Patents

Literature

147 results about "Engineering analysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engineering analysis involves the application of scientific analytic principles and processes to reveal the properties and state of a system, device or mechanism under study. Engineering analysis is decompositional: it proceeds by separating the engineering design into the mechanisms of operation or failure, analyzing or estimating each component of the operation or failure mechanism in isolation, and re-combining the components according to basic physical principles and natural laws.

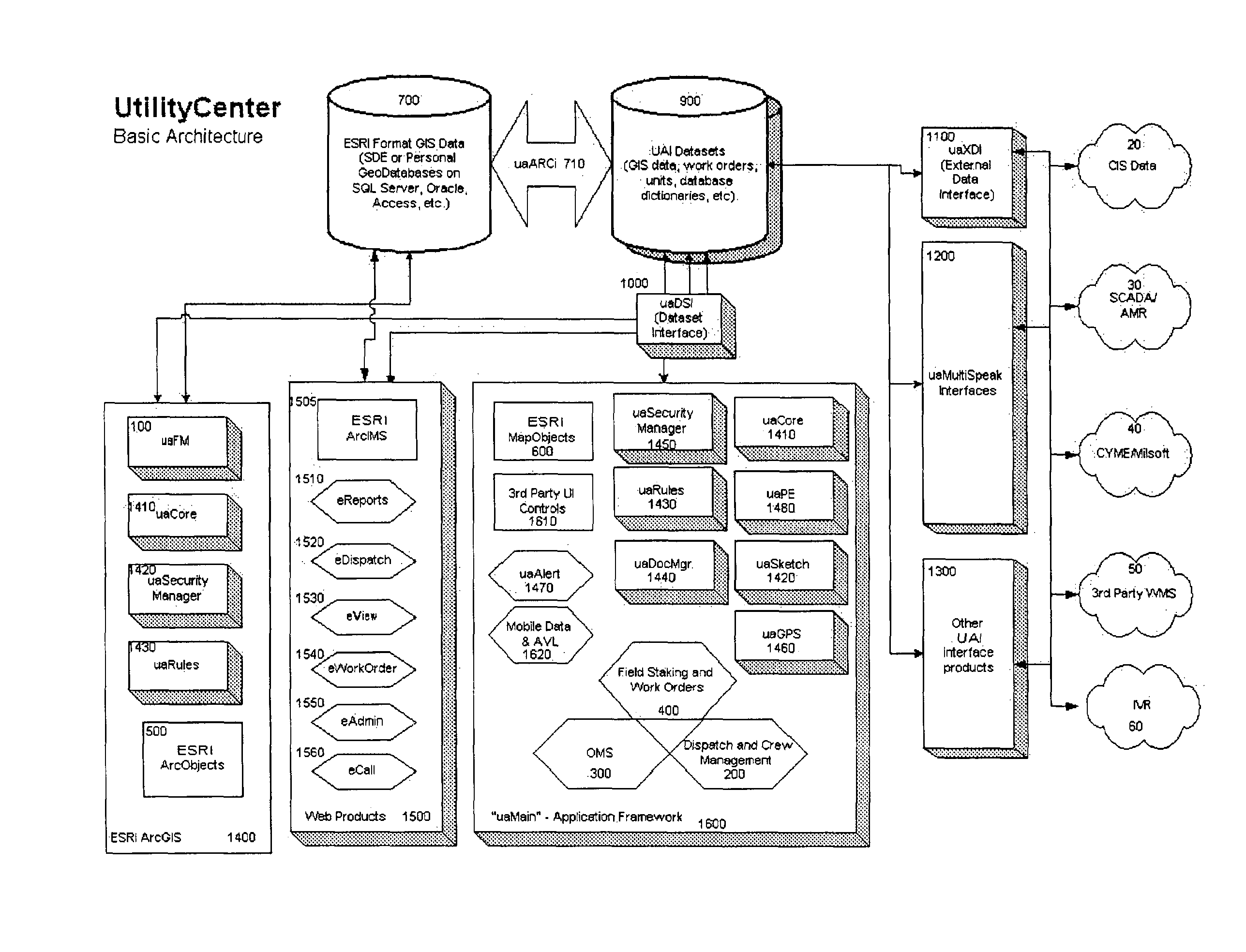

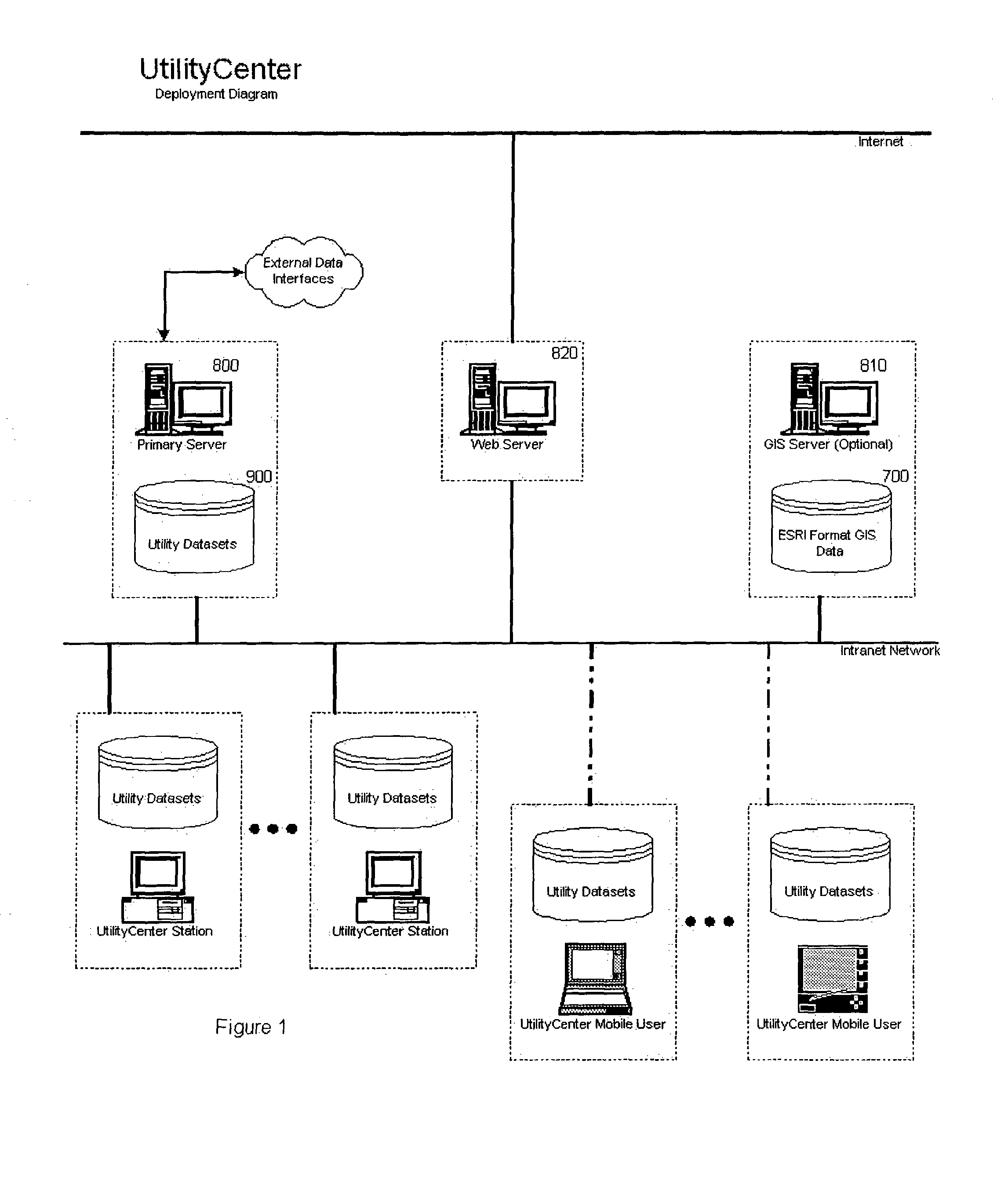

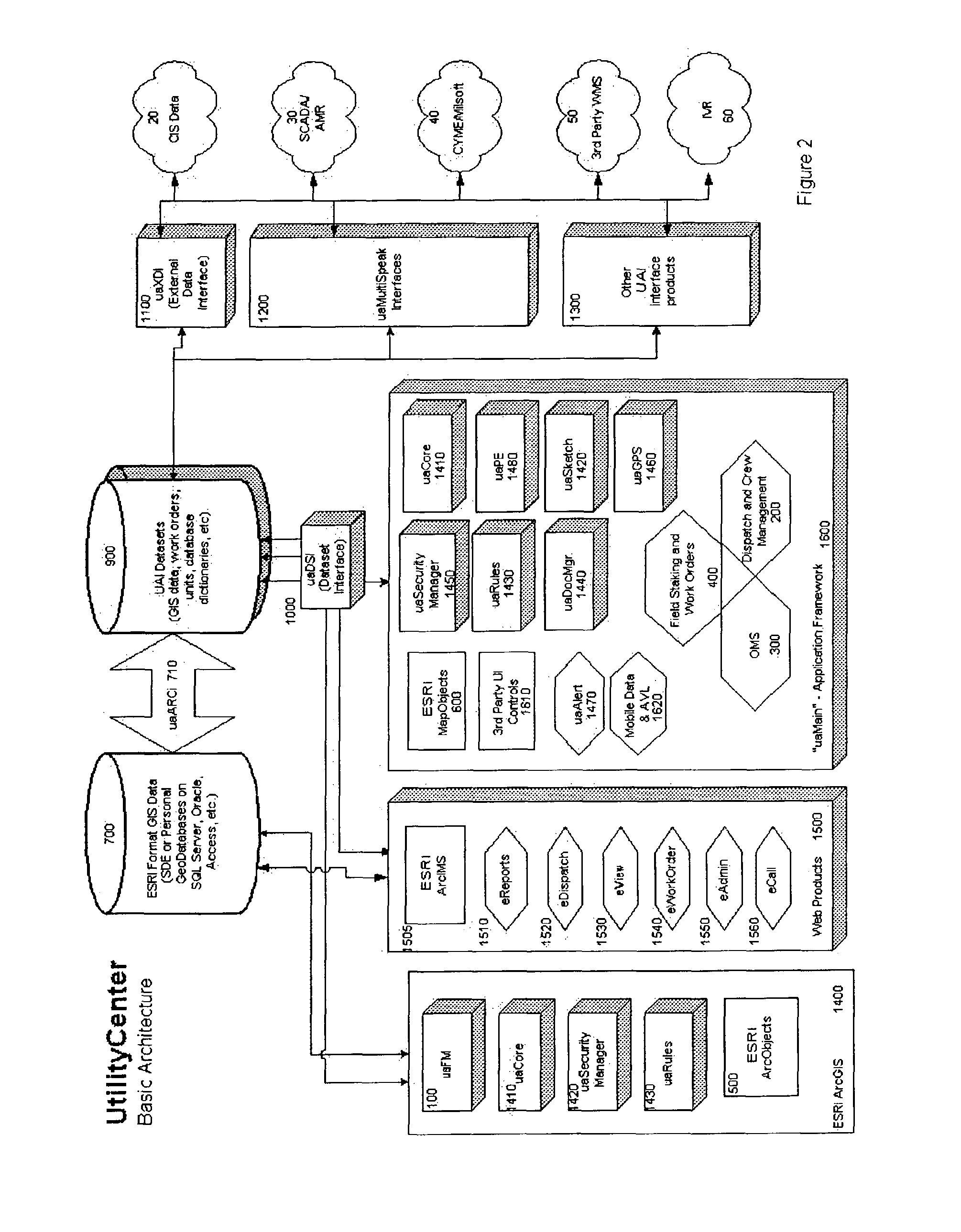

Automated utility supply management system integrating data sources including geographic information systems (GIS) data

InactiveUS7739138B2Accurate field collectionAccurate verificationMultiprogramming arrangementsResourcesData OriginData acquisition

An automated management system for managing data, outage repair, load switching, job workflow and crew dispatching, crew workflow, installation, maintenance and restoration of utility services by integrating geographic information systems (GIS) data with many other data sources so as to gather, transform, manipulate, analyze, and produce desired information for continuously supplying utility and relevant services. The data sources include customer information systems (CIS) and billing data, interactive voice recognition (IVR) call management data, supervisory control and data acquisition (SCADA), mobile crew management (MCM) data, automatic meter reading (AMR) data, automated vehicle location (AVL) data, engineering analysis data supported by 3rd party software packages (such as load monitoring and balancing), etc. In particular, the system allows an on-site engineer to retrieve data (ex. field maps, work orders, codes) or enter, via a portable device, inspection data (ex. such as poles or underground facilities, code violations).

