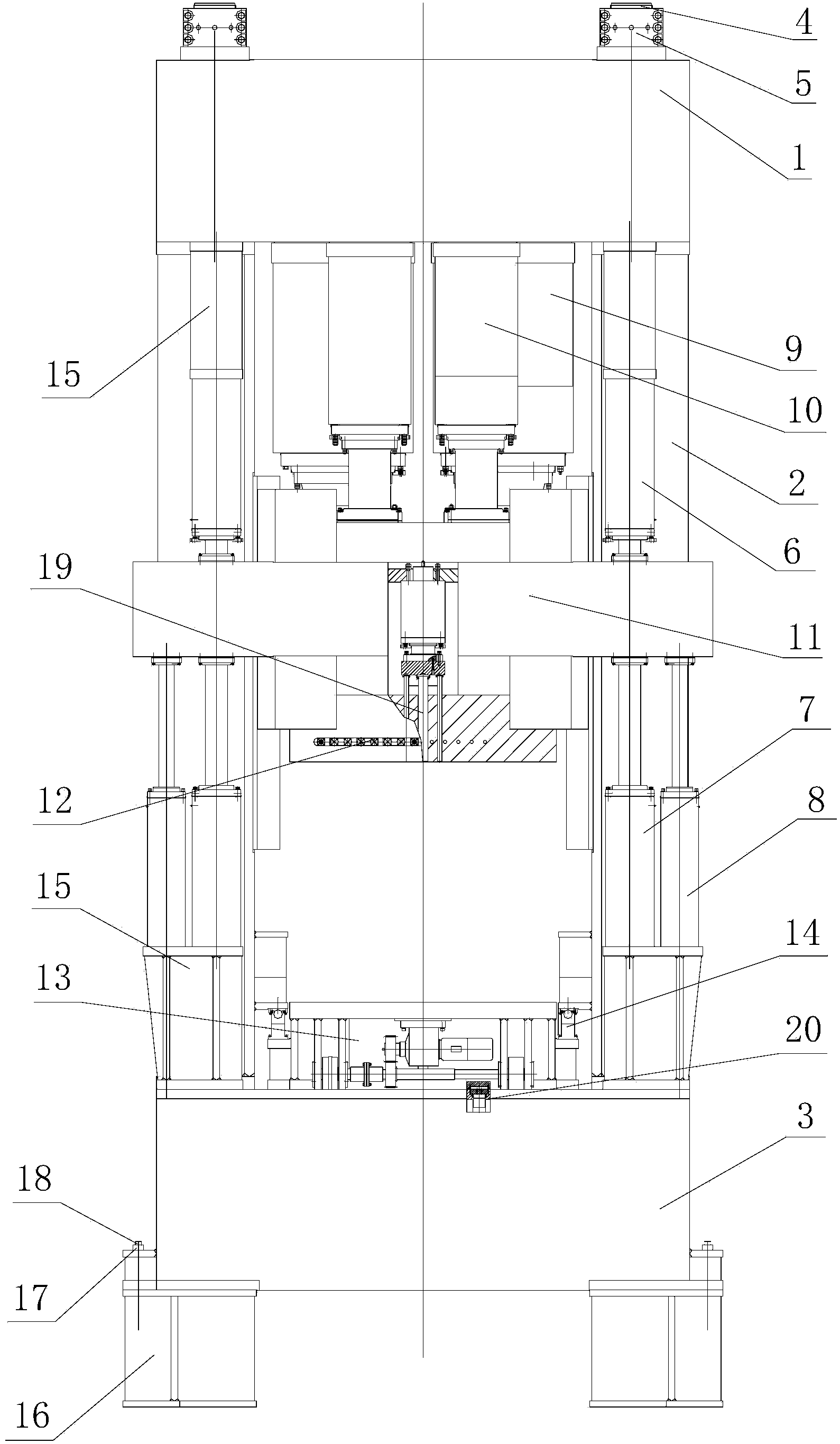

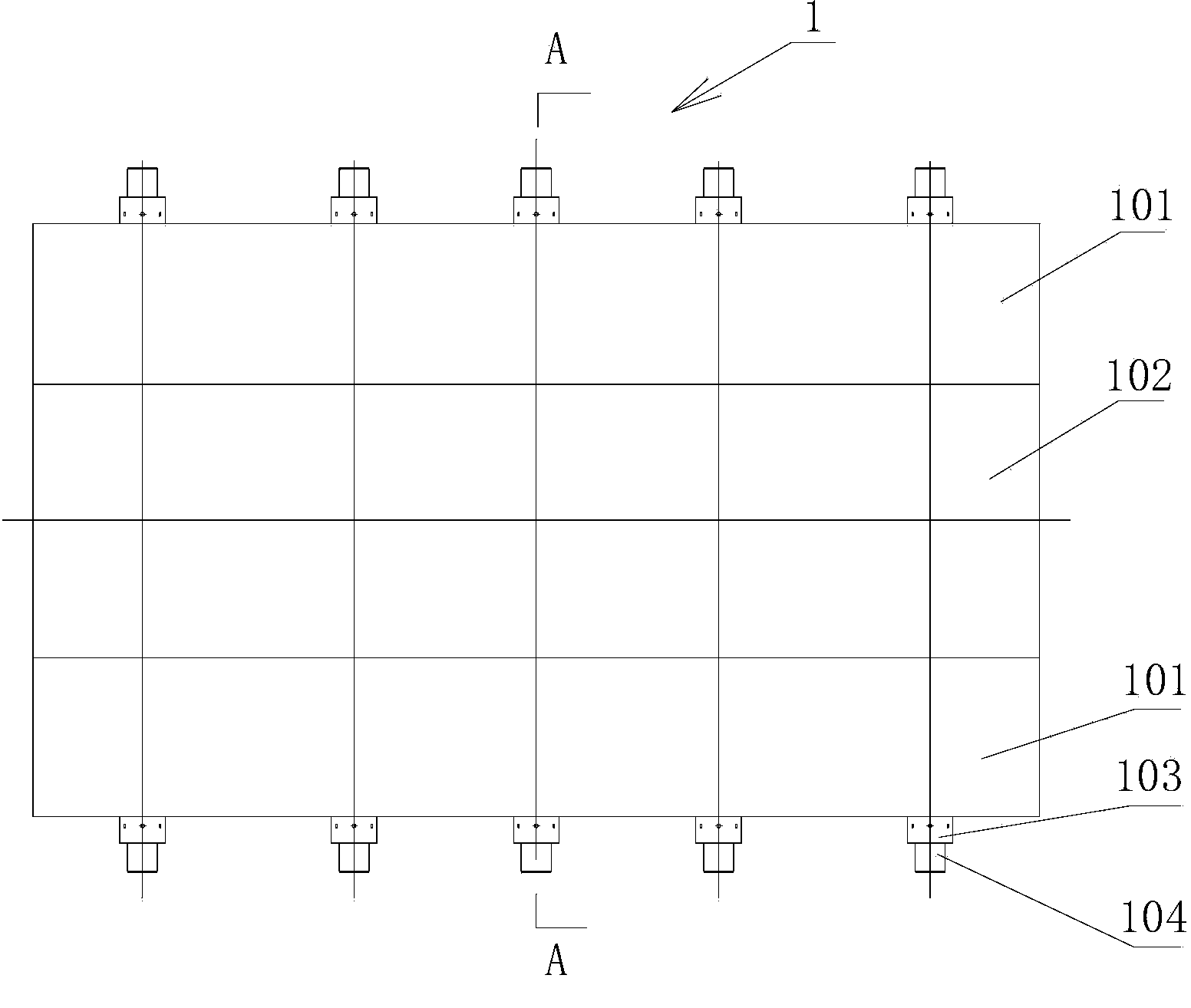

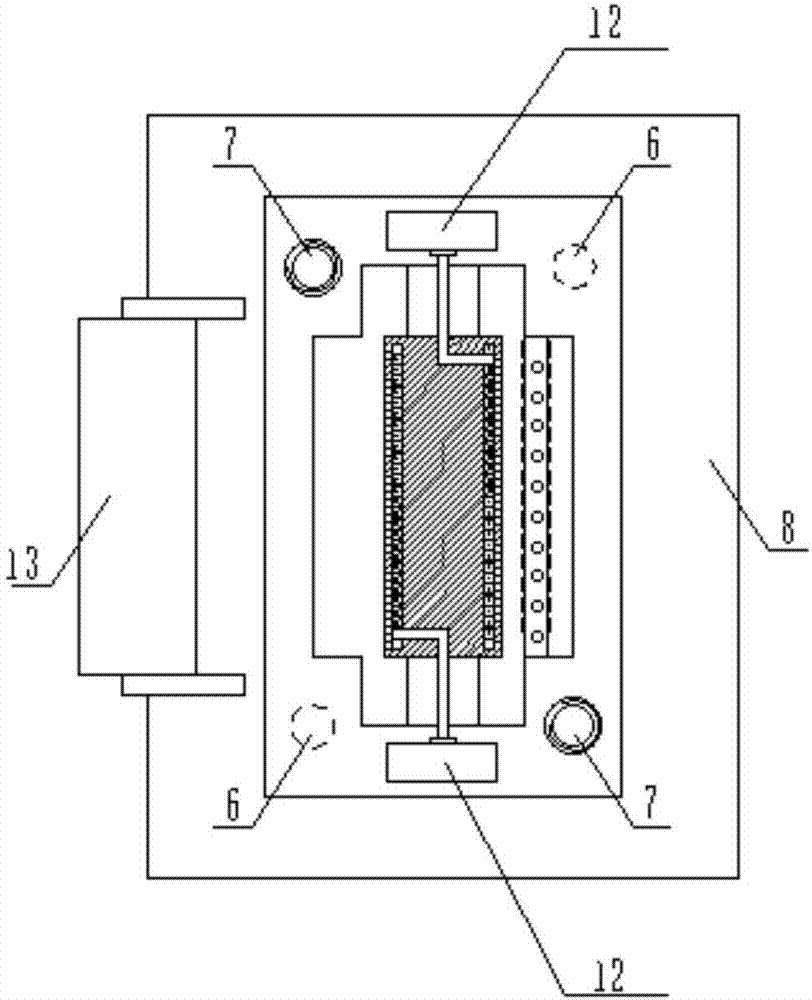

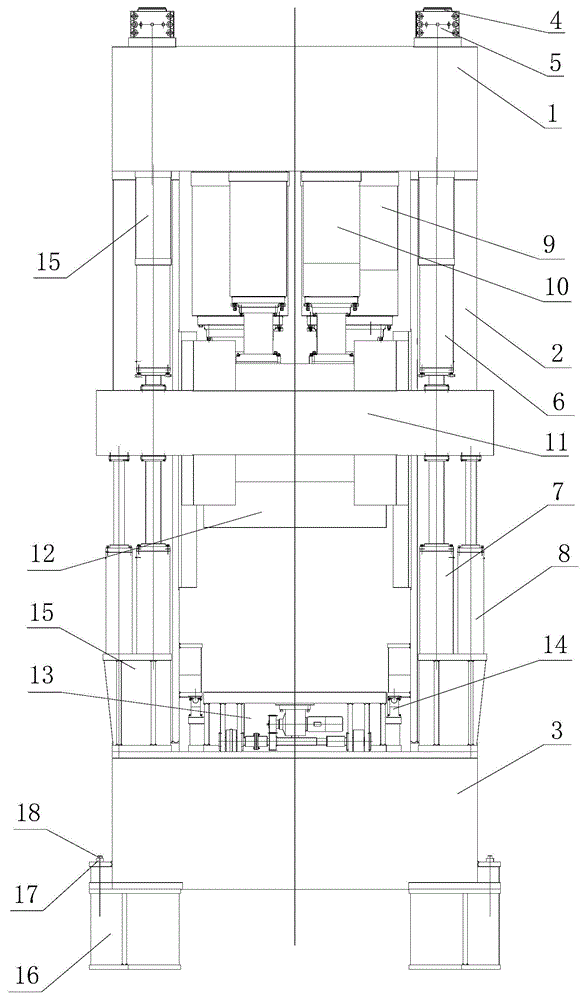

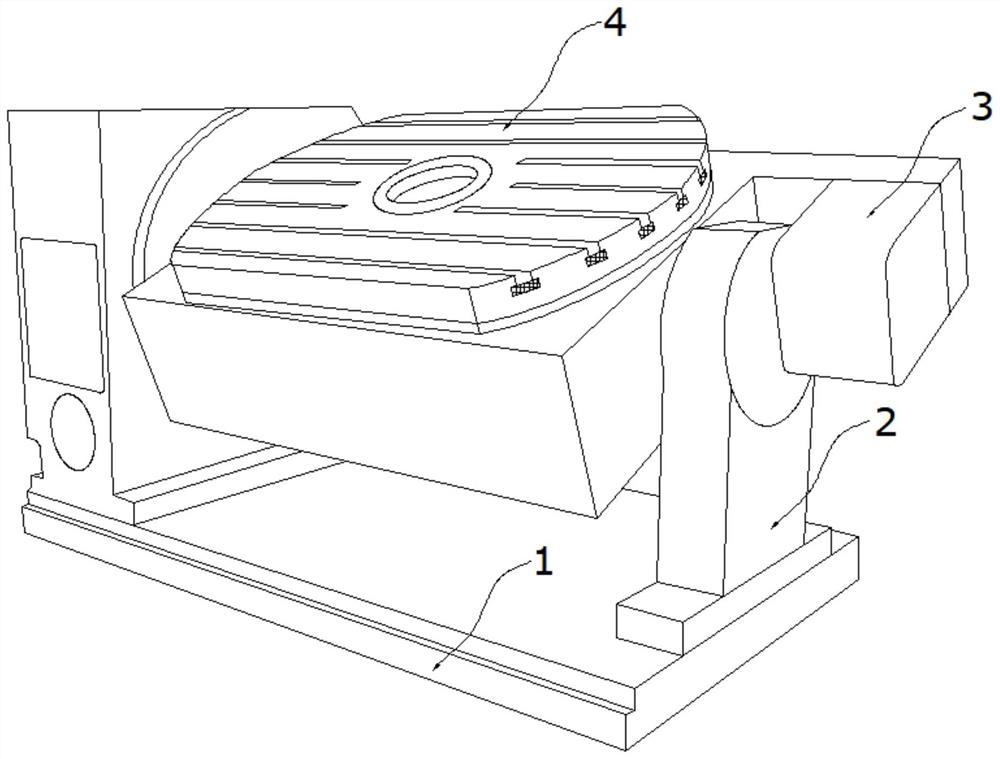

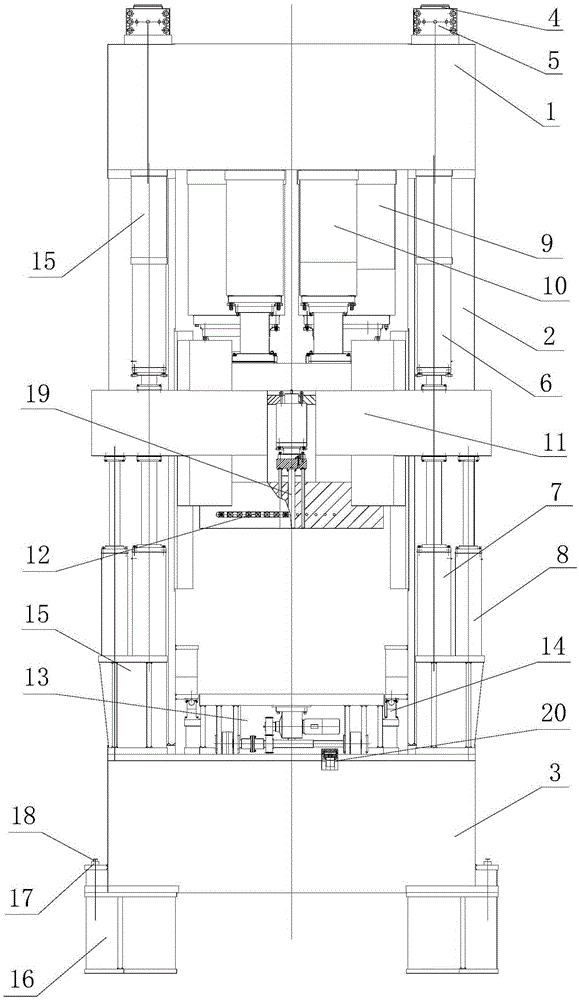

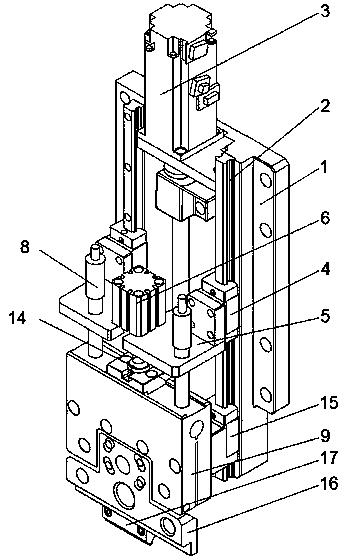

Heavy-duty isothermal forging hydraulic press

ActiveCN103447434AReduce manufacturing costHigh leveling accuracyForging/hammering/pressing machinesForging press detailsAviationLeveling effect

