Umbrella valves dedicated to piezoelectric pumps

A technology for umbrella valves and piezoelectric pumps, which is applied to parts, control valves, and valve devices of pumping devices for elastic fluids, and can solve the problems of poor consistency and air tightness of pump valves, poor product matching capabilities, and Air leakage and other problems can be improved to achieve the effect of improving the sealing effect and working performance, obvious cost-effective comprehensive features, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

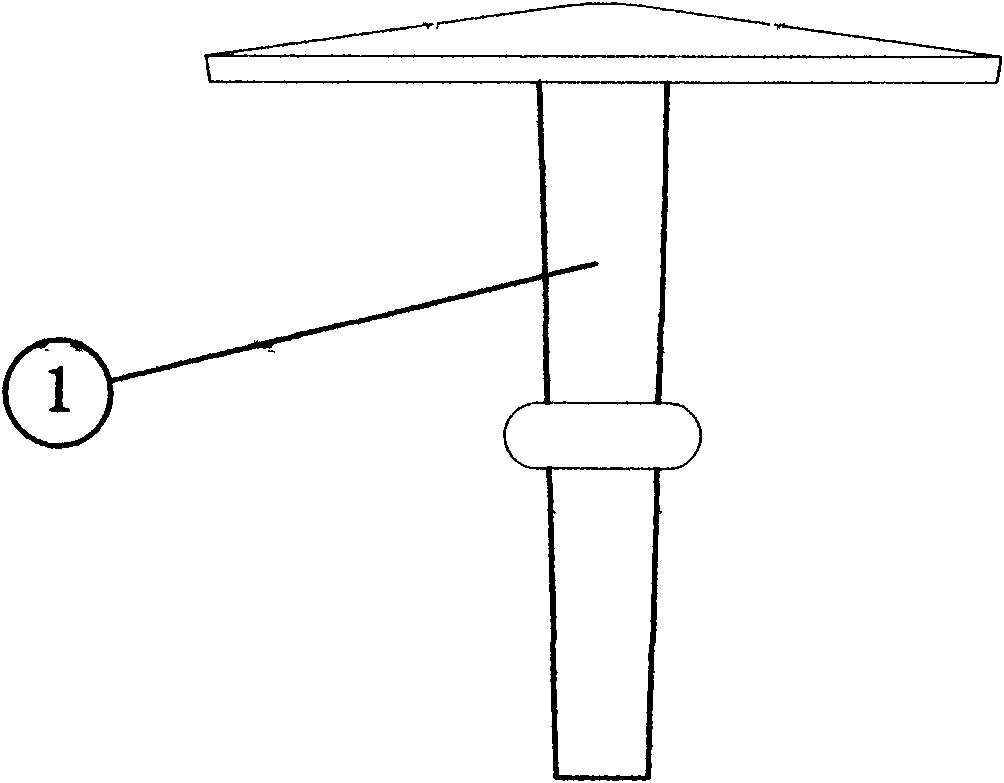

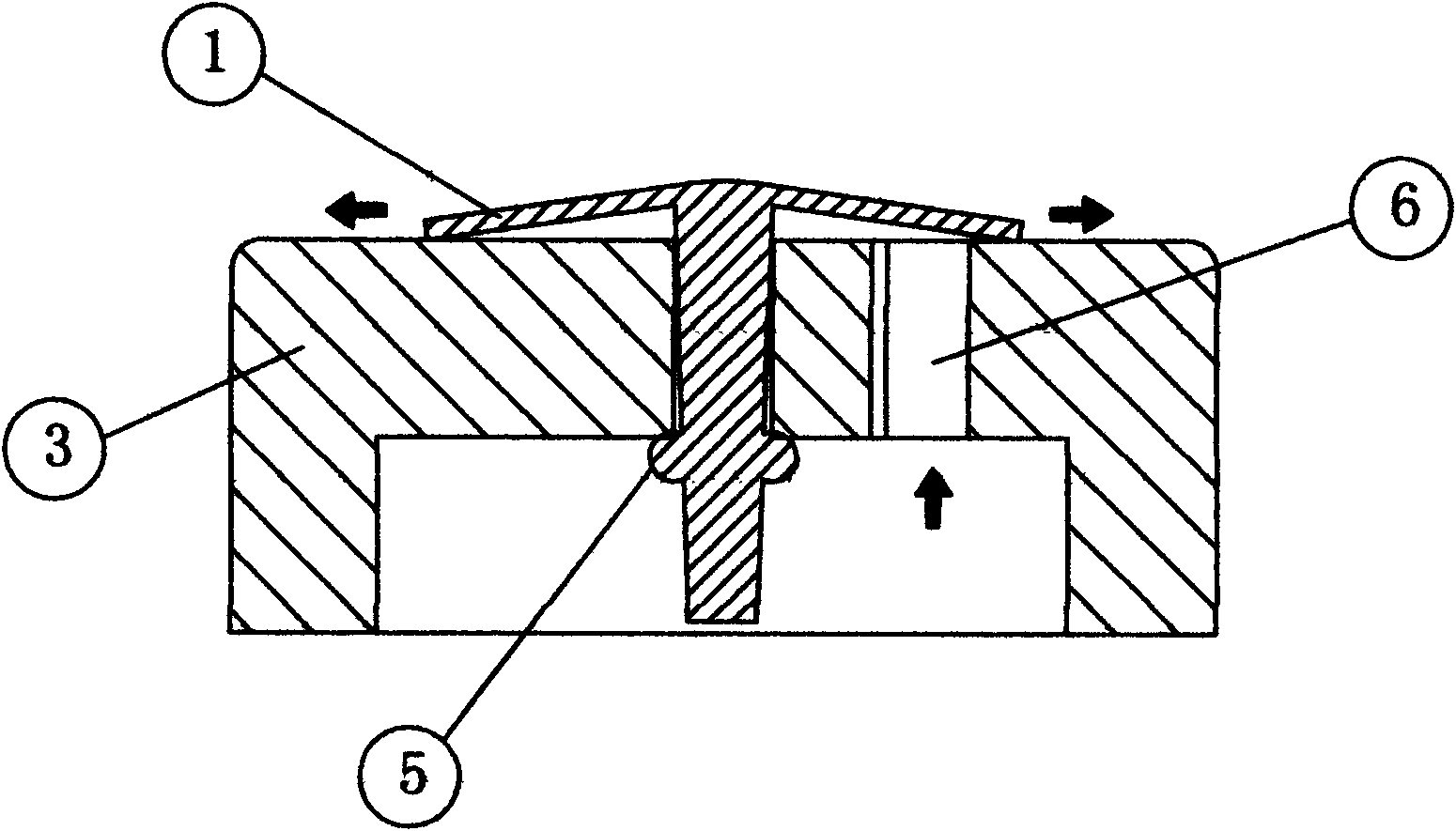

[0053] Embodiment 1: Referring to Fig. 2(a), this is a structure in which the umbrella valve A 1 is connected and matched with the valve frame A 3, and the umbrella handle in the umbrella valve A 1 passes (or passes through) and is located in the valve frame A 3 The hole in the center, the limit boss 5 on the umbrella handle is stuck outside the through hole of the valve frame A3, because the pressure of the fluid on the upper and lower sides of the umbrella surface of the umbrella valve A1 is different, the umbrella valve A1 is opened The umbrella-shaped plane of the umbrella-shaped plane can reciprocate up and down, just like the wings of a flying butterfly move up and down. The umbrella-shaped lower plane opened by the umbrella-shaped valve A 1 and the fluid inlet and outlet on the valve frame A 3 are opened and closed through the flow hole 6 With the cooperation, the passage hole 6 has the characteristics of opening and closing as a whole. In addition, there is another way...