Owner:UAI +1

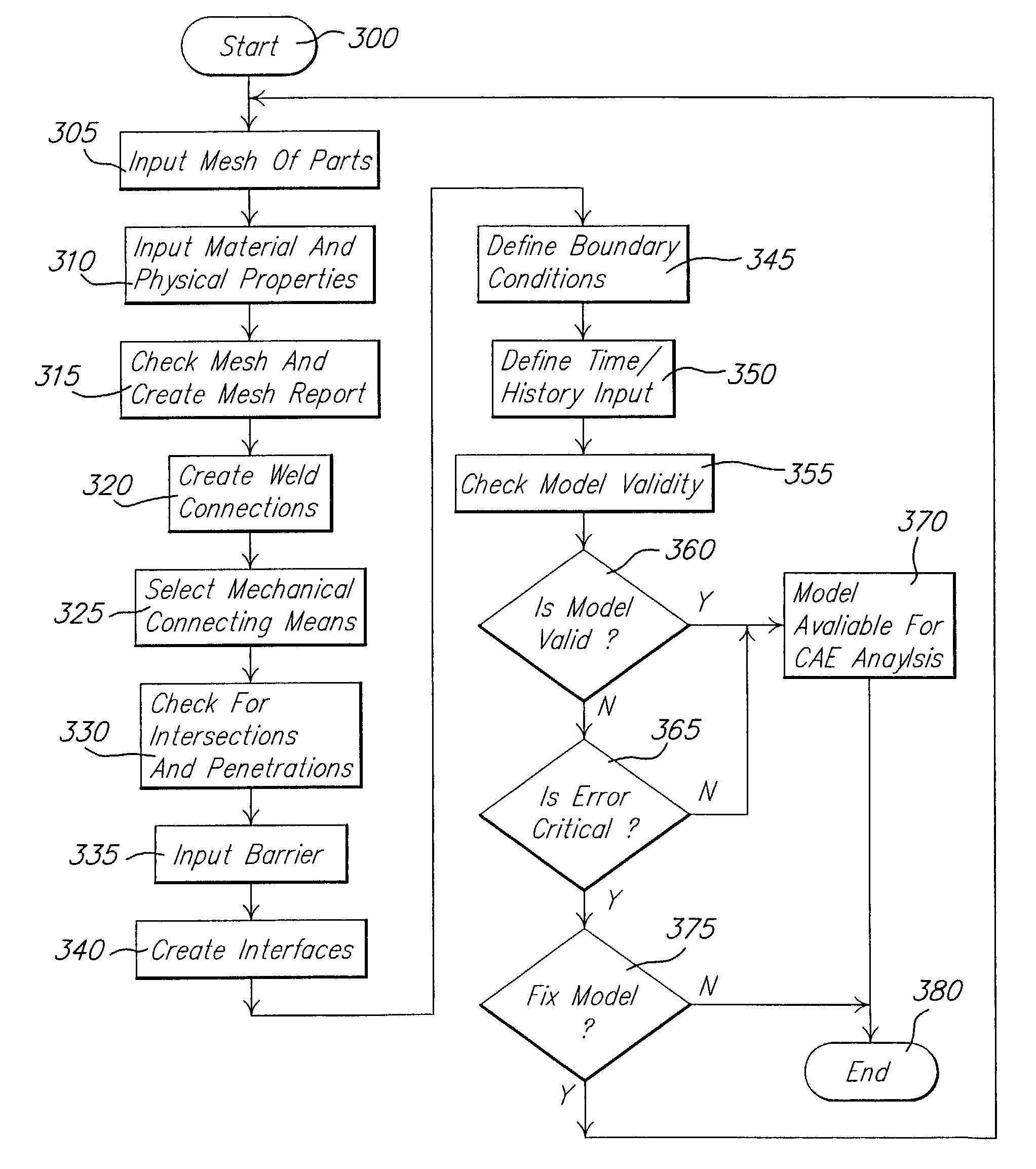

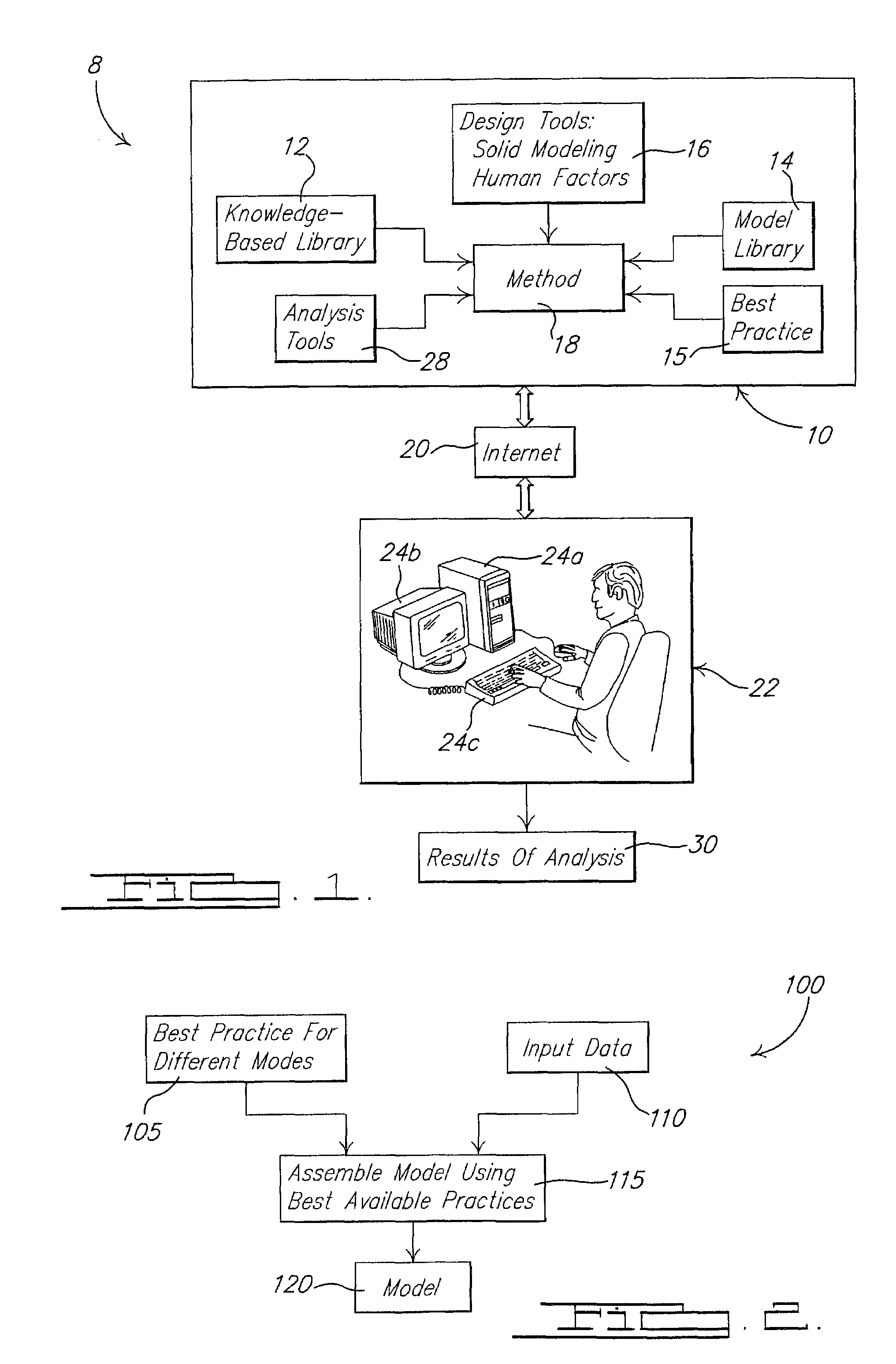

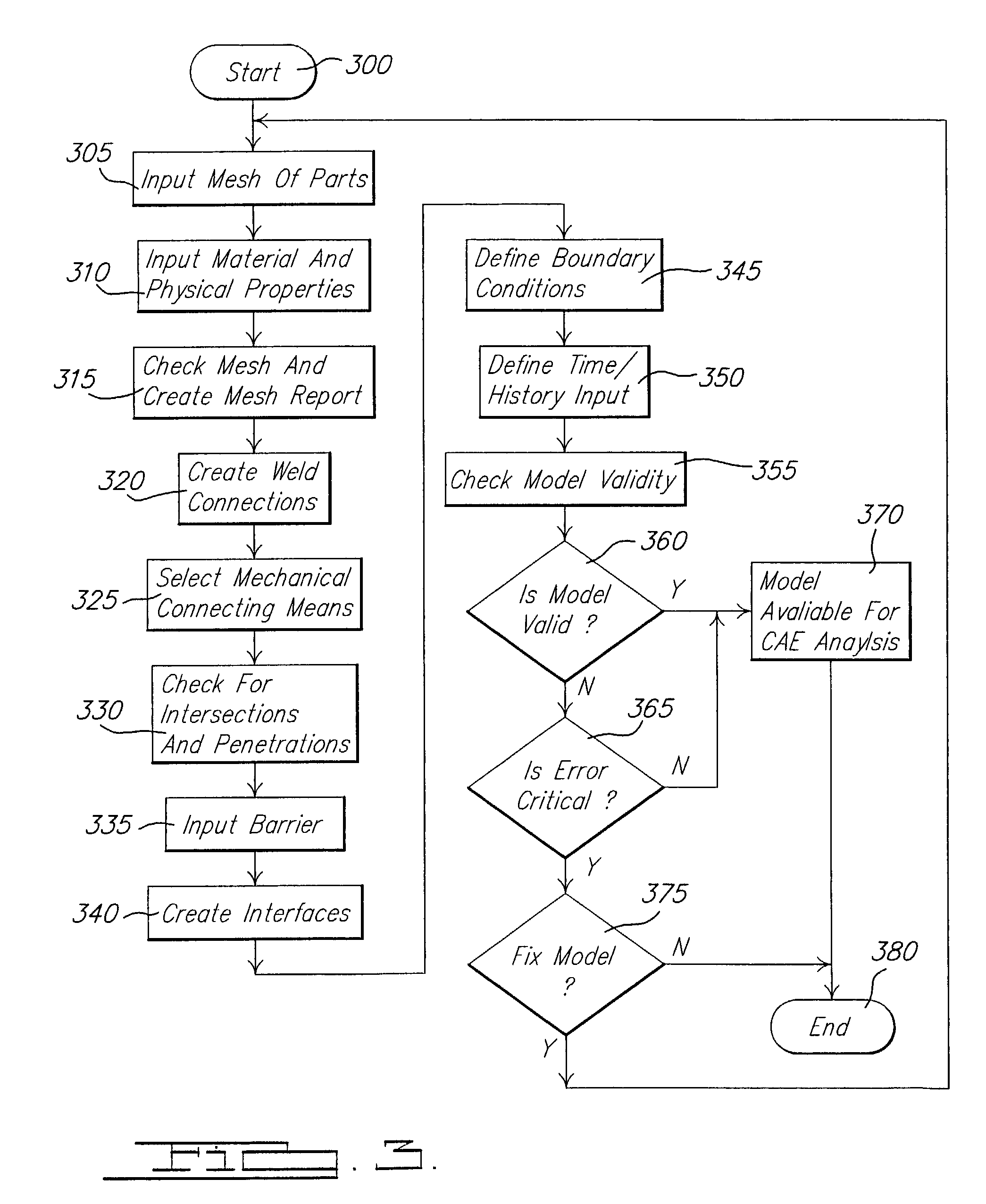

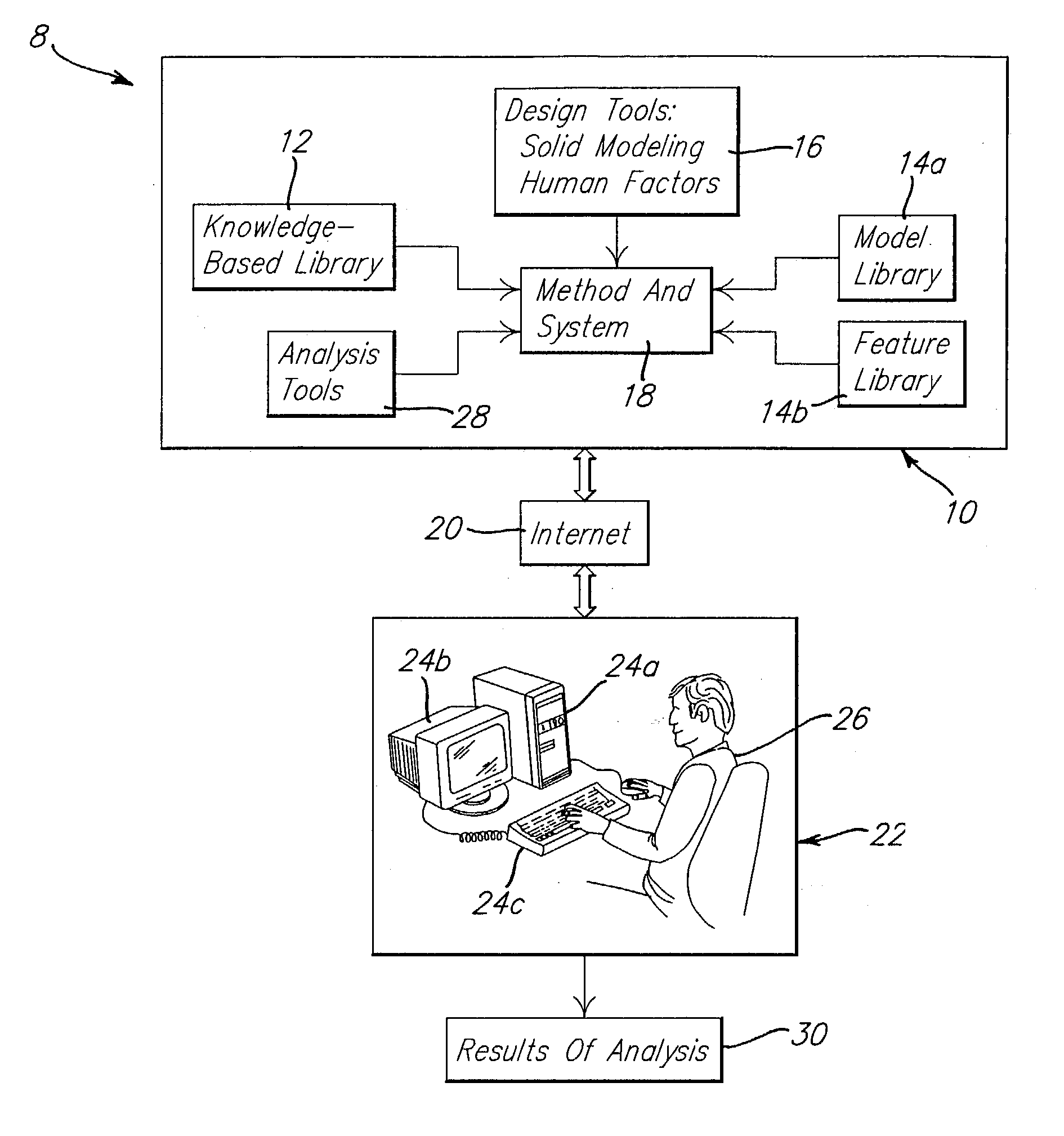

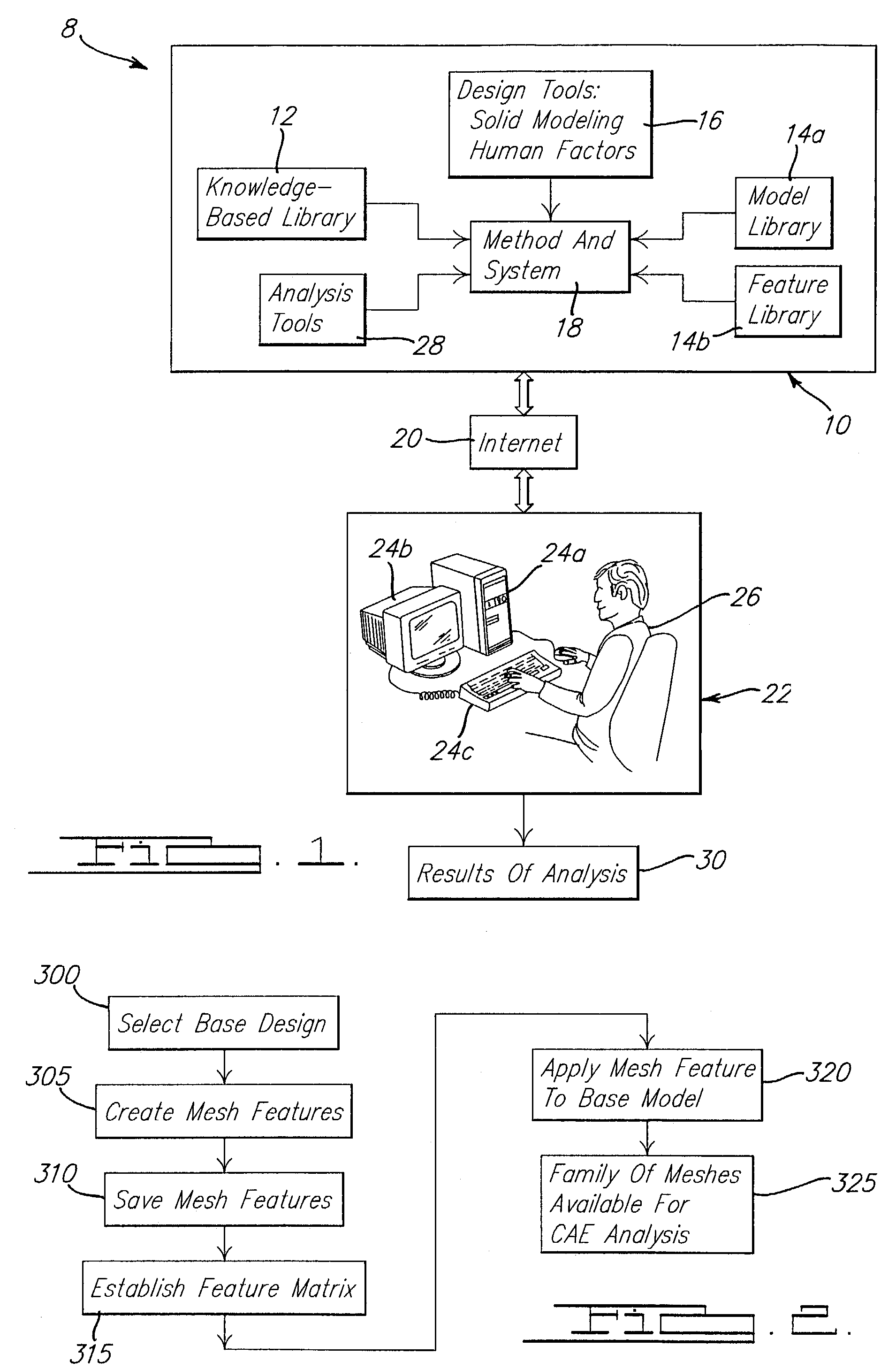

System and method of interactively assembling a model

ActiveUS7467074B2Improve efficiencyImprove model qualityGeometric CADDesign optimisation/simulationAssembly softwareComputerized system

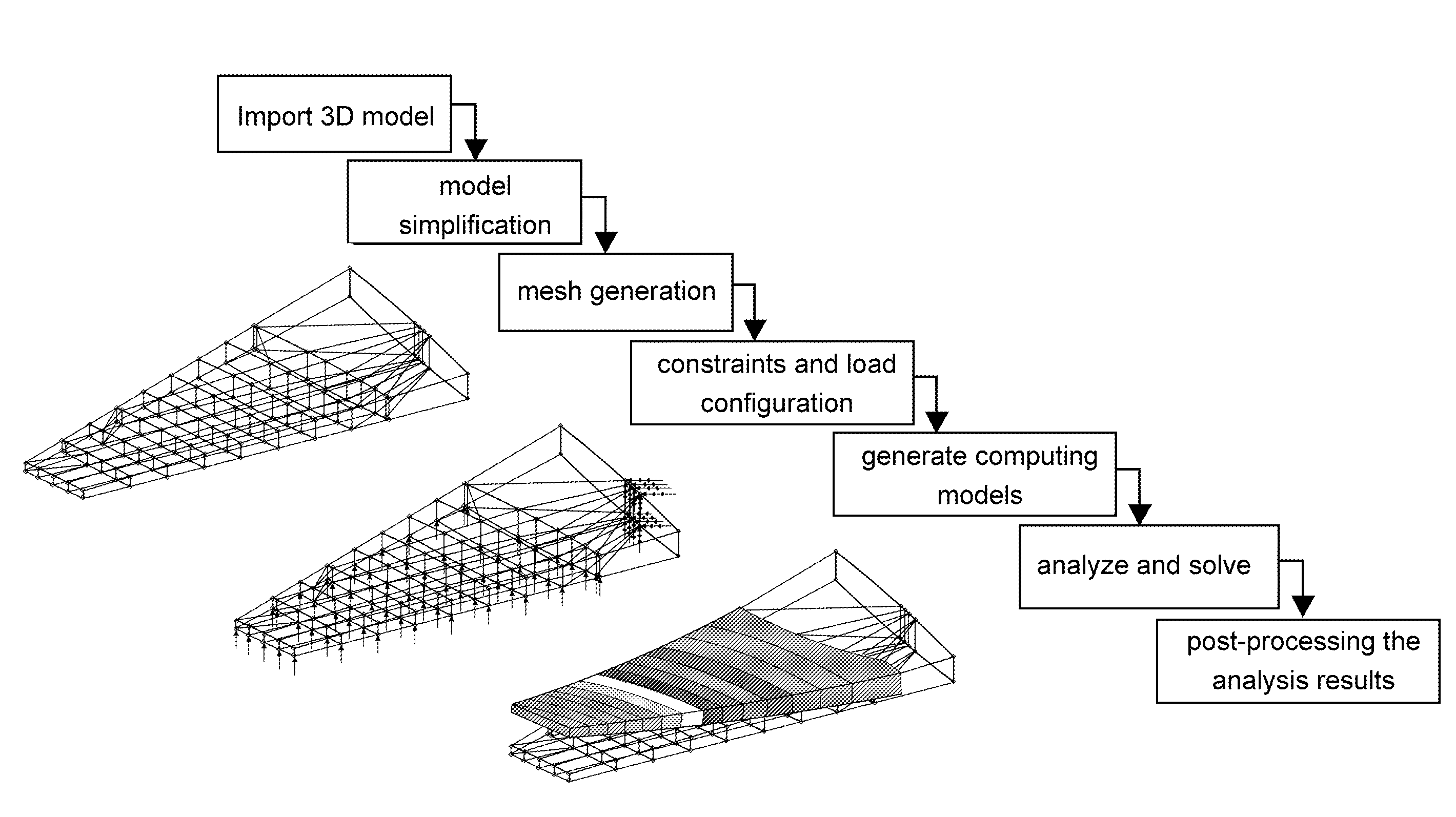

A system and method for assembling a mesh model for engineering analysis by a user is provided. The system includes a user computer system, a remotely located computer system and a data storage means. The method includes the steps of selecting a plurality of component parts having a best practice mesh model format and selecting a predetermined property for each of the selected component parts, wherein the predetermined property is selected from a best practice library stored on the data storage means. The method also includes the steps of determining if the mesh model for each of the selected component parts meets a predetermined mesh quality condition using a best practice mesh quality checking software program. The method further includes the steps of selecting a best practice connecting means for connecting the selected component parts, wherein the connecting means is selected from a best practice library of mesh models of connecting means stored in the data storage device, and assembling the selected component parts together using the connecting means and the best practice properties into a new mesh model using a best practice mesh assembly software program, and the assembled mesh model is available for further analysis.

Owner:FORD MOTOR CO

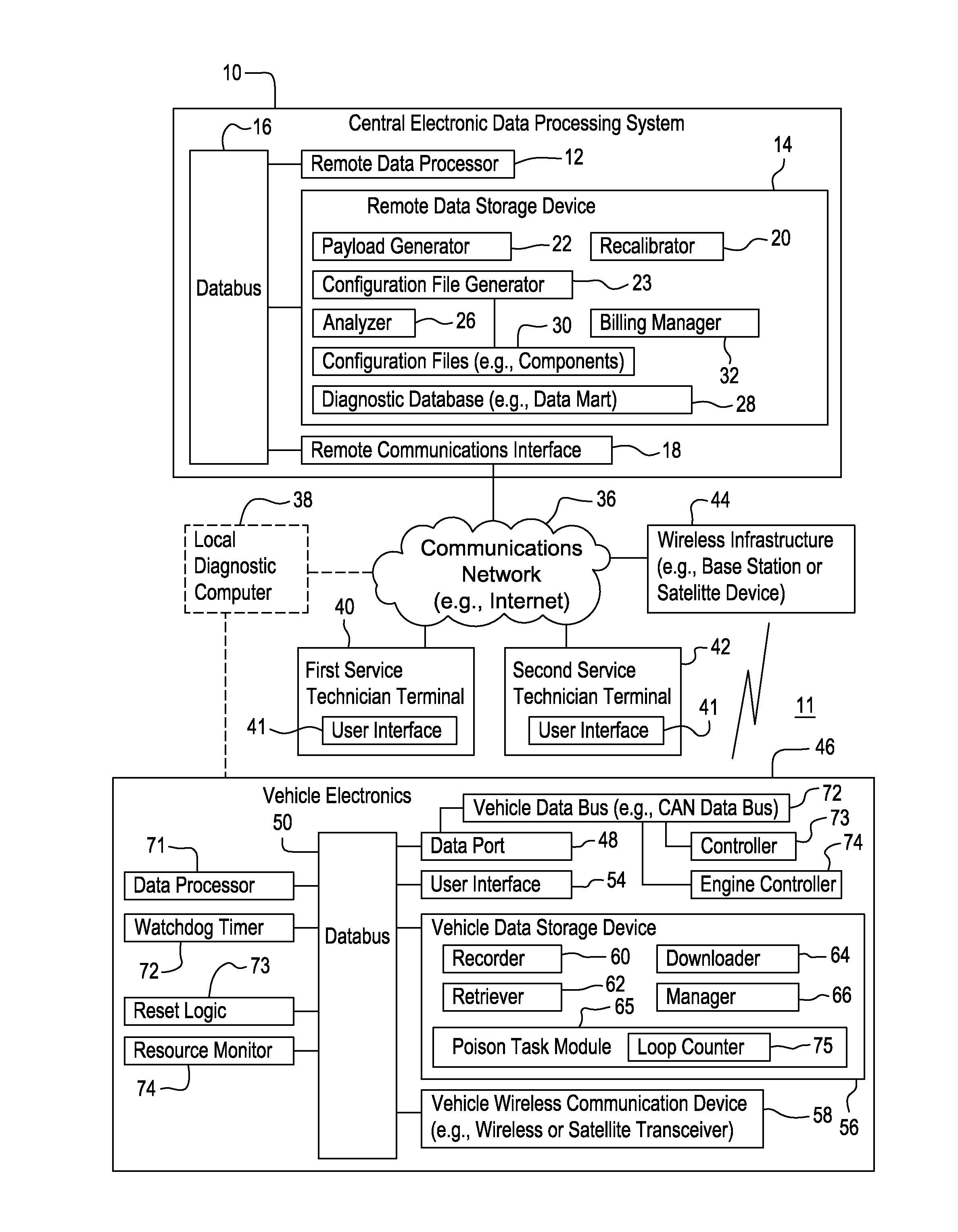

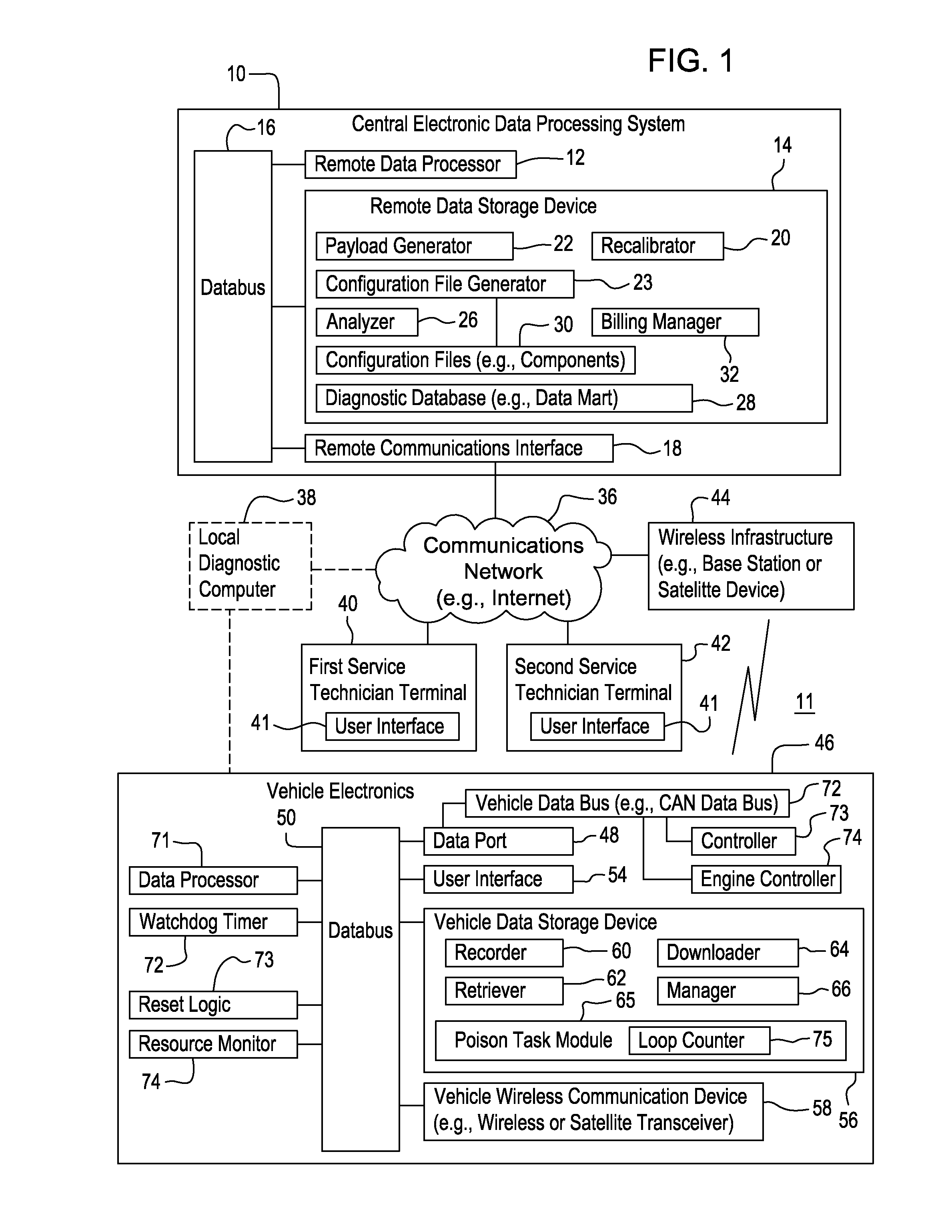

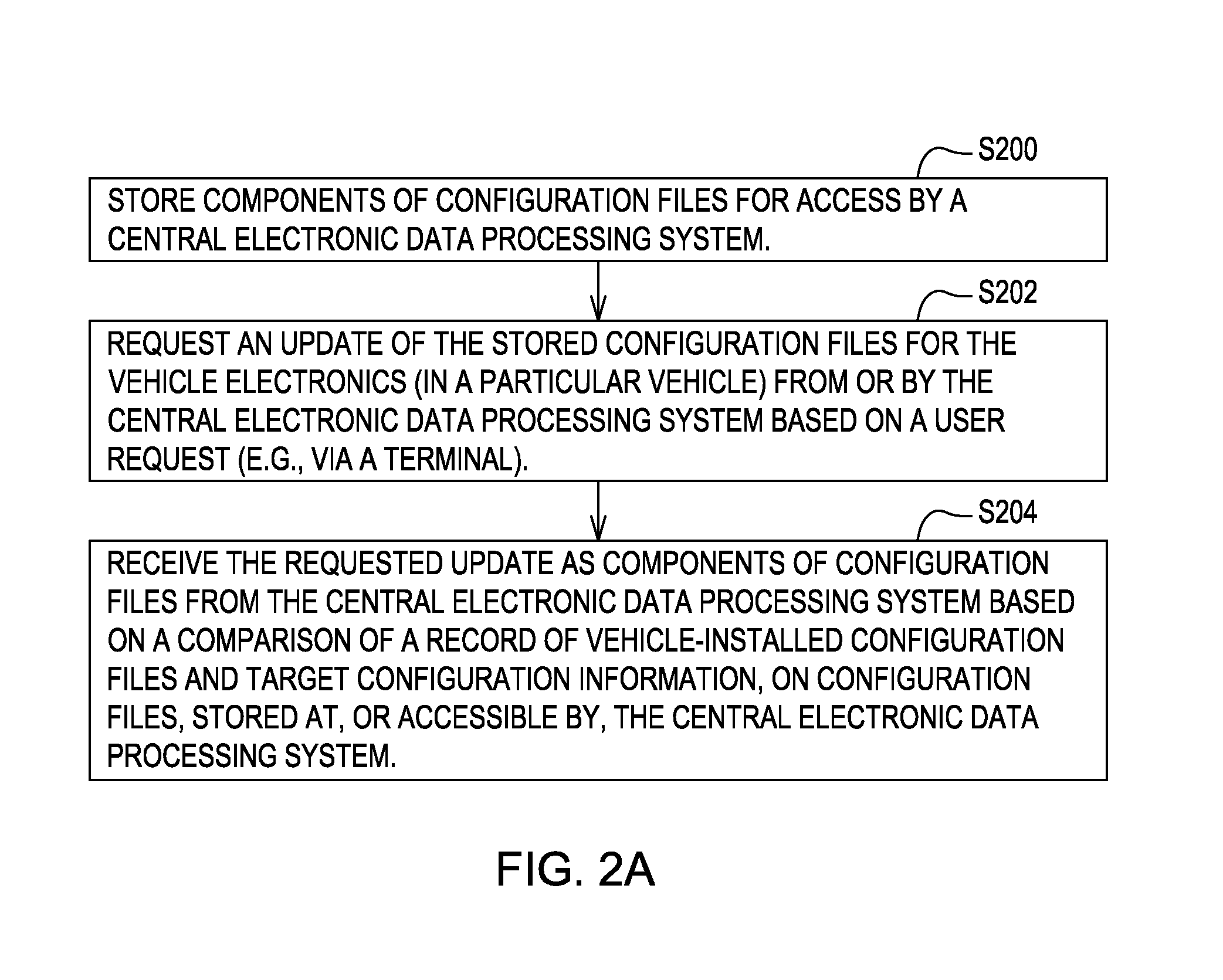

Method and system for performing diagnostics or software maintenance for a vehicle

ActiveUS20120041636A1Vehicle testingRegistering/indicating working of vehiclesData processing systemDiagnostic data

A method and system for performing diagnostics or software maintenance on a vehicle comprises recording high-fidelity data at the vehicle consistent with configuration files to support engineering analysis or diagnostics on vehicle components, systems or performance. Supplemental data is retrieved via a low bandwidth transmission at the vehicle to supplement the recorded high-fidelity data. The recorded high-fidelity data and retrieved supplemental data is processed to generate a diagnostic status report message from transmission to the central electronic data processing system. A data processor or central electronic data processing system organizes the diagnostic report message, the recorded high fidelity data and the retrieved supplemental data into a data mart or diagnostics database to support engineering analysis or diagnostics on vehicle components, systems or performance.

Owner:DEERE & CO

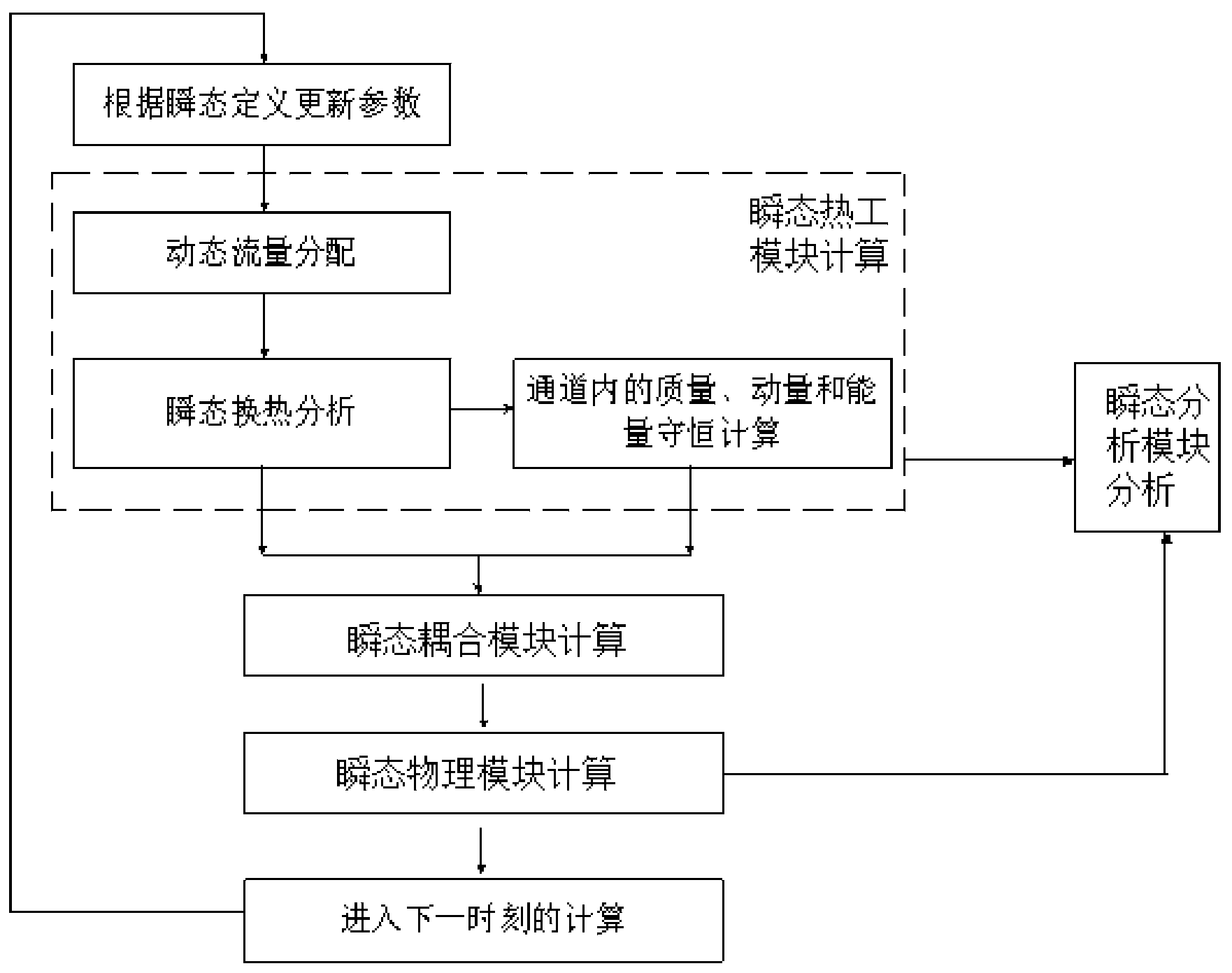

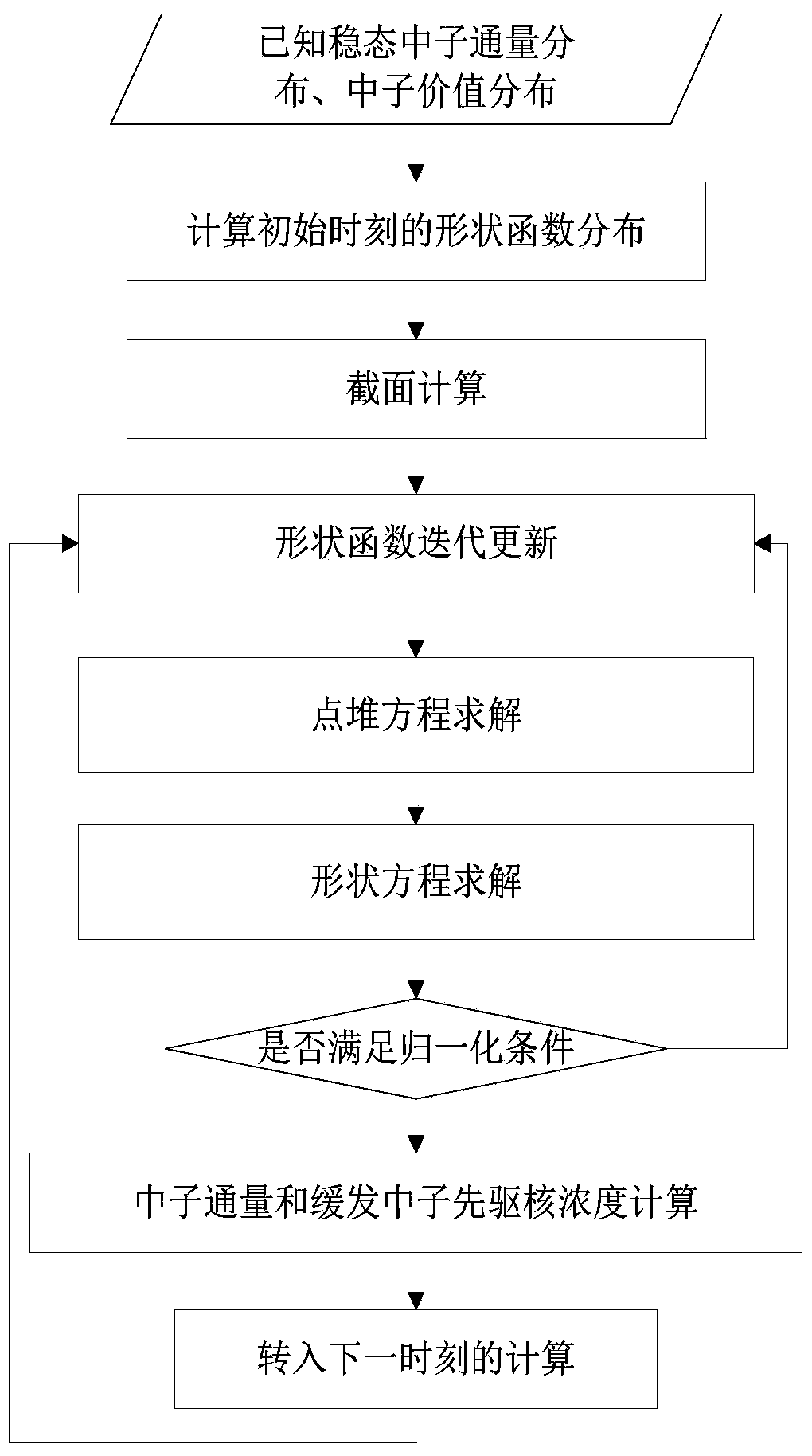

Safety analysis calculating device for transient nuclear heat coupling of supercritical water reactor