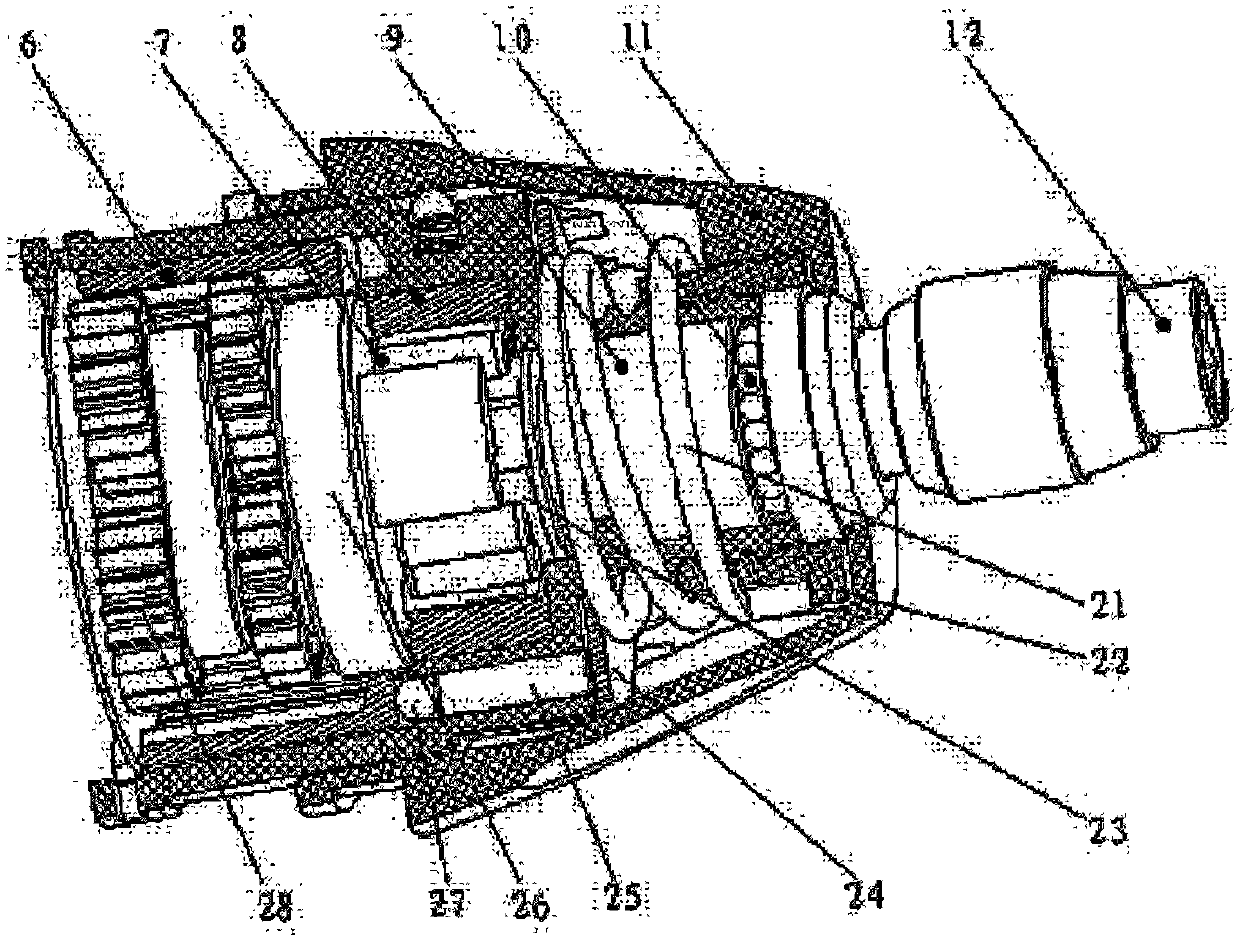

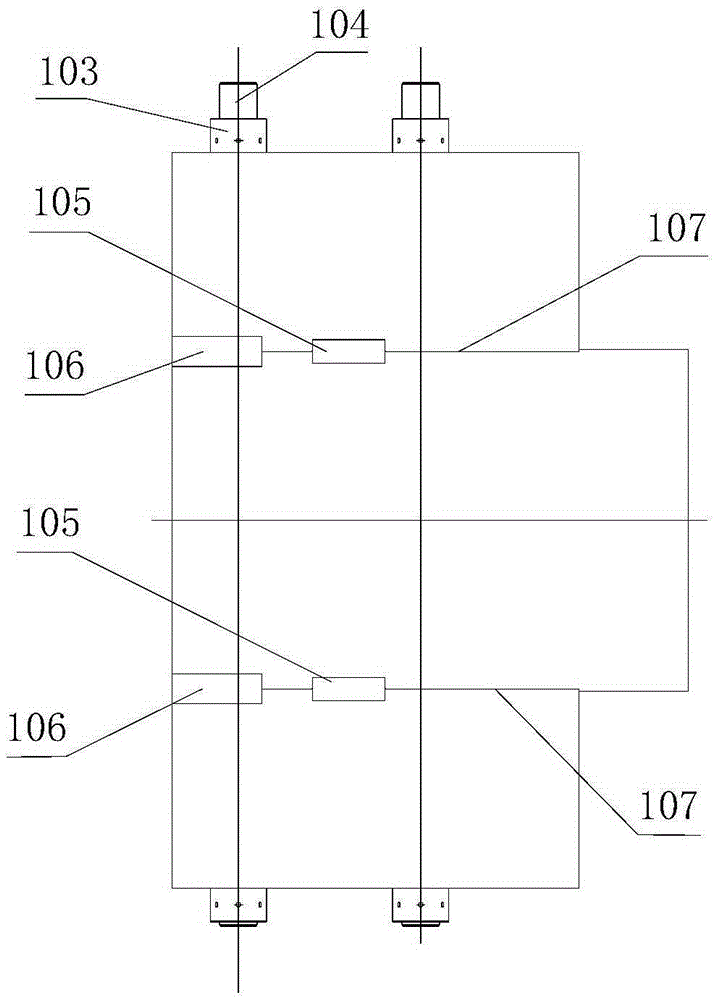

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

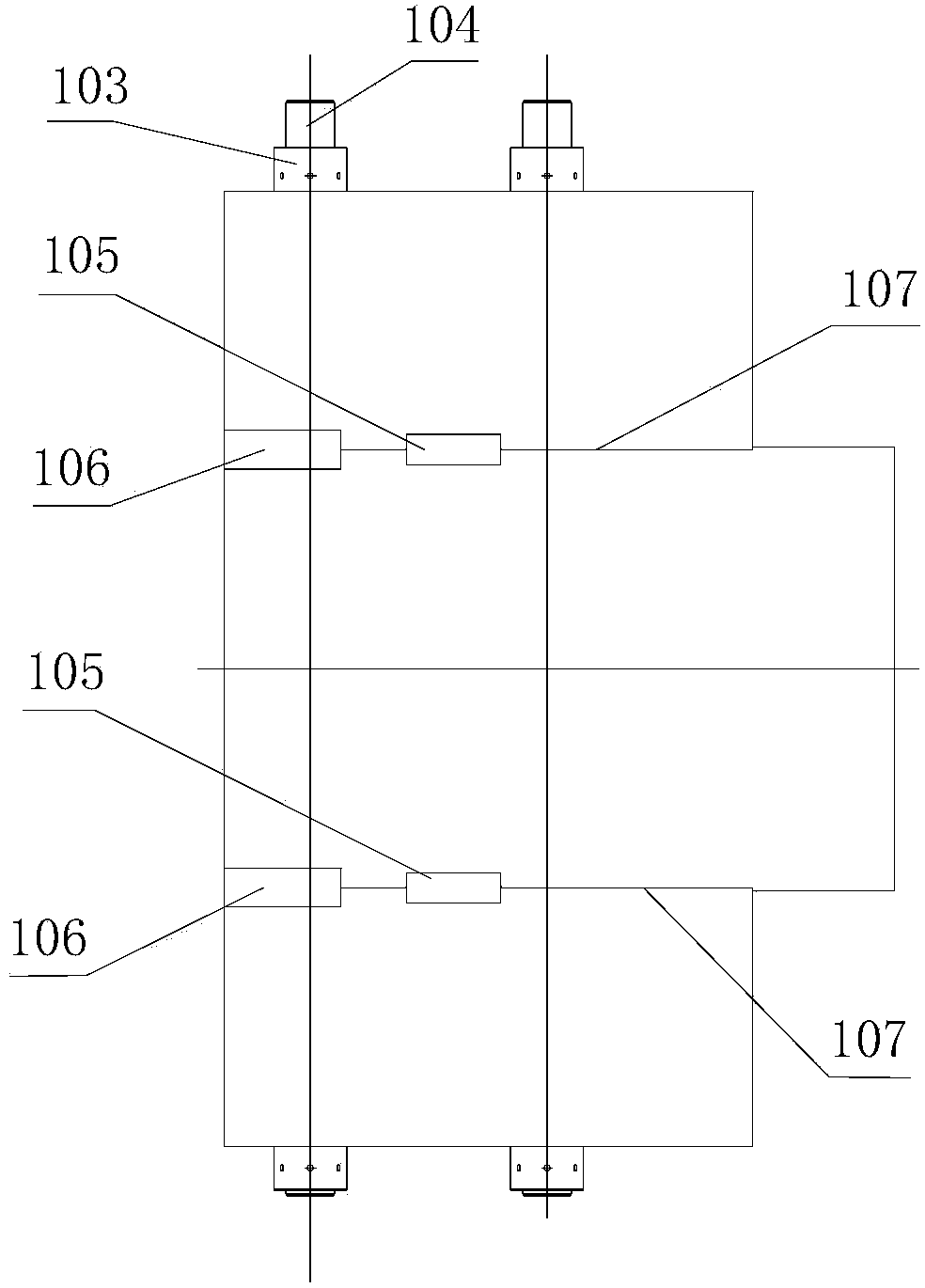

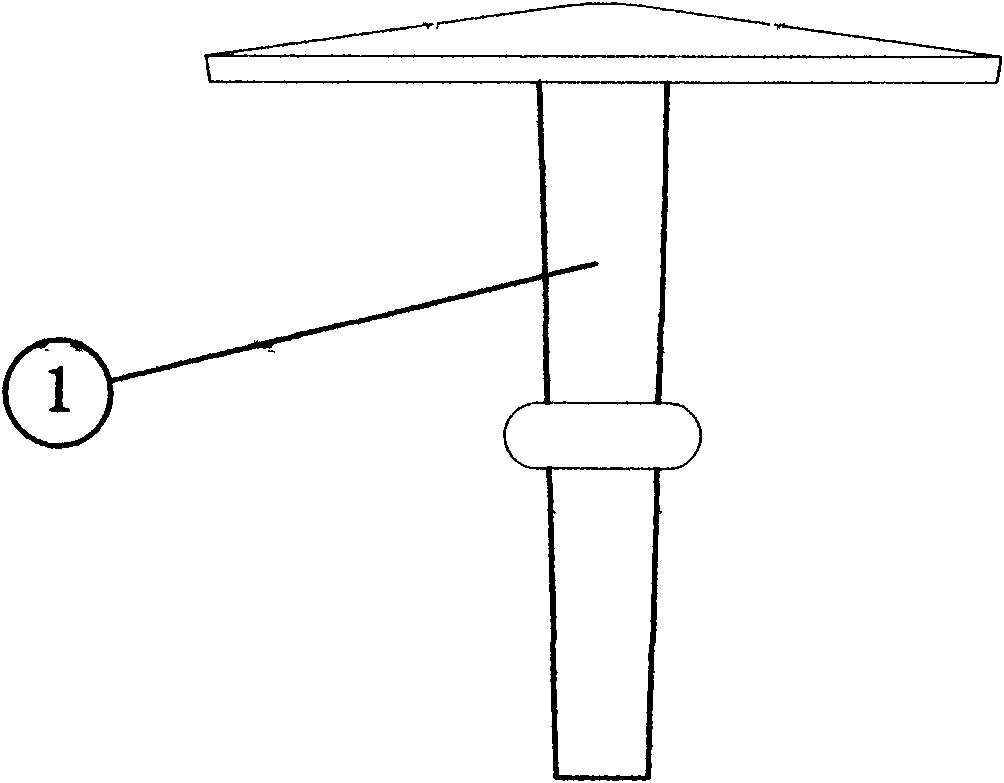

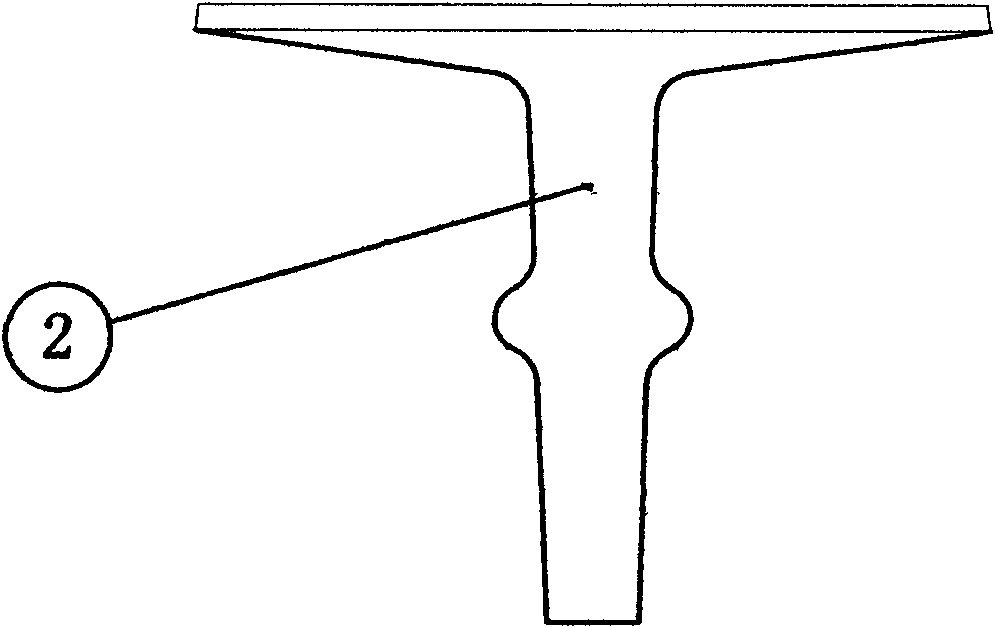

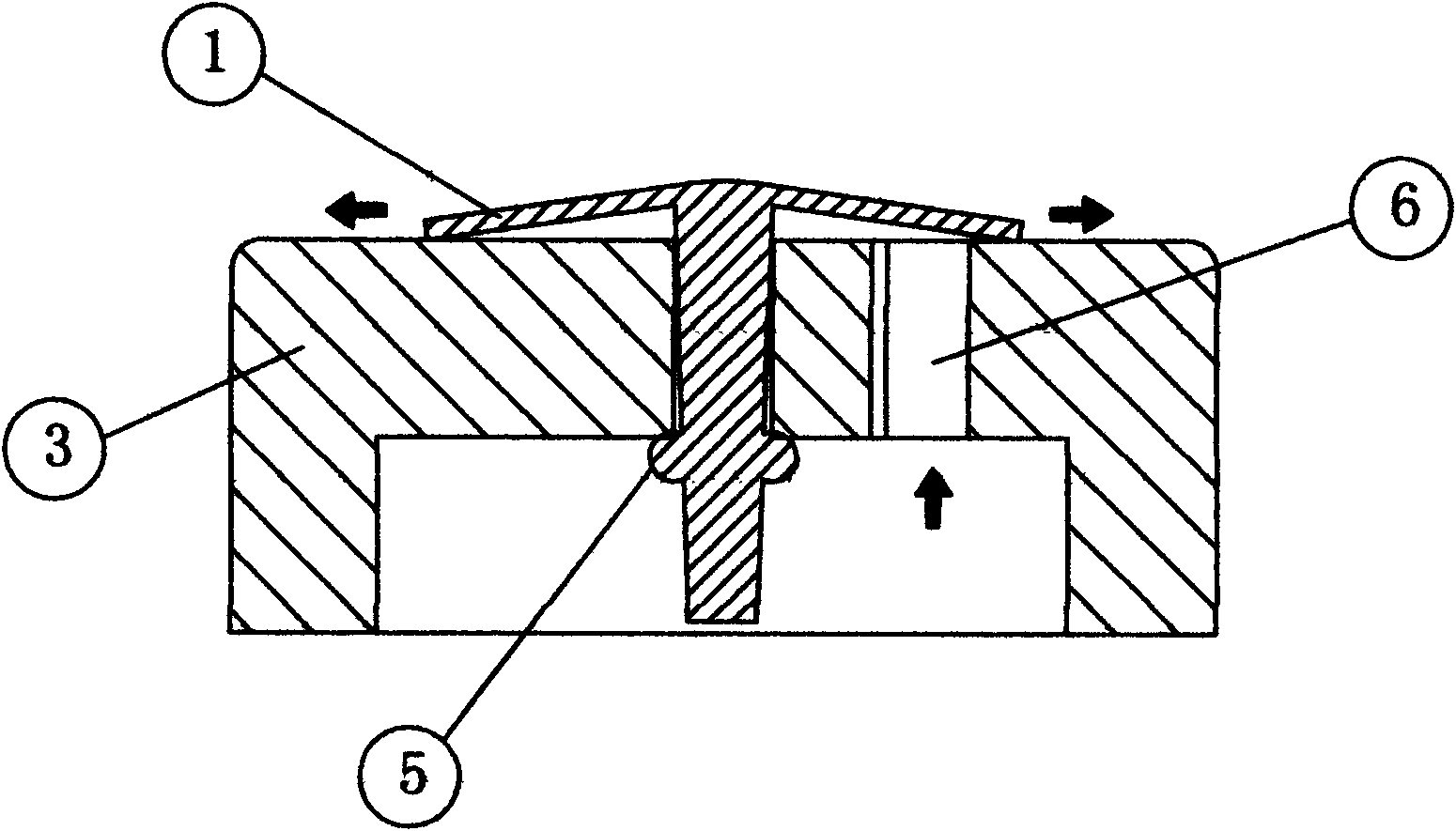

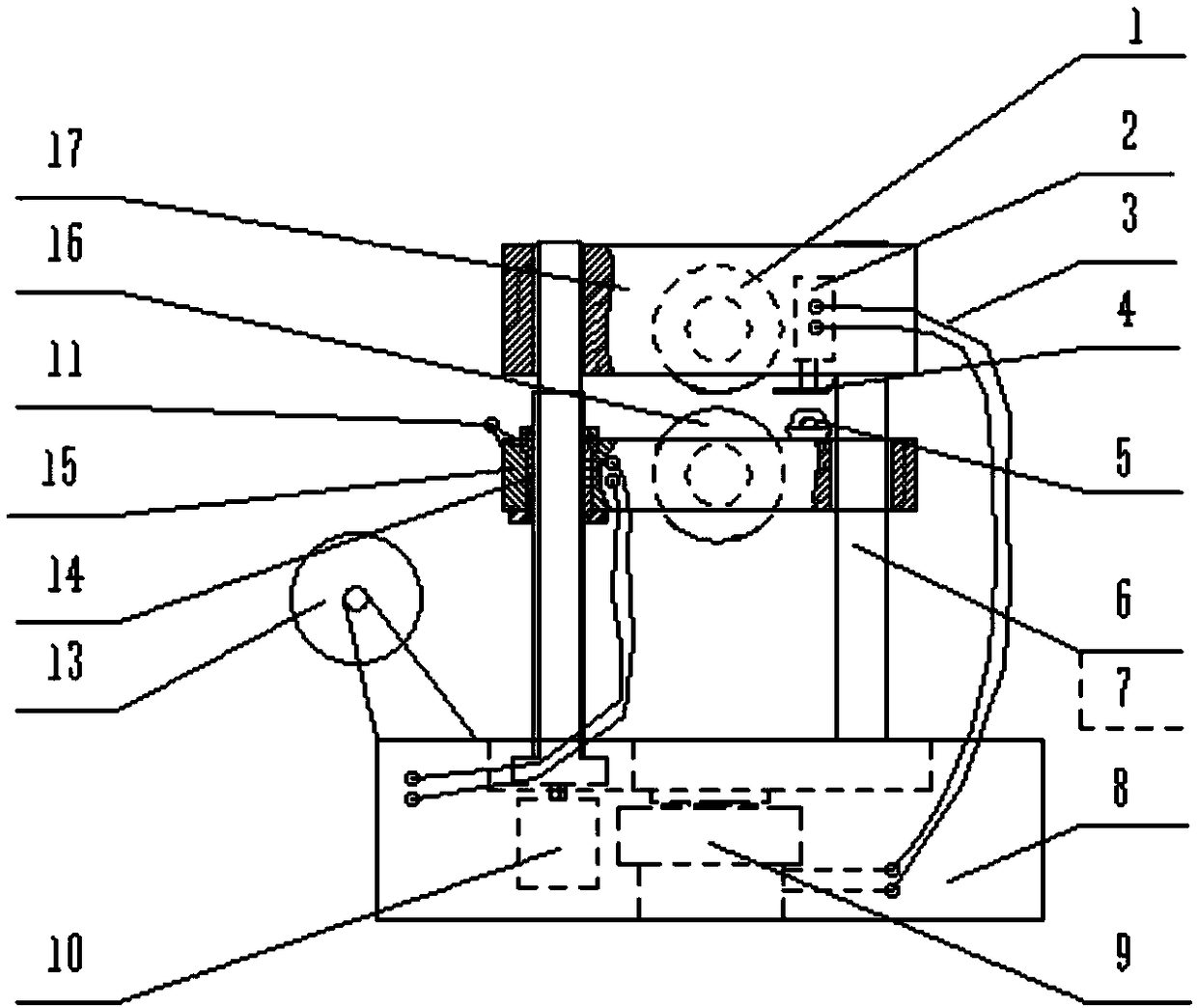

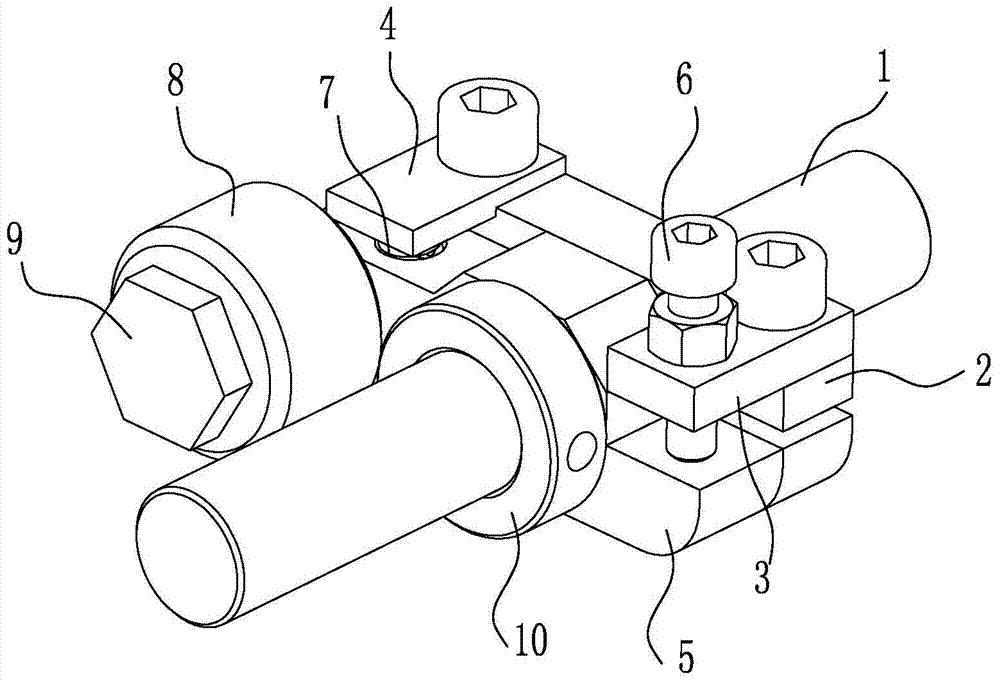

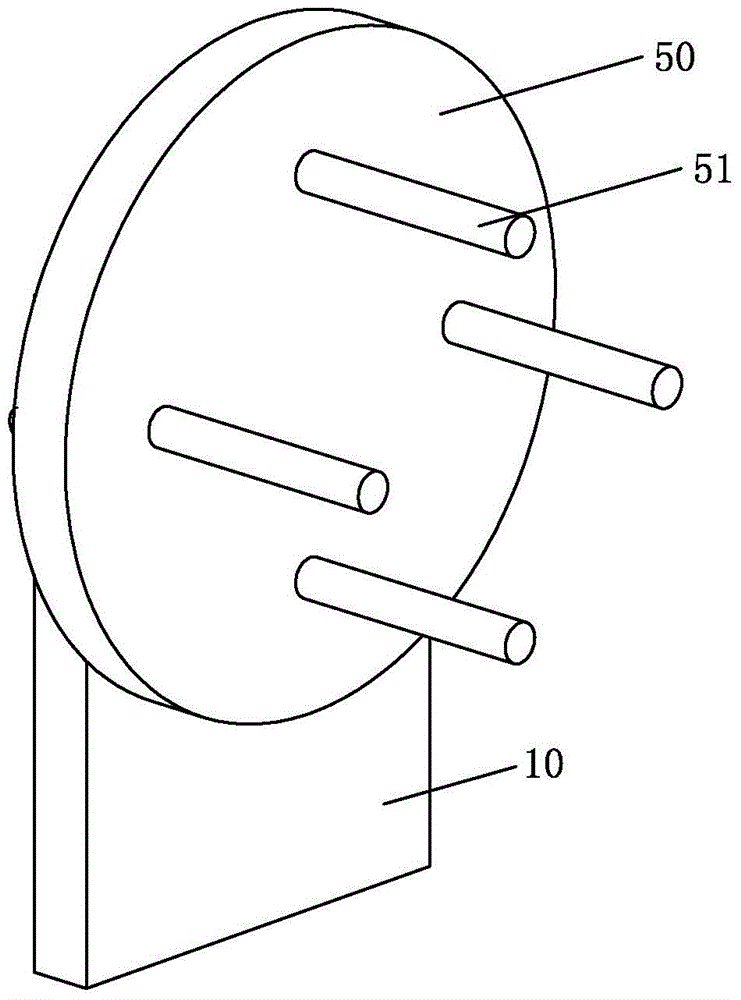

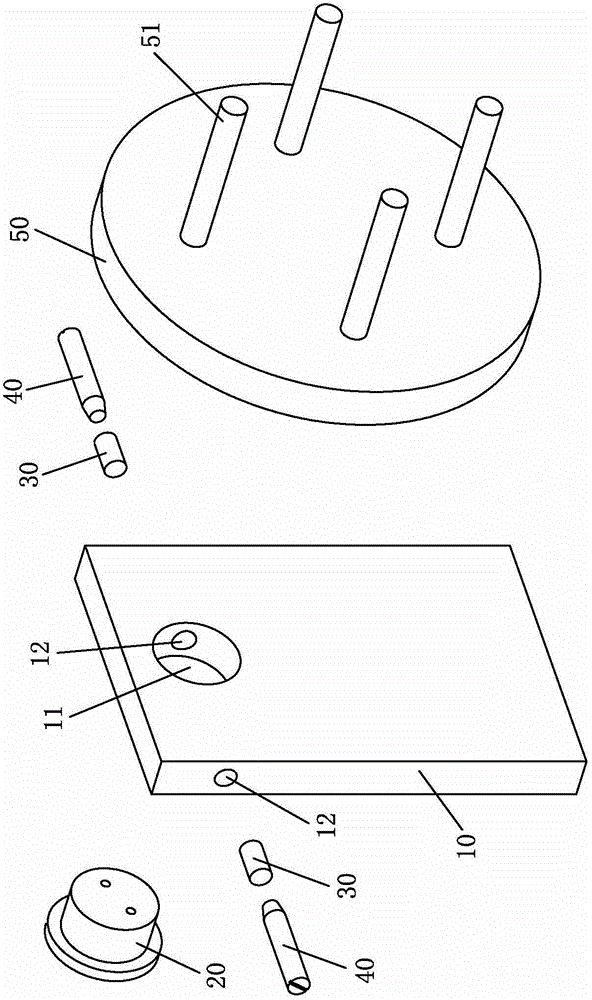

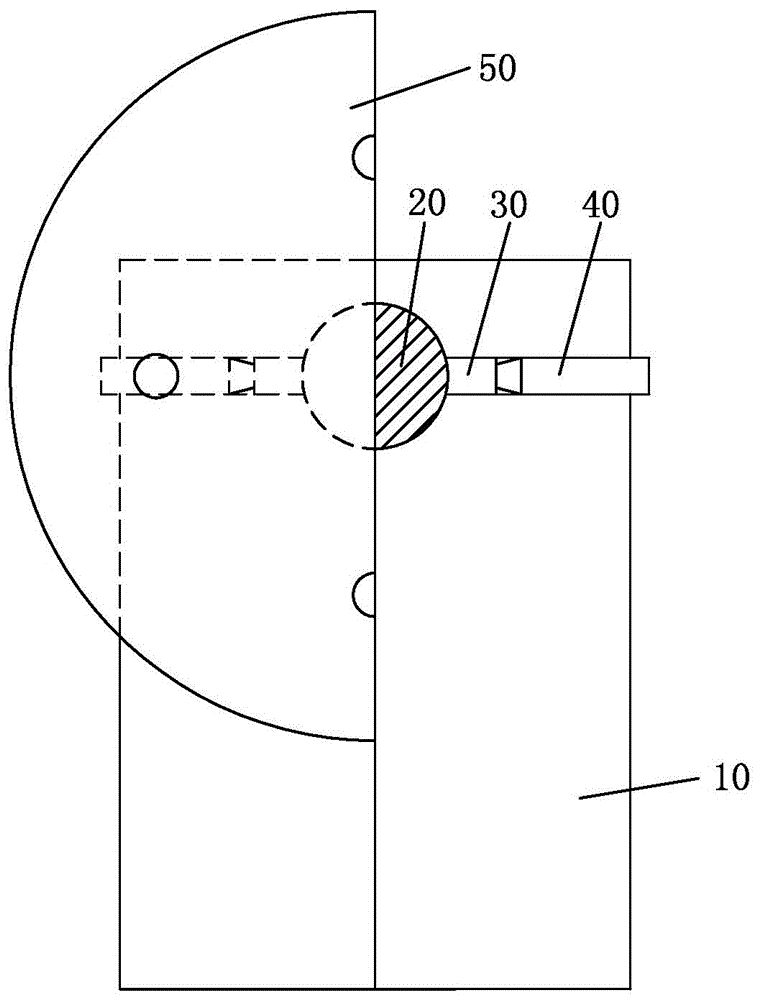

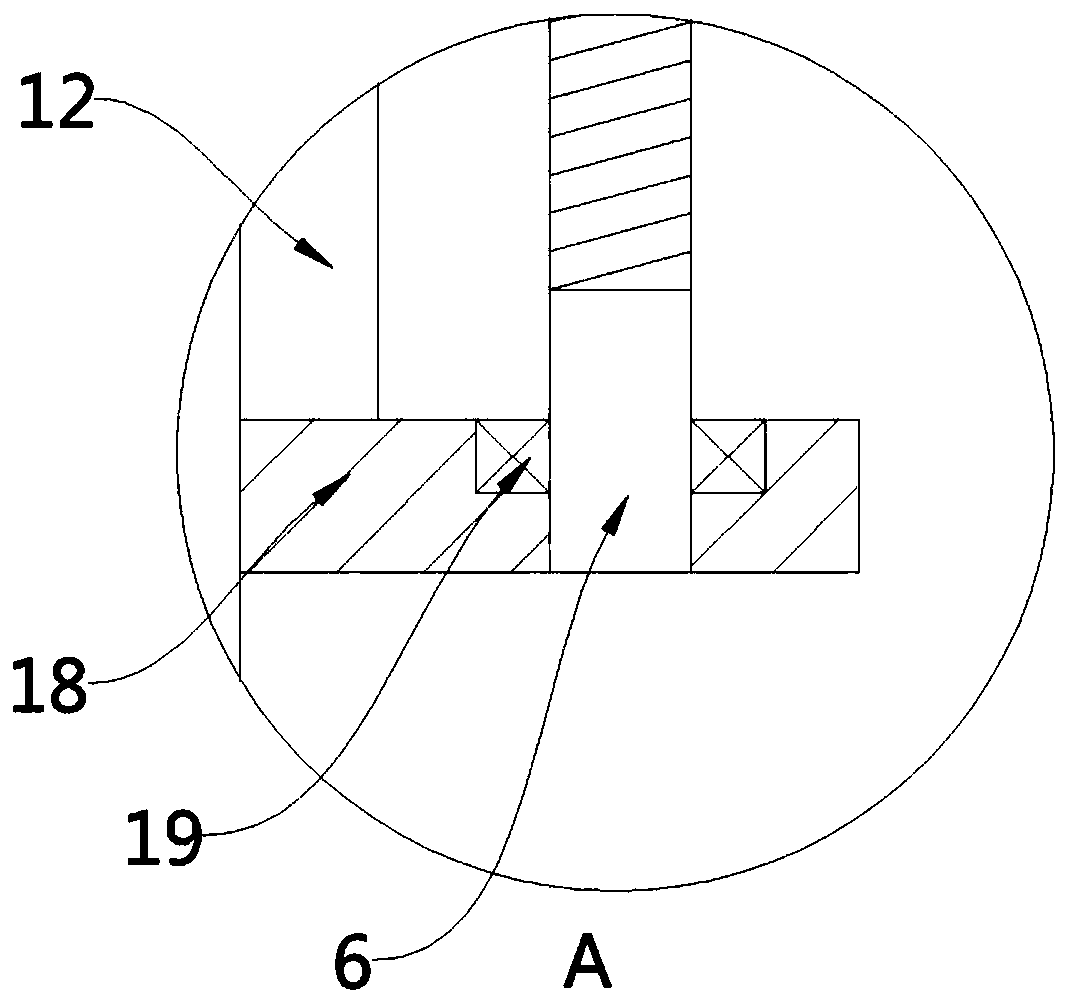

Umbrella valves dedicated to piezoelectric pumps

InactiveCN102287365ASimple structureQuick responsePositive displacement pump componentsCheck valvesMedical equipmentAutomatic control

An umbrella valve dedicated for use in a piezoelectric pump. Among micropump pump valves are actuation source-less valve, piezoelectrically actuated valve, thermally actuated valve, memory alloy valve, and piezoelectric valve, all of which have a certain shortcoming, for instance, the valves have complex structures and increased manufacturing costs, some provide a product with poor consistency and poor air-tightness. The umbrella valve dedicated for use in the piezoelectric pump structurally consists of the umbrella valve (A1) and a valve frame (A3). A valve rod of the umbrella valve is passed through and arranged at a central through hole of the valve frame. Distributed around the central through hole of the valve frame is a flow-pass through hole (6). The flow-pass through hole correspondingly matches the opening and closing of the umbrella valve that is opened. The umbrella valve is provided with characteristics of a simple structure, increased sensitivity, great sealing effect, reduced manufacturing costs, and great operational performance, and is applicable in the fields and scenarios of various fluids, comprising gases, water, and specifically liquids, such as in water processing, chemical engineering analysis, medical equipment, biomedicine, and automatic control.