Embodiment 2

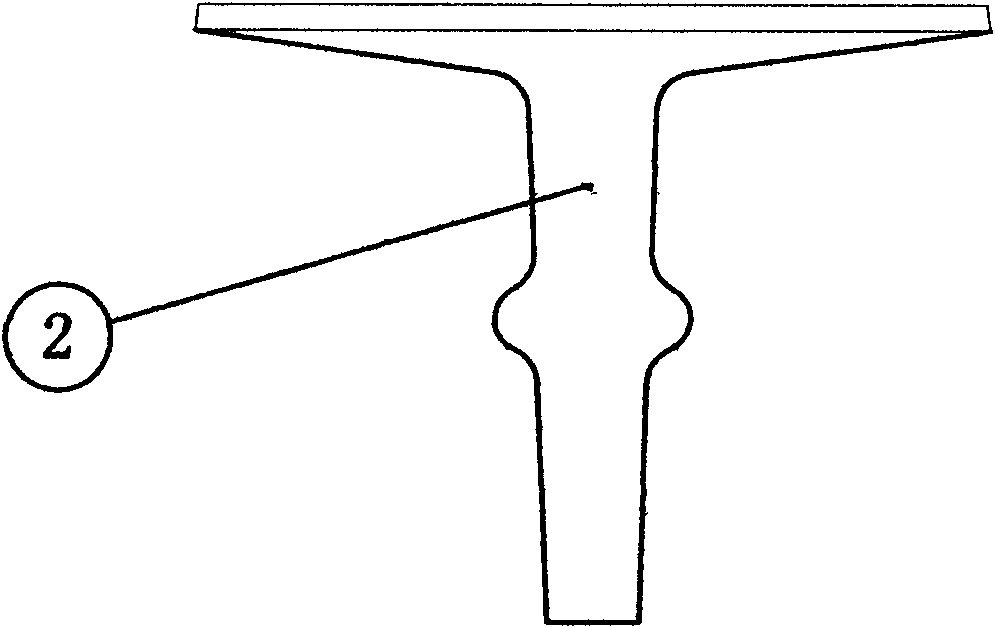

[0054]Embodiment 2: Referring to Fig. 2(b), it is basically the same as Fig. 2(a), the difference is that the umbrella valve in Fig. 2(b) is umbrella valve B 2, which is an umbrella valve B 2 with valve The cross-sectional diagram of the connection and cooperation of the frame B 4, the umbrella handle of the upper and lower umbrella valve B 2 passes through and is located in the center hole of the valve frame B 4, and the limit boss 5 on the umbrella handle is stuck on the valve frame B 4 Outside the through hole, due to the different pressures of the fluid acting on the upper and lower sides of the umbrella surface of the umbrella valve, the umbrella-shaped lower inclined surface of the umbrella valve B 2 and the fluid inlet and outlet on the valve frame B 4 are opened and closed through the flow hole 6. Closed cooperation, in order to cooperate better, the umbrella-shaped lower slope opened by the umbrella valve B 2 corresponds to the slope above the valve frame B 4 and serve...

Embodiment 3

[0055] Embodiment 3: It is the combination of the above two embodiments, that is, the valve handle of the umbrella valve has a limited boss 5, the upper surface of the opened umbrella is raised or flat, and the lower surface of the opened umbrella is It is an upward circular inclined surface or a circular arc surface, as a matching surface with the fluid inlet and outlet of the valve frame through the flow hole (6).

[0056] see image 3 and Figure 4 , the valve frame A 3 is used as the first structure schematic diagram, the central through hole is used to pass through the handle of the umbrella valve, and the central through hole is surrounded by three flow holes 6 with arc-shaped grooves in cross-section, which are used as fluid passage through.

[0057] see Figure 5 and Figure 6 , the valve frame A 3 is used as the second structural diagram, which is basically the same as image 3 and Figure 4 , the difference is that four passage holes 6 with arc-shaped grooves in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com