InactiveCN103902784AImprove economyImprove reliabilitySpecial data processing applicationsInformation technology support systemSystems analysisCoupling

The invention discloses a safety analysis calculating device for transient nuclear heat coupling of a supercritical water reactor, and belongs to the field of nuclear power plant design and reactor safety analysis. The safety analysis calculating device for transient nuclear heat coupling of the supercritical water reactor is applicable to the supercritical water reactor. According to the safety analysis calculating device, a transient physical analysis program is built by using the space-time disperse solution of a double-group space-time kinetic equation, a transient heat engineering analysis program is built through calculation of flow distribution among channels and the solution of flowing heat exchange inside the channels, on this basis, a physical calculation program is embedded into a transient system analysis program to build a supercritical transient coupling analysis program so as to analyze safety of a system. Particularly, due to the fact that a space-time kinetics quasi-static solution model built through the double-group neutron space-time kinetic equation is combined with a multi-channel analysis method, compared with a sub-channel model, the calculation time is shortened on the basis that precision is ensured, then economy of the supercritical water reactor design is improved, and the safety analysis calculating device accords with the development trend of safety analysis.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

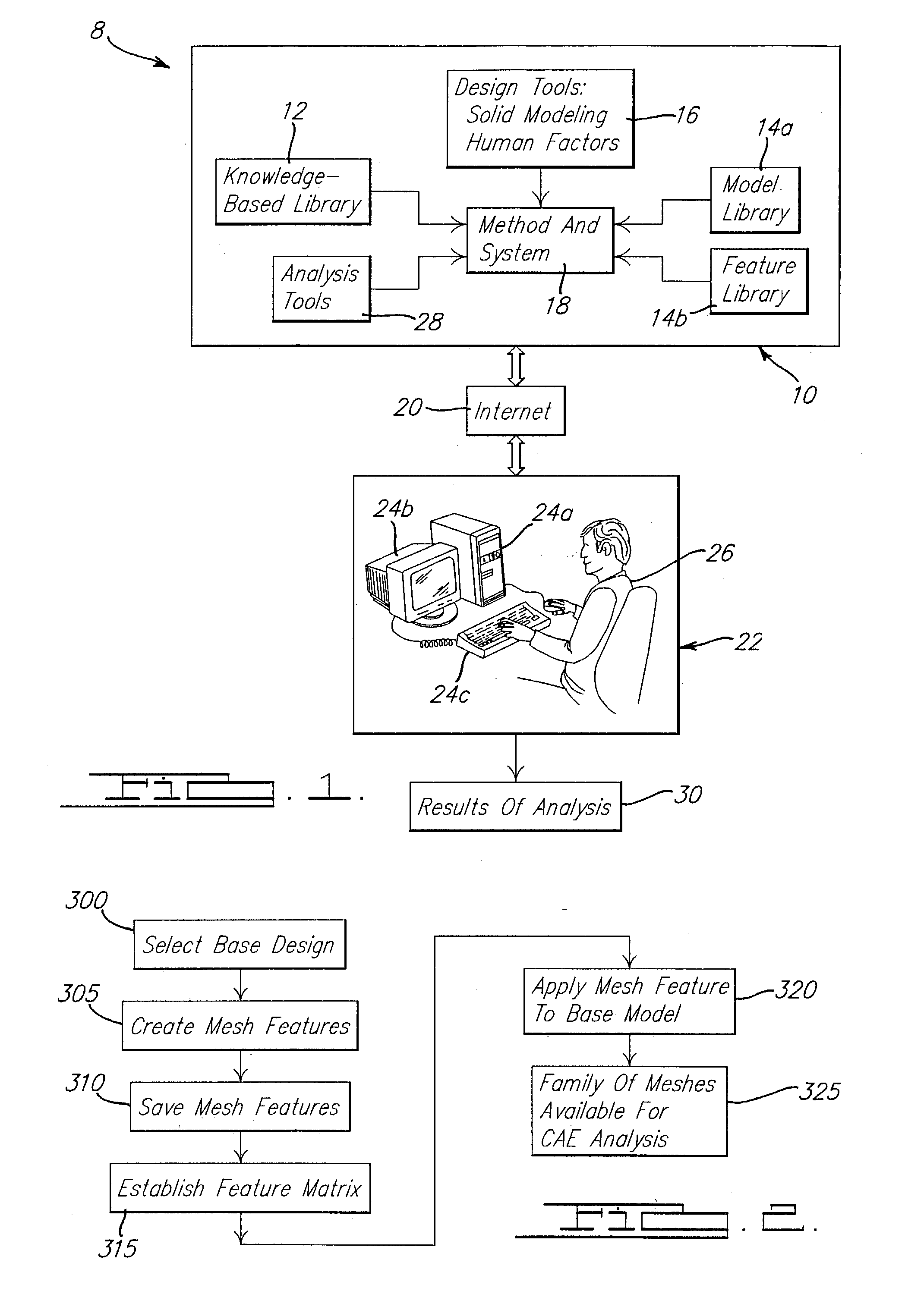

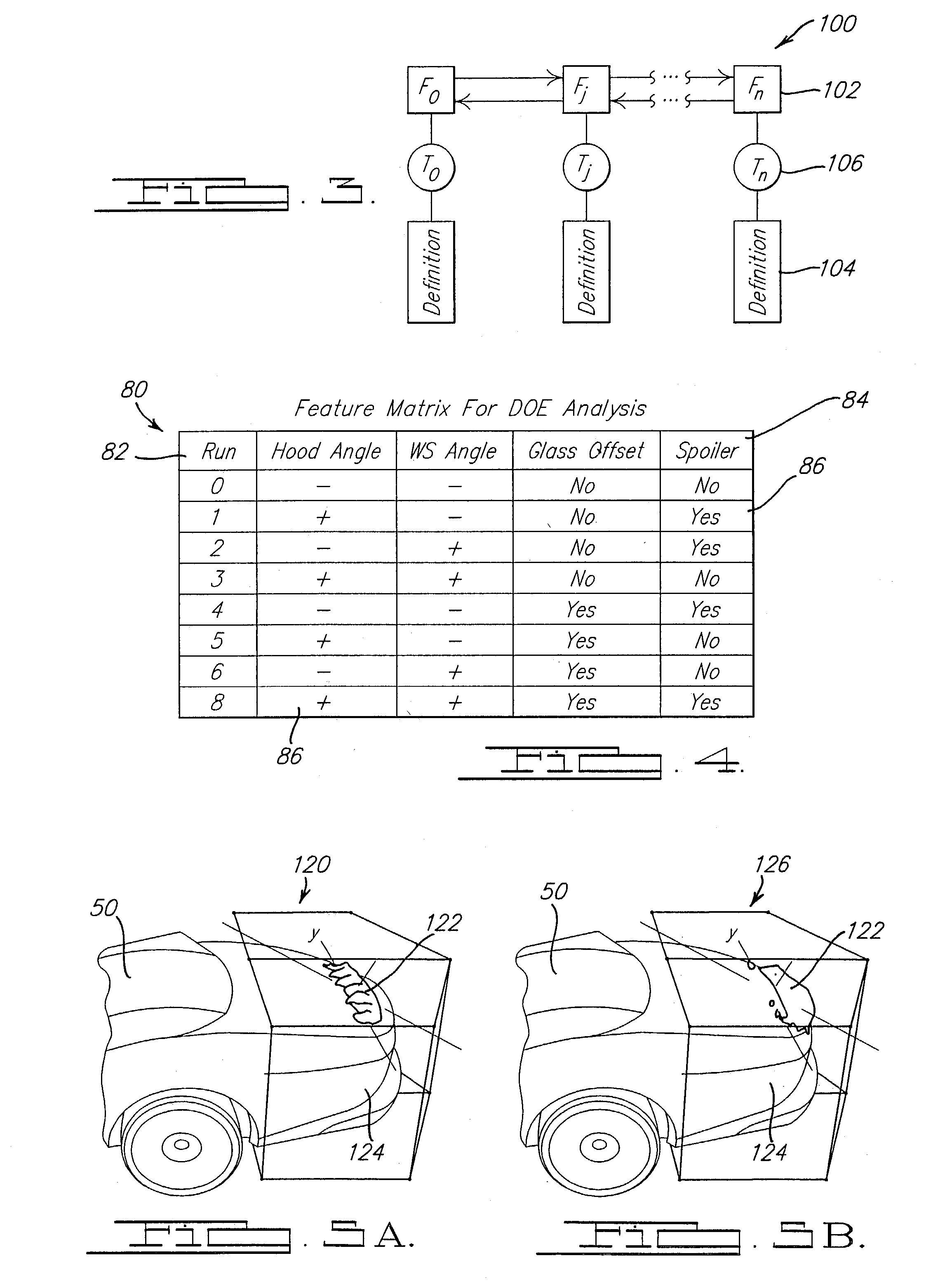

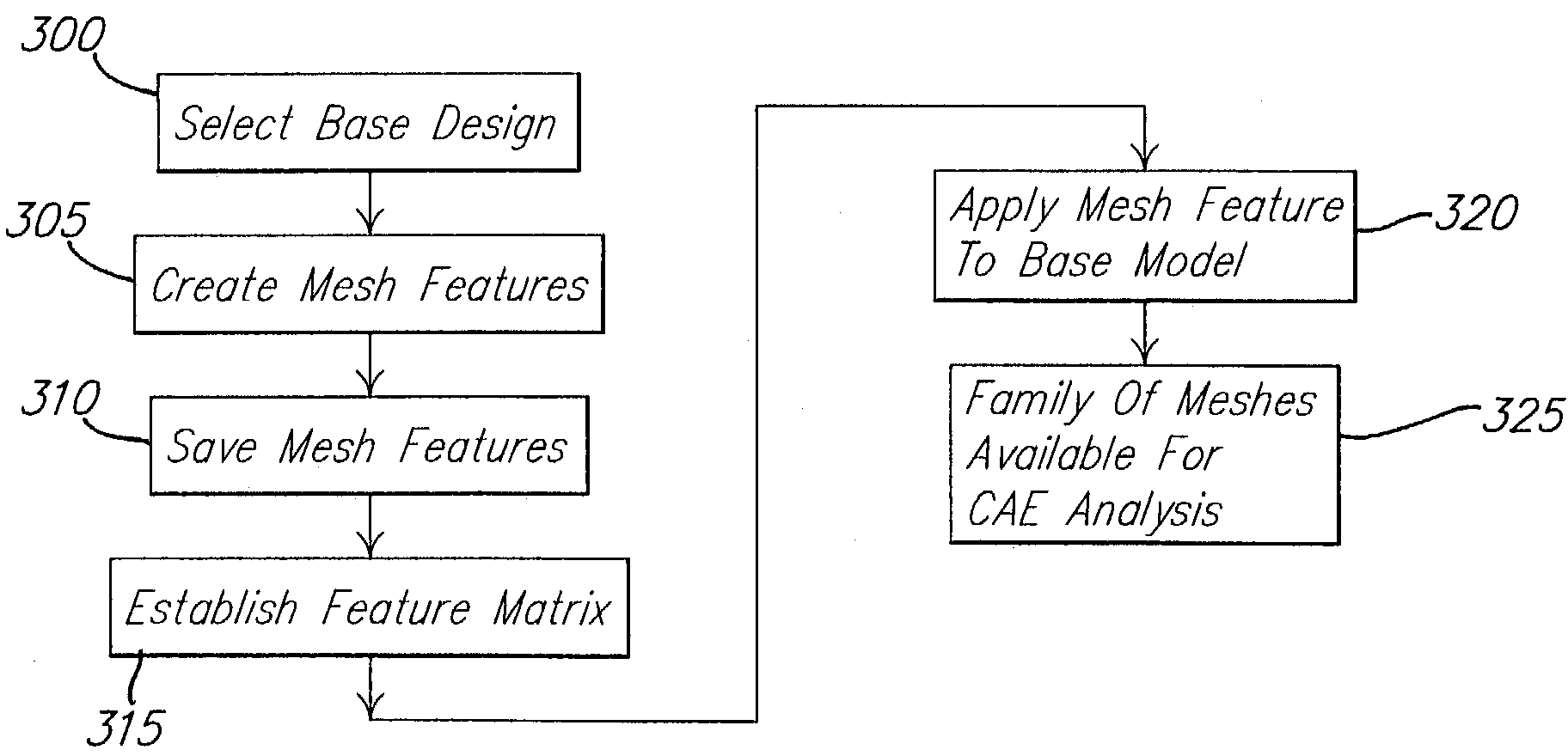

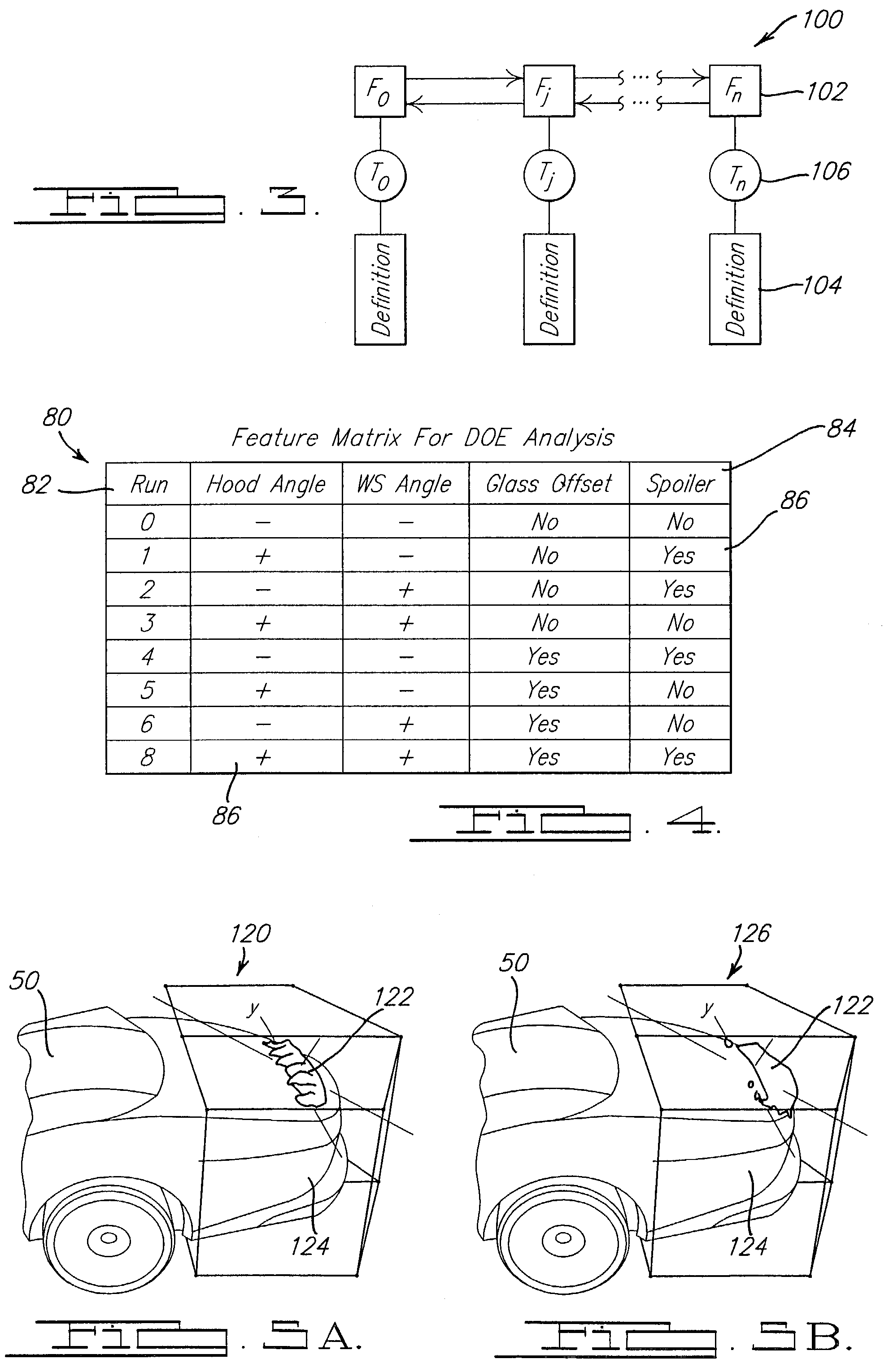

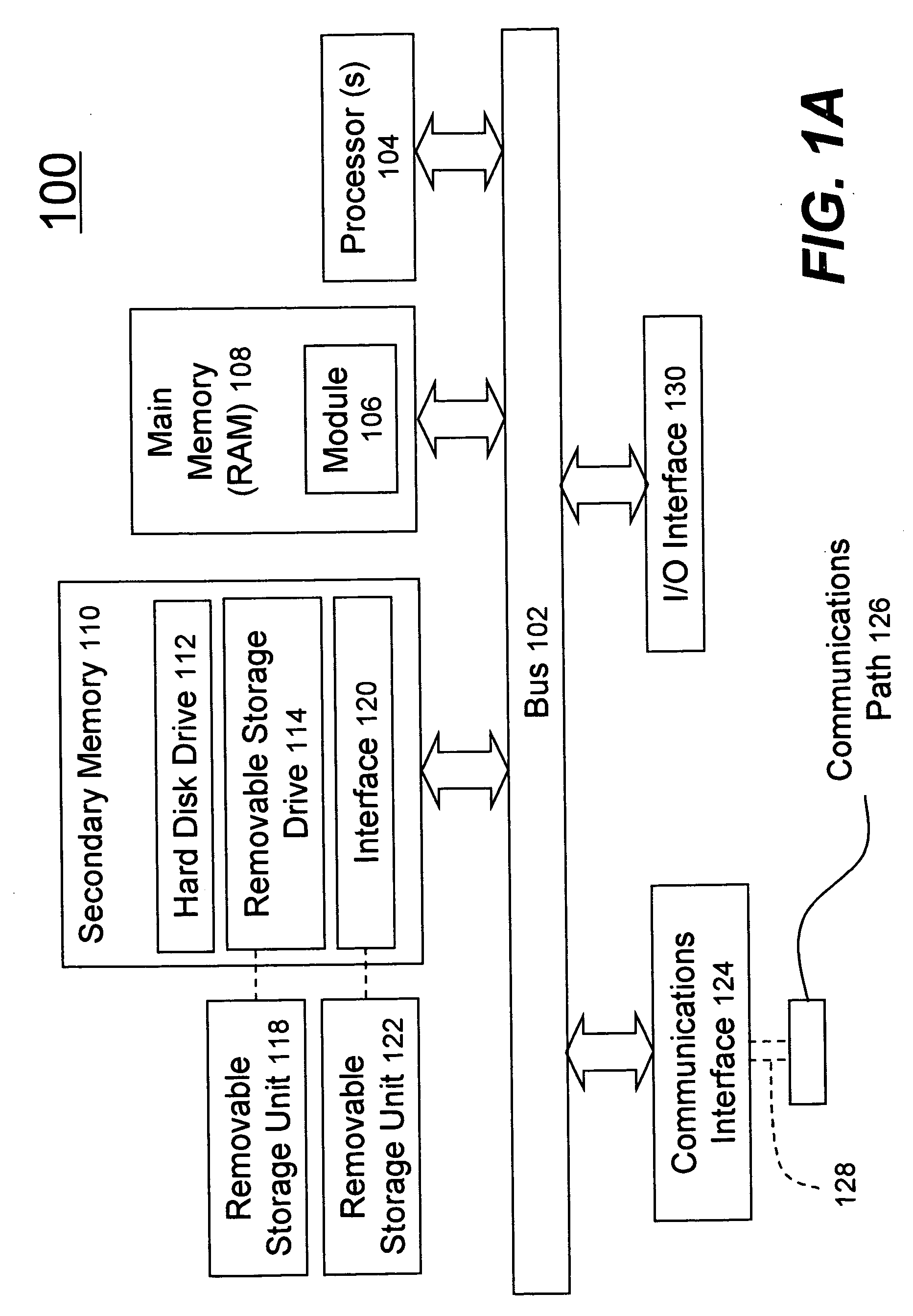

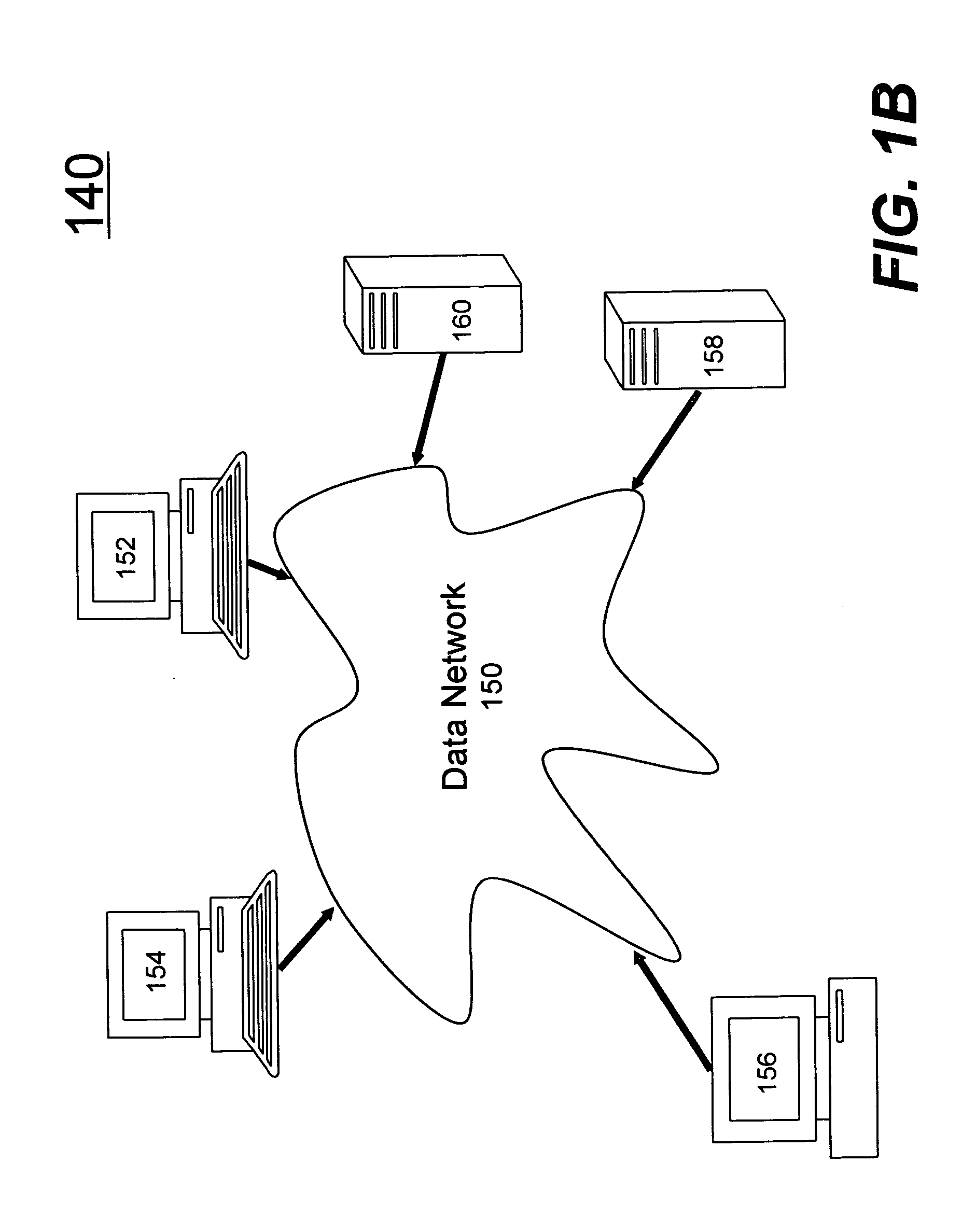

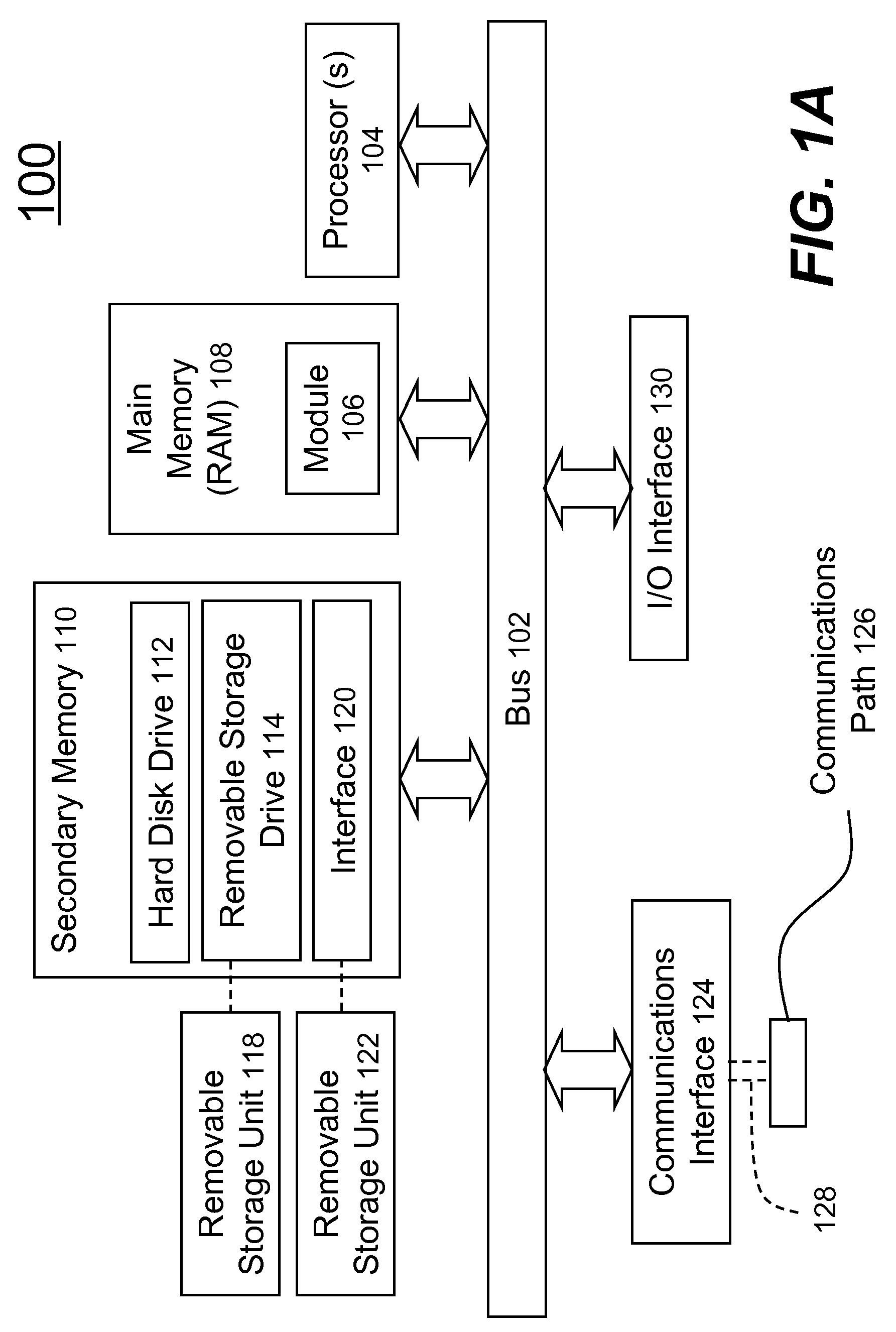

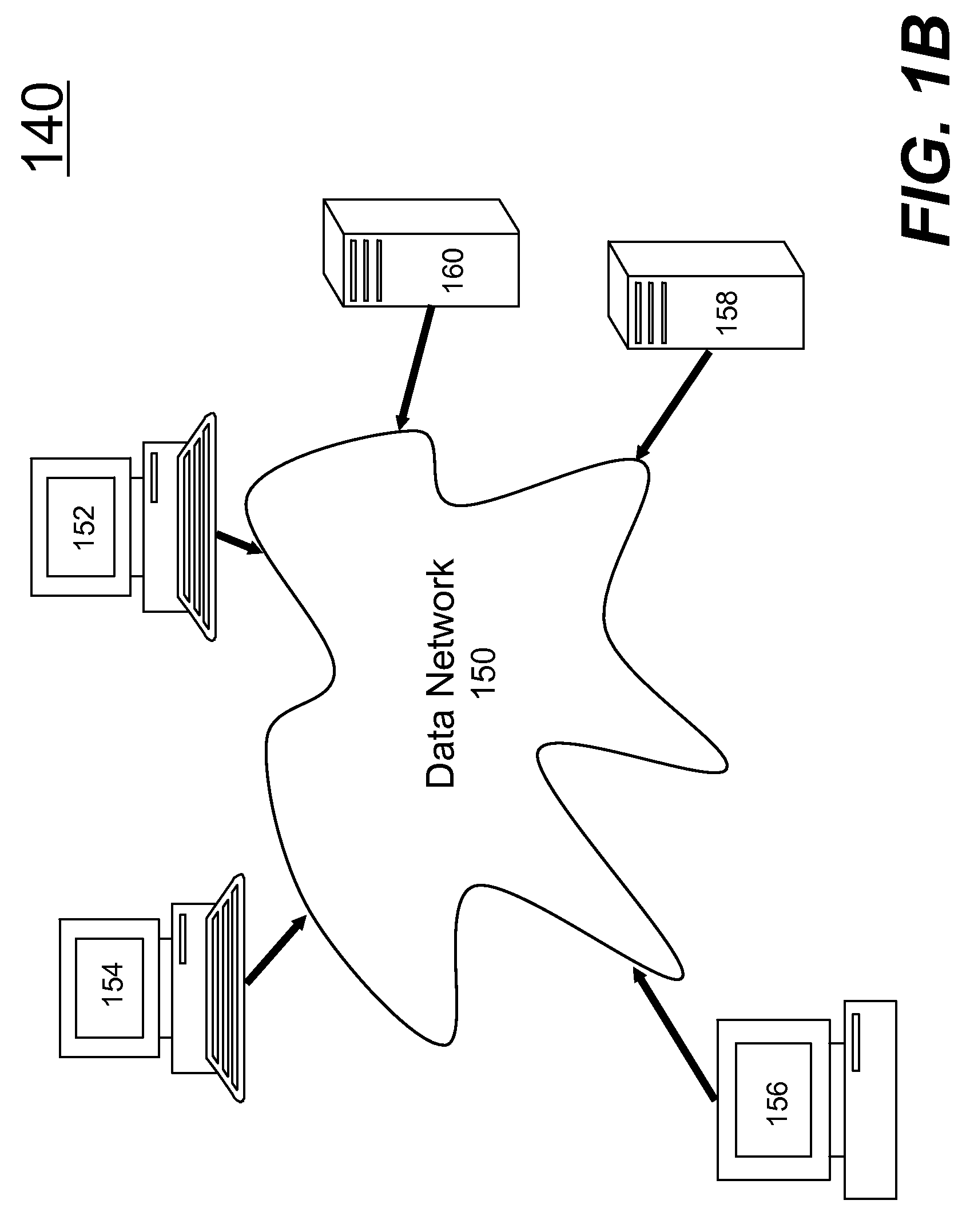

System and method of interactively generating a family of mesh models

A system and method for interactively generating a family of mesh models is provided for use in engineering analysis. The system includes a user computer system having a memory, a processor, a user input device and a display device. The system also includes a remotely located computer system having a processor, a memory, and a data storage means and in communication with the user computer system. The system further includes a computer-generated geometric mesh base model stored in the data storage means, a computer-generated mesh feature stored in the data storage means, and a new mesh model including the base mesh model with a mesh feature that is stored in the data storage means. The method includes the steps of selecting a base model from a model library maintained in the data storage means. The method also includes the steps of creating a mesh feature that is defined by a modifiable set of parameters and saving the mesh feature in a mesh feature library maintained in the data storage means. The method further includes the steps of establishing a feature matrix by the user containing instructions for selectively applying the mesh feature to the base mesh model and using the feature matrix to selectively apply the mesh feature to the base model to generate a new mesh model that is available for further analysis.

Owner:FORD MOTOR CO

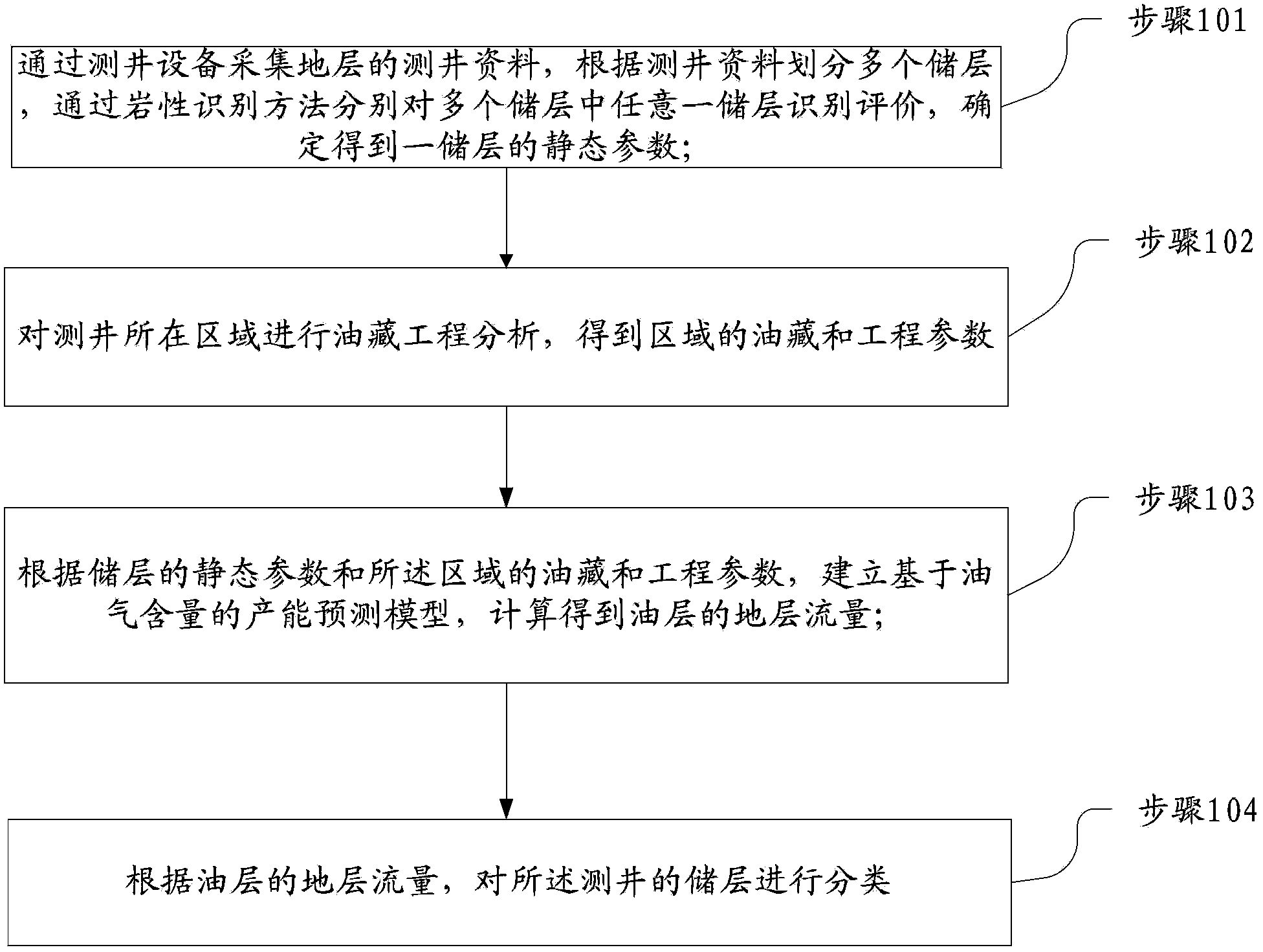

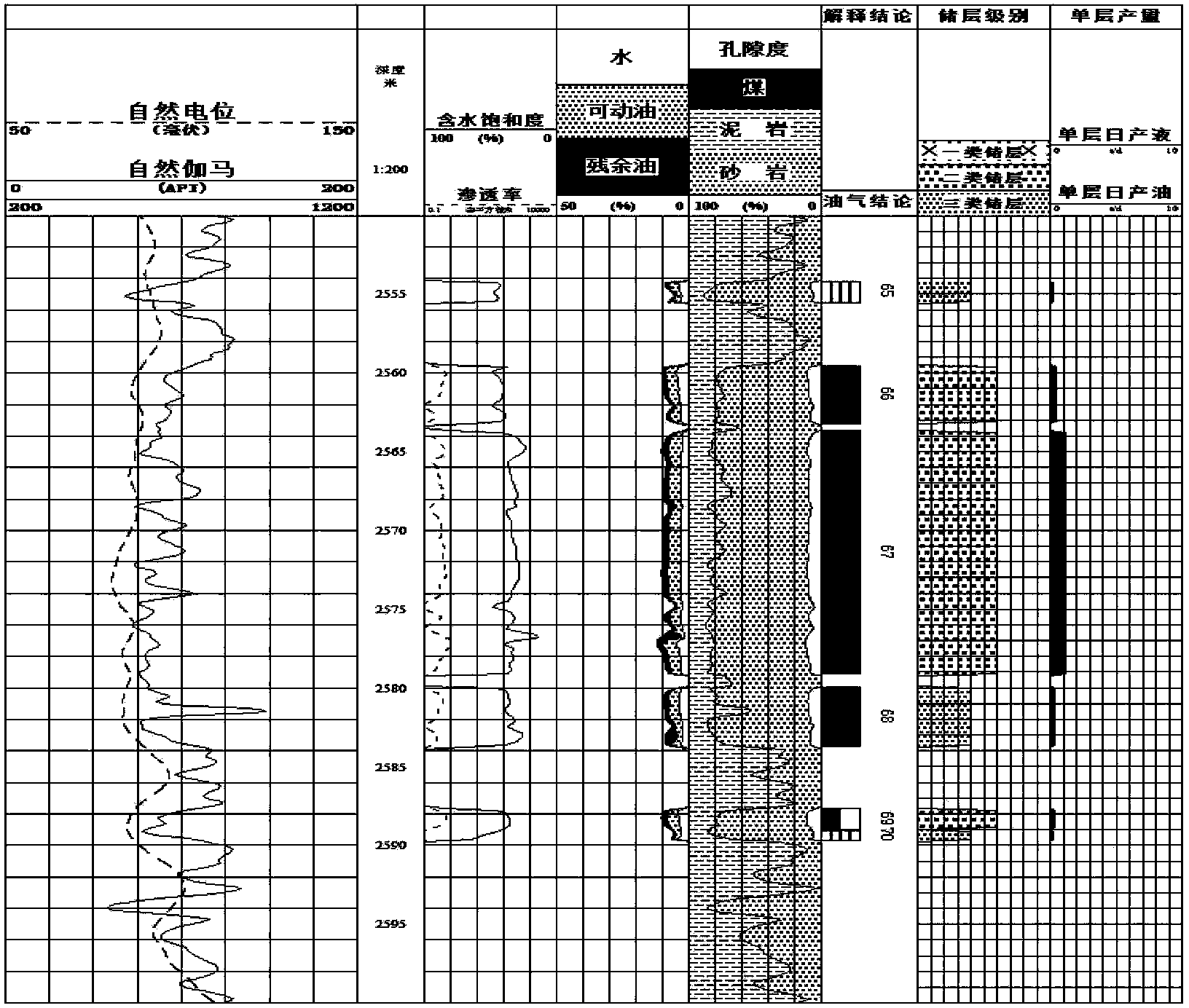

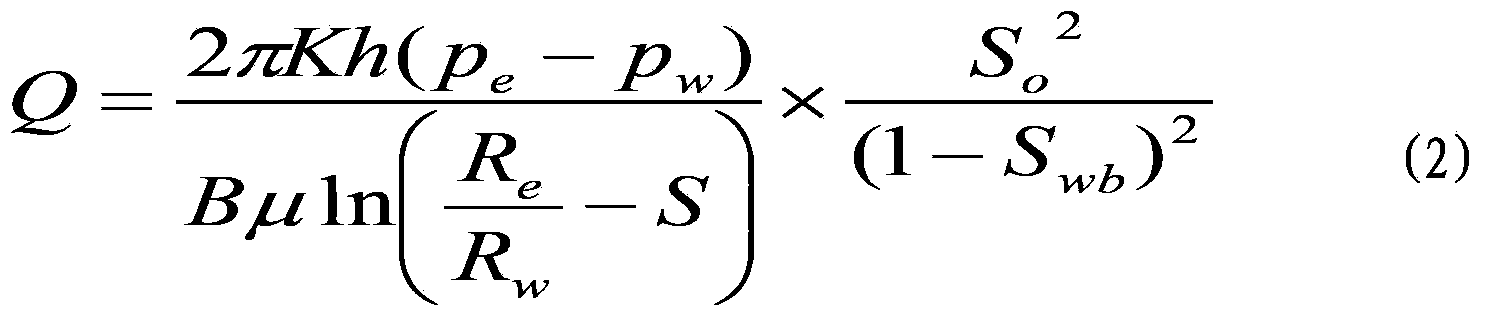

Productivity prediction system and method based on oil gas content