Owner:胡军 +1

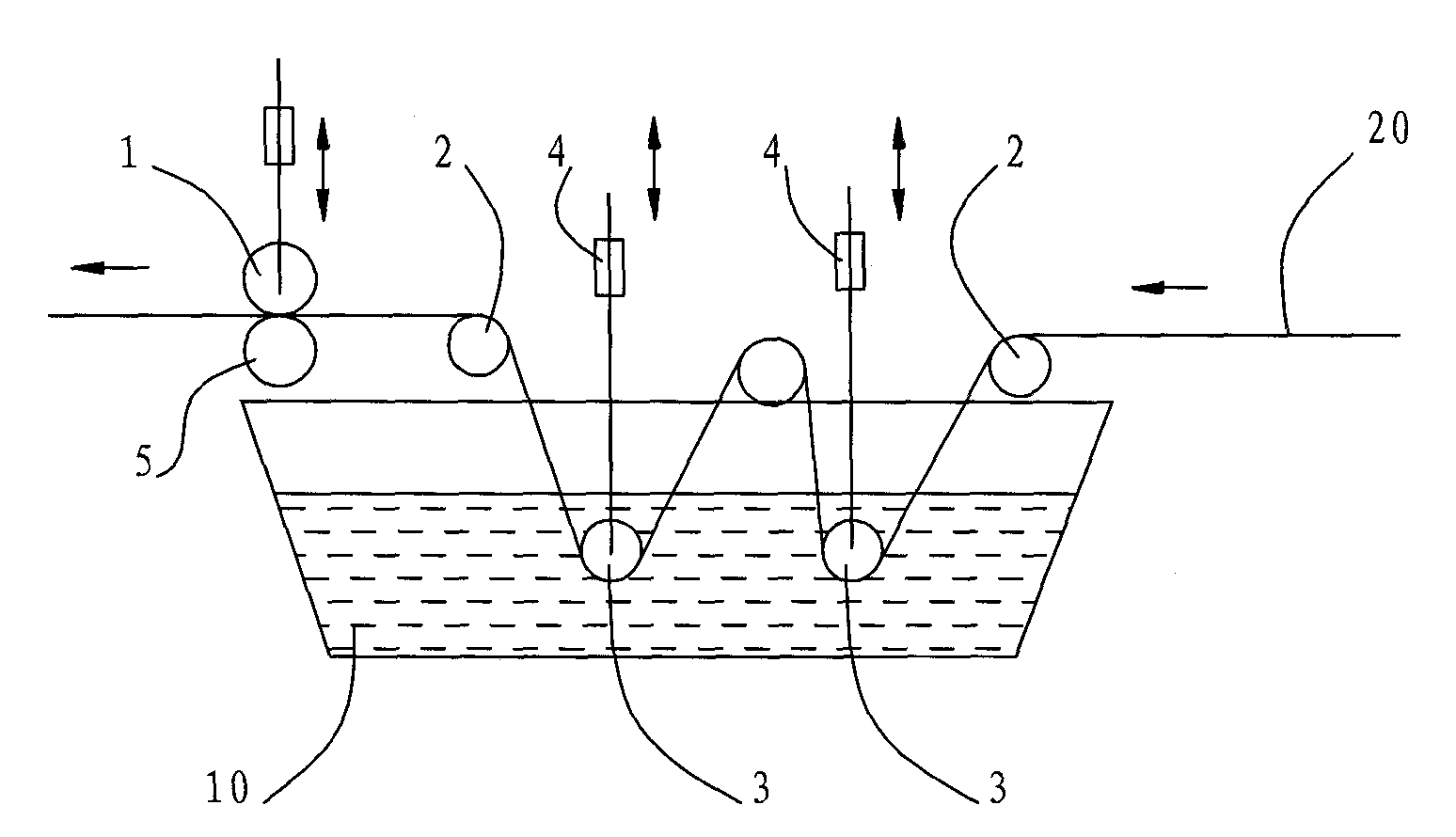

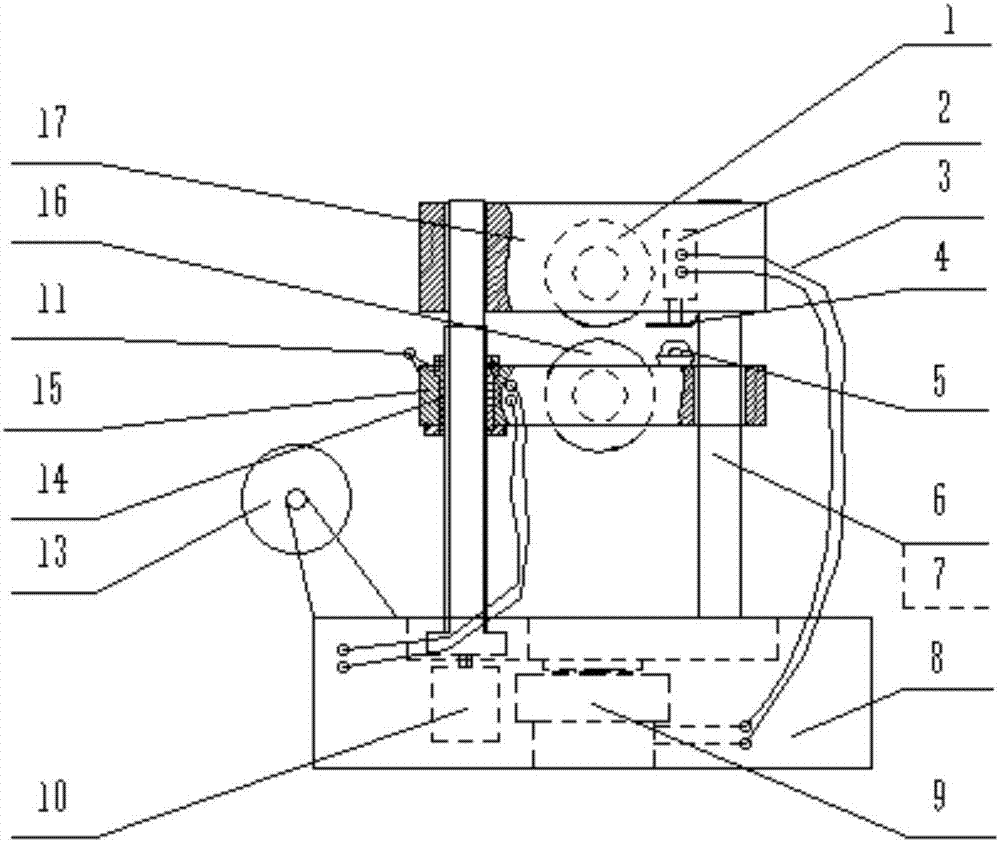

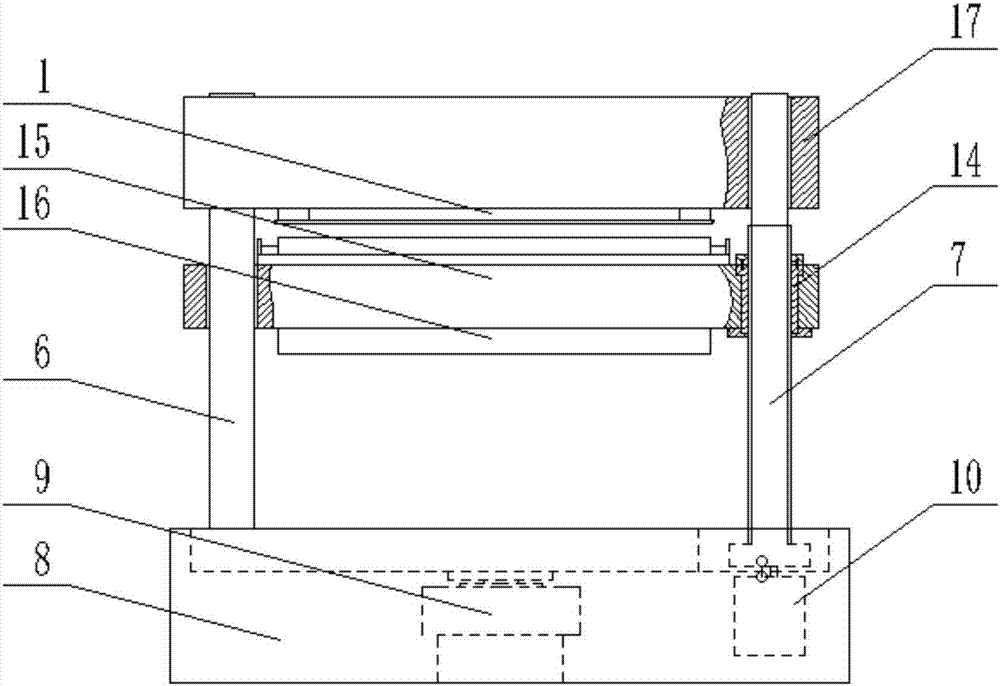

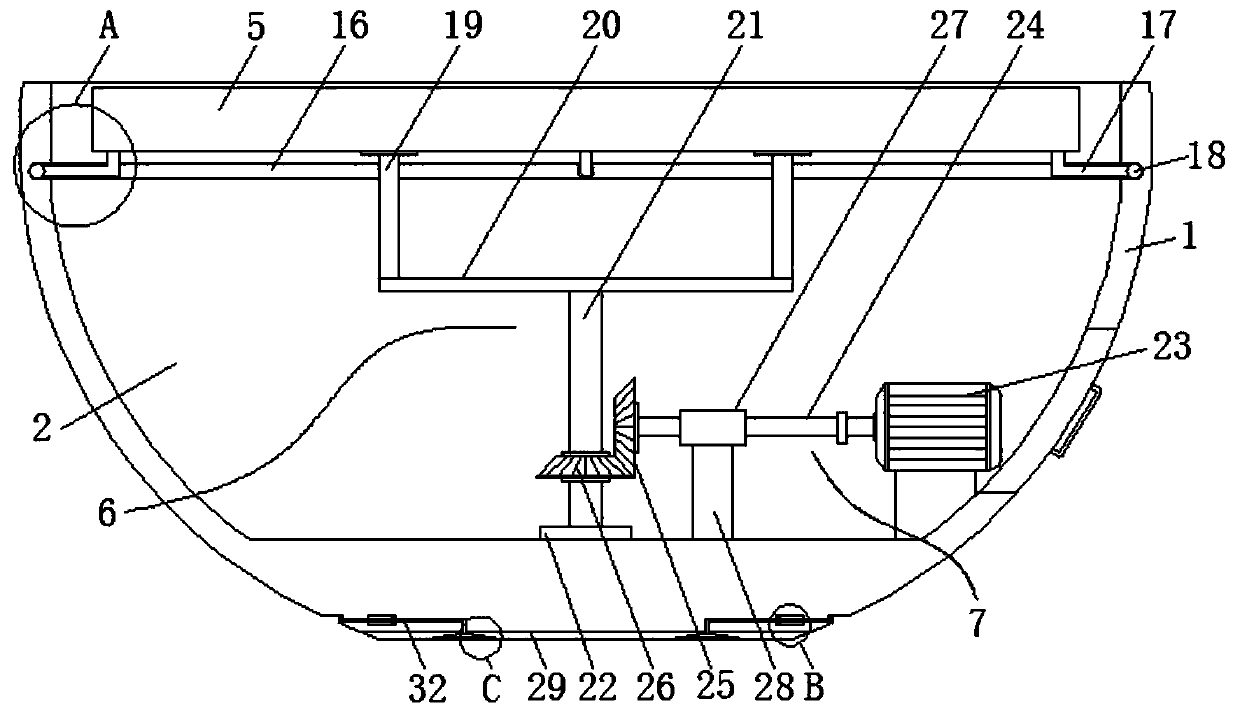

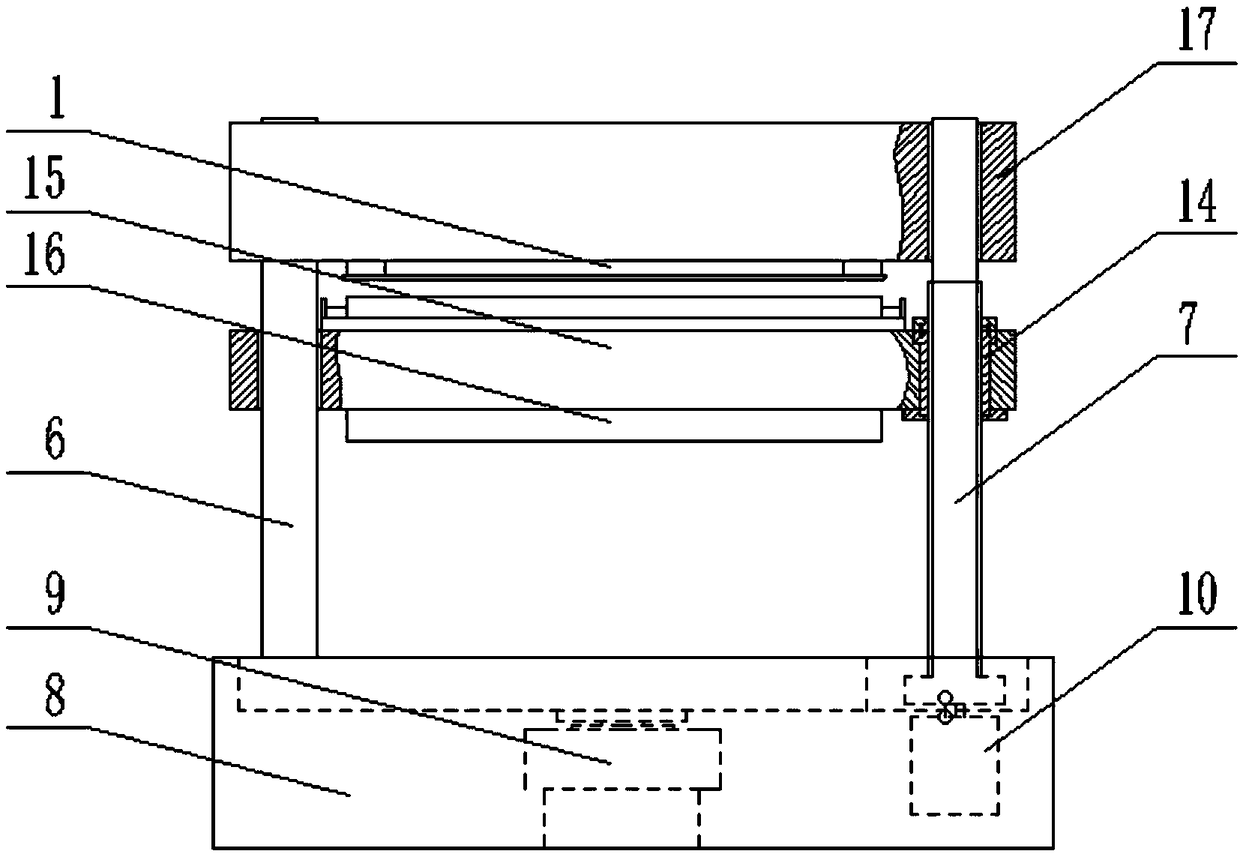

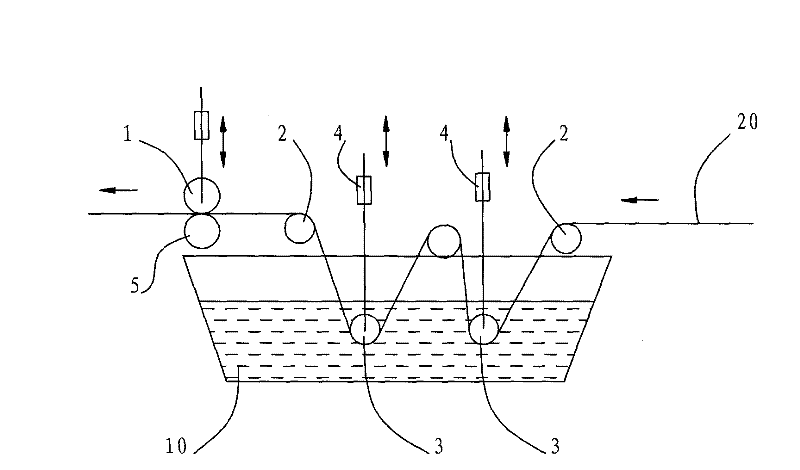

Processing device for dip-coating waterproof rolls

ActiveCN101831812ASolve the situation of scratched tire base fabricReduce work intensityTextiles and paperEngineeringDip-coating

The invention relates to a processing device for dip-coating waterproof rolls, which comprises a material pool and base fabric, the material pool is filled with coating, the side wall of the material pool and / or the bottom of the material pool are provided with a heating mechanism, the material pool is internally provided with a material delivering roll pair formed by an upper material picking-up roll and a lower material picking-up roll, the upper material picking-up roll is positioned above the coating, part of the lower material picking-up roll is soaked in the coating, the upper material picking-up roll and the lower material picking-up roll move in same direction or in opposite directions, the coating is delivered to the upper material picking-up roll through the lower material picking-up roll, and the base fabric is in connection with the surface of the upper material picking-up roll. One end of the material pool is a material inlet end which is provided with a guiding roll and a tensioning roll, and the guiding roll and the tensioning roll are positioned above the coating and are connected with a lifting mechanism; and one end of the base fabric is connected with the upper material picking-up roll after sequentially passing through the guiding roll and the tensioning roll. The invention has the characteristics of simple and reasonable structure, small whole machine volume and occupation, flexible operation, low manufacturing cost, low energy consumption, high production efficiency and wide application range.