ActiveCN103352693ASolve the problem of poor determination of permeabilitySolve the limitation of not considering the content of oil and gas resources in the formationBorehole/well accessoriesLithologyReservoir engineering

The invention discloses a productivity prediction system and method based on oil gas content, and belongs to the field of oil development and engineering. The system comprises a static parameter confirming module, an oil reservoir and engineering parameter confirming module, a productivity prediction model establishment module and an evaluation module, wherein the static parameter confirming module is used for collecting logging information of strata through logging equipment, partitioning a plurality of reservoir beds according to the logging information, performing recognition and evaluation on any one of the plurality of reservoir beds through a lithology identification method, and confirming that static parameters of one reservoir bed is obtained; the oil reservoir and engineering parameter confirming module is used for performing reservoir engineering analysis on the region where the logging is located, and obtaining oil reservoir and engineering parameters of the region; the productivity prediction model establishment module is used for establishing a productivity prediction model based on the oil gas content and obtaining a stratum flow of an oil layer through calculation according to the static parameters in the reservoir beds and the oil reservoir and engineering parameters of the region; and the evaluation module is used for classifying the reservoir beds of the logging according to the stratum flow of the oil layer. The productivity prediction system and method based on the oil gas content can solve the problem that oil phase permeability is difficult to confirm, thereby improving the accuracy of the productivity prediction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

System and method of interactively generating a family of mesh models

A system and method for interactively generating a family of mesh models is provided for use in engineering analysis. The system includes a user computer system having a memory, a processor, a user input device and a display device. The system also includes a remotely located computer system having a processor, a memory, and a data storage means and in communication with the user computer system. The system further includes a computer-generated geometric mesh base model stored in the data storage means, a computer-generated mesh feature stored in the data storage means, and a new mesh model including the base mesh model with a mesh feature that is stored in the data storage means. The method includes the steps of selecting a base model from a model library maintained in the data storage means. The method also includes the steps of creating a mesh feature that is defined by a modifiable set of parameters and saving the mesh feature in a mesh feature library maintained in the data storage means. The method further includes the steps of establishing a feature matrix by the user containing instructions for selectively applying the mesh feature to the base mesh model and using the feature matrix to selectively apply the mesh feature to the base model to generate a new mesh model that is available for further analysis.

Owner:FORD MOTOR CO

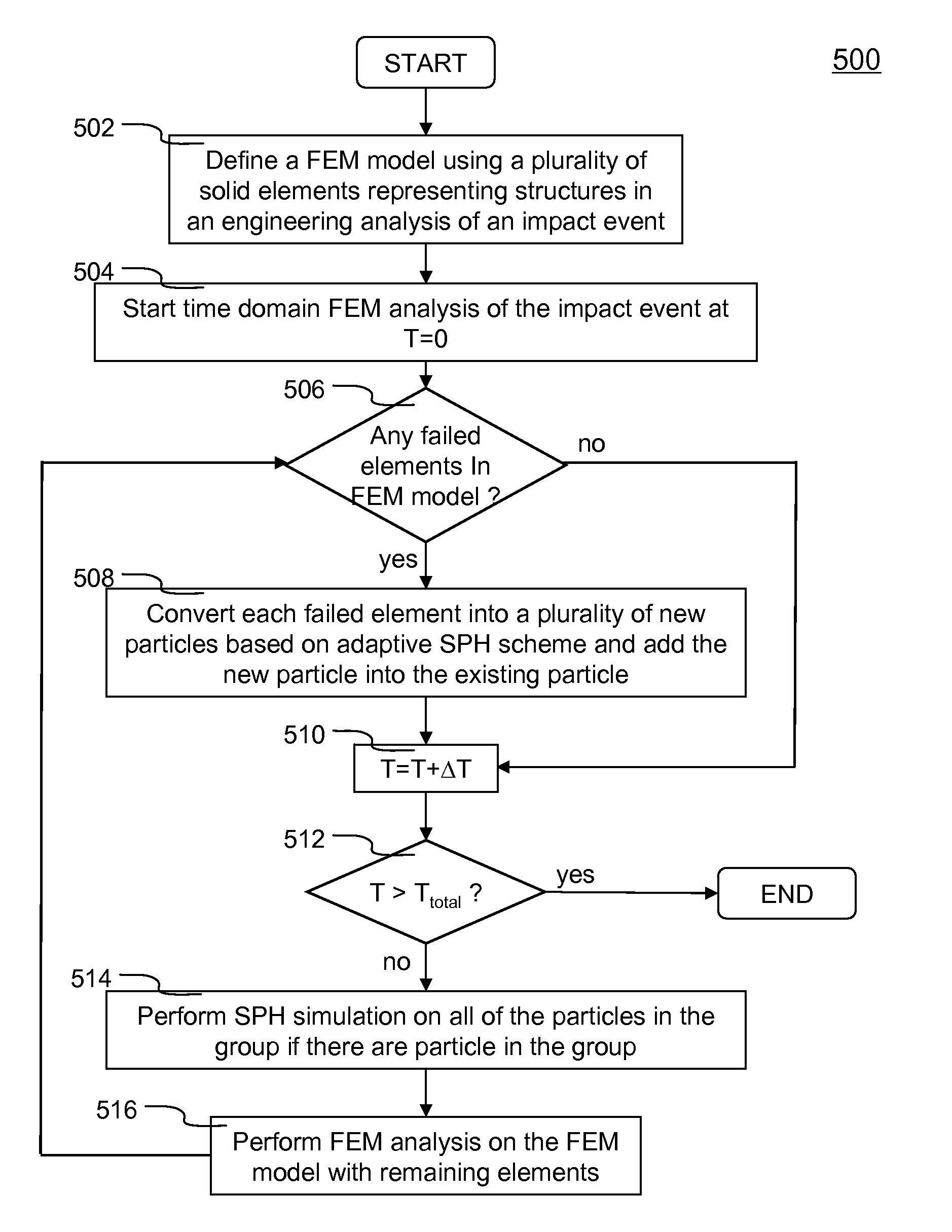

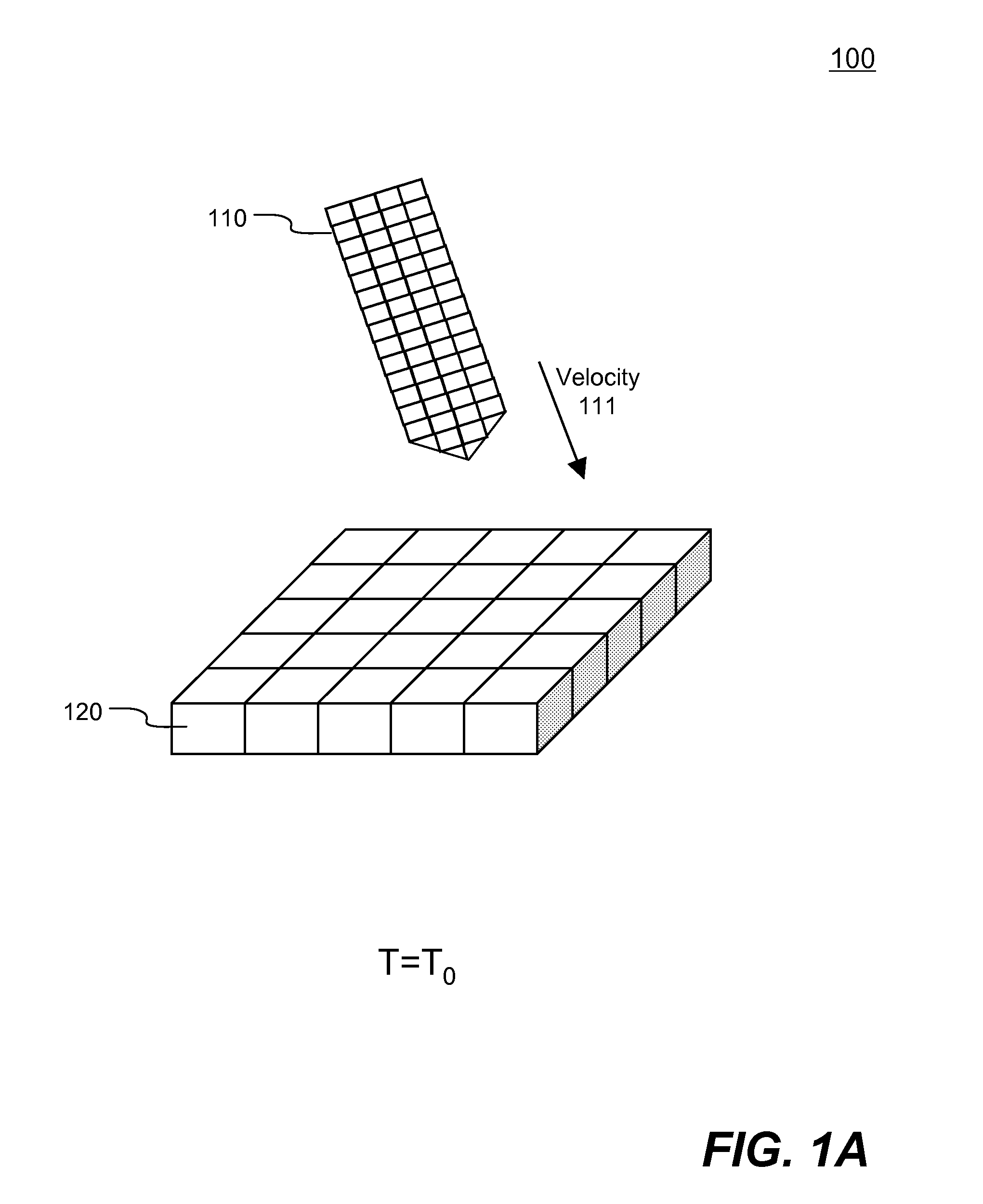

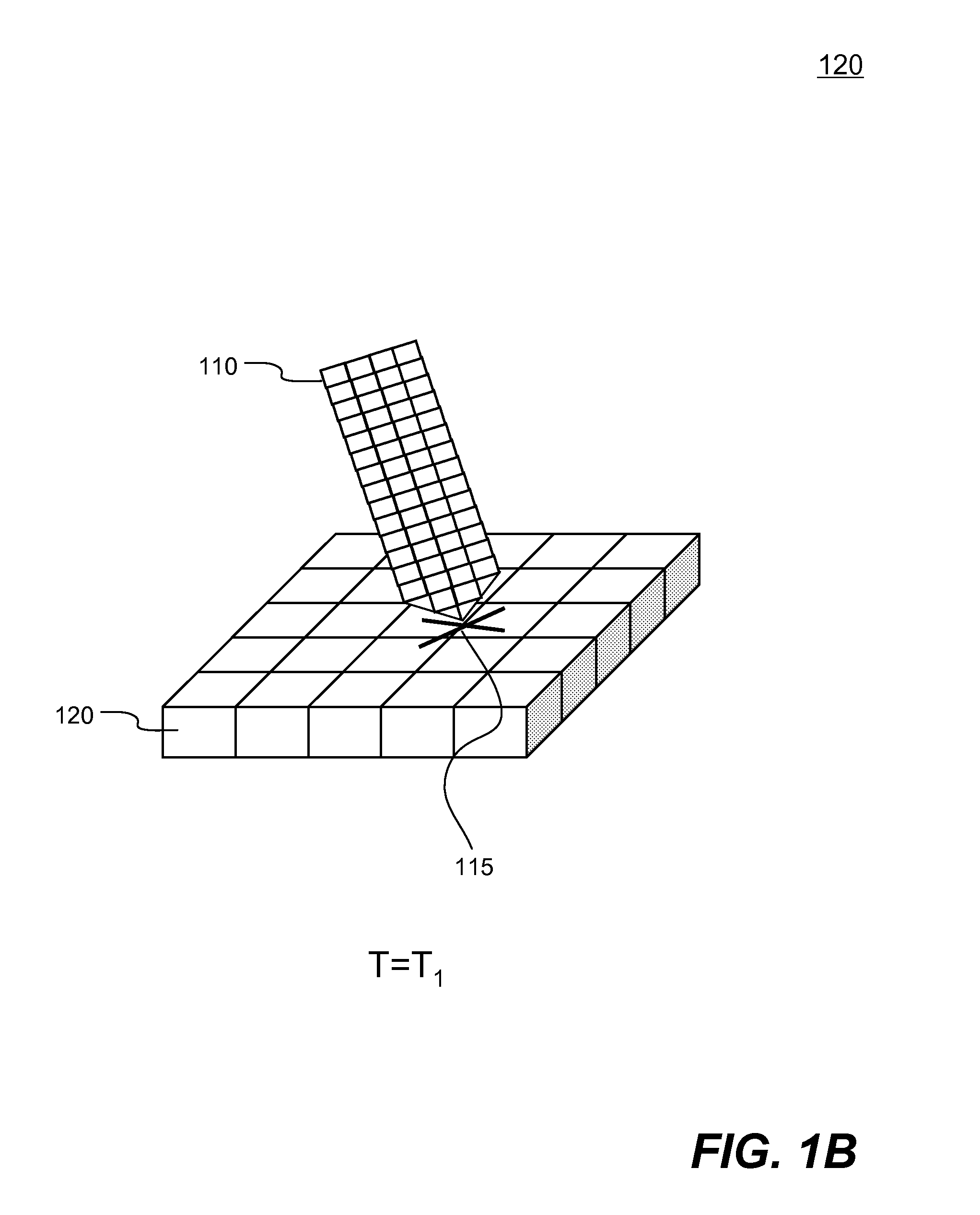

Methods and systems of engineering analysis using a hybrid approach with FEM and adaptive SPH

ActiveUS20090228246A1Real timeComputation using non-denominational number representationInvestigating material hardnessSmoothed-particle hydrodynamicsMomentum

Systems and methods of computer aided engineering analysis using hybrid approach of finite element method (FEM) and adaptive smoothed particle hydrodynamics (SPH) are described. According to one aspect, a computer-aided engineering analysis is performed to simulate an impact event between structures. A FEM grid model is created to represent the structures using a plurality of solid elements which represents geometry and material properties. Once a contact between two structures resulted into a material or structural failure according to predefined material constitutive equation, solid elements representing the failed portion of the structure are removed. Each failed solid element is then replaced by a plurality of particles to be analyzed using the SPH analysis. The particles replacing the failed element inherit all of the states and properties of the failed element, such as location, mass, velocity, acceleration, etc. The replacement is conducted according to the principles of mass, momentum and energy conservation.

Owner:ANSYS

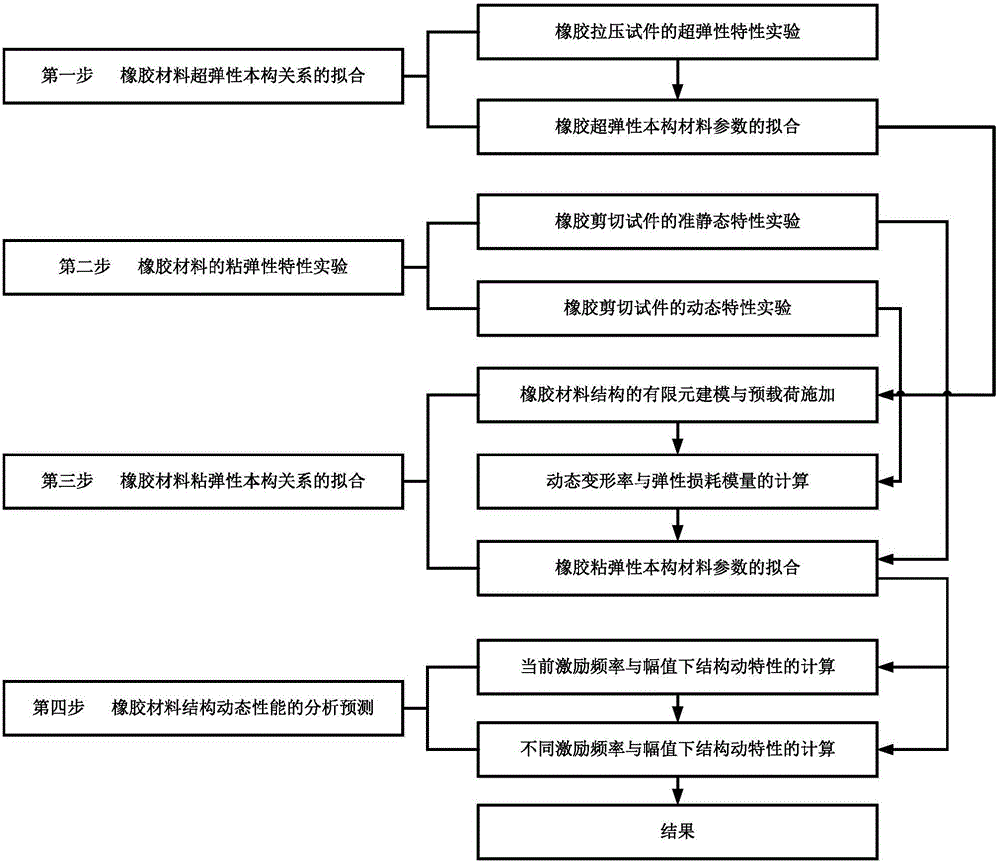

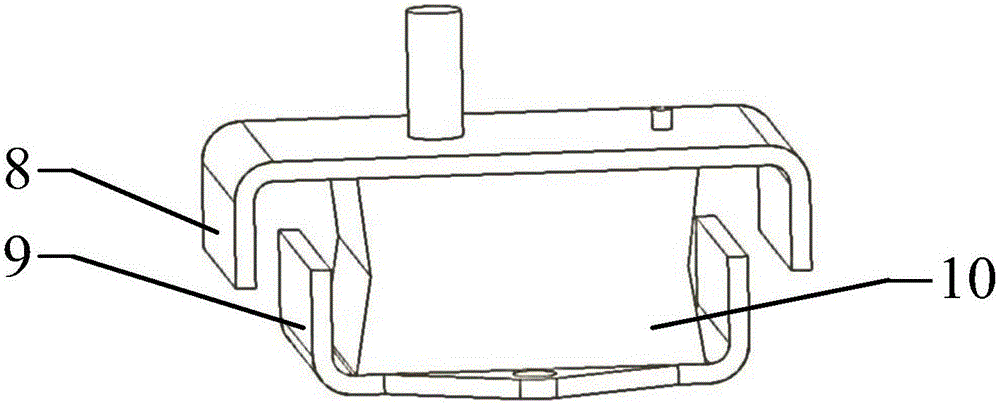

Step-by-step analysis and prediction method for dynamic performances of rubber material structure

ActiveCN105069241AAccurate analysisMeet the needs of analysisSpecial data processing applicationsRubber materialElement analysis

The present invention relates to an analysis and prediction method for dynamic performances of a rubber material structure, and particularly to a step-by-step analysis and prediction method for the dynamic performances of the rubber material structure. The step-by-step analysis and prediction method is used for performing finite element analysis and prediction of the high-frequency dynamic performances on the rubber material structure. The method comprises the following test and prediction steps: step one, fitting a super-elastic constitutive relation of the rubber material; step two, performing a viscoelasticity property test on the rubber material under different strain amplitudes; step three, fitting a viscosity constitutive relation of the rubber material; and step four, analyzing and predicating the dynamic performances of the rubber material structure. A calculation result is a final result, without the need of superposition of the calculation result, thereby reducing the computational difficulty and shortening the solution time; and an actual modeling and analysis process is more simple, clear, and easy to understand and operate, and has higher prediction accuracy, so as to meet the requirements of engineering analysis.

Owner:SHANDONG UNIV

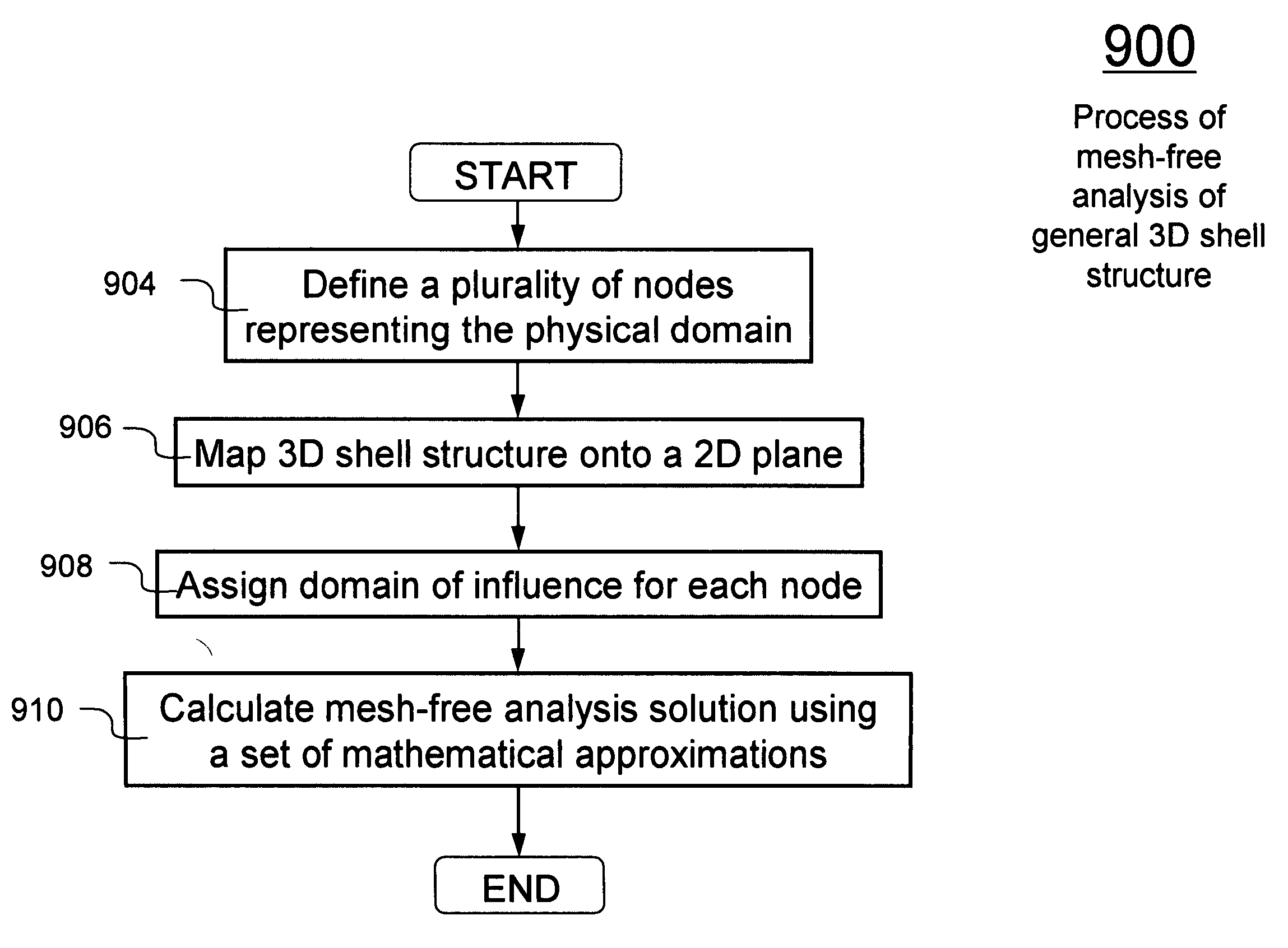

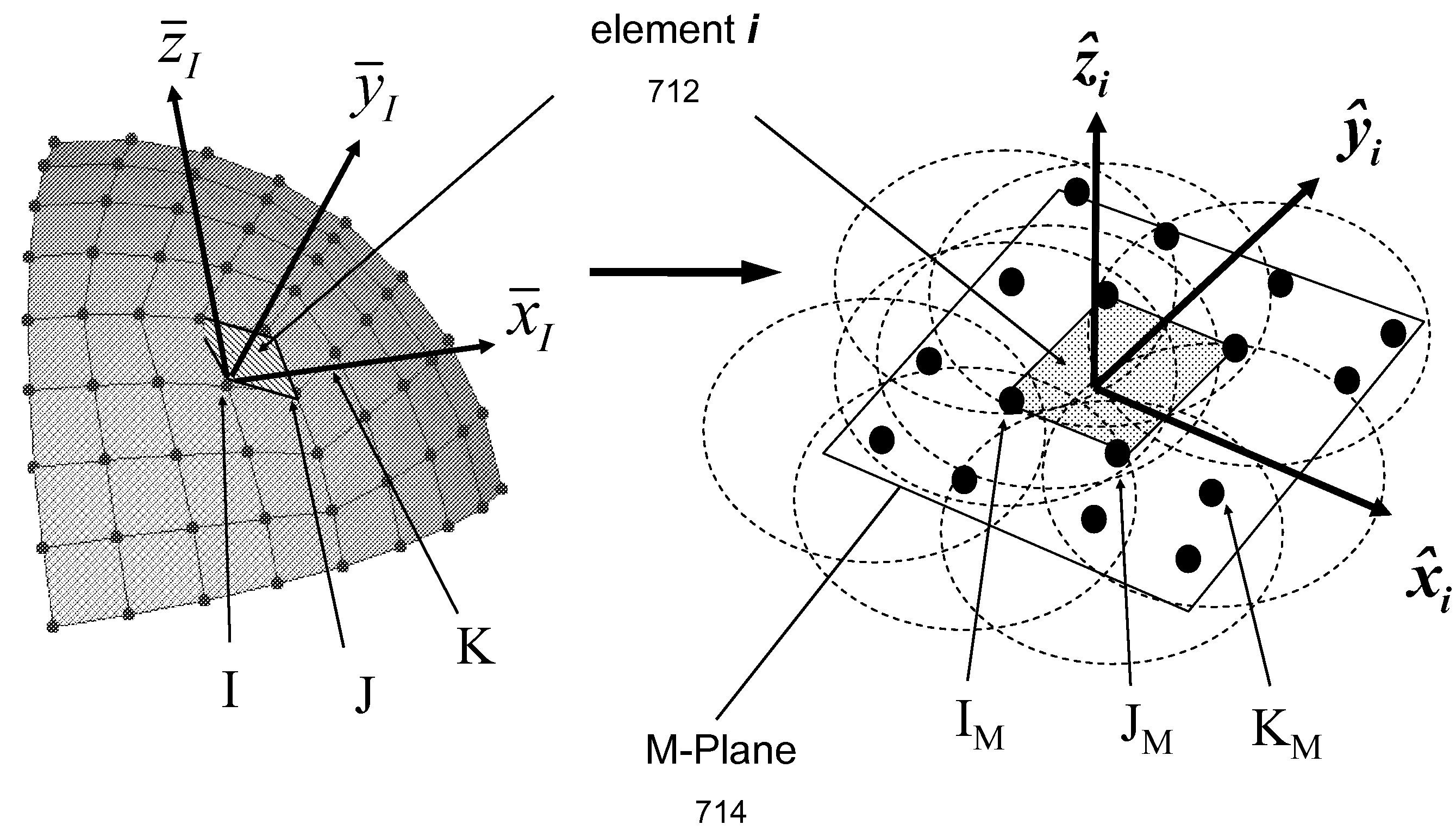

Method and system for mesh-free analysis of general three-dimensional shell structures

ActiveUS20060103648A1Computation using non-denominational number representationDesign optimisation/simulationThree-dimensional spaceComputer science

A method, system and computer program product pertained to engineering analysis of a general three-dimensional (3-D) shell structure using the mesh-free technique is disclosed. The structural responses are solved with mesh-free technique after the 3-D shell structure is mapped to a two-dimensional plane. According to one aspect, the present invention is a method for mesh-free analysis of a general three-dimensional shell structure, the method comprises: defining the general shell structure as a physical domain represented by a plurality of nodes in a three-dimensional space, creating a plurality of projected nodes by mapping the plurality of nodes in the three-dimensional space onto a two-dimensional plane, assigning a plurality of domain of influences, one for each of the plurality of projected nodes, and calculating a solution of the physical domain using a set of mathematical approximations pertaining to each of the plurality of projected nodes.

Owner:ANSYS

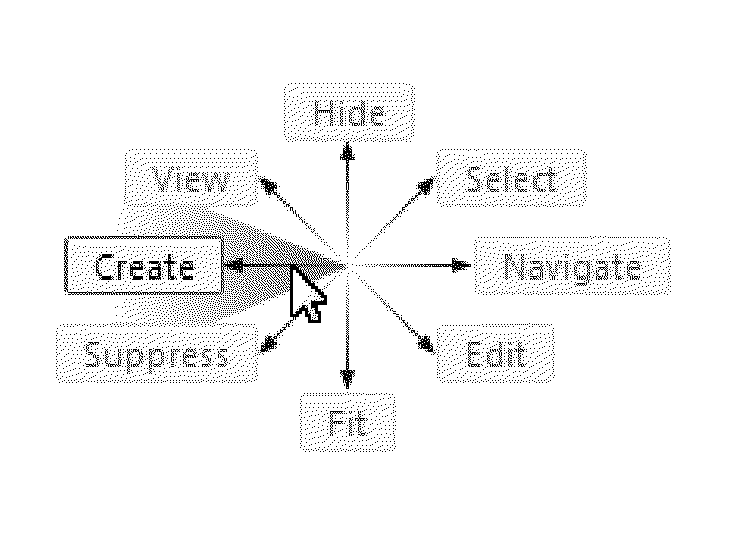

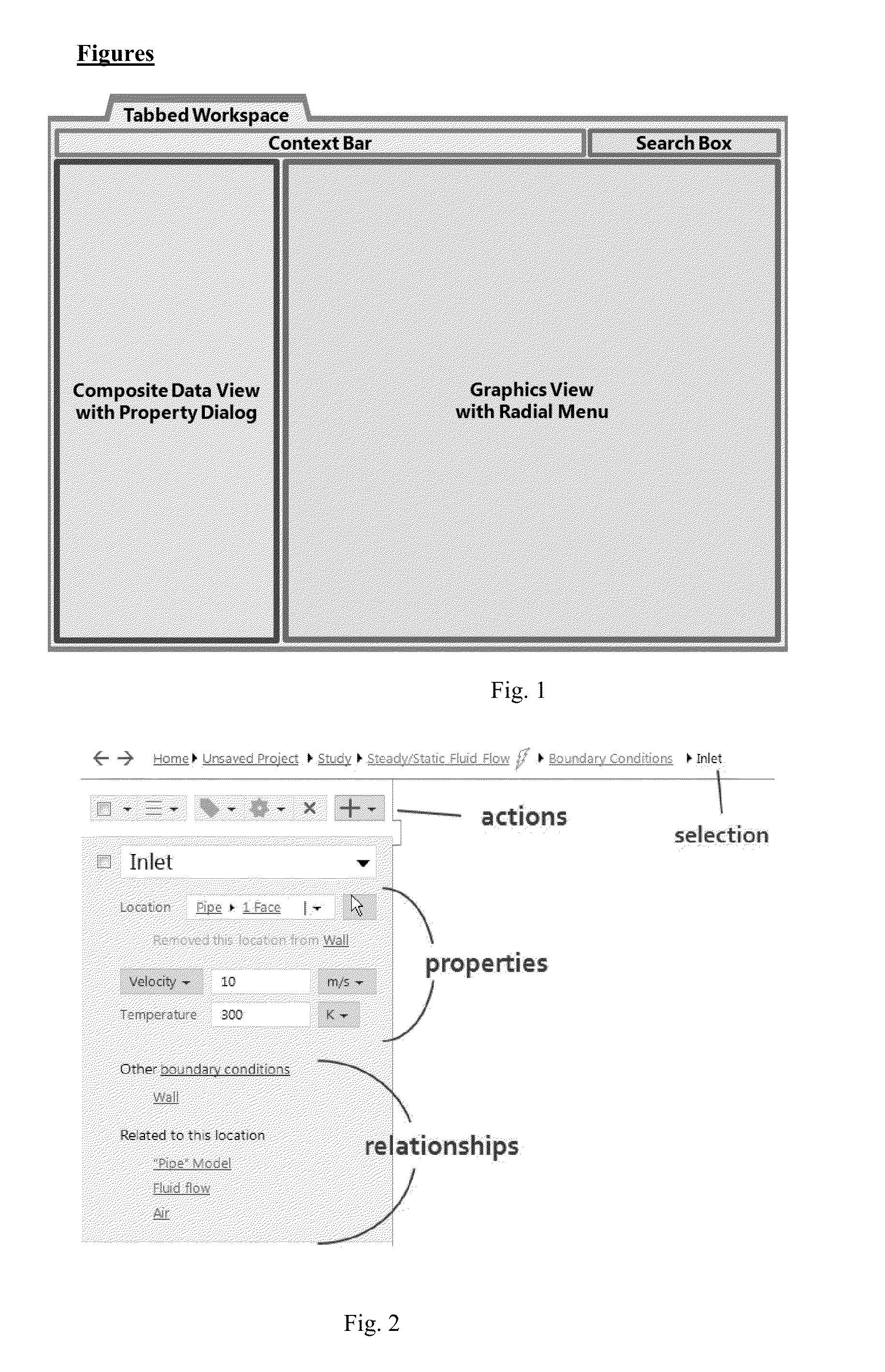

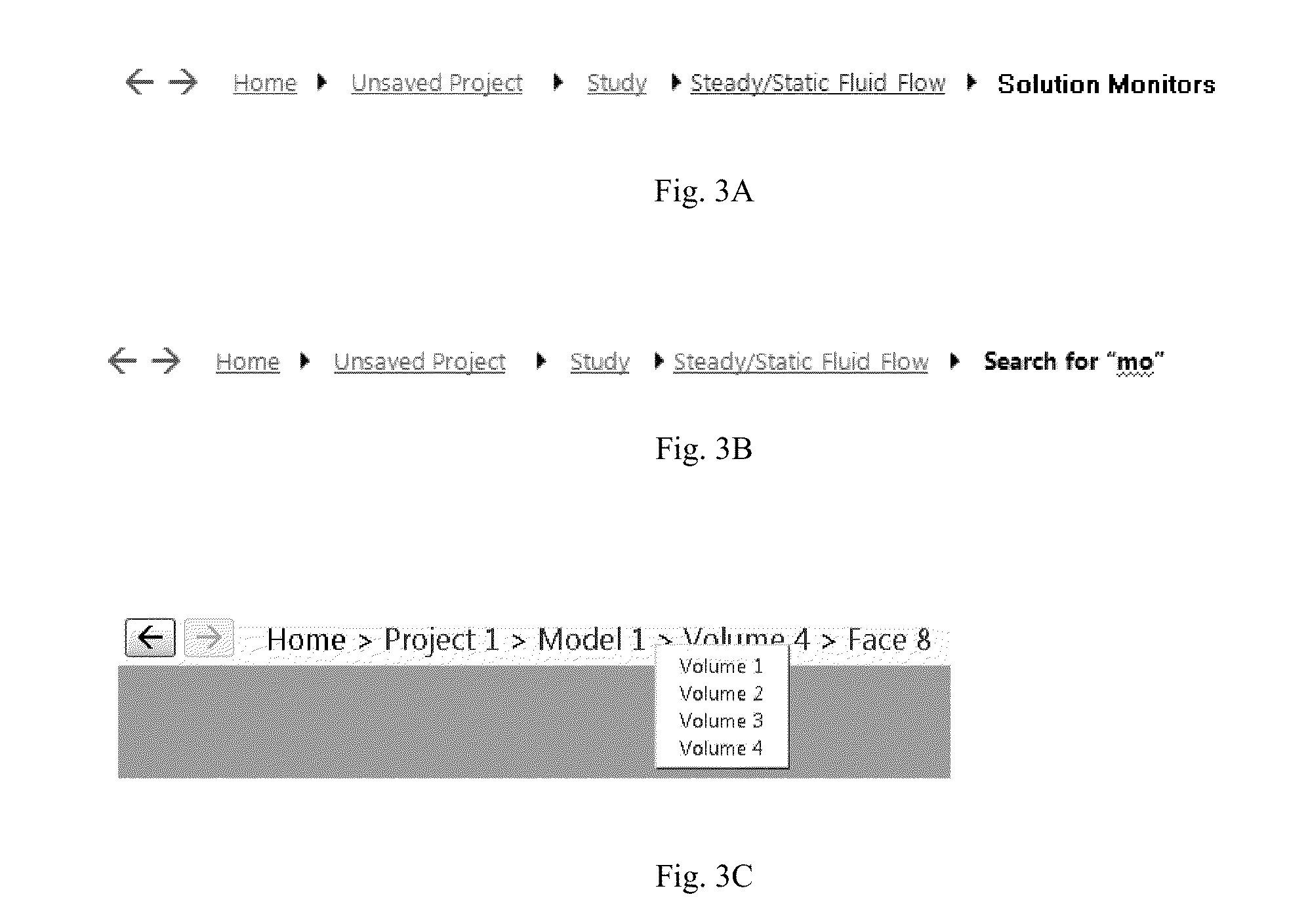

User interface and method of data navigation in the user interface of engineering analysis applications

A user interface and method. A user interface and method of using said interface that uniquely applies a web browser navigation style to engineering analysis applications is disclosed herein. The user interface, which may be implemented at least in part by use of a computer system, may comprise a browser panel, a tabbed workspace, a graphics view, a search box, and a search and select bar.