Owner:鞍山科顺建筑材料有限公司

Flexible mechanical arm and control method thereof

The invention discloses a flexible mechanical arm and a control method thereof and aims at achieving the effects that the flexible mechanical arm can be simple in structure, and the structure can be changed so as to adapt to various environments. According to the technical scheme, the flexible mechanical arm mainly comprises a hand-shaped body, a driving assembly and a control assembly, when the pressure of an elastic cavity in the hand-shaped body is changed, the elastic cavity is bent or is changed from the bent state to the straightened state, due to the fact that the elastic cavity can have deformation, when an execution body abuts against a contact object, the execution body can have self deformation so as to be adapted to the contact object, and the driving assembly for controlling the pressure in the elastic cavity is arranged, so that the pressure in the elastic cavity is increased or decreased, and precise detection and control are achieved through the control assembly.

Owner:EAST CHINA JIAOTONG UNIVERSITY

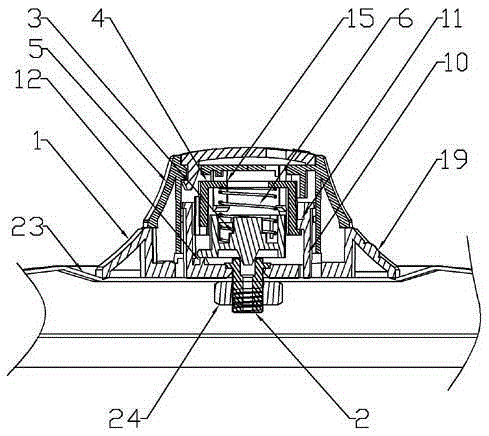

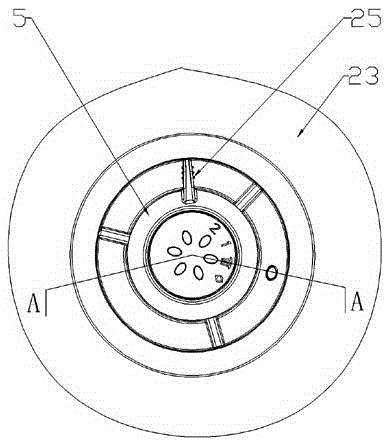

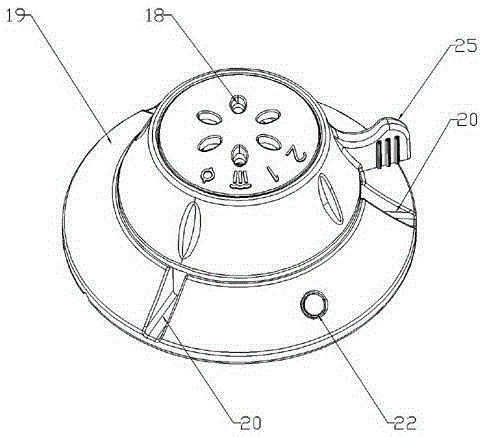

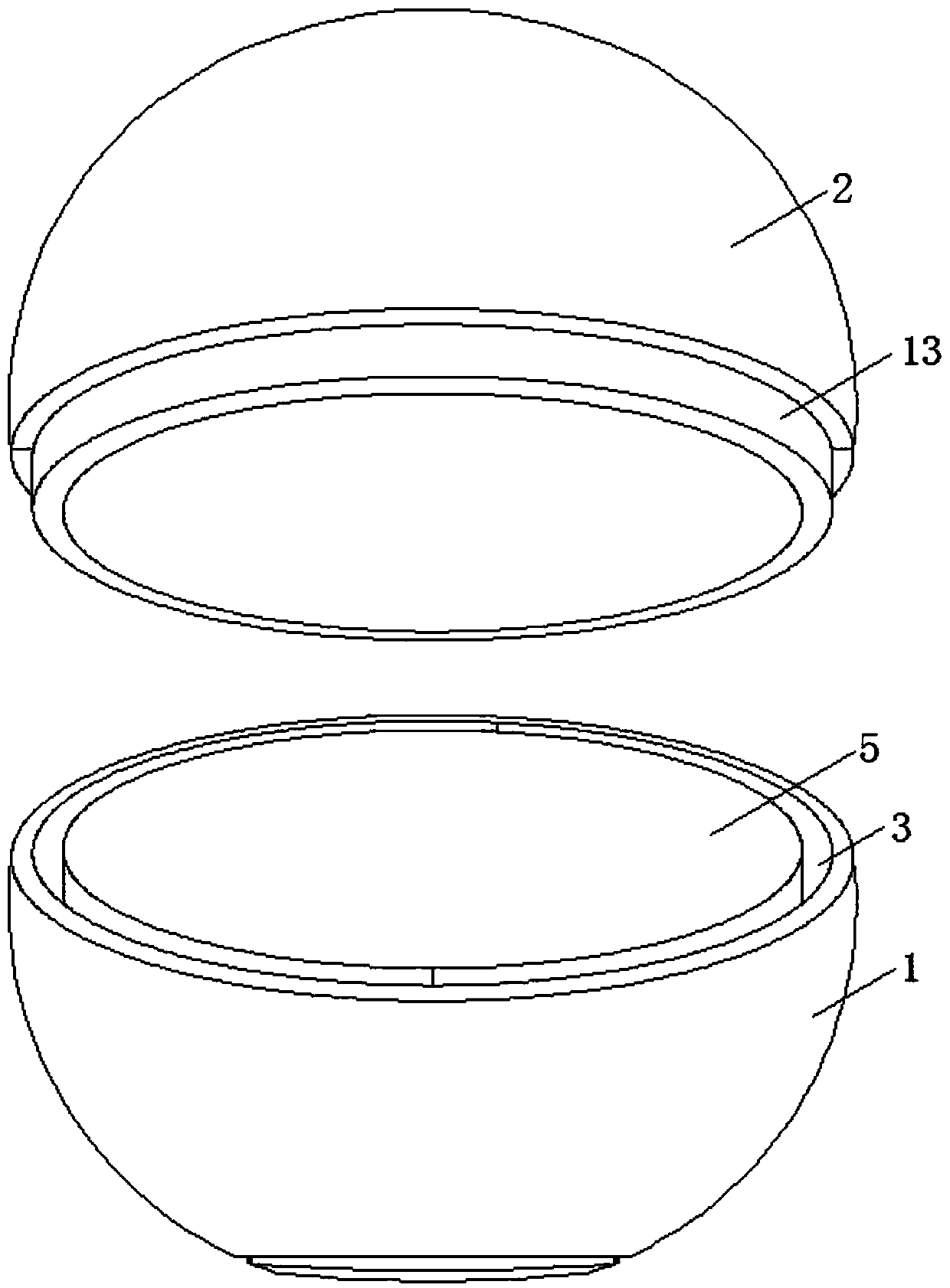

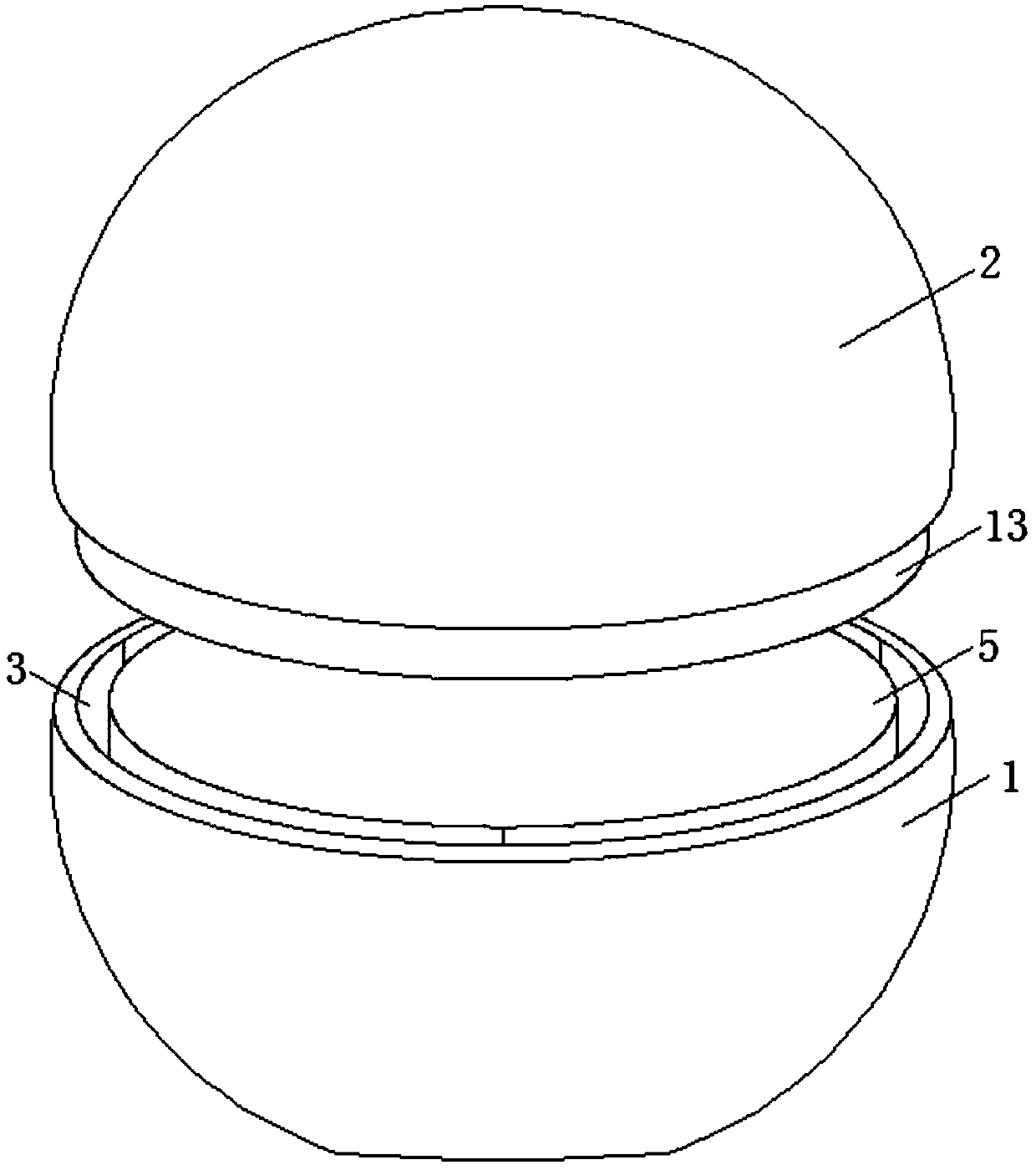

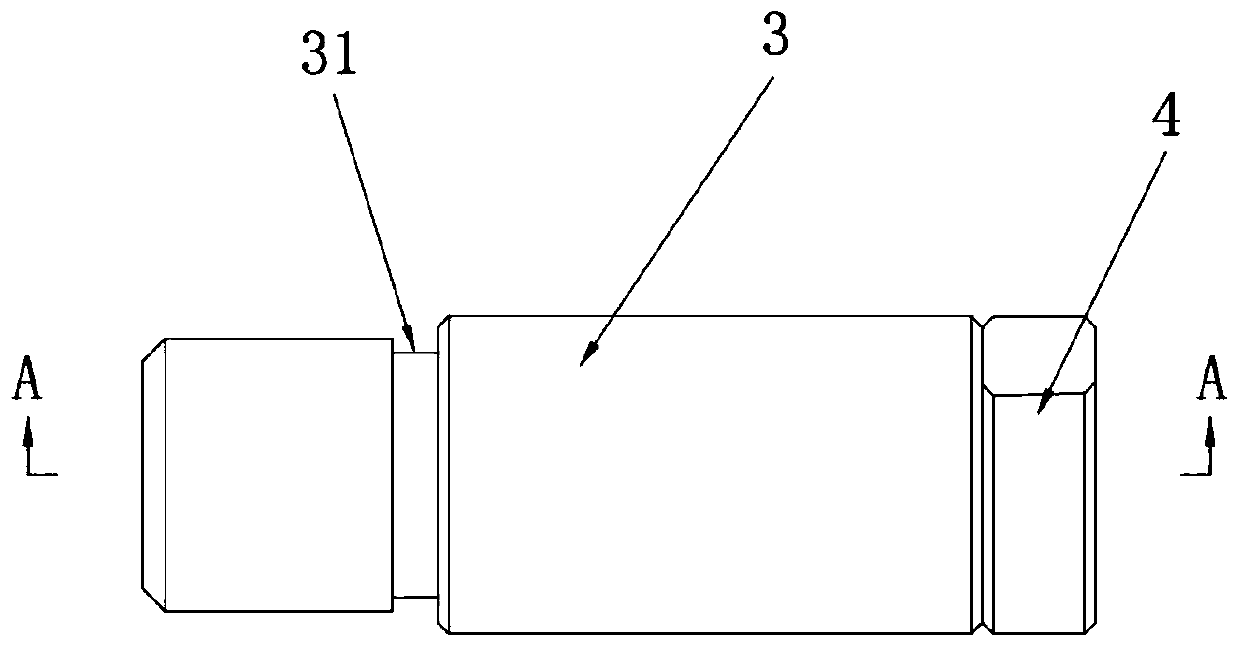

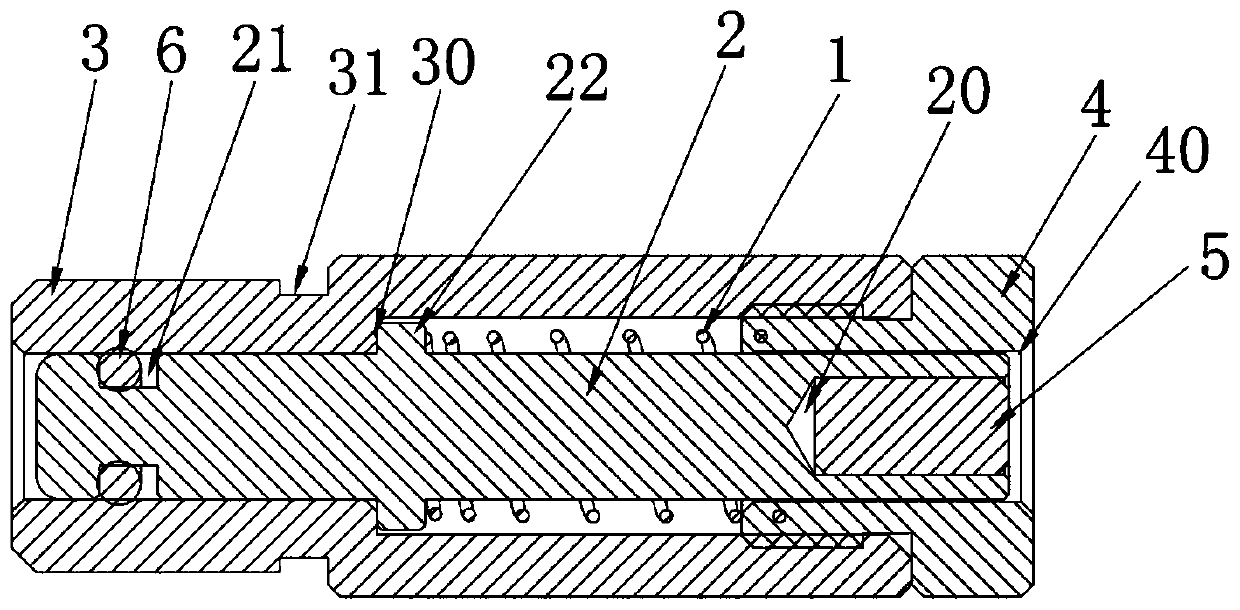

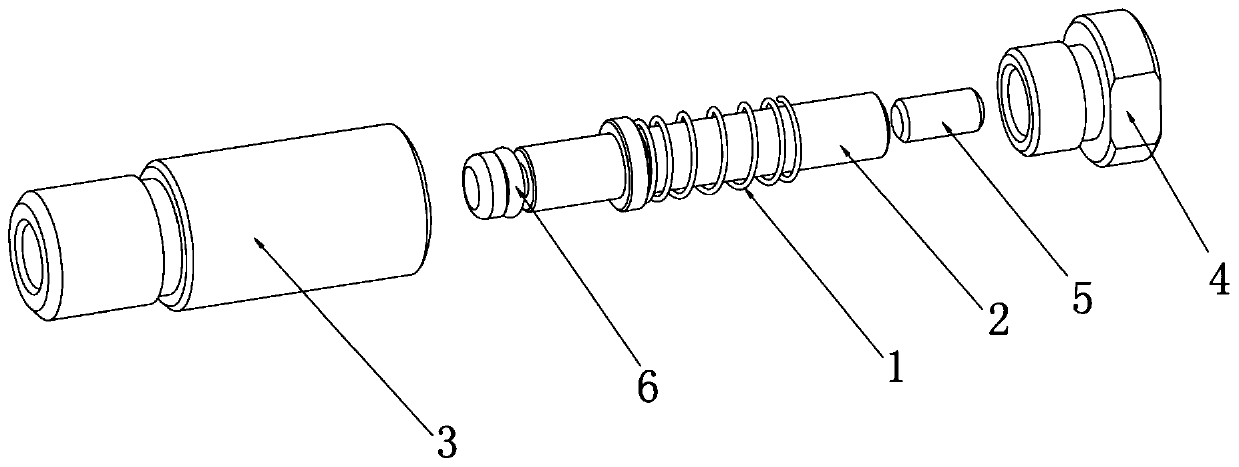

Spring type multi-gear pressure-limiting valve with pressure adjustable

ActiveCN105286626ARegulating pressureIncrease or decrease in pressureEqualizing valvesSafety valvesEngineeringExhaust pipe