Owner:SAS IP

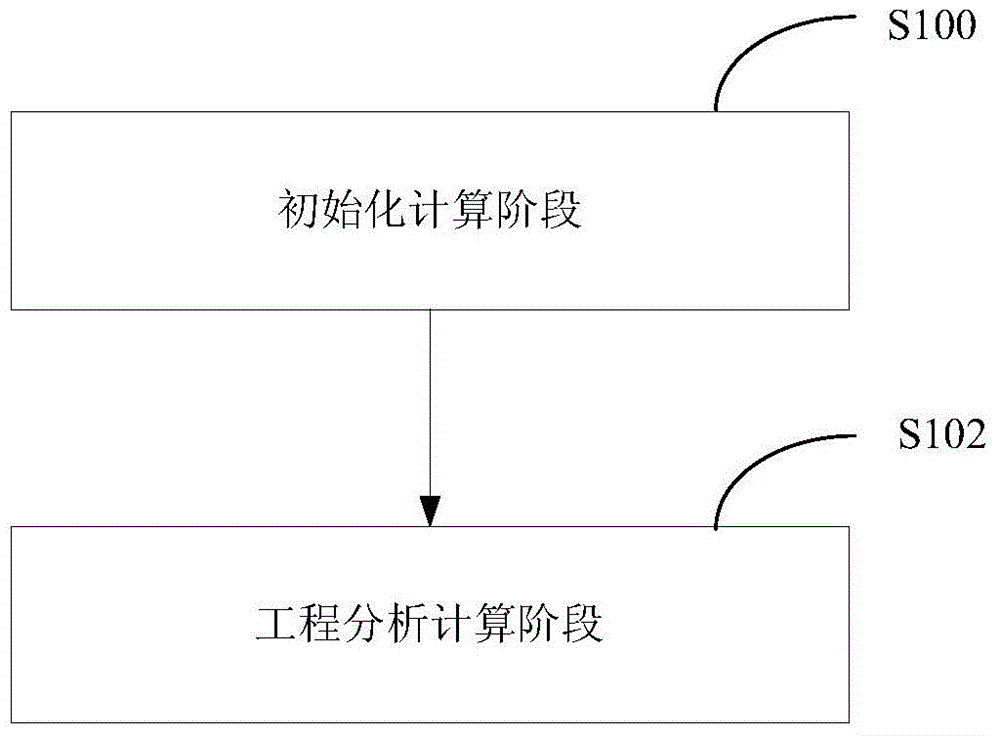

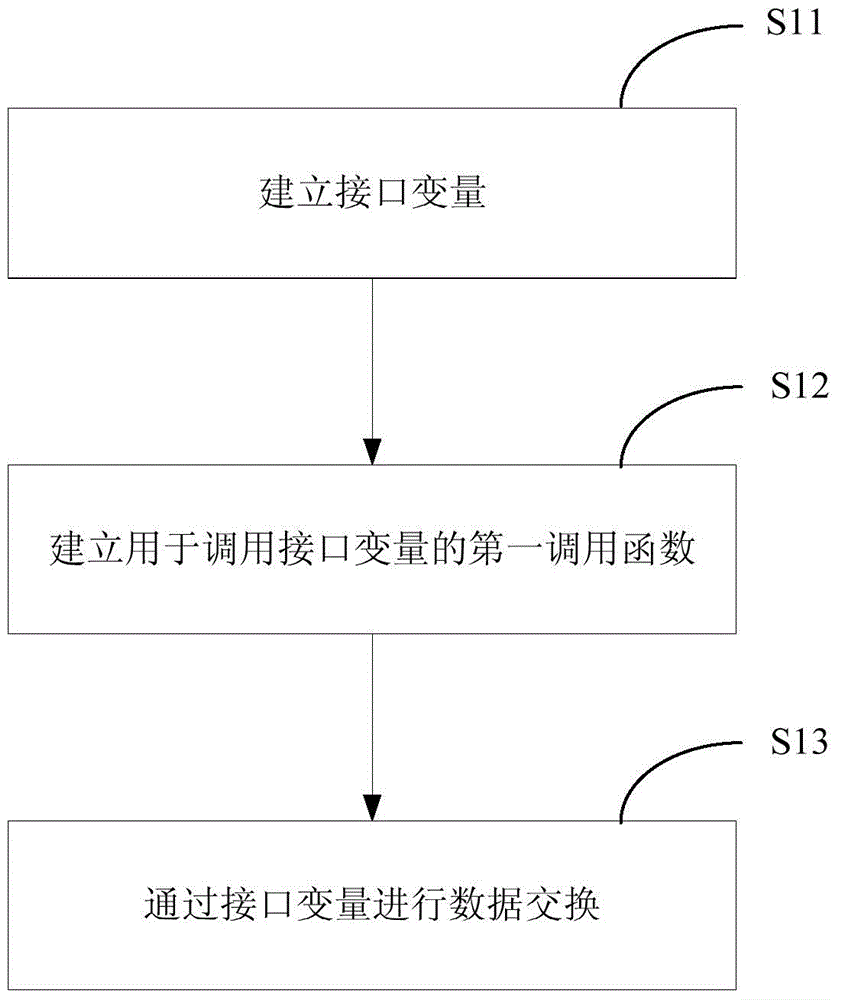

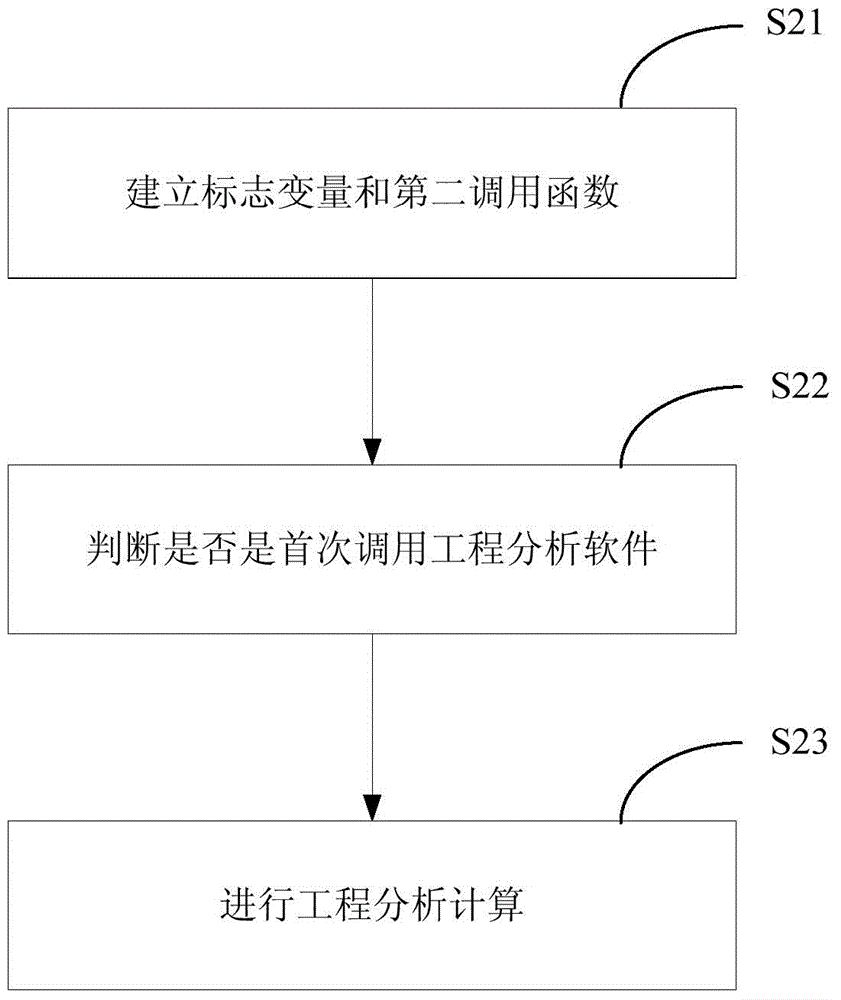

Method for integrating engineering analysis software in nuclear power simulation system and nuclear power simulation system

ActiveCN103559071ATroubleshooting Integrating Engineering Analysis SoftwareHigh precisionSoftware simulation/interpretation/emulationNuclear powerSoftware engineering

The invention discloses a method for integrating engineering analysis software in a nuclear power simulation system. The method is characterized by comprising the following steps of creating a data exchange mechanism, to be more specific, establishing an interface variable of the engineering analysis software and a first call function of the interface variable, and performing data exchange through the interface variable; creating a synchronous operation mechanism: establishing a marking variable, a calling period and a second calling function for calling the engineering analysis software, and judging whether calling the engineering analysis software is performed for the first time or not to enter an engineering analysis calculation stage. The invention further discloses the nuclear power simulation system. By means of the method for integrating the engineering analysis software in the nuclear power simulation system and the nuclear power simulation system, accuracy and credibility of nuclear power simulation can be improved.

Owner:中广核(北京)仿真技术有限公司 +1

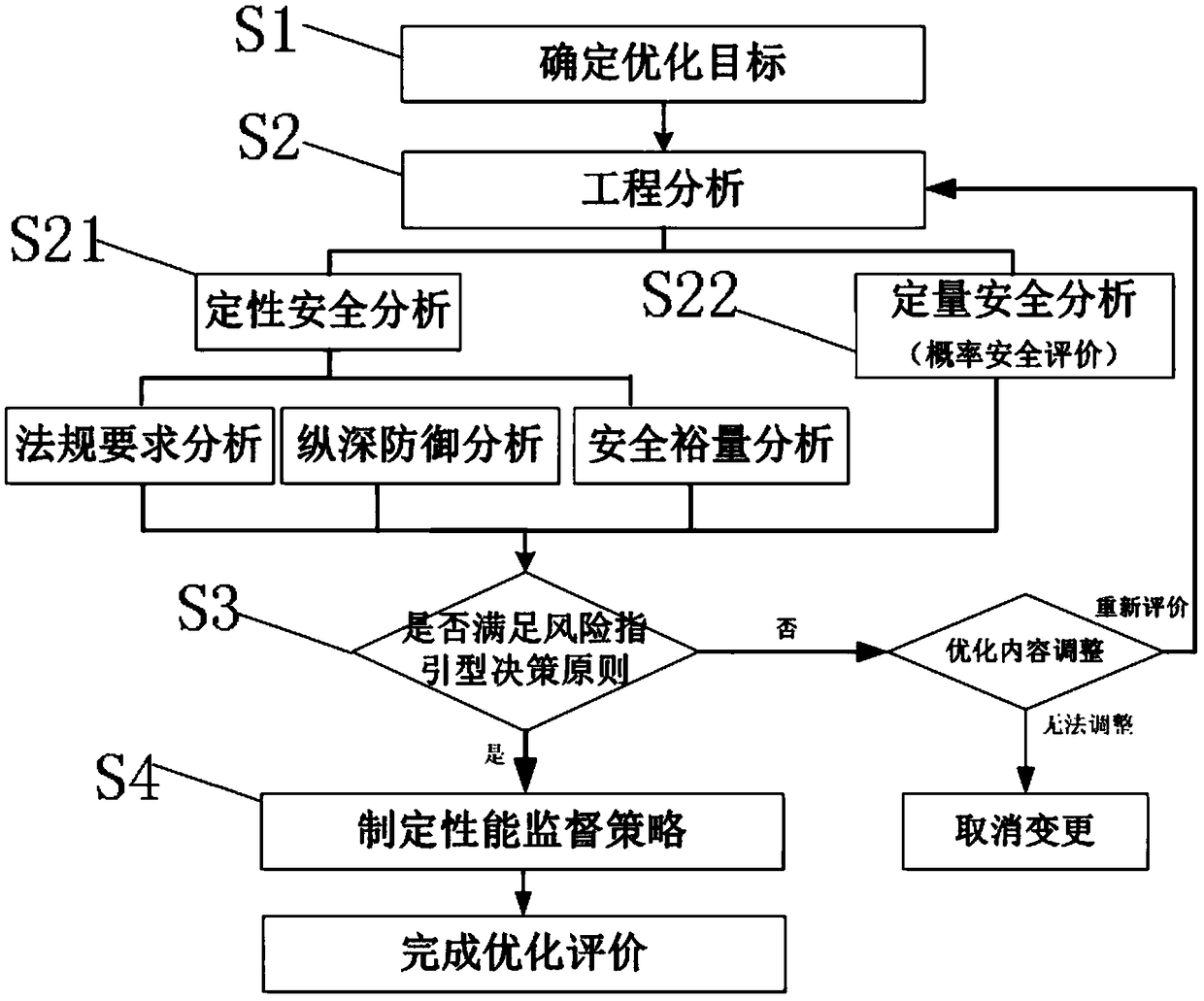

Risk-guided analysis method for optimization of technical specifications of nuclear power plants

InactiveCN109064035AProcess improvement and clarityOptimize risk assessmentResourcesNuclear powerEngineering

The invention provides a risk-guiding analysis method for optimizing technical specifications of a nuclear power plant, comprising the following steps: S1, determining an optimization objective: determining an optimization objective according to the actual situation of the nuclear power plant; S2, engineering analysis, specifically including step qualitative safety analysis and quantitative safetyanalysis; S21, qualitative safety analysis: evaluate and analyze the compliance of the regulation requirements, the compliance of the defense in depth and the compliance of the safety margin for theoptimization objective formulated in S1 step; S22, quantitative safety analysis is probabilistic safety assessment: evaluating the influence of optimization on the safety of nuclear power plant and the influence of optimization on the PSA model of the power plant, obtaining quantitative evaluation results, and comprehensively judging whether the optimization of the technical specifications of thenuclear power plant is acceptable or not; S3, risk-guiding decision-making principle judgment; S4, formulating a performance monitoring strategy; The invention establishes a set of risk evaluation system and a performance tracking strategy to ensure that the risk-guided decision principle is met optimally.

Owner:SUZHOU NUCLEAR POWER RES INST +3

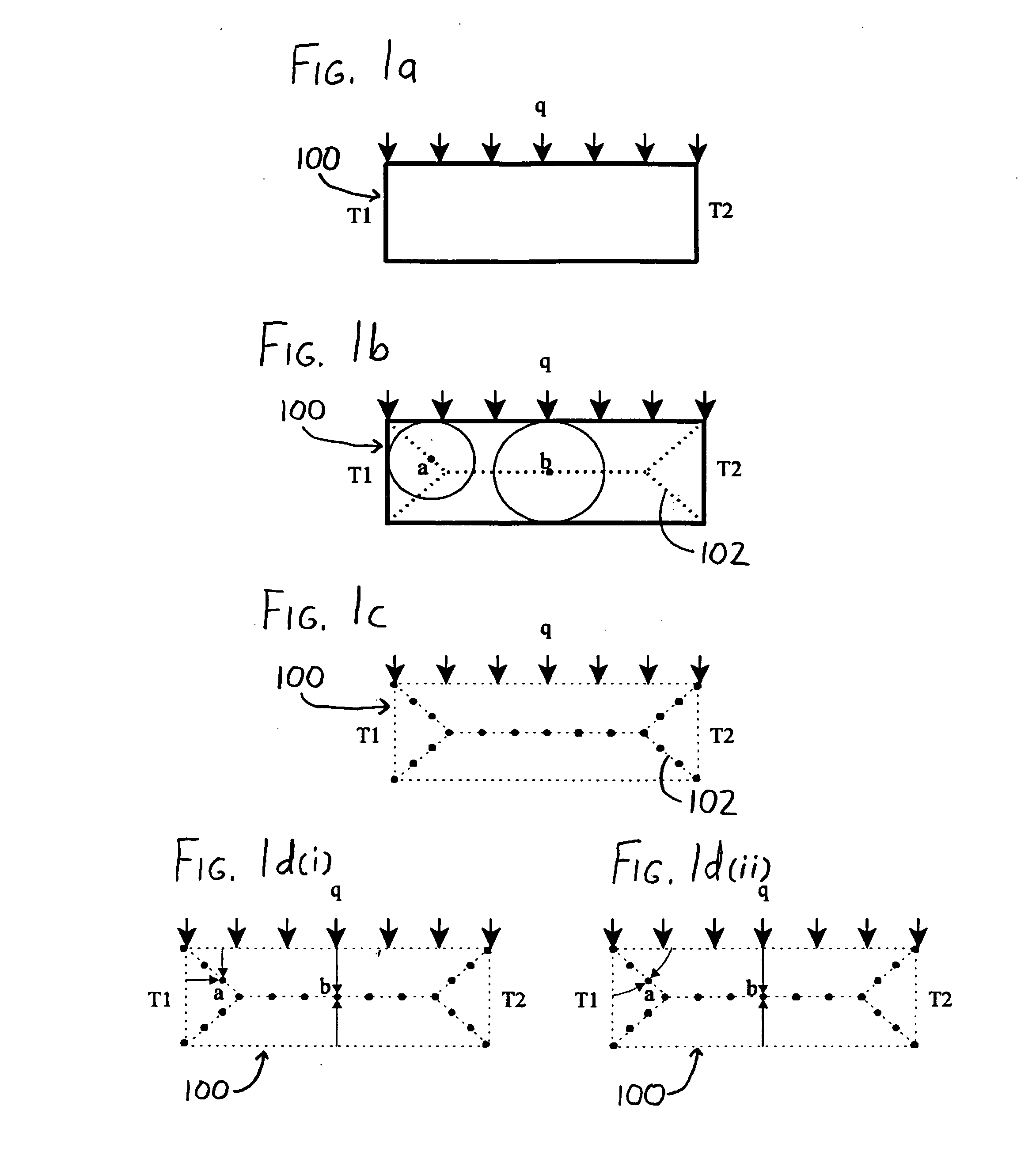

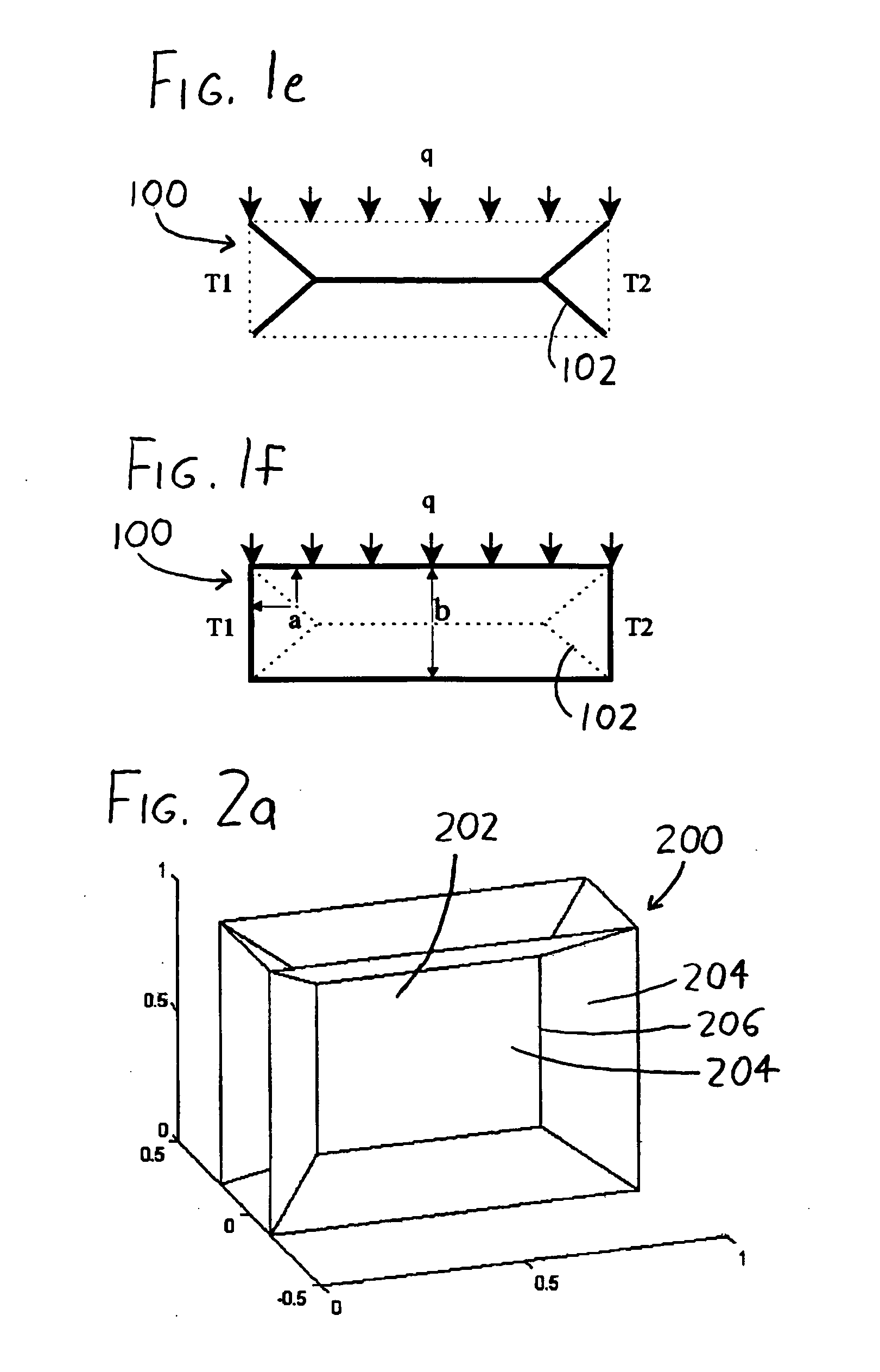

Analysis of boundary and/or initial value problems in thin objects and spaces

InactiveUS20060277008A1Computation using non-denominational number representationDesign optimisation/simulationGeometric modelingGoverning equation

A method for simplifying engineering analysis of CAD geometric models, one which retains much of the accuracy of detailed finite element (FE) analysis while avoiding its computational burdens, is described. A skeleton, such as an exact or approximate medial mesh, is defined within the model, and the skeleton is then meshed. Known field values (physical values of interest, and / or their derivatives) are then “projected” onto the skeleton, as by interpolation or coordinate transformation, and these field values and the governing equations for the model and its engineering problem are then used to solve for unknown field values across all or desired portions of the skeletal mesh. The newly-determined field values may then be projected outwardly from the skeletal mesh to the remainder of the geometric model, again via interpolation or other methods. The method is found to be particularly efficient and accurate (again in comparison to standard FE methods) when applied to thin geometric objects, e.g., metal or plastic sheet, ribbed plates, thin cavities in plastics-forming molds, etc.

Owner:WISCONSIN ALUMNI RES FOUND

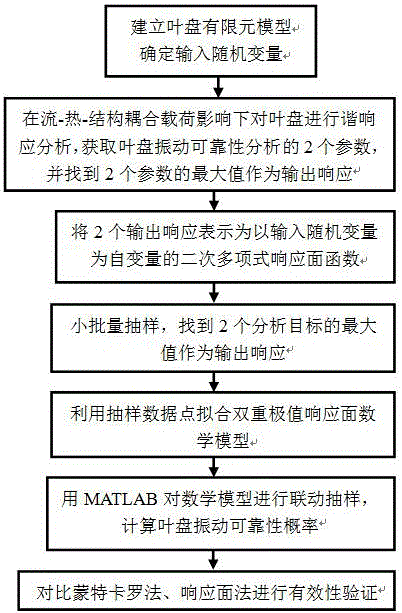

Dual extreme value response surface method for calculating leaf disc vibration reliability

InactiveCN106485032AImprove computing efficiencyReduce computing costDesign optimisation/simulationComplex mathematical operationsMathematical modelEngineering

Owner:HARBIN UNIV OF SCI & TECH

Photoinduced thermal deformation image quality analyzing method of transmission-type optical element

InactiveCN102620917AFitting the temperature field is accurateSimple methodTesting optical propertiesPath lengthImaging quality

The invention belongs to the thermal-optical field of optical instruments and relates to a photoinduced thermal deformation image quality analyzing method of a transmission-type optical element. According to the method, factors such as atmosphere, power, wavelength, refractive index and temperature coefficient, are considered; a thermal analysis model is established through finite element software I-DEAS (Integrated Design Engineering Analysis Software), radiation heat exchange and conduction heat exchange of all surfaces are considered to solve the temperature field distribution of the optical element and the coordinate position and deformation amount of each node; optical surface face-type fitting is realized through a Zernike polynomial and a novel cylindrical coordinate fitting method is provided to realize accurate fitting of a temperature field from characteristics of a heat source of an optical system, thereby calculating a geometrical journey through which lights pass at different clear aperture positions and a reactive index function of material, so as to obtain the wave-front distortion and PV (Page View) and RMS (Root-Mean-Square) values. The method disclosed by the invention has the advantages of simplicity in realization, high accuracy and good program generality, and is suitable for calculating the wave aberration of any transmission-type optical element.