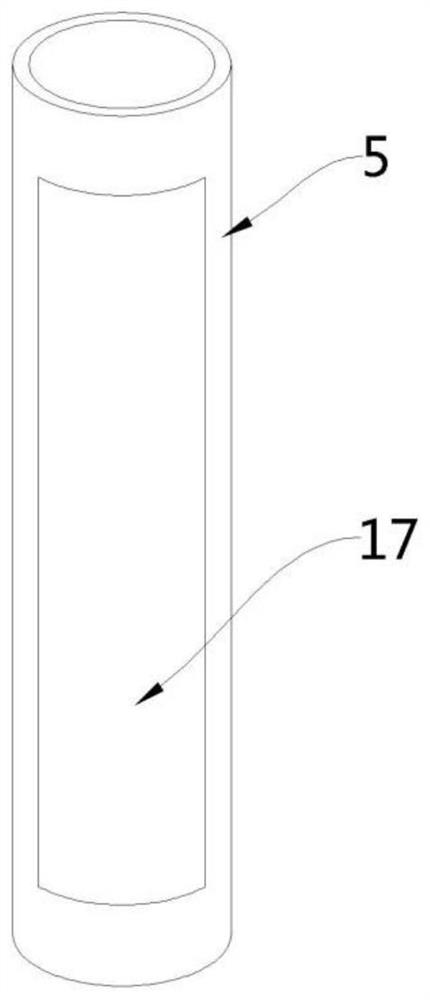

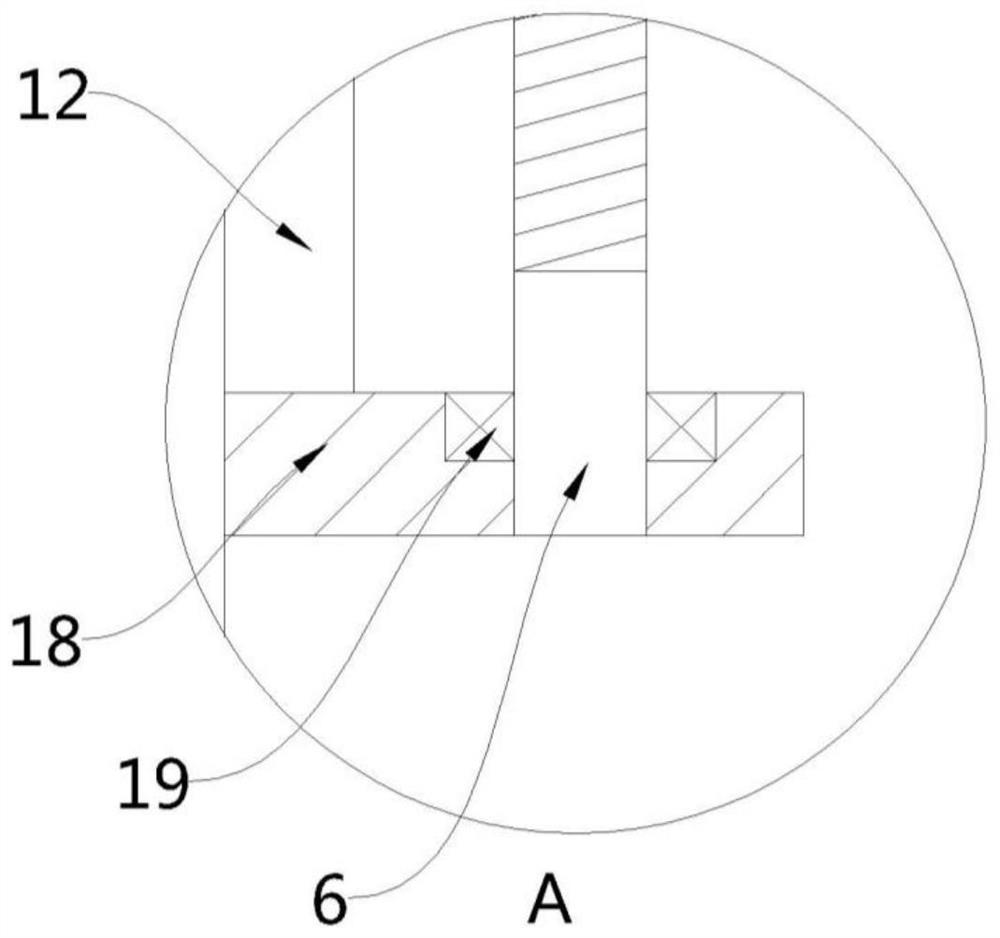

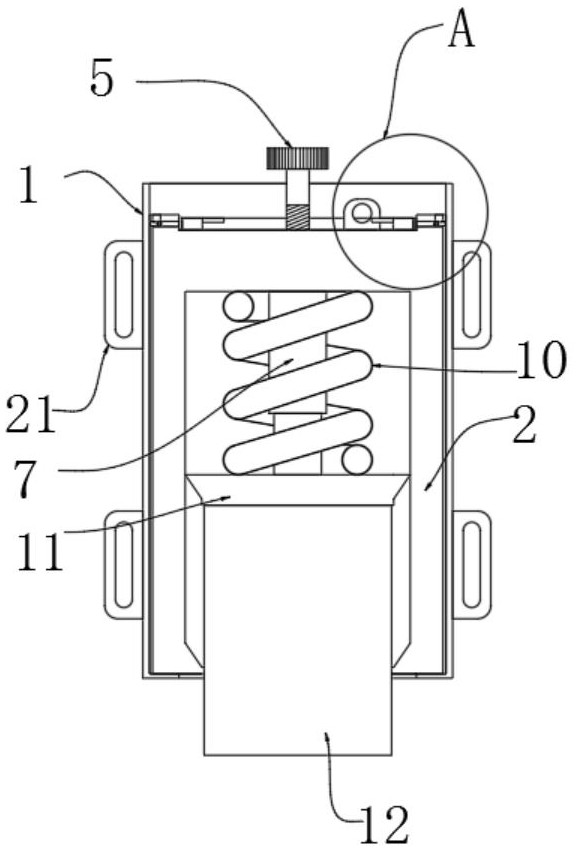

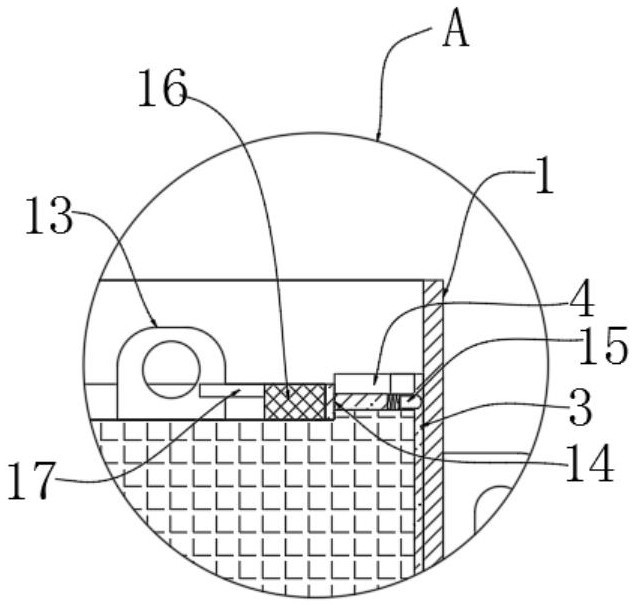

The invention discloses a spring type multi-gear pressure-limiting valve with the pressure adjustable and aims at achieving the effects that the spring type multi-gear pressure-limiting valve with the pressure adjustable is simple in structure, safe, stable and convenient to use and capable of satisfying various cooking requirements of consumers. The spring type multi-gear pressure-limiting valve comprises a valve seat (1), an exhaust pipe (2) and a pressure adjusting mechanism, the pressure adjusting mechanism comprises a lower valve element (3), an upper valve element (4), a rotary cover (5) and a pressure limiting spring (6), the lower valve element (3) is sleeved with the upper valve element (4) and provided with multiple valve element grippers, sliding grooves are formed in the inner wall of the upper valve element (4), multiple groups of step clamping positions are evenly distributed on the outer wall of the upper valve element (4), an inner ring seat is arranged on the valve seat (1), an air outlet of the exhaust pipe (2) is located inside the inner ring seat, and multiple valve seat clamping pillars are arranged on the inner wall of the inner ring seat. The spring type multi-gear pressure-limiting valve is applied to the technical field of pressure-limiting valves.

Owner:ZHUHAI DOUBLE HAPPINESS ELECTRIC APPLIANCE

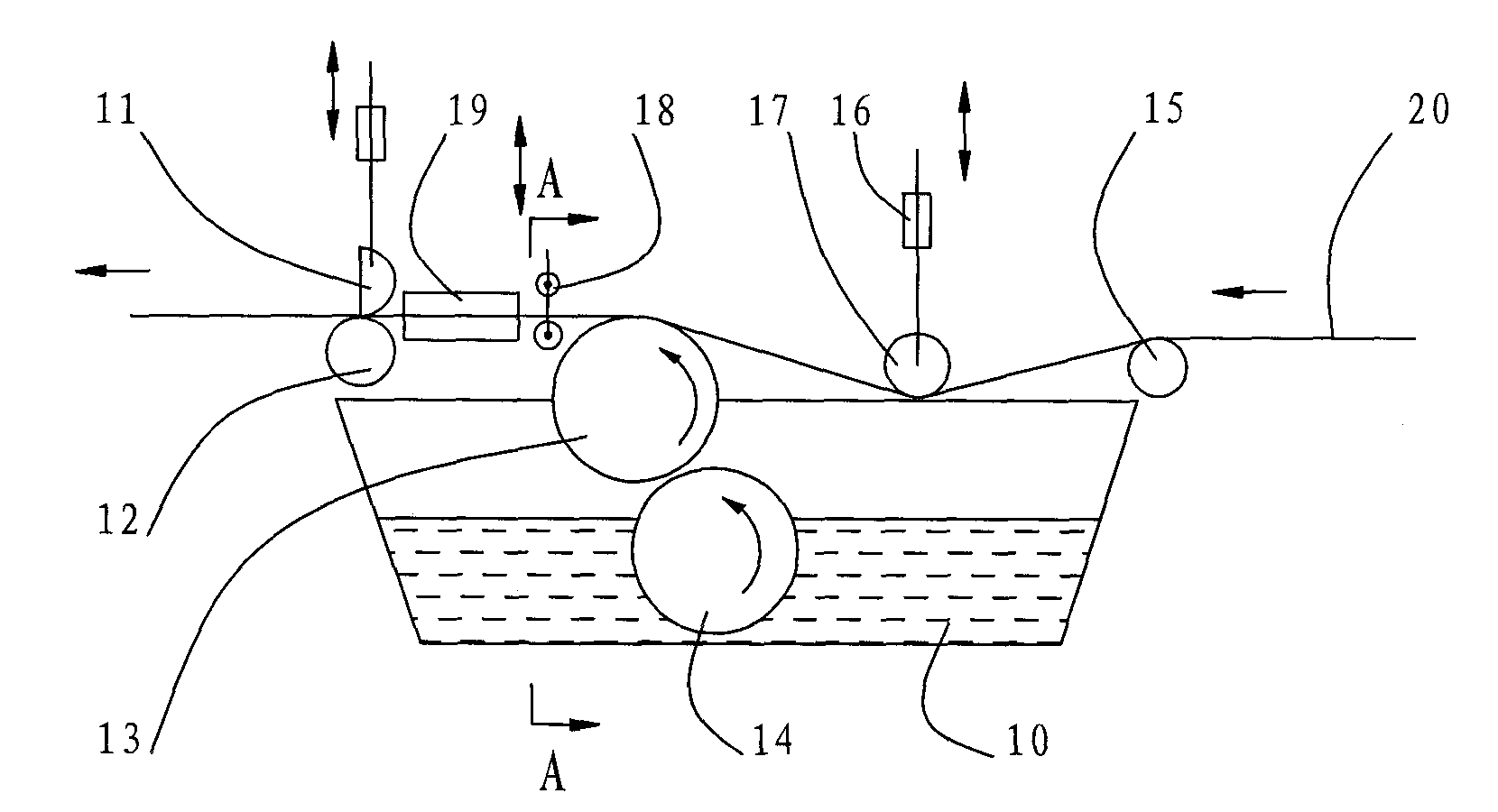

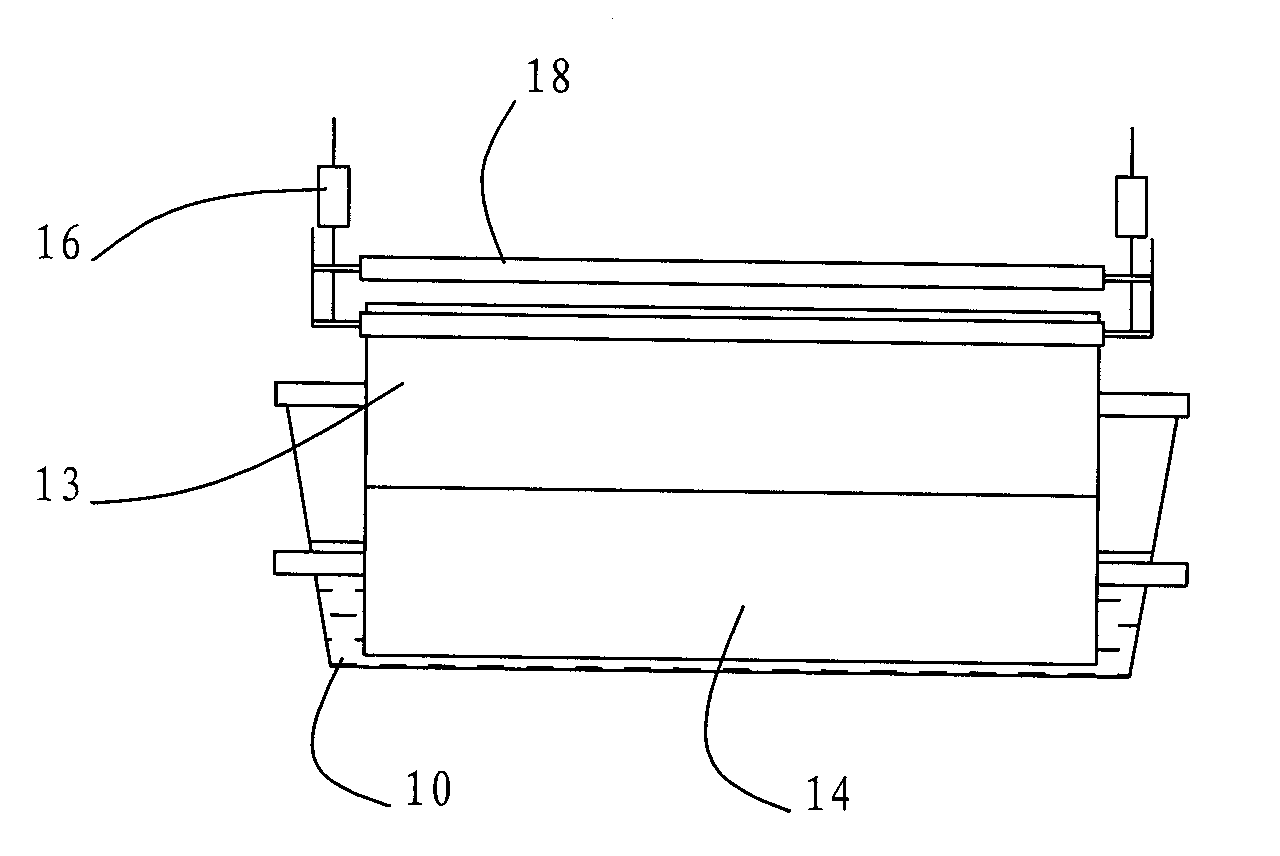

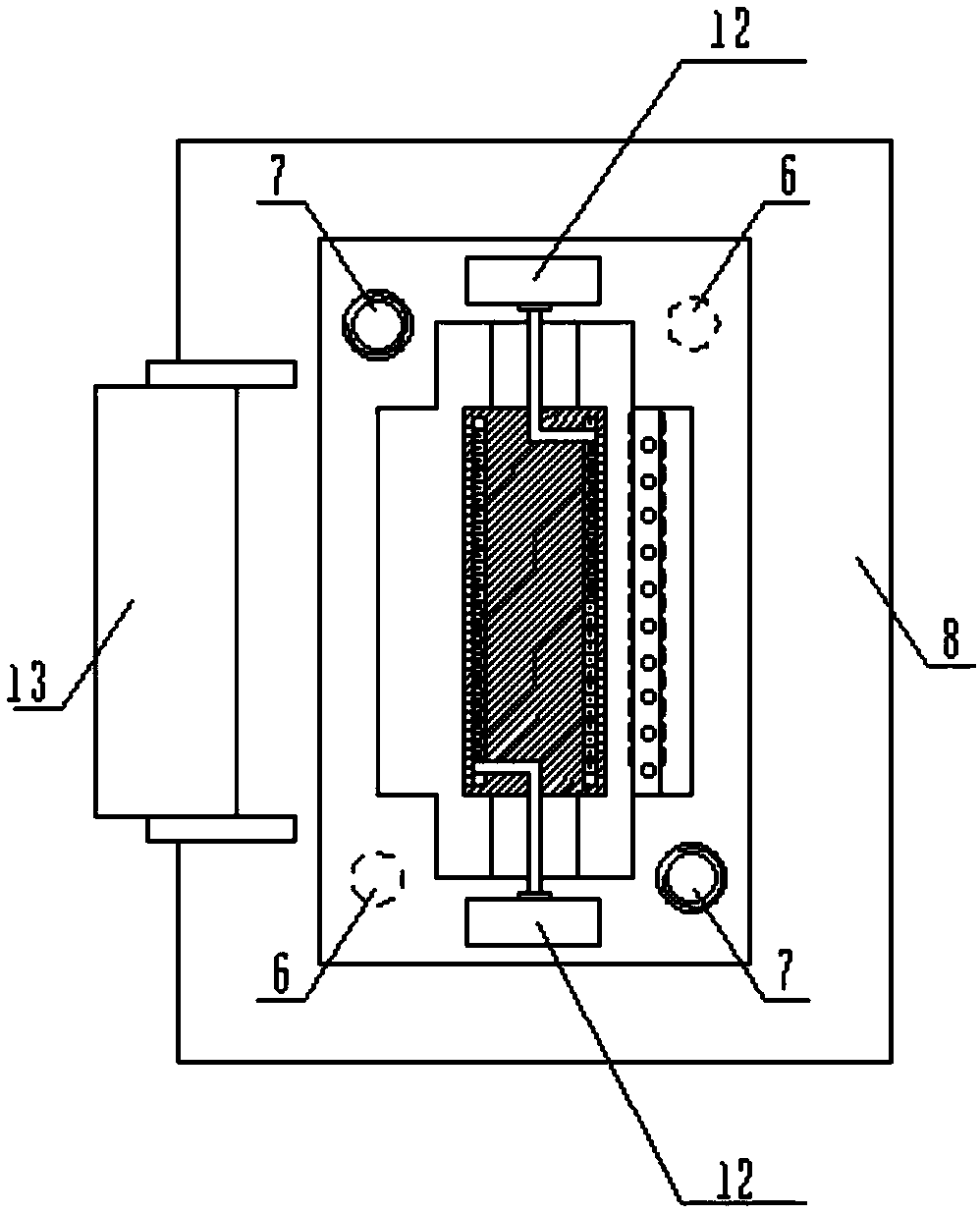

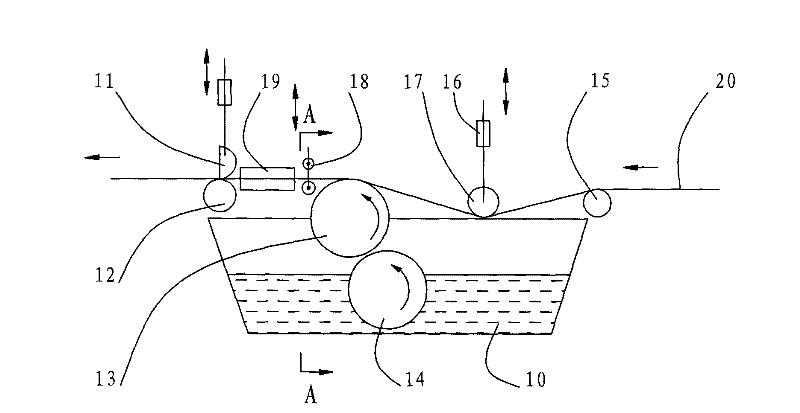

Roller printing machine

ActiveCN107323069AImprove printing and dyeing layeringAvoid printing uneven colorRotary intaglio printing pressApparatus for force/torque/work measurementSelf adaptiveDyeing

The invention discloses a roller printing machine, belonging to the technical field of printing and dyeing. The roller printing machine comprises a printing machine base, a lead screw, a feed rod, a driving nut, a lower crossbeam, a lower printing roller, an upper crossbeam, an upper printing roller, a motor and a feed rod fine adjustment mechanism, wherein the rapid adjustment and accurate adjustment of the distance between the lower printing roller and the upper printing roller can be realized by the feed rod fine adjustment mechanism through the screw-thread fit between the lead screw and the driving nut; a driven roller is arranged on the lower crossbeam of the roller printing machine of the embodiment; a pressure sensor and a piezoelectric signal converter are arranged on the upper crossbeam; and the distance between a driving roller and the driver roller can be automatically adjusted according to the thickness of raw materials to be processed and the requirements of printing and dyeing pressure, thereby realizing the self-adaptive adjustment of pressure in the printing and dyeing process, improving the poor printing and dyeing layering of the roller printing machine and avoiding the phenomenon of defective goods such as uneven printing colors.

Owner:JIANGSU KUNTAI MACHINERY

Heavy-duty isothermal forging press with four corner leveling function

InactiveCN104416105AGuaranteed parallelismReduced leveling response timeForging press drivesPistonEngineering

The invention relates to a heavy-duty isothermal forging press with a four corner leveling function. The heavy-duty isothermal forging press with the four corner leveling function comprises an upper transverse beam, a lower transverse beam and a stand column which are connected through tie rods and lock nuts to form an integrally stressed frame body, wherein the upper transverse beam is fixed with the bottoms of a main cylinder and a side cylinder, piston ends of the main cylinder and the side cylinder are fixedly installed with a sliding block, an upper cushion plate is fixedly arranged on a lower plane of the sliding block, and a movable workbench is installed on the lower transverse beam. The heavy-duty isothermal forging press with the four corner leveling function is characterized in that upper leveling cylinders are fixedly arranged at four corners of the upper transverse beam, lower leveling cylinders are fixedly arranged on the lower transverse beam at positions corresponding to the upper leveling cylinders on the upper transverse beam, and each of upper leveling cylinders and lower leveling cylinders has an independent leveling control system. The heavy-duty isothermal forging press with the four corner leveling function has the advantages that since the pressure of the leveling cylinders at a certain corner of the sliding block is controlled to be increased or decreased through a control loop and the leveling cylinders at the opposite corner are simultaneously controlled, the levelness of the sliding block in the downward forging process is guaranteed; not only can the leveling response time be shortened and can the sliding block leveling accuracy and production efficiency be improved, but also the loss of the main tonnage of a hydraulic press can be avoided, the energy can be greatly saved and the production cost is reduced.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Transfer device

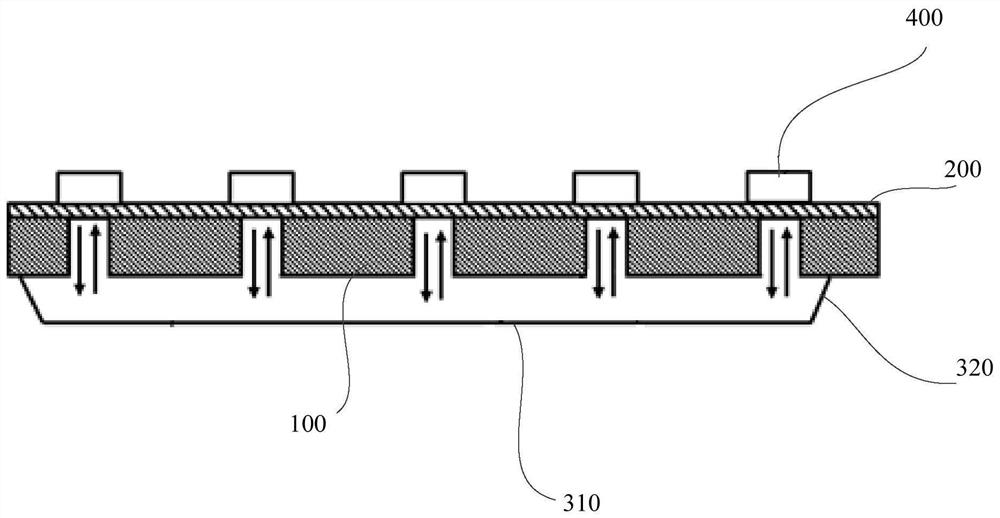

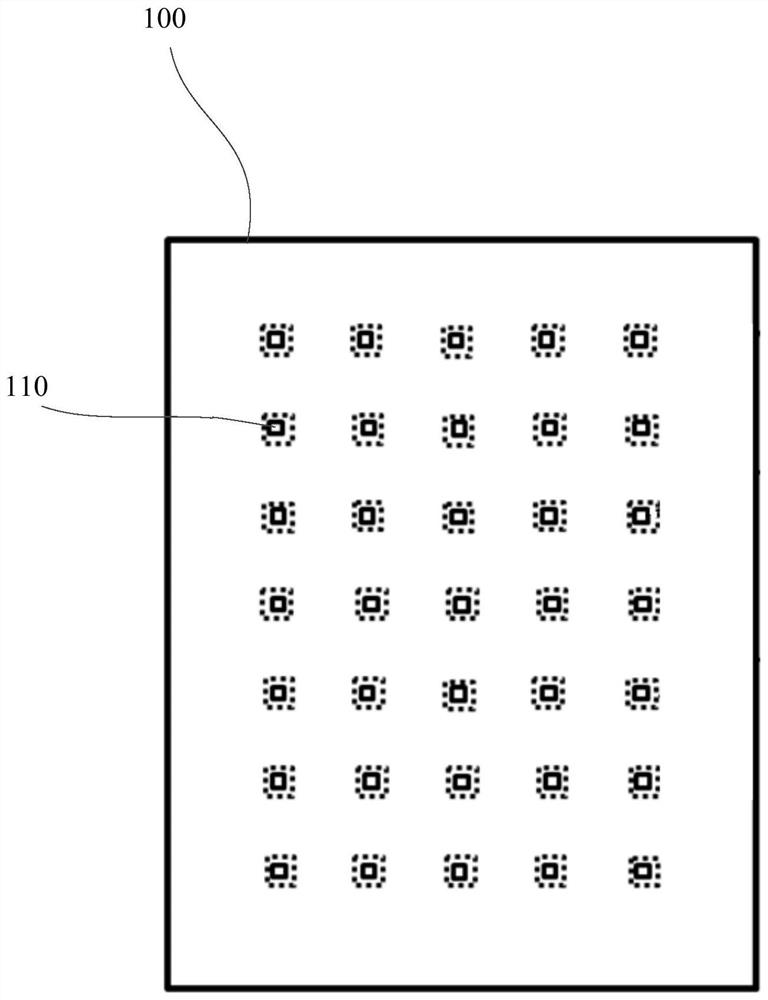

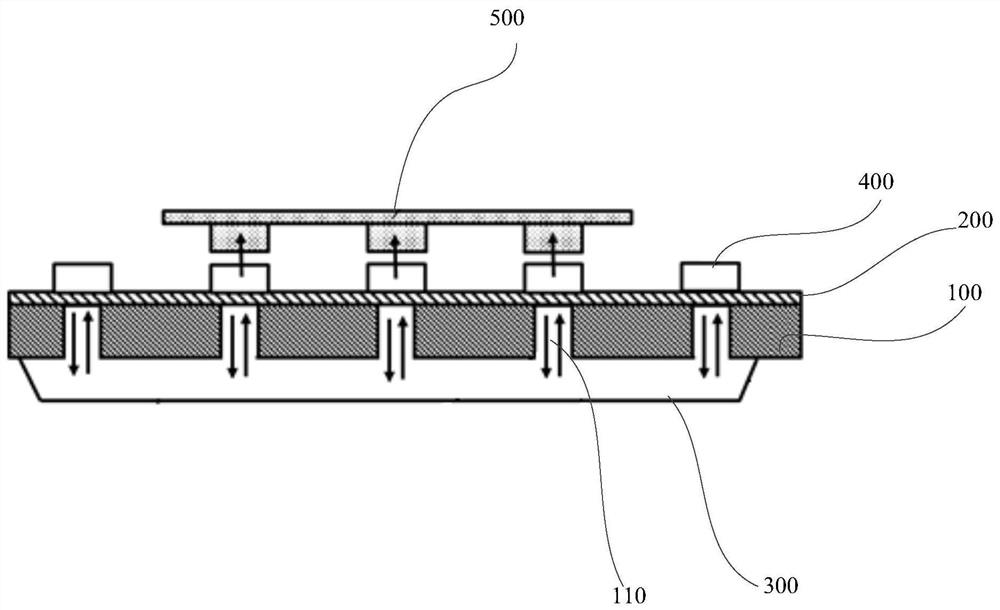

PendingCN112017988AChange adhesionEasy transferSemiconductor/solid-state device manufacturingConveyor partsLead bondingEngineering