Owner:CHANGCHUN UNIV OF SCI & TECH

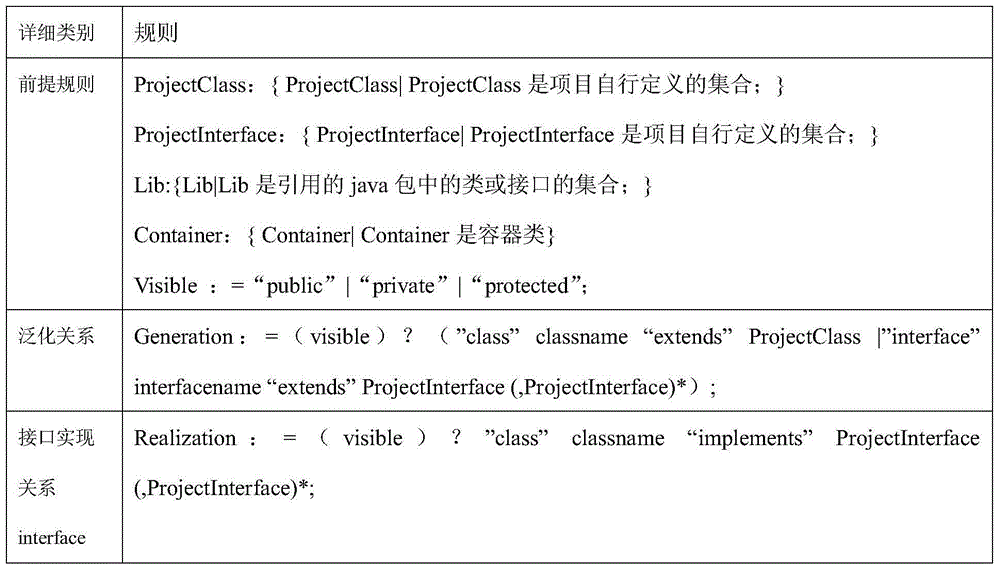

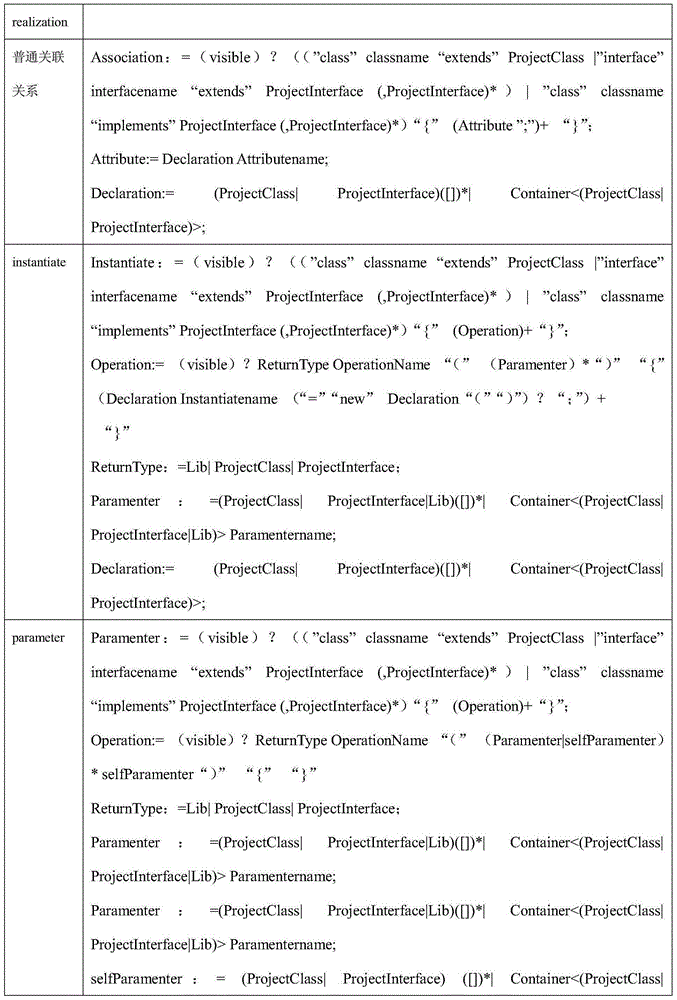

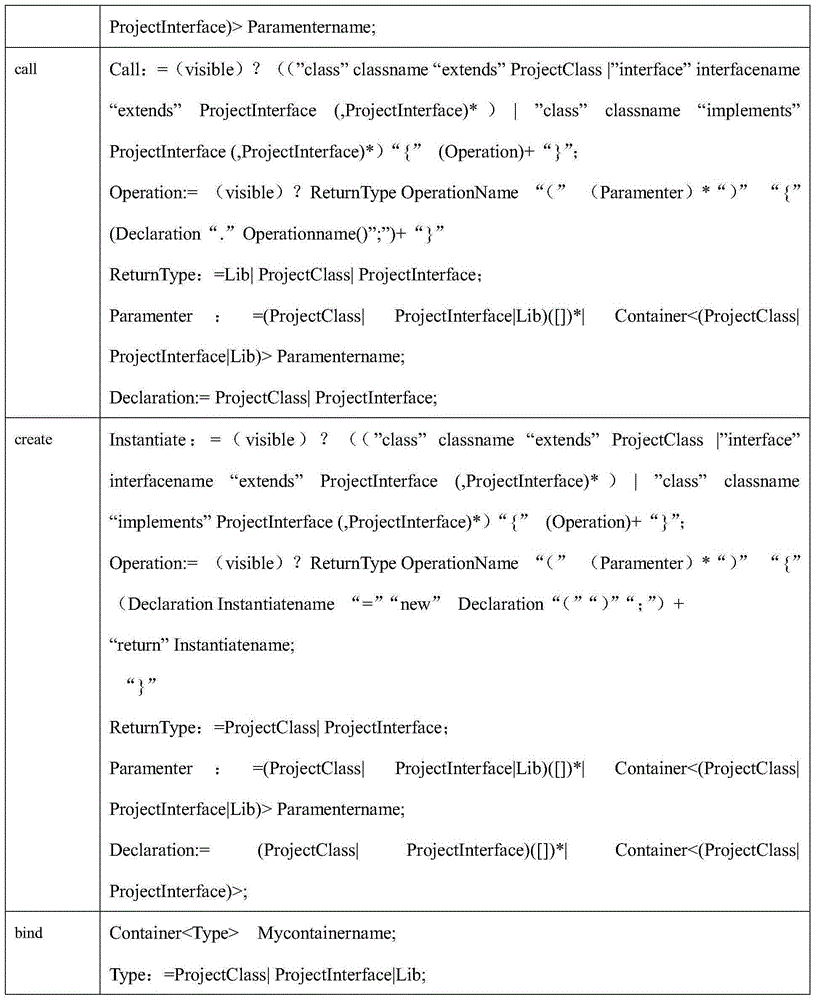

Reverse engineering based model base structuring method

InactiveCN104391706ARealize the structureSpecial data processing applicationsSpecific program execution arrangementsSource code fileRelational database

The invention discloses a reverse engineering based model base structuring method. The reverse engineering based model base structuring method includes steps of capturing source codes of an open source project from Internet by web crawlers; clearing the captured source codes to acquire effective source code files; subjecting the effective source codes to reverse engineering analysis to structure an initial UML (unified modeling language) class diagram; simplifying the initial UML class diagram to obtain a simple UML class diagram; storing the simple UML class diagram into a diagram database. A great many source codes on Internet can be converted into UML class diagram models, these models are stored into a non-relation database after simplified, and a model base is structured. By simplifying the reverse engineering, the class diagram models generated contain more code structure information, and the reverse engineering based model base structuring method is more accurate than other methods.

Owner:NANJING UNIV

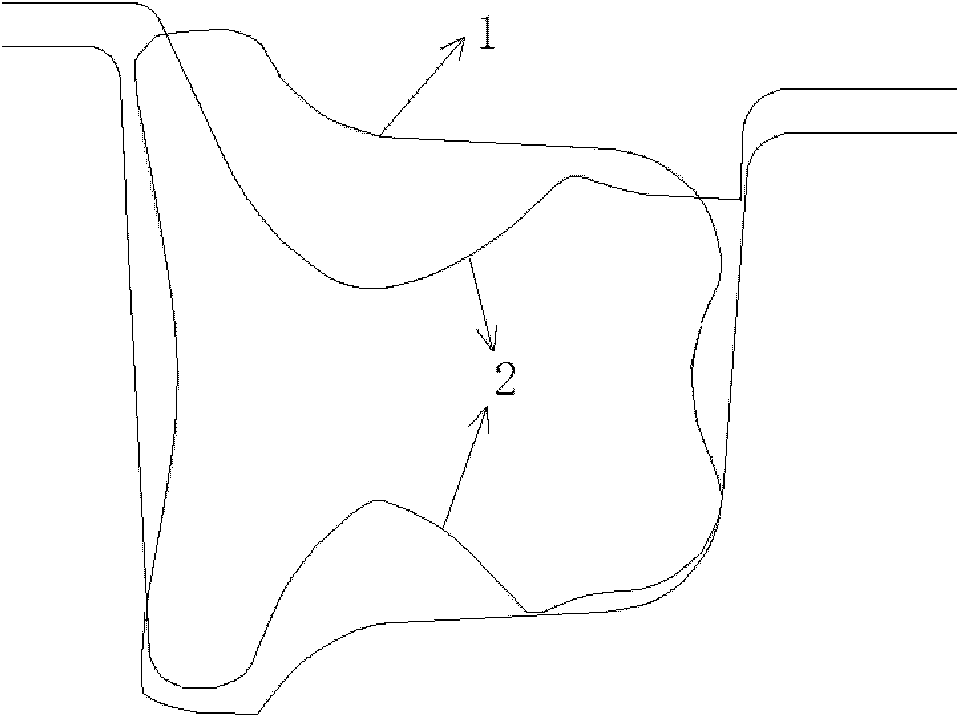

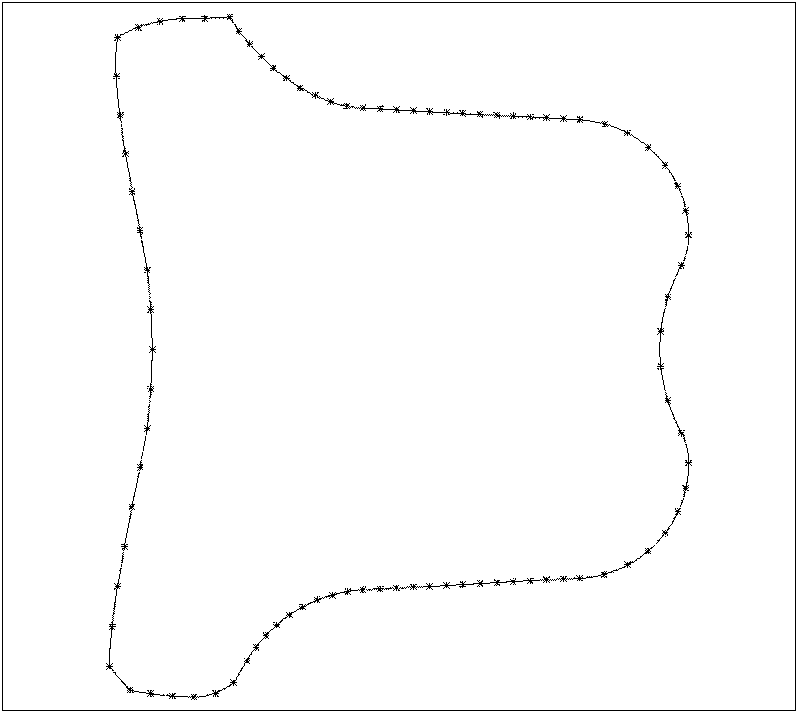

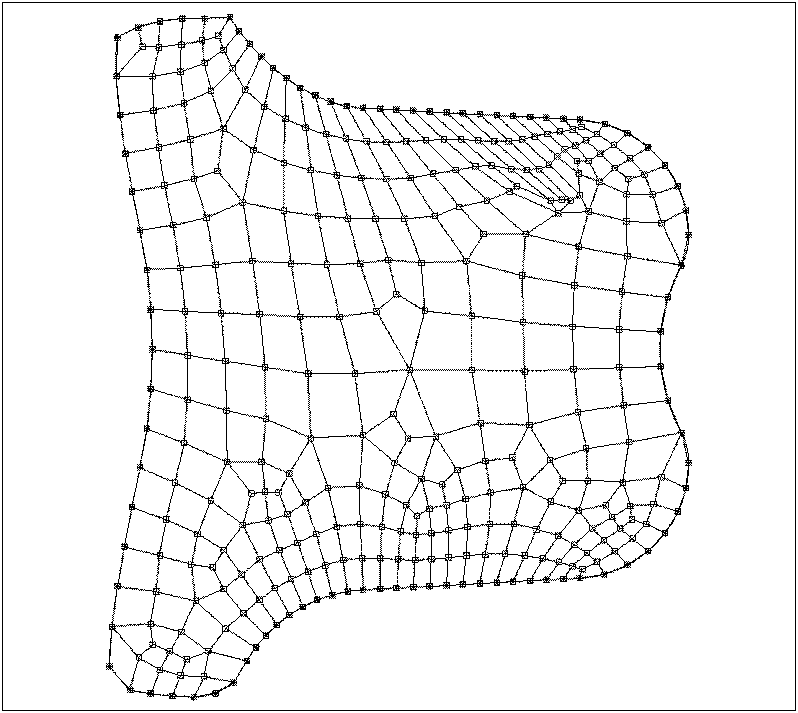

Mesh generation method of modeling structural steel knifing pass rolling process

InactiveCN103034745AMeet the needs of simulationThe simulation needs to be accurateSpecial data processing applicationsCouplingElastic plastic

The invention relates to the pretreatment field of the finite element engineering analysis, in particular to a mesh generation method of a modeling structural steel knifing pass rolling process. The mesh generation method of the modeling structural steel knifing pass rolling process is characterized by including the steps that (101) seed points are arranged on the outline boundary in the two dimensional plane of the rolled piece with an original shape, (102) mesh generation is proceed in the two dimensional plane to form quadrilateral elements, and (103) the meshes in the two dimensional plane are expanded to form three-dimensional finite element meshes which is the rolled piece model eight nodes hexahedron mesh generation. Compared with the prior art, the mesh generation method of the modeling structural steel knifing pass rolling process has the advantages that three-dimensional finite element meshes produced by the mesh generation method can meet the requirement of structural steel knifing pass rolling process modeling, and finally achieves the aim of modeling knifing pass rolling process accurately and successfully; the rolled piece meshes produced by the generation method can meet the requirement of three-dimensional elastic-plastic heat-machine coupling model analog, ensures enough computational accuracy, and improves stability of calculating.

Owner:ANGANG STEEL CO LTD

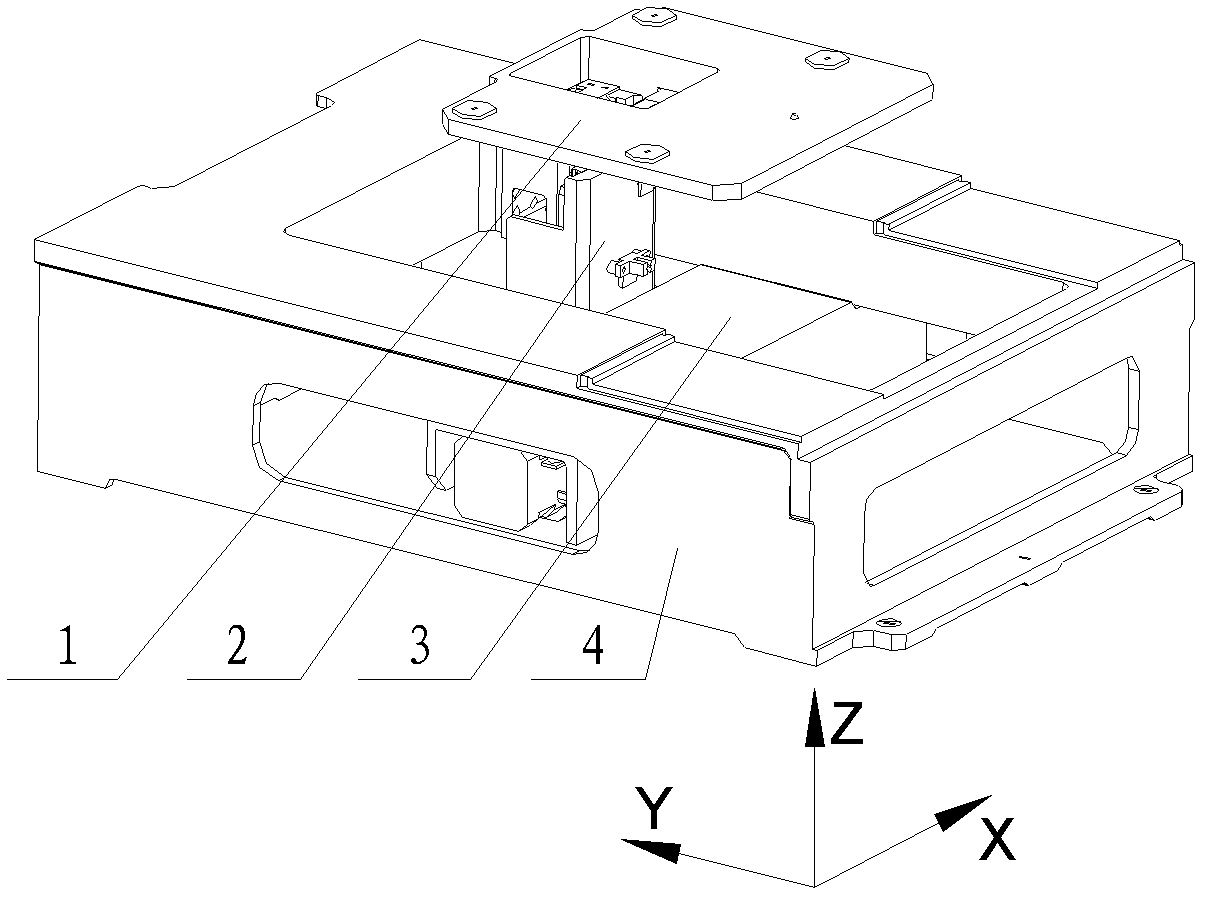

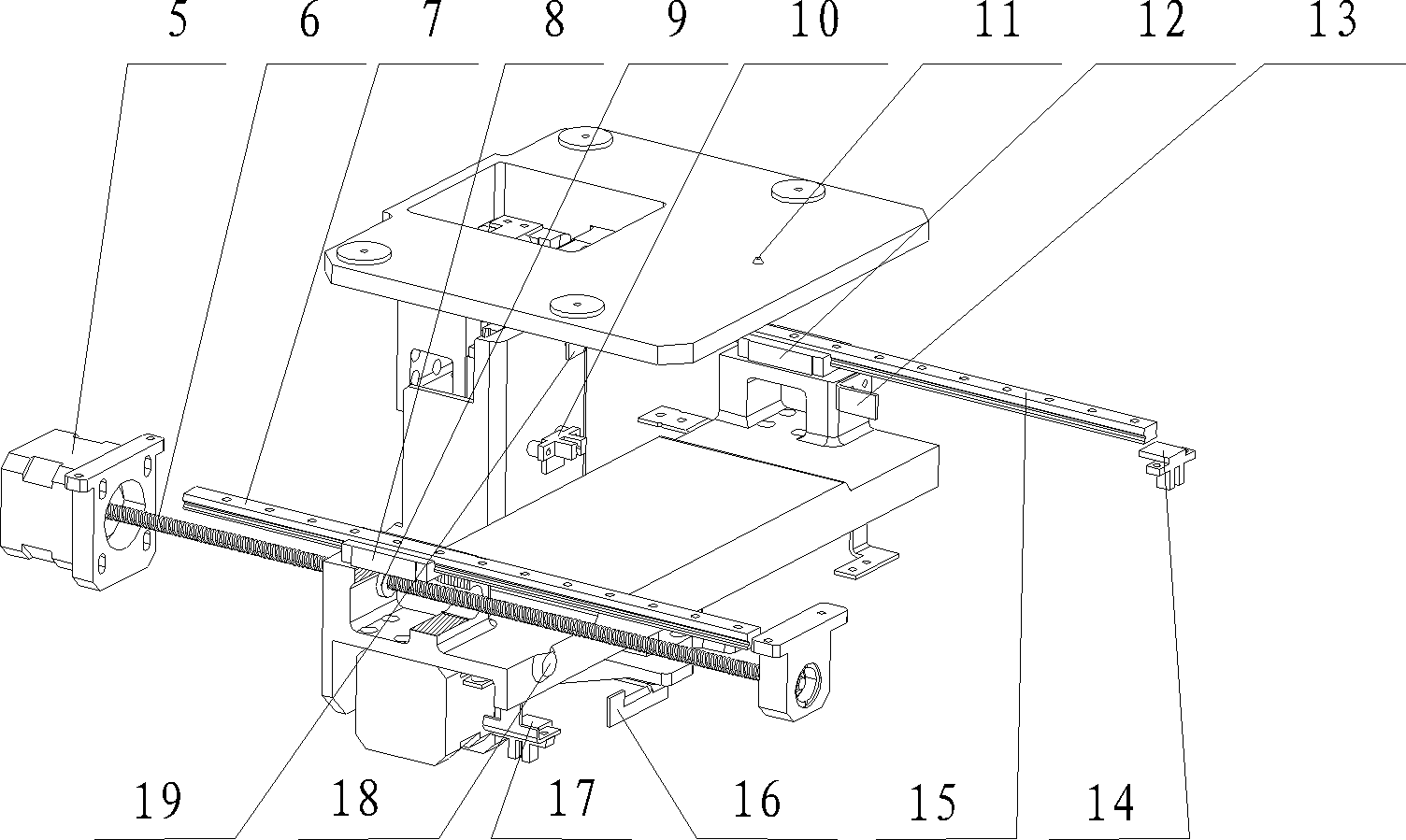

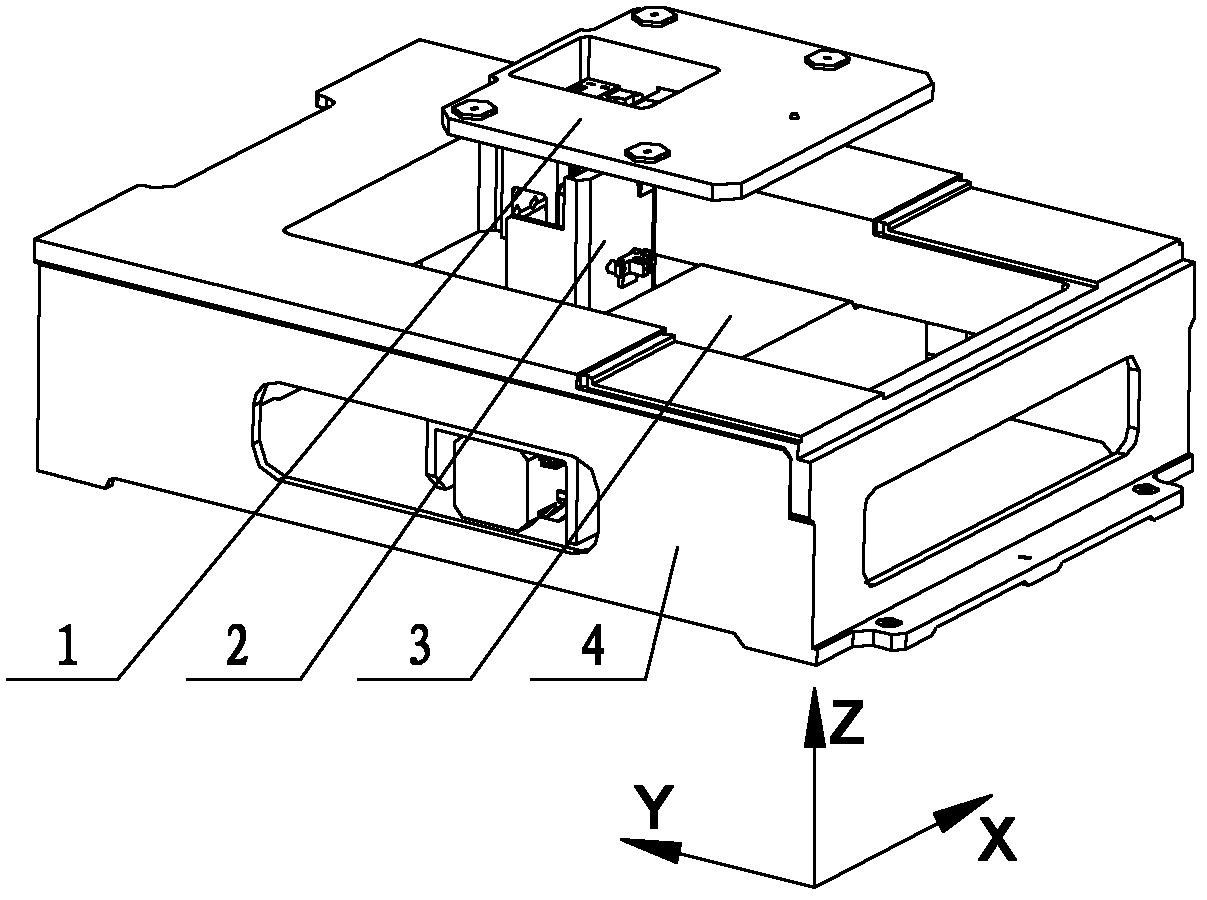

Full-automatic three-dimensional precision positioning motion sample injector

The invention provides a full-automatic three-dimensional precision positioning motion sample injector which comprises a Y-axis movement assembly, an X-axis movement assembly, a Z-axis movement assembly and a tray, wherein the Y-axis movement assembly comprises a Y-axis movement base, a Y-axis left guide rail, a Y-axis left guide rail slider, a Y-axis right guide rail, a Y-axis right guide rail slider and a Y-axis drive mechanism; the Y-axis left guide rail and the Y-axis right guide rail are connected with the Y-axis movement base; and the Y-axis left guide rail is connected with the Y-axis drive mechanism. The X-axis movement assembly and the Z-axis movement assembly comprise corresponding movement bases, guide rails, guide rail sliders and drive mechanisms. The X-axis movement base is suspended on the Y-axis movement base through connecting the Y-axis left guide rail slider and the Y-axis right guide rail slider, the Z-axis movement base is suspended on the X-axis movement base through connecting the X-axis guide rail slider, and the tray is connected with the Z-axis guide rail slider. The full-automatic three-dimensional precision positioning motion sample injector has the advantages of small occupation space, high position precision, stable performance and safety in operation, and can be applied to the accurate positioning of a sample injector device of analytical instruments in the fields such as medical treatment and public health, biological engineering, chemical pharmacy, chemical engineering analysis and the like.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