The present invention provides a transfer device, comprising: a temporary substrate provided with a plurality of through holes; a bonding glue layer which is arranged on the surface of the temporary substrate, wherein the bonding glue layer covers the plurality of through holes, and the bonding glue layer is used for receiving the LED chips, so that the LED chips are in one-to-one correspondence with the through holes; and a pressure device which is connected with the plurality of through holes, wherein the pressure device is used for increasing or decreasing the pressure of the fluid medium in the through holes, so that part of the bonding adhesive layer covering the through holes deforms under the action of the pressure of the fluid medium. According to the transfer device, the bonding glue layer covering the through hole can fluctuate up and down under the pressure effect of the fluid medium through the pressure device, so that the adhesive capacity between the LED bonding glue layers is reduced, and the pickup equipment can pick up and transfer an LED conveniently.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Electric screw driver with adjustable output torque

InactiveCN105500263AIncrease or decrease in pressureAchieve the purpose of adjustmentSpannersWrenchesCoil spring

Owner:宁波中旺工具有限公司

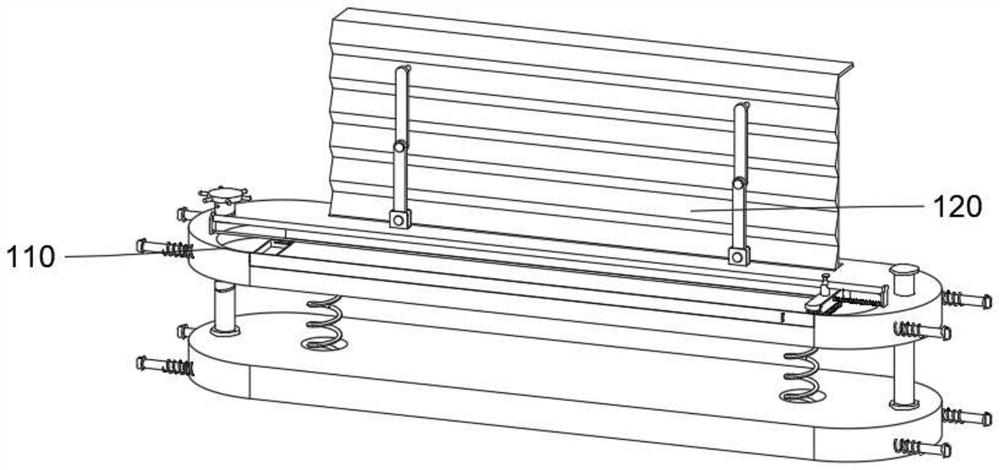

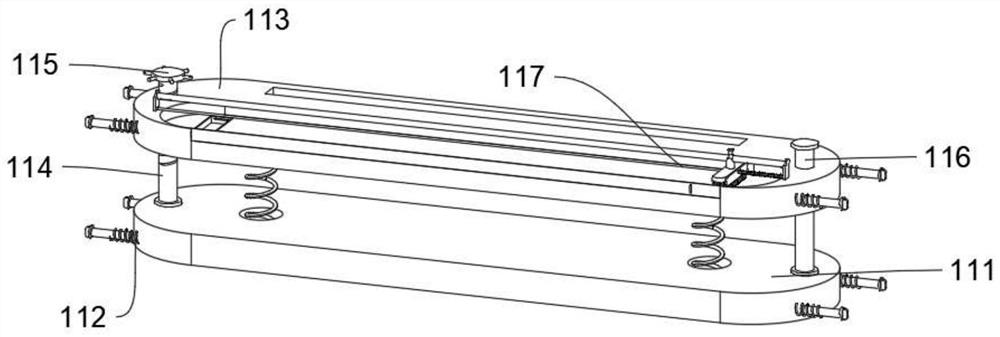

Model exhibition platform for technology promotion

Owner:池州市普丰科技服务有限公司

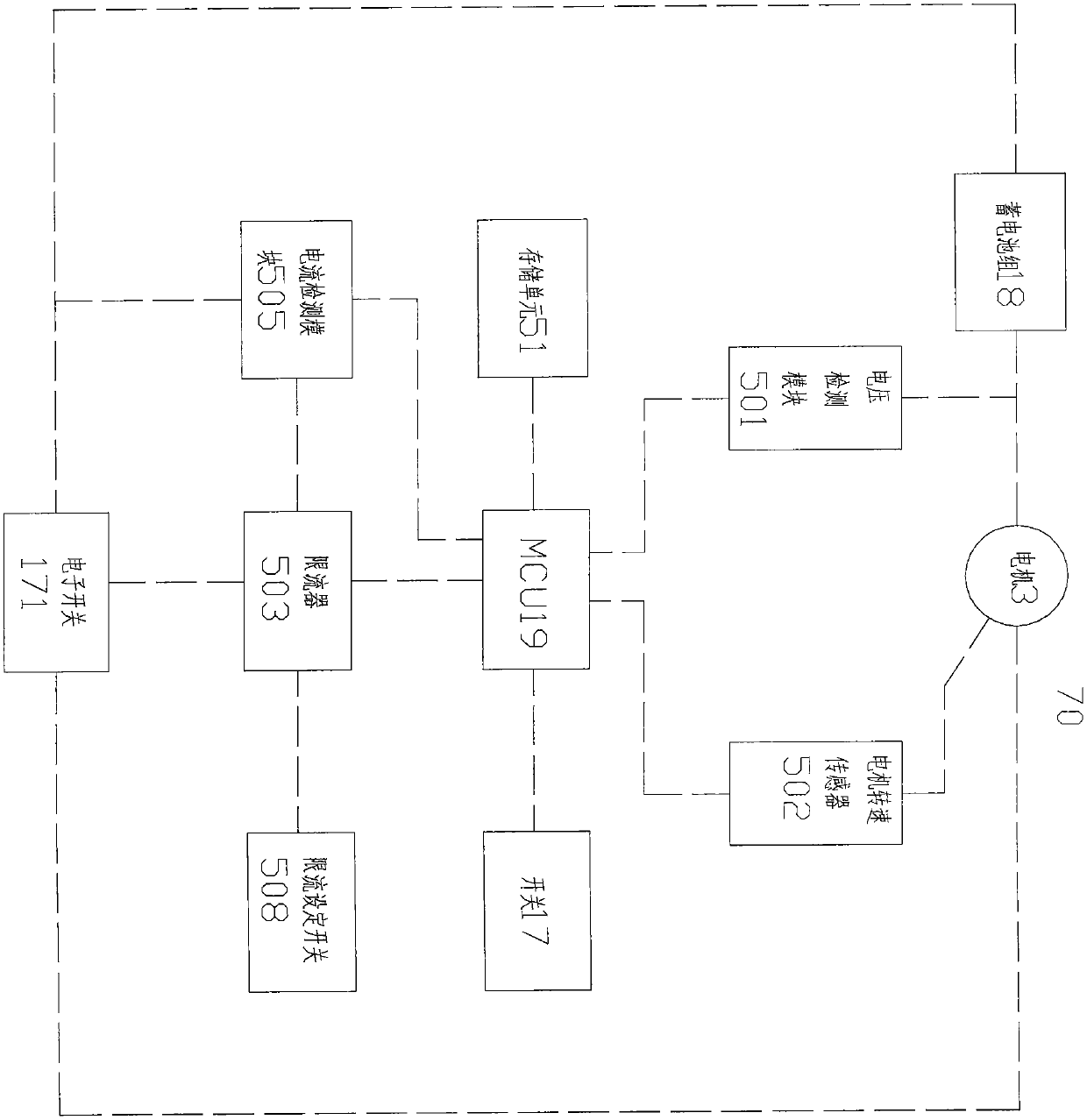

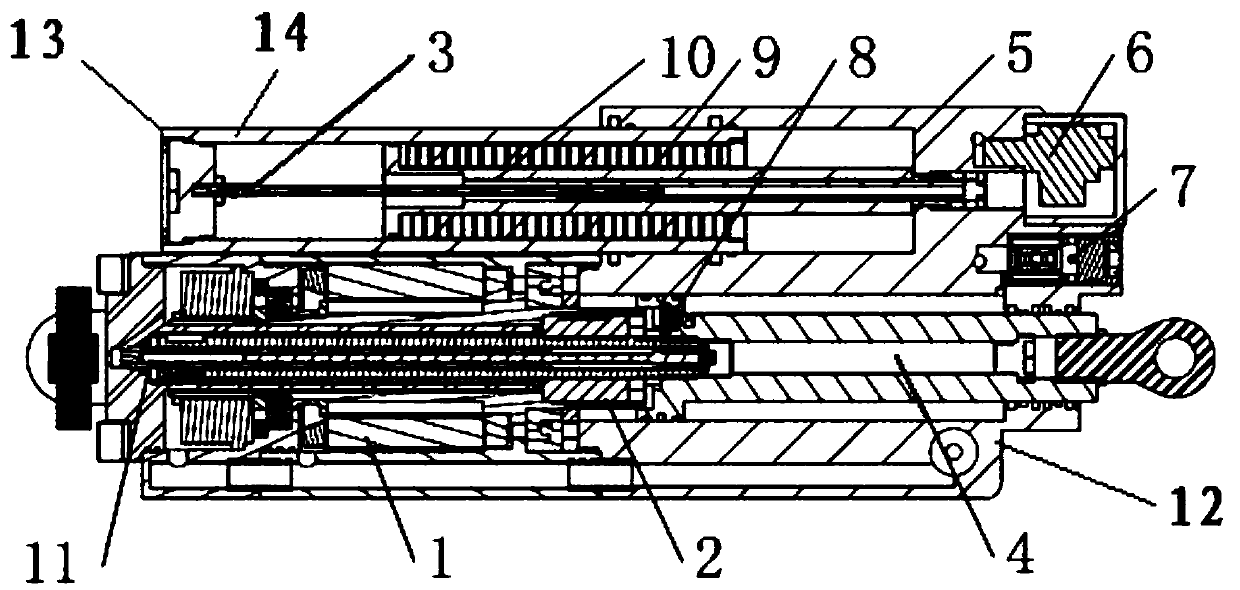

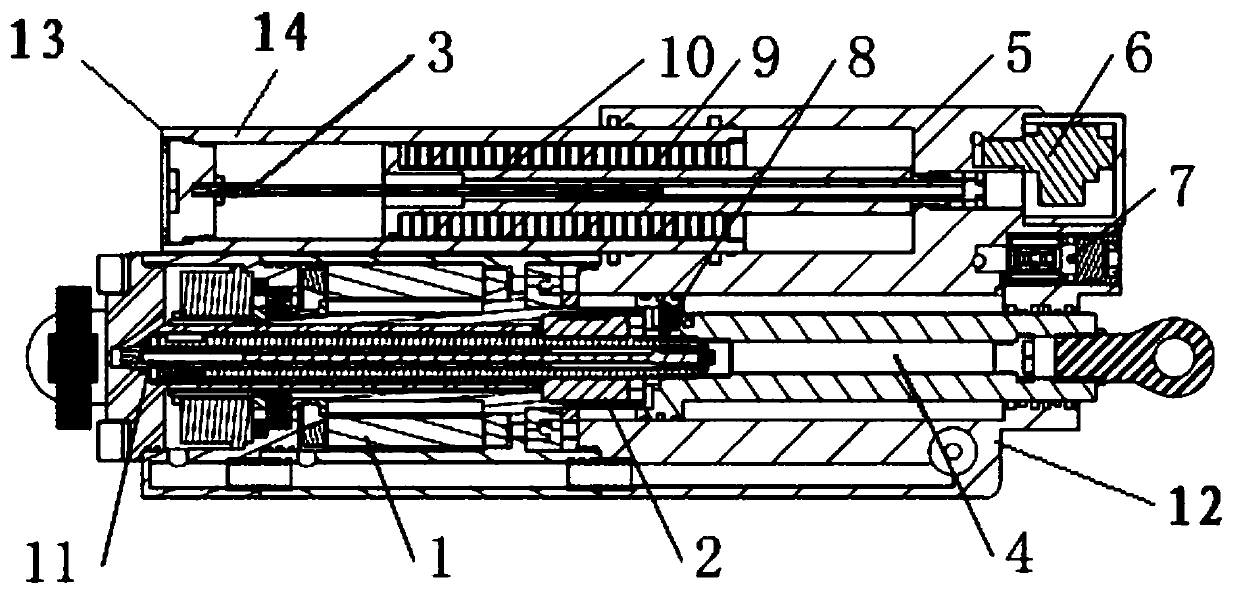

Oil lubrication electric steering engine with position locking function

ActiveCN109572977AIncrease or decrease in pressureImprove securitySteering ruddersLubrication elementsBall screwFuel tank

The invention provides an oil lubrication electric steering engine with a position locking function and relates to the field of design of deep-sea outboard electric steering engines. The oil lubrication electric steering engine with the position locking function comprises a moment motor, a ball screw pair, a self-pressurized fuel tank, a locking piston rod, a locking valve block, an electromagnetic locking valve and a steering engine housing, wherein the steering engine housing is of a shell structure with a hollow cavity inside; the moment motor is fixedly mounted at one end, in the axial direction, of the cavity of the steering engine housing in the axial direction; the ball screw pair is fixedly mounted on the axis of the moment motor in the axial direction; the locking piston rod is coaxially in abut joint with the ball screw pair; the self-pressurized fuel tank is horizontally arranged at the top of the steering engine housing; an open end of the locking valve block is arranged onthe external wall of one end, in the axial direction, of the self-pressurized fuel tank in the axial direction in a sleeving manner; the electromagnetic locking valve is fixedly mounted at the external end, in the axial direction, of the locking valve block; and the cavity of the steering engine housing is filled with lubrication oil liquid. Except for a steering function, the oil lubrication electric steering engine with the position locking function also has functions such as a seawater pressure compensation function, an any position power-off locking function, and a lubrication oil liquidautonomous circulation filtering function.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

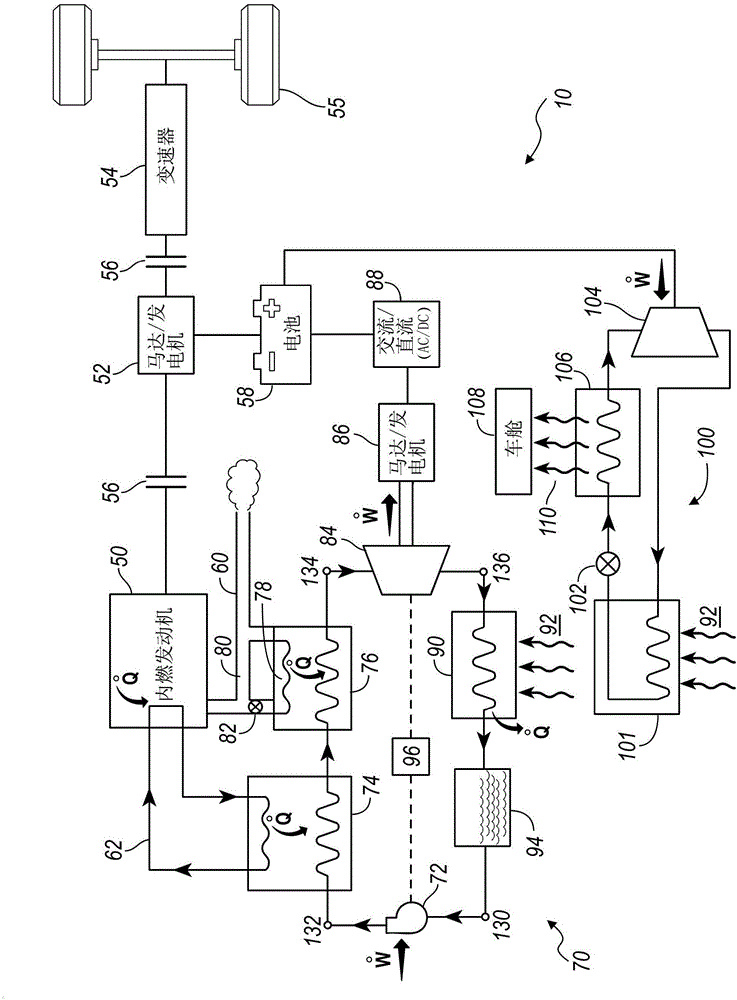

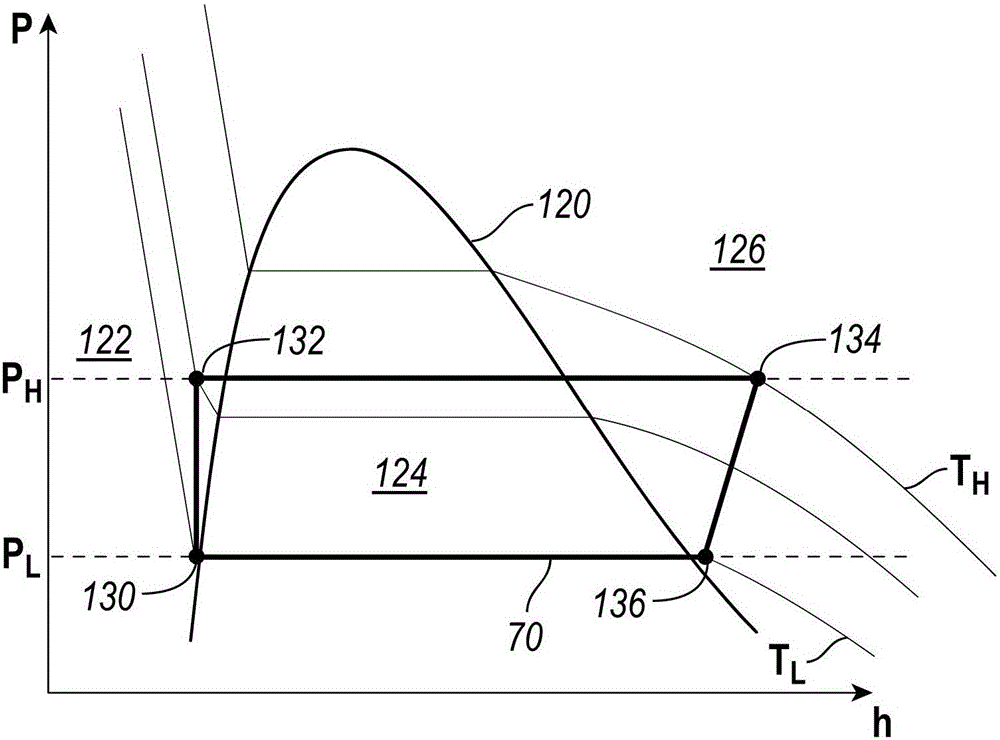

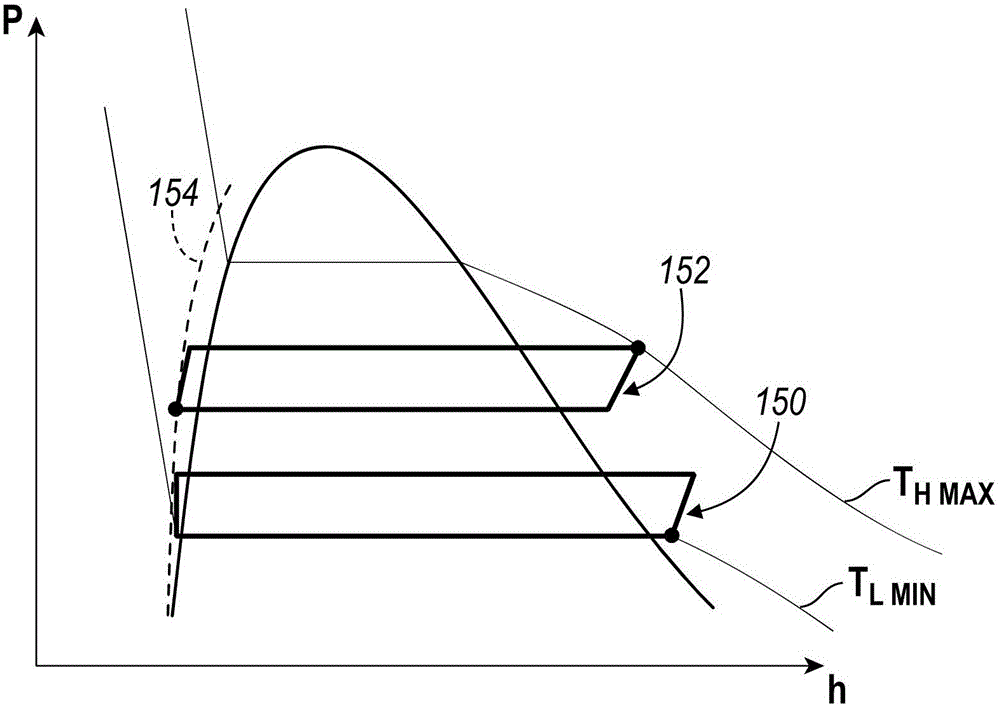

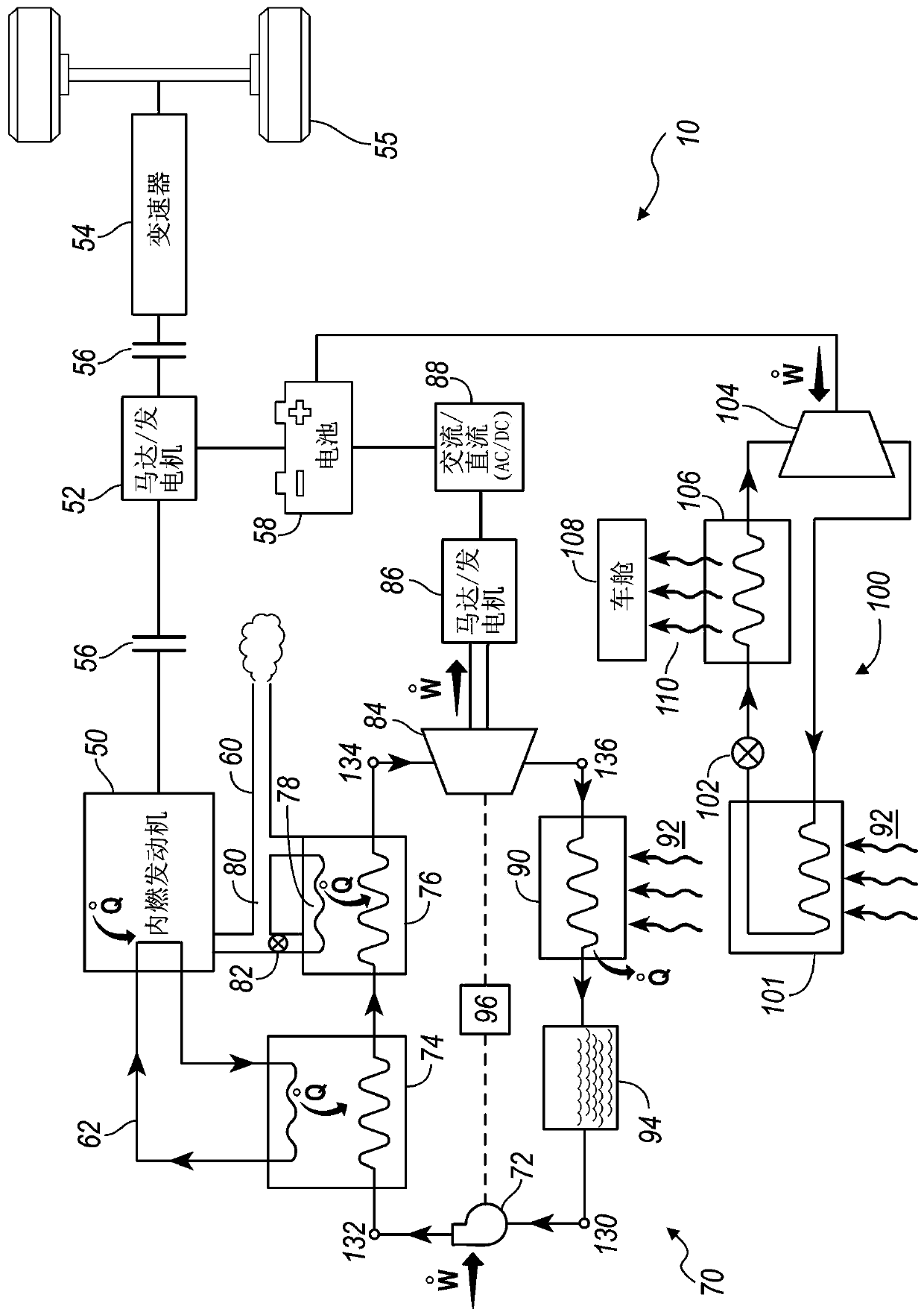

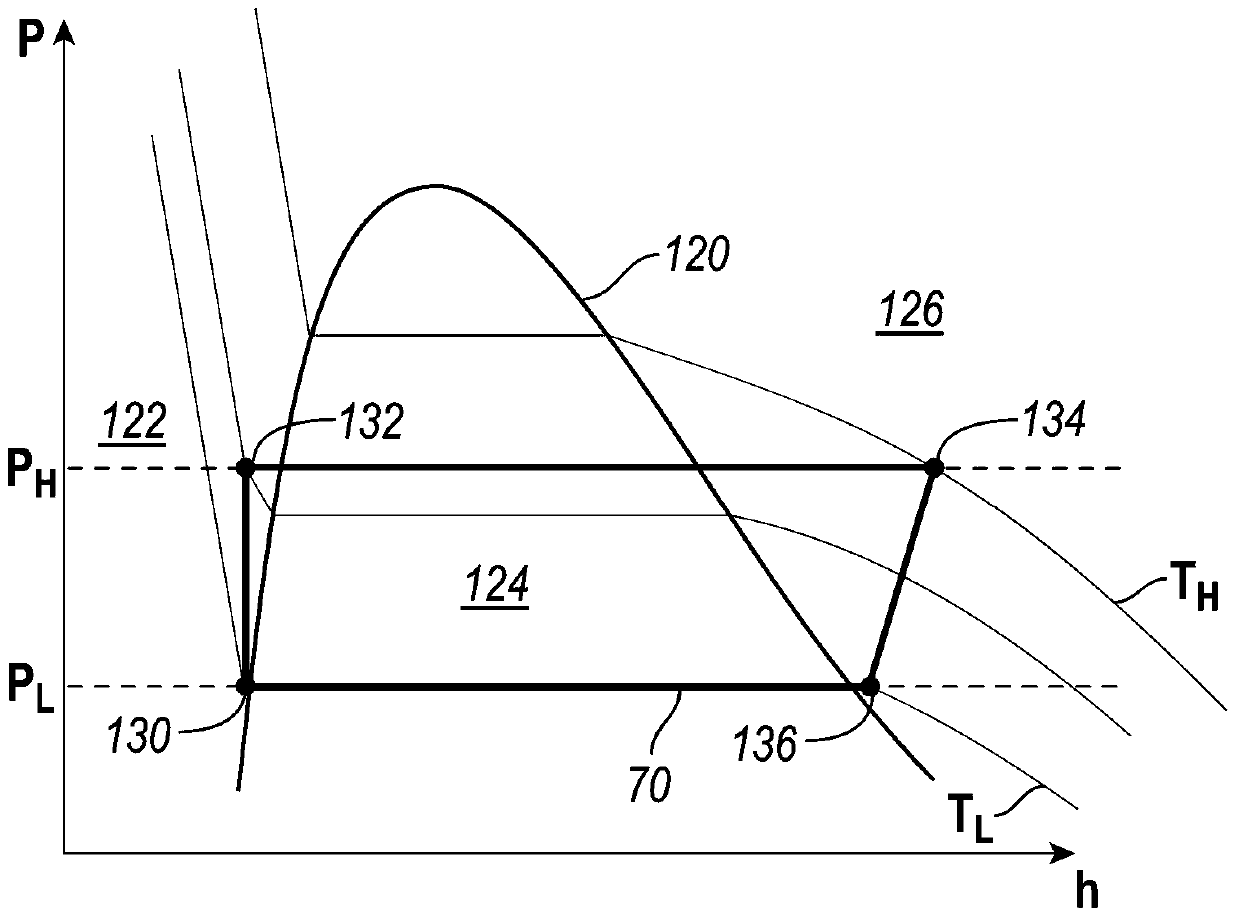

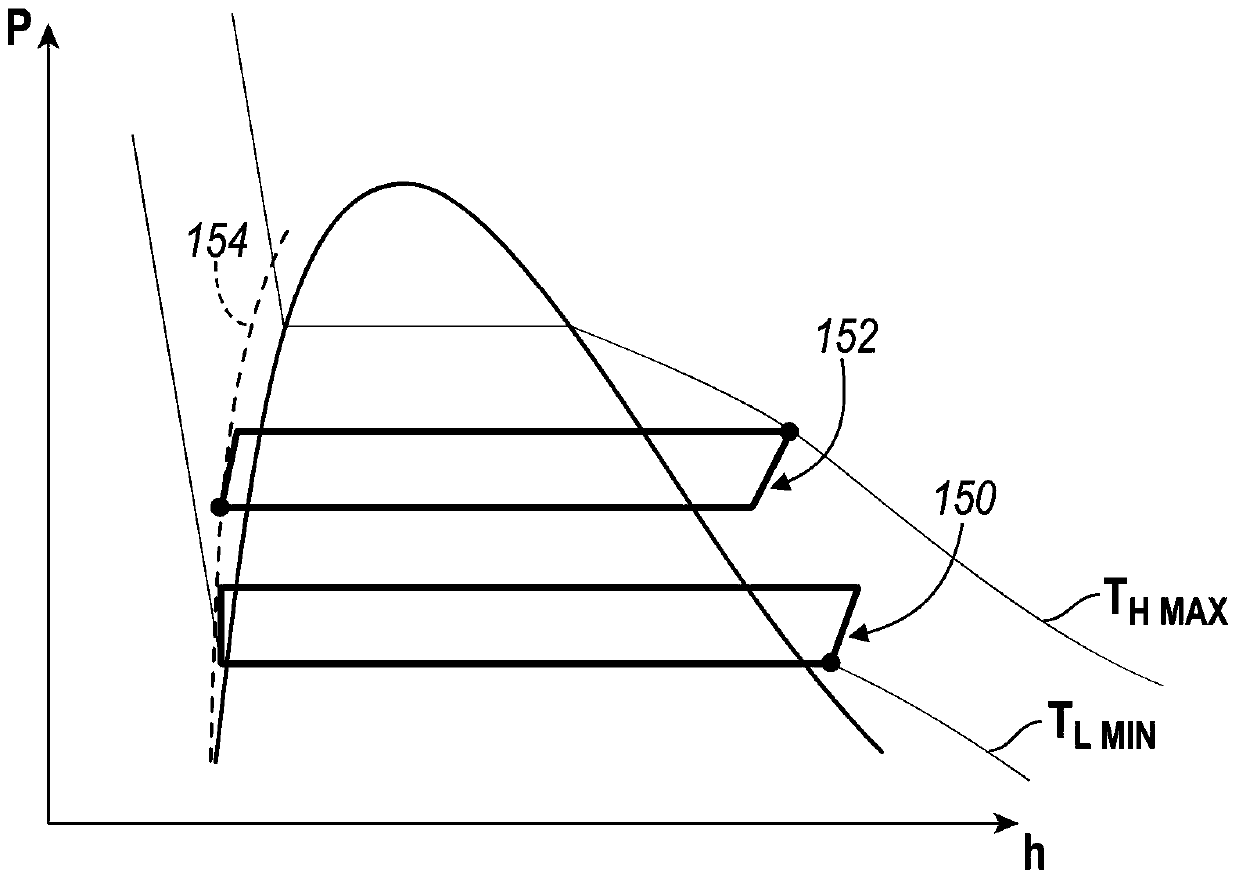

Method And System Of Controlling A Thermodynamic System In A Vehicle

ActiveCN105781786AImprove efficiencyTemperature increase or decreaseHybrid vehiclesAir-treating devicesWorking fluidEngineering

The invention provides a method and system of controlling a thermodynamic system in a vehicle. The vehicle has a vehicle system with a waste heat fluid. An expander, a condenser, a pump, and an evaporator are provided in sequential fluid communication in a thermodynamic cycle containing a working fluid. The evaporator is configured to transfer heat from the waste heat fluid to the working fluid. At least one valve adjacent to the pump is controlled to control fluid flow through at least one chamber to maintain a pressure of the fluid at a pump inlet at a threshold pressure above a saturated vapor pressure associated with a temperature at a condenser outlet when ambient temperature varies.

Owner:FORD GLOBAL TECH LLC

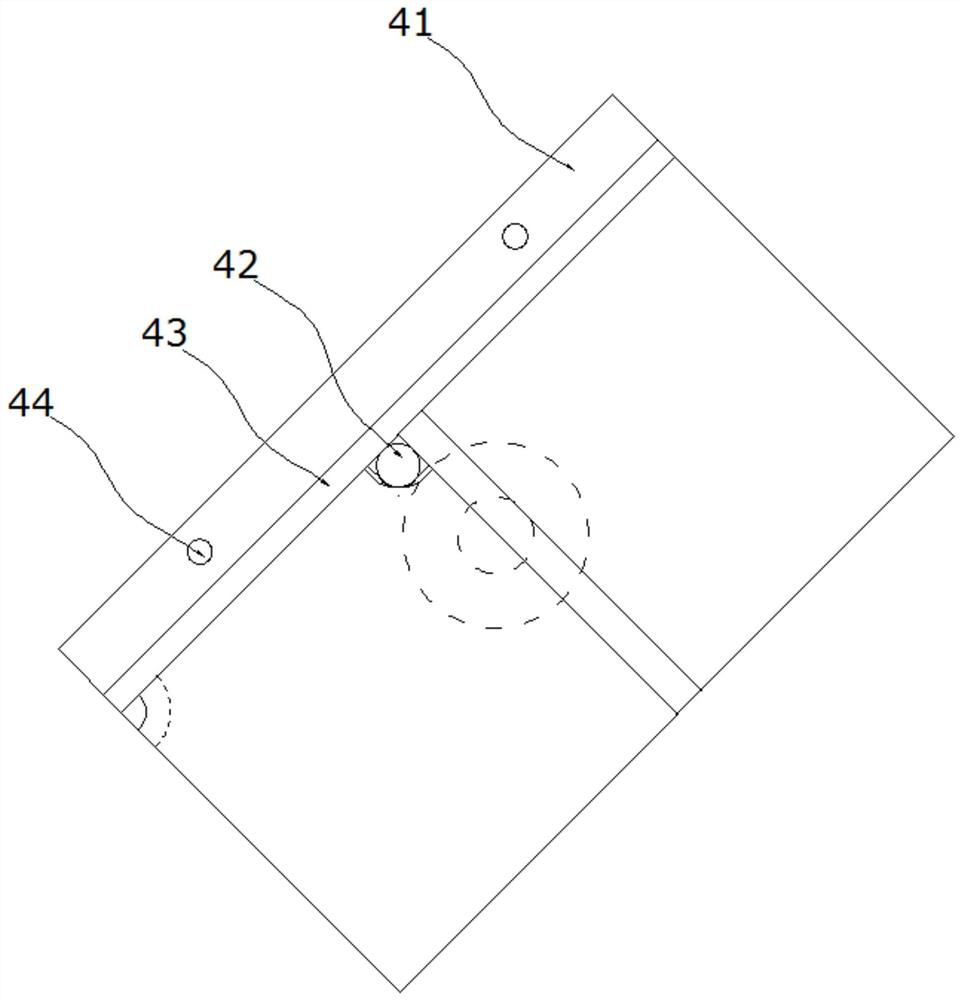

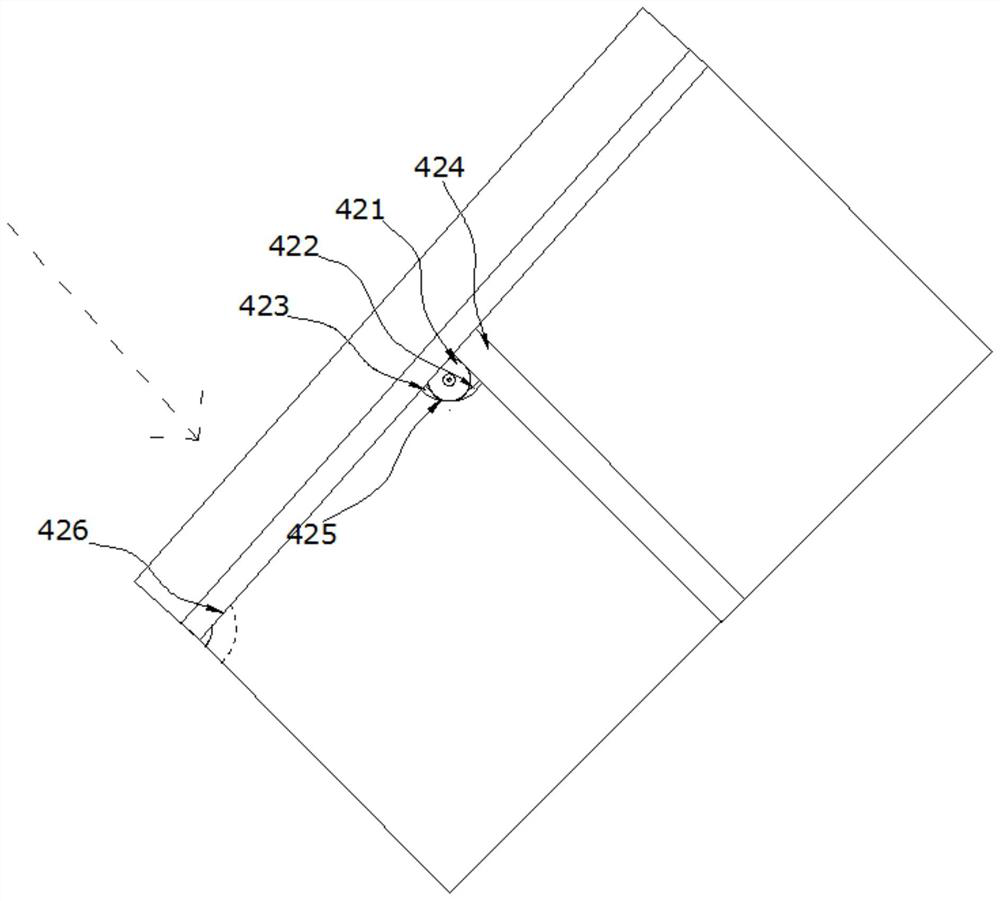

Workbench suitable for machine tool

ActiveCN113458811AIncrease or decrease in pressureImprove machining accuracyLarge fixed membersEngineeringMachine tool

The invention discloses a workbench suitable for a machine tool. The workbench comprises a bottom frame, two fixing piles, a workbench body, rotating seats, an upper positioning table, a lower damping table, a deviation measuring assembly and an alignment assembly, wherein the two fixing piles are arranged on the bottom frame, the workbench body is inserted between the two fixing piles, the rotating seats are arranged on the side edges of the fixing piles and penetrate through the fixing piles to be connected with the workbench body, the upper positioning table is used for fixing a workpiece, the lower damping table is arranged on the side, not stressed, of the upper positioning table, the deviation measuring assembly is arranged at the bottom of the lower damping table and is used for detecting the inclination degree of the workbench body, and the alignment assembly is arranged on the side surface of the workbench body and corresponds to the movement direction of a machining shaft head of the machine tool. If the workbench body is displaced due to vibration or other external force factors, the pressure on the deviation measuring assembly can be increased or reduced, then the deviation direction of the workbench body can be judged, then the deviation displacement of the workbench body can be obtained through the increased or reduced pressure, so that the workbench body can be rapidly stopped and adjusted once the workbench body is deviated, and the machining precision of the workpiece is improved.

Owner:龙岩市日兴机械有限公司

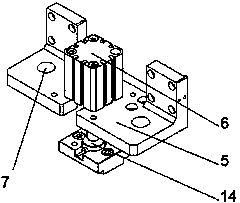

Pressure control device of fluid transportation pump

PendingCN110131164AImprove securityIncrease or decrease in pressureMachines/enginesPump controlReciprocating motionEngineering

The invention relates to a fluid transportation pump, in particular to a pressure control device of the fluid transportation pump. The pressure control device is arranged in a fluid medium output channel and is close to a sealing cavity formed by a pump cover and a pump body; the pressure control device is sequentially sleeved with a fixing sleeve and a pressure rod from outside to inside; the pressure rod reciprocates in the fixing sleeve; the fixing sleeve is partially embedded in a blind hole formed in the pump body; a spring for pushing the pressure rod to reset is further arranged betweenthe fixing sleeve and the pressure rod; the pressure rod is sleeved with the spring; the other end of the pressure rod is sleeved with an end cover; the end cover is connected with the fixing sleeveand is used for limiting and abutting against the spring; a through hole for reciprocating through the pressure rod is formed in the middle of the end cover; a blind hole is further formed in the tailof the pressure rod; and a magnet is arranged in the blind hole. By the aid of the pressure control device, the whole machine is controlled to shut down and stop operation under the high pressure, sothat the safety is increased, and the energy saving and environmental protection effects are achieved.

Owner:INTRADIN SHANGHAI MACHINERY

A kind of flexible robot hand and its control method

The invention discloses a flexible robot hand and its control method, aiming to provide a flexible robot hand and its control method with a simple structure, which can change the structure to adapt to various environments. When the pressure of the elastic cavity in the hand-shaped body changes, the driving component and the control component will bend or gradually straighten from the bending, and because the elastic cavity can be deformed, when the actuator body collides with the contact object, The executive body can deform itself to adapt to the contact object, and a driving component is set to control the pressure in the elastic cavity to realize the increase or decrease of the pressure in the elastic cavity, and the control component can accurately detect and control it.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Pressure regulating device and pressure regulating method for preparing hot melt adhesive

ActiveCN113893780AIncrease or decrease in pressureImprove securityPressure vessels for chemical processAir volumeEngineering

The invention relates to the technical field of hydraulic pressure, in particular to a pressure regulating device and pressure regulating method for preparing a hot melt adhesive, and the pressure regulating device for preparing the hot melt adhesive comprises a shell body and a piston pressure regulating assembly arranged in an inner cavity of the shell body. The piston pressure regulating assembly divides the inner cavity into an upper cavity and a lower cavity which not communicate with each other. A pressure through hole communicating with the inner cavity of an isolation sleeve is formed in the upper cavity, and a pressure guide hole communicating with the inner cavity of a reaction kettle is formed in the lower cavity. The piston pressure regulating assembly is suitable for moving up and down in the inner cavity when pressure difference is generated between the upper cavity and the lower cavity, so that the air volume of the upper cavity and the lower cavity is changed, and the pressure in the inner cavity of the isolation sleeve and the pressure in the inner cavity of the reaction kettle are further regulated until the pressures of the inner cavity of the isolation sleeve and the inner cavity of the reaction kettle reach new balance. The pressure regulating device and the pressure regulating method for preparing the hot melt adhesive can effectively solve the problem that the isolation sleeve is damaged due to a traditional pressure regulating device and a traditional pressure regulating method.

Owner:常州威斯敦粘合材料有限责任公司

A roller printing machine

ActiveCN107323069BAdjustable spacingFine pitch adjustmentRotary intaglio printing pressApparatus for force/torque/work measurementPulp and paper industryScrew thread

The invention discloses a roller printing machine, belonging to the technical field of printing and dyeing. The roller printing machine comprises a printing machine base, a lead screw, a feed rod, a driving nut, a lower crossbeam, a lower printing roller, an upper crossbeam, an upper printing roller, a motor and a feed rod fine adjustment mechanism, wherein the rapid adjustment and accurate adjustment of the distance between the lower printing roller and the upper printing roller can be realized by the feed rod fine adjustment mechanism through the screw-thread fit between the lead screw and the driving nut; a driven roller is arranged on the lower crossbeam of the roller printing machine of the embodiment; a pressure sensor and a piezoelectric signal converter are arranged on the upper crossbeam; and the distance between a driving roller and the driver roller can be automatically adjusted according to the thickness of raw materials to be processed and the requirements of printing and dyeing pressure, thereby realizing the self-adaptive adjustment of pressure in the printing and dyeing process, improving the poor printing and dyeing layering of the roller printing machine and avoiding the phenomenon of defective goods such as uneven printing colors.

Owner:JIANGSU KUNTAI MACHINERY

Heavy Isothermal Forging Hydraulic Press

ActiveCN103447434BGuaranteed accuracyGuaranteed stiffnessForging/hammering/pressing machinesForging press detailsAviationLeveling effect

The invention relates to a heavy-duty isothermal forging hydraulic press, which comprises an upper transverse beam, a lower transverse beam, upright posts, a main cylinder, side cylinders and a slide block, wherein an upper baseplate is fixed on the lower plane of the slide block; and a movable workbench is arranged on the lower transverse beam. The heavy-duty isothermal forging hydraulic press is characterized in that the upper transverse beam and the lower transverse beam form a combined beam body structure; leveling cylinders are fixed on the four corners of the upper end of the upper transverse beam and the upper end of the lower transverse beam; each leveling cylinder is provided with an independent leveling control system; an upper knock-out device is arranged on the slide block; movable workbench positioning mechanisms are arranged on the lower part of the movable workbench body and in the lower transverse beam; and the movable workbench body is further provided with a movable workbench clamping device. The heavy-duty isothermal forging hydraulic press is characterized in that a combined transverse beam is light in weight and is convenient to transport and produce, and the manufacturing cost can be reduced; a leveling effect is achieved via the leveling cylinders, the leveling response time is shortened, and energy is saved greatly; through the upper knock-out device, successful demolding of workpieces can be realized, and the workpiece forging and pressing quality is ensured; and accurate positioning and stable running of a press workbench can be realized, and the production requirement of forging equipment for heavy-duty aviation forgings is met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

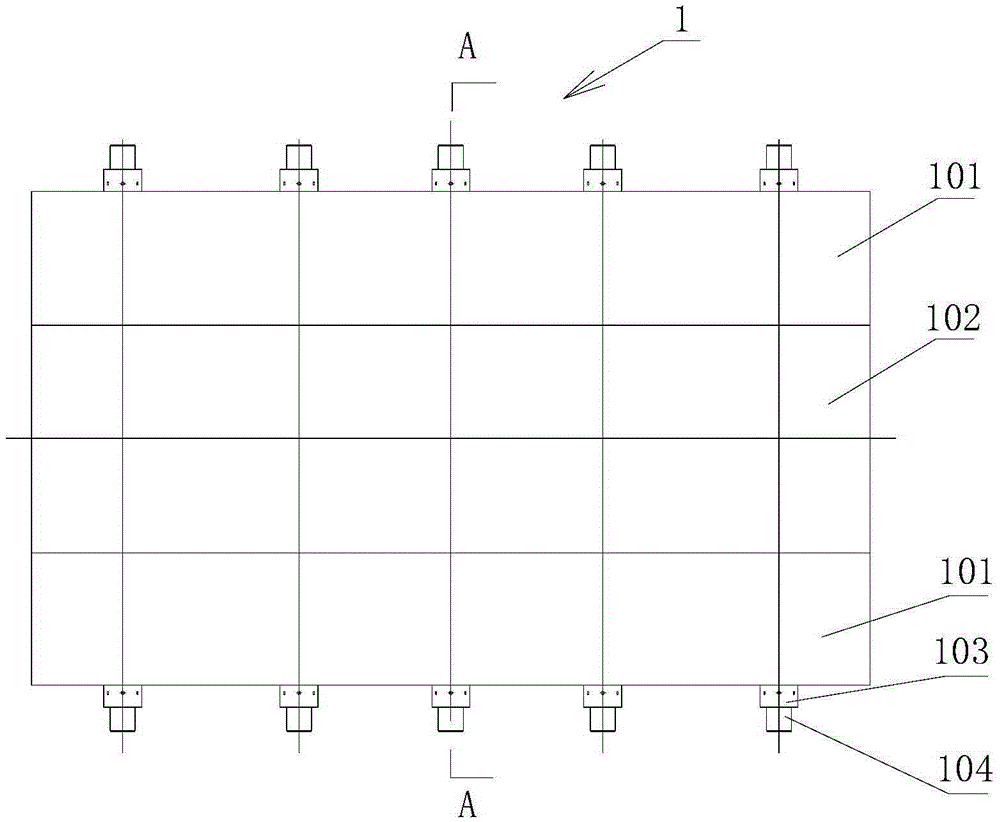

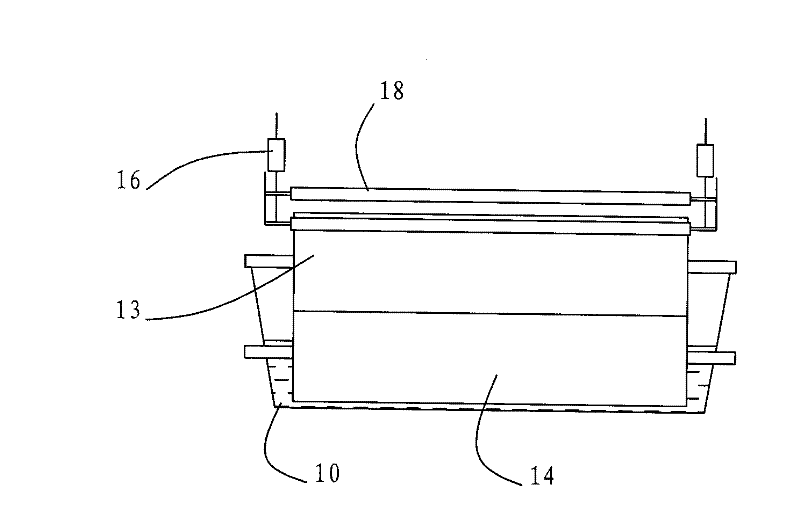

plate-making machine (ctp) into plate press roller mechanism

ActiveCN104890349BConvenience to workIncrease or decrease in pressureForme preparationComputer to plateEngineering

The invention discloses a plate-feeding press wheel mechanism of a direct plate-making machine (CTP). A rocker arm is also rotated on the support shaft, the first end of the rocker arm is located below the limit block, and the limit block is equipped with an adjusting bolt whose lower end is on the upper surface of the first end of the rocker arm. The two ends are located under the pressure plate, and a compression spring is provided between the pressure plate and the upper surface of the second end of the rocker arm, and a pressure wheel device is installed on the second end of the rocker arm; the lifting of the rocker arm can be adjusted by adjusting the adjusting bolt on the limit block. Up and down, so as to drive the pressure roller installed on the rocker arm to increase or decrease the pressure between it and the plate. Due to the existence of the compression spring between the rocker arm and the platen, there can be an appropriate pre-tightening force between the pressure roller and the plate, so that it is no longer necessary to adjust the pressure of the pressure roller due to changes in the thickness of the plate, making the process Version stability has been improved.

Owner:WEIFANG HUAGUANG DIGITAL EQUIP

An oil-lubricated electric steering gear with position locking function

ActiveCN109572977BIncrease or decrease in pressureImprove securitySteering ruddersLubrication elementsBall screwRoller screw

The invention provides an oil lubrication electric steering engine with a position locking function and relates to the field of design of deep-sea outboard electric steering engines. The oil lubrication electric steering engine with the position locking function comprises a moment motor, a ball screw pair, a self-pressurized fuel tank, a locking piston rod, a locking valve block, an electromagnetic locking valve and a steering engine housing, wherein the steering engine housing is of a shell structure with a hollow cavity inside; the moment motor is fixedly mounted at one end, in the axial direction, of the cavity of the steering engine housing in the axial direction; the ball screw pair is fixedly mounted on the axis of the moment motor in the axial direction; the locking piston rod is coaxially in abut joint with the ball screw pair; the self-pressurized fuel tank is horizontally arranged at the top of the steering engine housing; an open end of the locking valve block is arranged onthe external wall of one end, in the axial direction, of the self-pressurized fuel tank in the axial direction in a sleeving manner; the electromagnetic locking valve is fixedly mounted at the external end, in the axial direction, of the locking valve block; and the cavity of the steering engine housing is filled with lubrication oil liquid. Except for a steering function, the oil lubrication electric steering engine with the position locking function also has functions such as a seawater pressure compensation function, an any position power-off locking function, and a lubrication oil liquidautonomous circulation filtering function.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

Automobile instrument panel capable of shielding sunlight based on spring damping

InactiveCN113043846ADoes not affect observationStable supportDashboardsVibration suppression adjustmentsPlate pressureIn vehicle

The invention relates to the technical field of vehicle-mounted instrument panels, in particular to an automobile instrument panel capable of shielding sunlight based on spring damping. The automobile instrument panel comprises a cushioning and light-shielding mechanism, the cushioning and light-shielding mechanism at least comprises a cushioning device, the cushioning device comprises a cushioning plate, a pressure plate is arranged over the cushioning plate, end connecting mechanisms are arranged at the ends of the pressure plate and the cushioning plate, each end connecting mechanism comprises a transverse rod, and the surface of each transverse rod is sleeved with an end pressure-buffering spring; and a light-shielding device which comprises a light-shielding shielding plate, a transverse plate is arranged at one end of the top of the light-shielding shielding plate, an adjusting mechanism is arranged at one end of the light-shielding shielding plate and comprises a cam, a guide rod is arranged at one end of the top of the cam, supporting blocks are arranged at the two ends close to the bottom surface of the cam, and a fixed motor is rotationally connected to one end of the cam. The arranged cushioning device can play a preliminary cushioning role on the instrument panel, and meanwhile, the light shielding device can block light rays irradiated into the instrument panel.

Owner:刘兴

Roll material rotating structure

InactiveCN104555534AModerate tensionIncrease or decrease in pressureWebs handlingEngineeringMechanical engineering

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Waterproof membrane dip coating processing device

ActiveCN101831812BSolve the situation of scratched tire base fabricReduce work intensityTextiles and paperEngineeringSmall footprint

A dip-coating processing device for waterproof coiled material, comprising a material tank and a tire base cloth, the material tank is filled with paint, the side wall of the material tank and / or the bottom of the material tank is provided with a heating mechanism, and the material tank is provided with an upper belt roller It is a pair of feeding rollers composed of the lower belt roller, the upper belt roller is located above the paint, the lower belt roller is partially immersed in the paint, the upper belt roller and the lower belt roller rotate in the same direction or in the opposite direction, and the paint passes through The lower belt material roll is transferred to the upper belt material roller, and the tire base cloth is in contact with the surface of the upper belt material roller. One end of the material pool is the feed end, which is provided with a guide roller and a tension roller, which are located above the paint, and the tension roller is connected with the lifting mechanism; one end of the tire base cloth passes through the guide roller in turn. After the roller and the tension roller, it is connected with the upper belt material roller. The invention has the characteristics of simple and reasonable structure, small overall volume, less land occupation, flexible operation, low production cost, low energy consumption, high production efficiency and wide application range.

Owner:鞍山科顺建筑材料有限公司

CELL crimping cylinder friction unit

PendingCN111189573AEasy to testAvoid large fluctuations in pressureElectrical testingApparatus for force/torque/work measurementDisplay deviceEngineering

The invention relates to the technical field of display accessory testing devices, in particular to a CELL crimping cylinder friction unit. The unit comprises a fixing plate, the unit is fixedly mounted in one side of external equipment through the fixing plate; a to-be-detected workpiece is conveyed to a position right below the unit provided by the invention; a servo cylinder pushes a fixing frame to move downwards; when the lower surface of a pressure head makes contact with the upper surface of the to-be-detected workpiece, the servo cylinder is closed, a low-friction air cylinder is started, the low-friction air cylinder pushes a pressure sensor and a pressure head inclination fine-adjustment device to move downwards; a limiting rod moves downwards along a guide hole in the fixing frame; the limiting rod avoids excessive downward movement of the pressure head inclination fine adjustment device; the pressure sensor transmits the pressure to a controller in real time, so that the controller controls the pressure in the low-friction air cylinder, the pressure value of the upper surface of the to-be-detected workpiece can be accurately controlled, the pressure value can be finelyadjusted conveniently, the test sensitivity is improved, and the measurement accuracy is improved.

Owner:苏州广林达电子科技有限公司

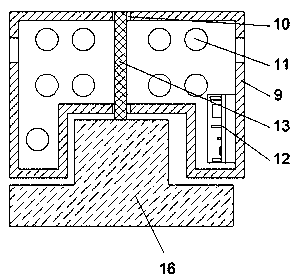

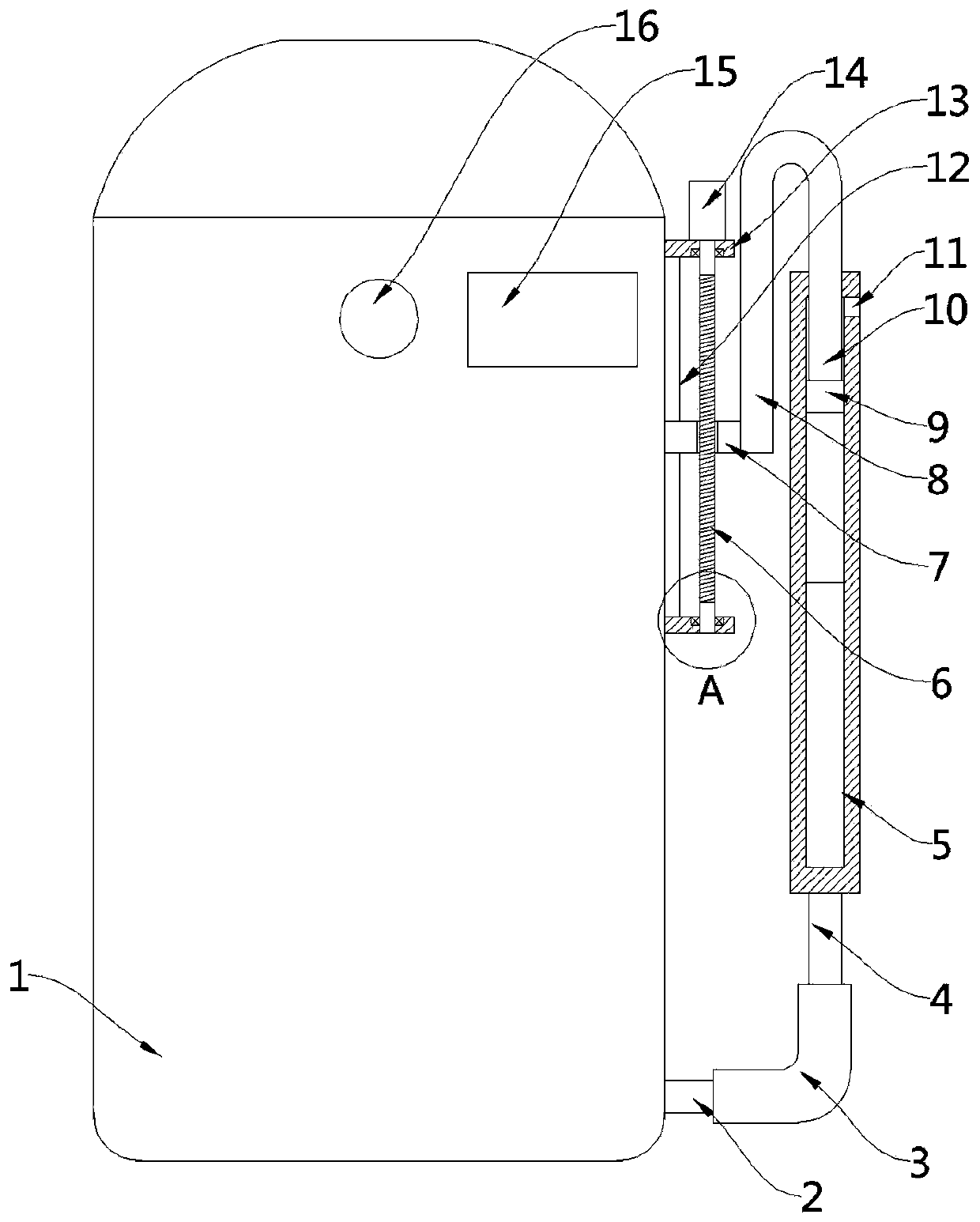

A high-precision water level measuring device for a water level gauge

ActiveCN111412962BHigh measurement accuracyEasy to useLevel indicators by pressure measurementInternal pressureEngineering

The invention provides a high-precision water level measuring device for a water level meter, which belongs to the technical field of water level meters, and includes a device that is arranged on one side of a furnace body and forms a connector structure through a first pipe body, an elbow joint, and a second pipe body and the furnace body. A display cylinder, the side wall of the display cylinder is provided with an observation port, the outside of the display cylinder is provided with a second pressure gauge for detecting the internal pressure of the display cylinder, and a display glass is provided at the observation port. The embodiment of the present invention has the advantages of convenient use and high measurement accuracy. It can measure the liquid level of the furnace body in real time and accurately according to the pressure change inside the furnace body. The first drive rod, the second drive rod and the The pressure plate moves up and down, thereby increasing or decreasing the pressure inside the display tube, so that the pressure inside the display tube and the furnace body are always equal, ensuring that the liquid level inside the display tube is equal to the liquid level inside the furnace body, and improving the display accuracy of the display tube.

Owner:江苏鑫亚达仪表制造有限公司

Pluggable brush holder brush box and installation method thereof

PendingCN114843857AImprove efficiencyAvoid noiseRotary current collectorContact member assembly/disassemblyElectric machineryEngineering

The invention discloses a plug-in brush holder brush box and a mounting method thereof, and relates to the field of motor brush holder brush boxes, the plug-in brush holder brush box comprises a brush box, a brush holder and a brush carrier, the inner wall of the brush box is fixedly connected with a plurality of groups of connecting feet, connecting grooves are formed in the connecting feet, two opposite groups of connecting grooves are uniformly provided with heating deformation bins on the opposite surfaces of the inner walls, and the heating deformation bins are connected with the brush box. The top end of the inner wall of the brush holder cavity is fixedly connected with a hollow fixing column, the lower end of the fixing column is slidably connected with a top column, the bottom end of the top column is connected with the top end of a carbon brush seat movably arranged in the brush holder cavity, the top end of the top column is provided with an adjusting spring in the fixing column, and the top end of the adjusting spring is in contact with a bottom foot of a screw. The screw rod is in threaded connection with the top end of the brush holder and the upper part extends out of the brush holder. According to the invention, the efficiency of replacing the carbon brush is greatly improved, the brush box and the brush holder can be in stable contact when the motor works, and the purpose of conveniently increasing or reducing the pressure between the carbon brush and the collector ring is achieved.

Owner:HUANENG POWER INTERNATIONAL

A portable flexible walking aid

The invention discloses portable flexible walking assisting equipment. The portable flexible walking assisting equipment comprises knee joint flexible actuating mechanisms (1), air pressure forming mechanisms (2), flexible fixing bands (3) and air pipes (4). In the walking process of a person, the air pressure forming mechanisms (2) make the air pressure of air bags of the knee joint flexible actuating mechanisms (1) rapidly increased or decreased, and the knee joint flexible actuating mechanisms (1) generate torque assisting the knees in bending and stretching. The weight of the person is adopted as the driving force of the equipment, and no other additional energy is needed; the flexible driving mode combining the pneumatic driving force of the air bags and the elastic force of torsion springs is adopted for the actuating parts, and the pneumatic driving force and the elastic force compensate for each other in the walking process of the person. By adopting the flexible driving mode combining the pneumatic driving force and the elastic force of the torsion springs, the structural inertia is small, the defects that a rigid mechanism like a common leg assistance device or an exoskeleton robot is large in inertia, likely to injure the knee joints of a person, poor in comfort and the like are overcome, and the safety and comfort of the equipment are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method and system for controlling a thermal system in a vehicle

ActiveCN105781786BImprove efficiencyTemperature increase or decreaseHybrid vehiclesAir-treating devicesWorking fluidIn vehicle

A vehicle has a vehicle system with a waste heat fluid. An expander, a condenser, a pump, and an evaporator are provided in sequential fluid communication in a thermodynamic cycle containing a working fluid. The evaporator is configured to transfer heat from the waste heat fluid to the working fluid. At least one valve adjacent to the pump is controlled to control fluid flow through at least one chamber to maintain a pressure of the fluid at a pump inlet at a threshold pressure above a saturated vapor pressure associated with a temperature at a condenser outlet when ambient temperature varies.

Owner:FORD GLOBAL TECH LLC

High-precision water level measuring device of water level gauge

ActiveCN111412962AHigh measurement accuracyEasy to useLevel indicators by pressure measurementEngineeringWater level

The invention provides a high-precision water level measuring device of a water level gauge and belongs to the technical field of water level indicators. The device comprises a display cylinder arranged on one side of a furnace body and forming a communicating vessel structure with the furnace body, an observation port is formed in the side wall of the display cylinder, a second pressure gauge used for detecting the internal pressure of the display cylinder is arranged outside the display cylinder, and display glass is arranged at the observation port. The device disclosed in an embodiment ofthe invention has the advantages of convenience in use and high measurement precision; the liquid level of the furnace body can be accurately measured in real time according to the pressure change inthe furnace body; the driving assembly is controlled by the controller to drive the first driving rod, the second driving rod and the pressing plate to move up and down, so that the pressure in the display cylinder is increased or reduced, the pressure in the display cylinder is always equal to that in the furnace body, the liquid level in the display cylinder is equal to that in the furnace body,and the display precision of the display cylinder is improved.

Owner:江苏鑫亚达仪表制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com