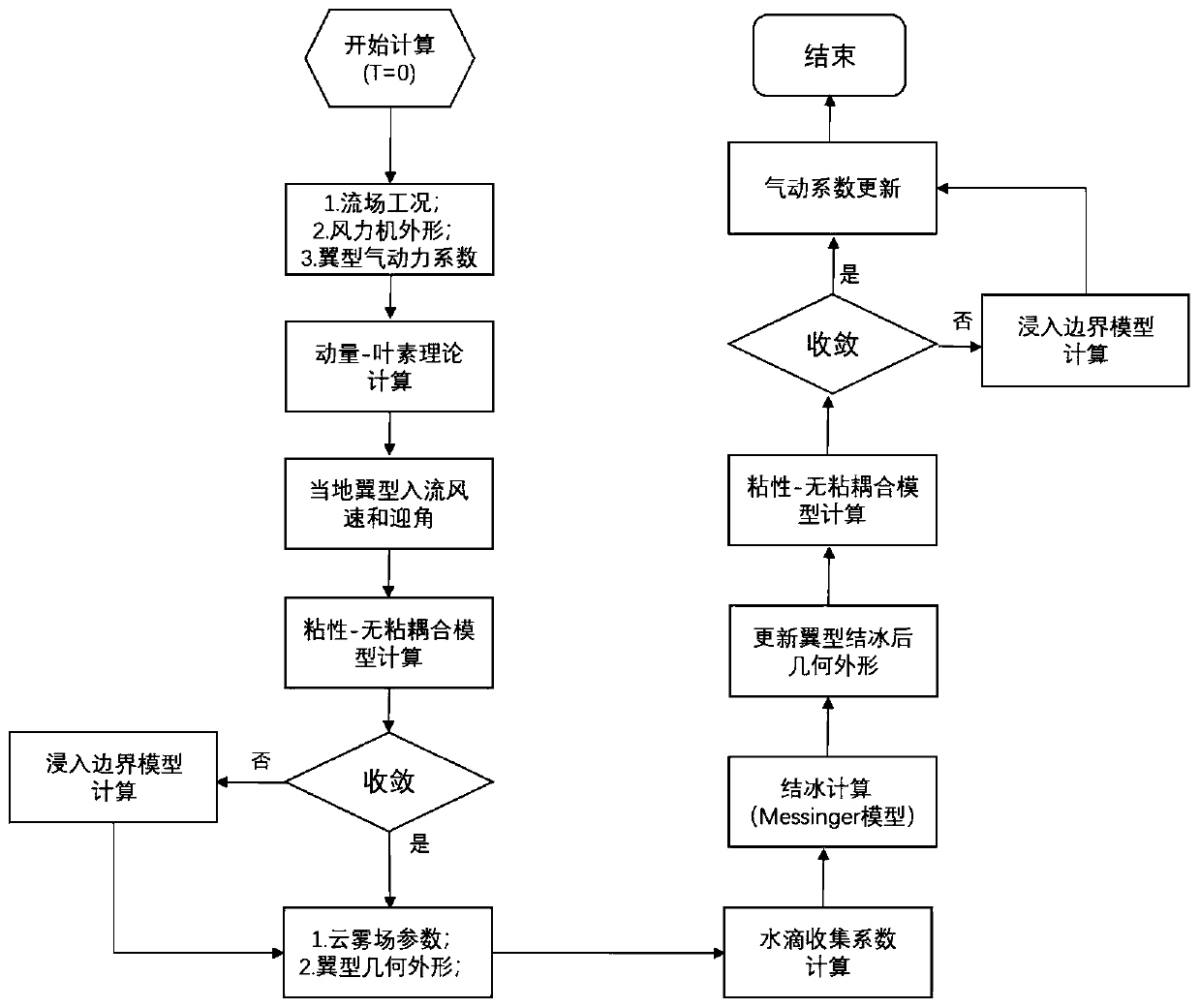

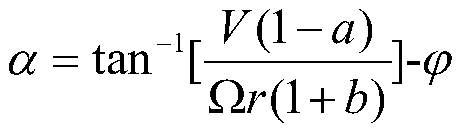

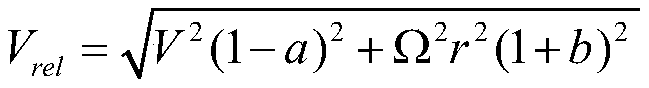

Numerical simulation method for icing of wind turbine

InactiveCN109751204ASimulation is accurateEffective simulationMachines/enginesWind motor monitoringMomentumCoupling

The invention relates to the technical field of testing of wind turbines, and discloses a numerical simulation method for icing of a wind turbine. According to the numerical simulation method for icing of the wind turbine, an ice-coated wind turbine quasi-three-dimensional calculation model is put forward based on a momentum-blade element theory model through a viscous non-sticky coupling method and an immersion boundary method; the viscous non-sticky coupling method has the characteristics of high calculation efficiency and accurate calculation results for wing-type turbulent flow under the attachment flow condition; and through the orthogonal Cartesian grid-based immersion boundary method, the accuracy of flow separation calculation can be ensured while grid reconstruction is avoided. The ice-coated wind turbine quasi-three-dimensional calculation model is based on the analysis of the momentum-blade element theory model, the problem of icing of the three-dimensional wind turbine is converted into a problem of two-dimensional wing-type icing extending towards different positions, and on this basis, the advantages of the viscous non-sticky coupling method and the advantages of theimmersion boundary method are sufficiently combined to achieve accurate and efficient simulation of icing of the wind turbine, and an important foundation is laid for engineering analysis of the ice-coated wind turbine.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

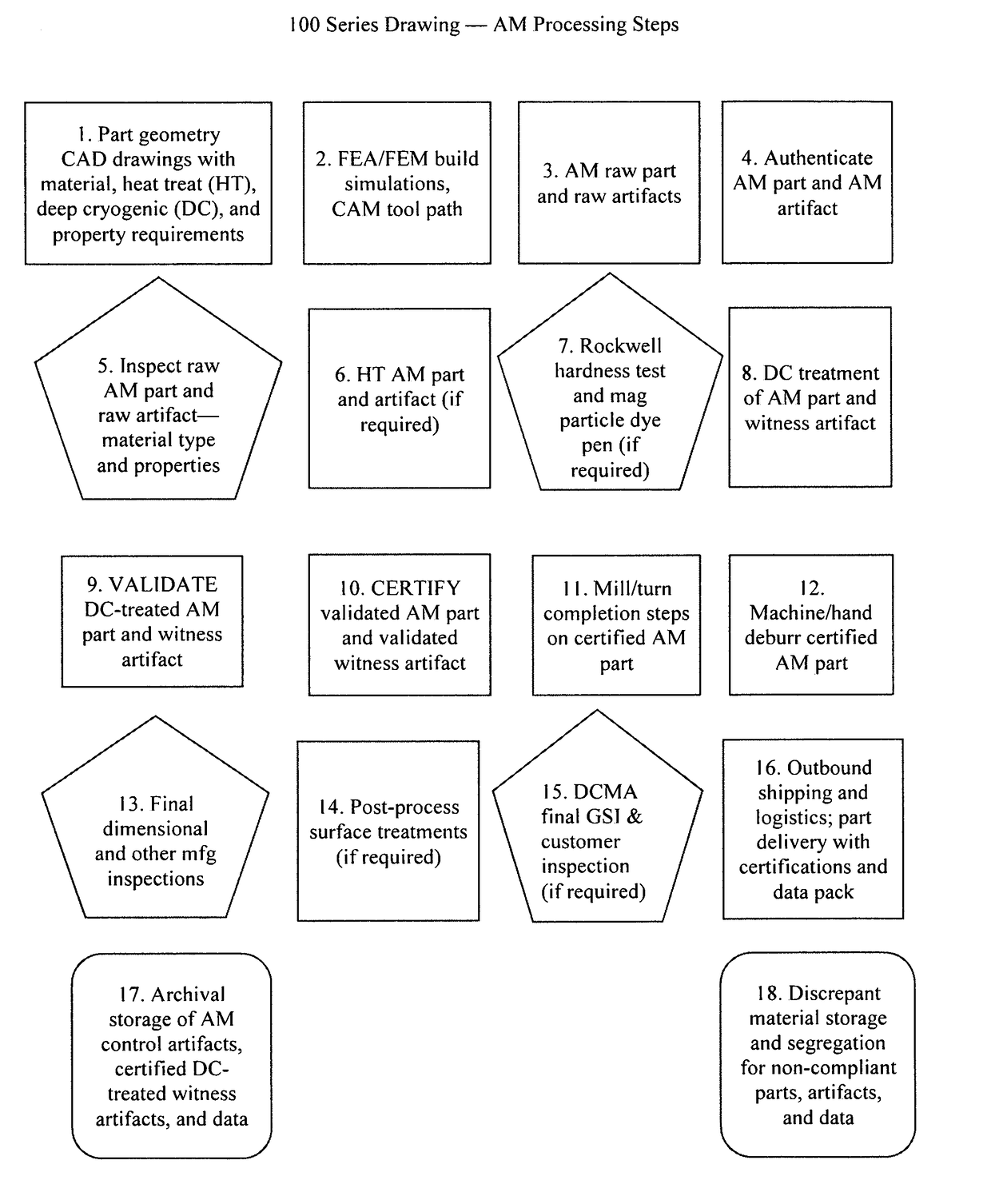

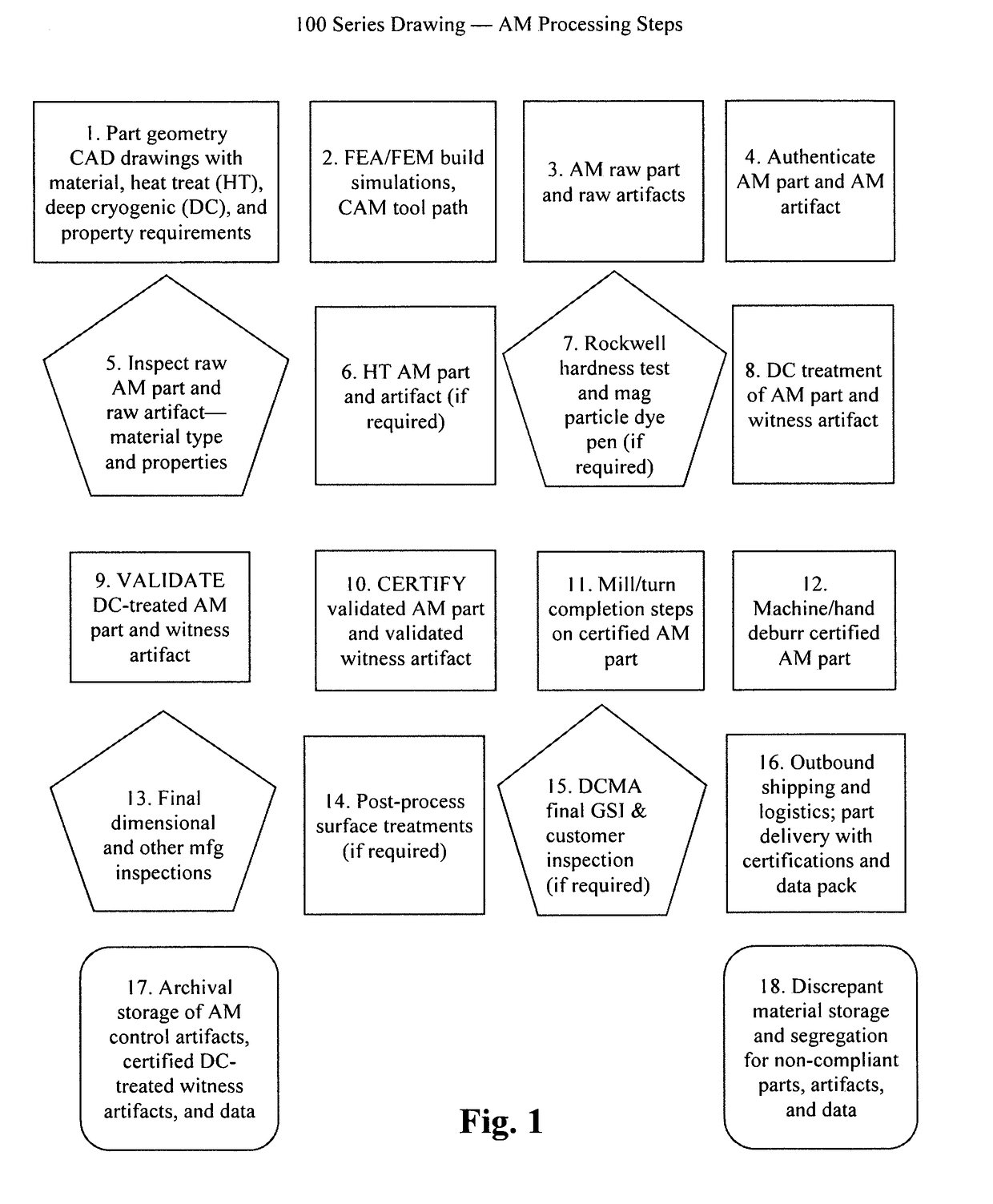

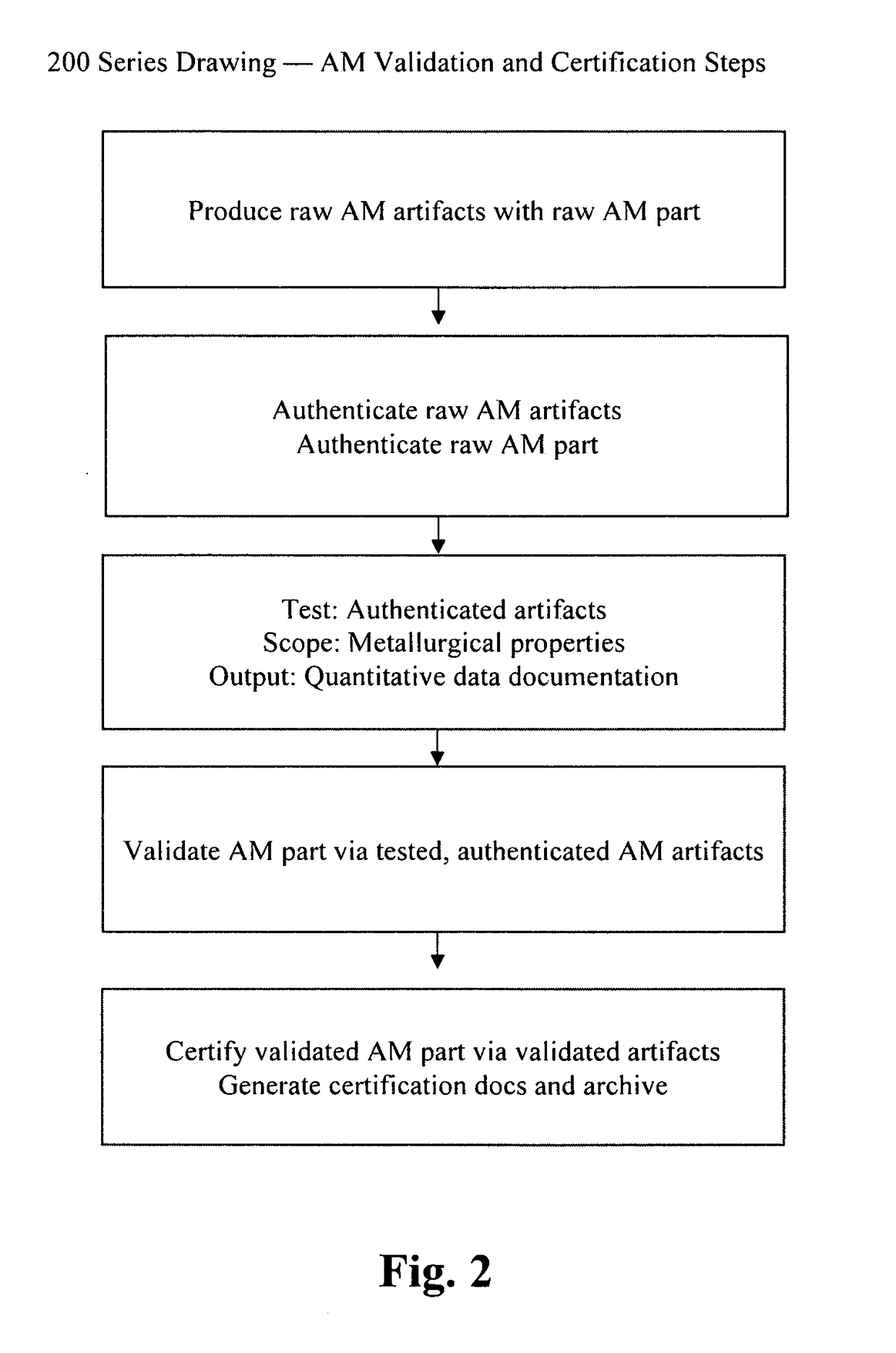

Authentication, Testing and Certification of Additive Manufactured Items and Cryogenically Processed Additive Manufactured Items

Embodiments describe a means to authenticate manufacture of AM parts to a third party using witness artifacts. Embodiments describe cryogenic processing of additive manufactured (AM) metal and metal-matrix items to improve mechanical, physical, electrical, and / or chemical properties. Embodiments also describe a method of scientific testing and engineering analysis that validate cryogenically treated, AM items by measuring and contrasting enhancements in wear, corrosion, fracture, fatigue, and electro-chemical properties against baseline samples. Embodiments also describe a certification method, using a MIL-STD format digitized or written report that outputs a standards-based, First Article Test report and certification statement. The embodiments describe a lean processing method and value stream map that captures defects and identifies and segregates discrepant parts along with proxy witness test samples. Embodiments also describe an archival storage method of authenticated, validated, and certified artifacts, identical in material alloy and metallurgical characteristics to the in-use AM part, that meet AS9100 ISO quality standards for such critical applications as space flight, military, FDA, medical, nuclear, and civilian aviation.

Owner:CAHN JACK

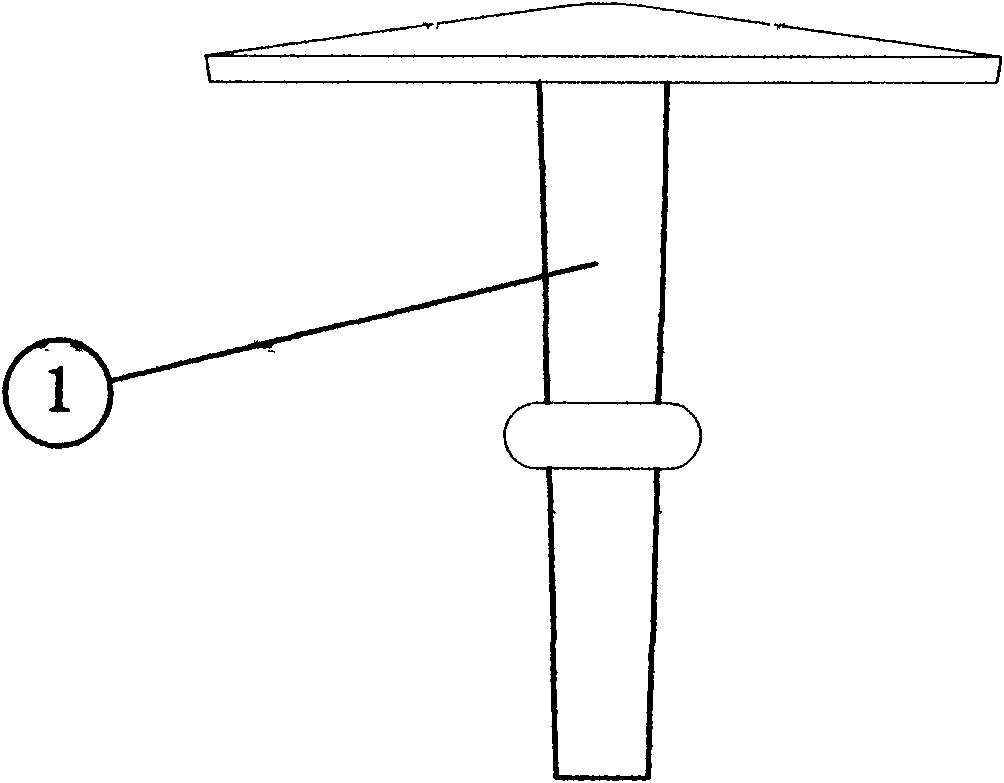

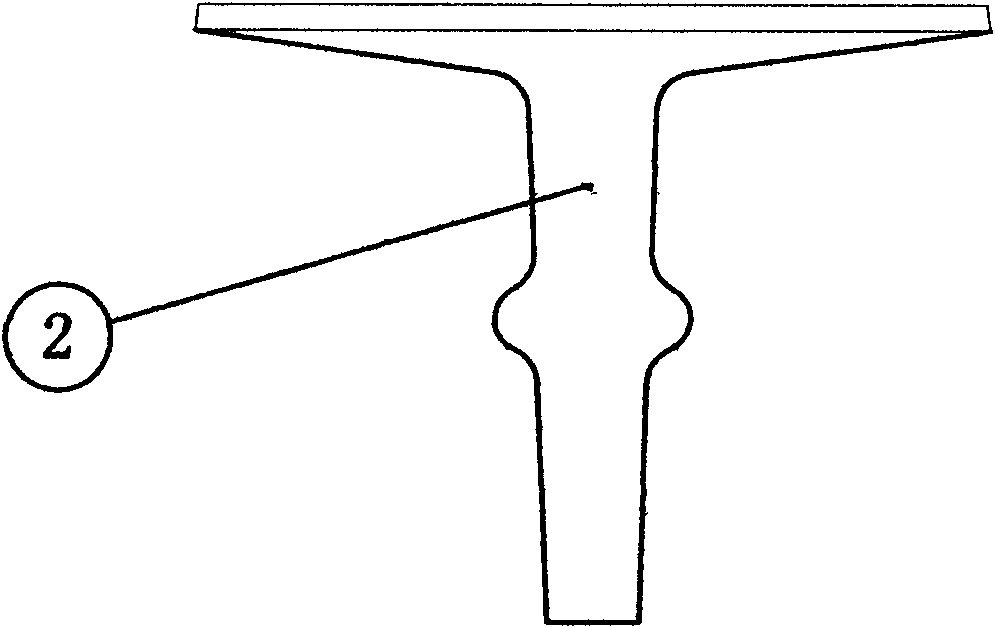

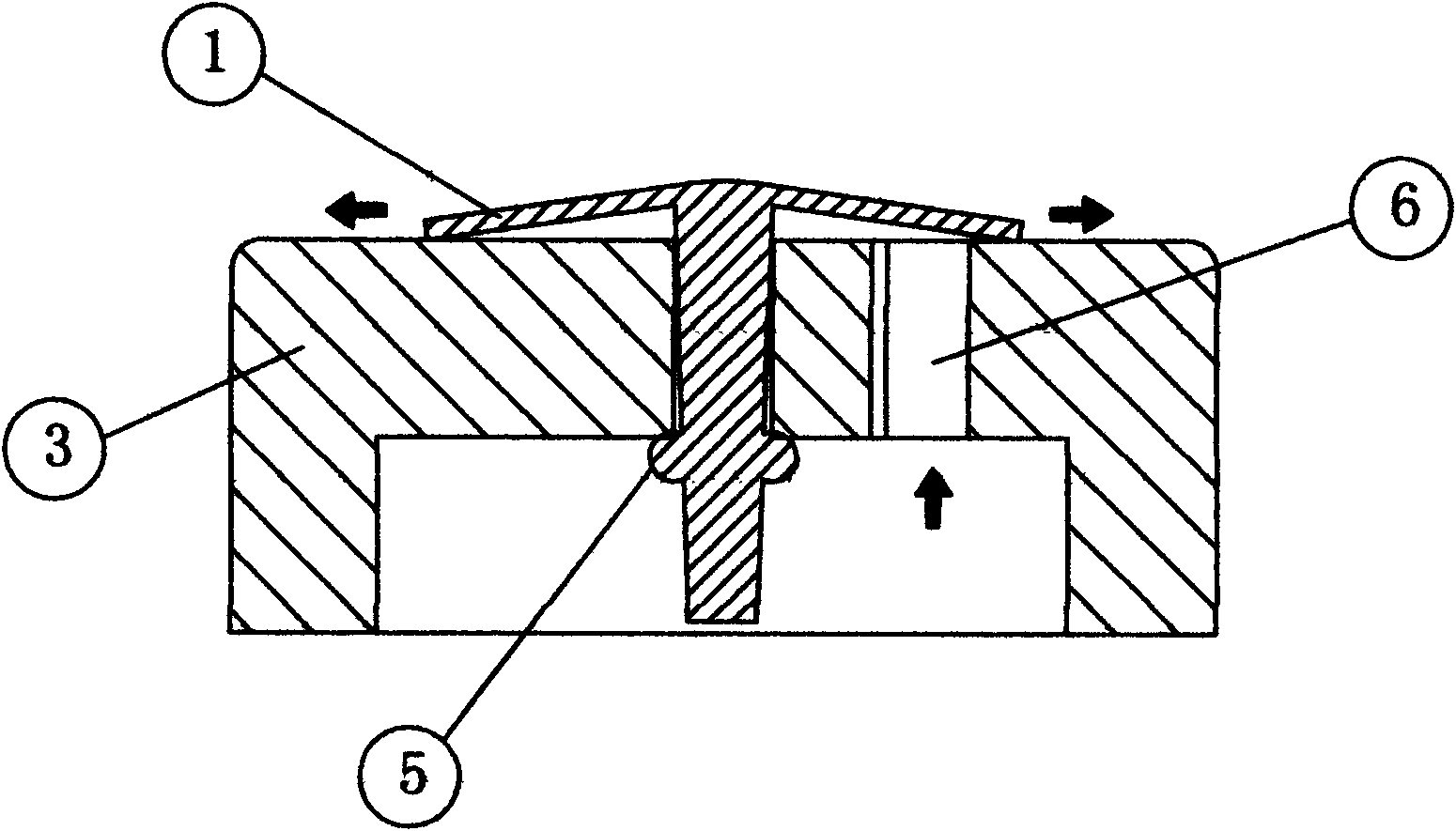

Umbrella valves dedicated to piezoelectric pumps

InactiveCN102287365ASimple structureQuick responsePositive displacement pump componentsCheck valvesMedical equipmentAutomatic control

An umbrella valve dedicated for use in a piezoelectric pump. Among micropump pump valves are actuation source-less valve, piezoelectrically actuated valve, thermally actuated valve, memory alloy valve, and piezoelectric valve, all of which have a certain shortcoming, for instance, the valves have complex structures and increased manufacturing costs, some provide a product with poor consistency and poor air-tightness. The umbrella valve dedicated for use in the piezoelectric pump structurally consists of the umbrella valve (A1) and a valve frame (A3). A valve rod of the umbrella valve is passed through and arranged at a central through hole of the valve frame. Distributed around the central through hole of the valve frame is a flow-pass through hole (6). The flow-pass through hole correspondingly matches the opening and closing of the umbrella valve that is opened. The umbrella valve is provided with characteristics of a simple structure, increased sensitivity, great sealing effect, reduced manufacturing costs, and great operational performance, and is applicable in the fields and scenarios of various fluids, comprising gases, water, and specifically liquids, such as in water processing, chemical engineering analysis, medical equipment, biomedicine, and automatic control.

Owner:胡军 +1

Method and system for mesh-free analysis of general three-dimensional shell structures

ActiveUS7499050B2Computation using non-denominational number representationDesign optimisation/simulationThree-dimensional spaceComputer science

A method, system and computer program product pertained to engineering analysis of a general three-dimensional (3-D) shell structure using the mesh-free technique is disclosed. The structural responses are solved with mesh-free technique after the 3-D shell structure is mapped to a two-dimensional plane. According to one aspect, the present invention is a method for mesh-free analysis of a general three-dimensional shell structure, the method comprises: defining the general shell structure as a physical domain represented by a plurality of nodes in a three-dimensional space, creating a plurality of projected nodes by mapping the plurality of nodes in the three-dimensional space onto a two-dimensional plane, assigning a plurality of domain of influences, one for each of the plurality of projected nodes, and calculating a solution of the physical domain using a set of mathematical approximations pertaining to each of the plurality of projected nodes.

Owner:ANSYS INC

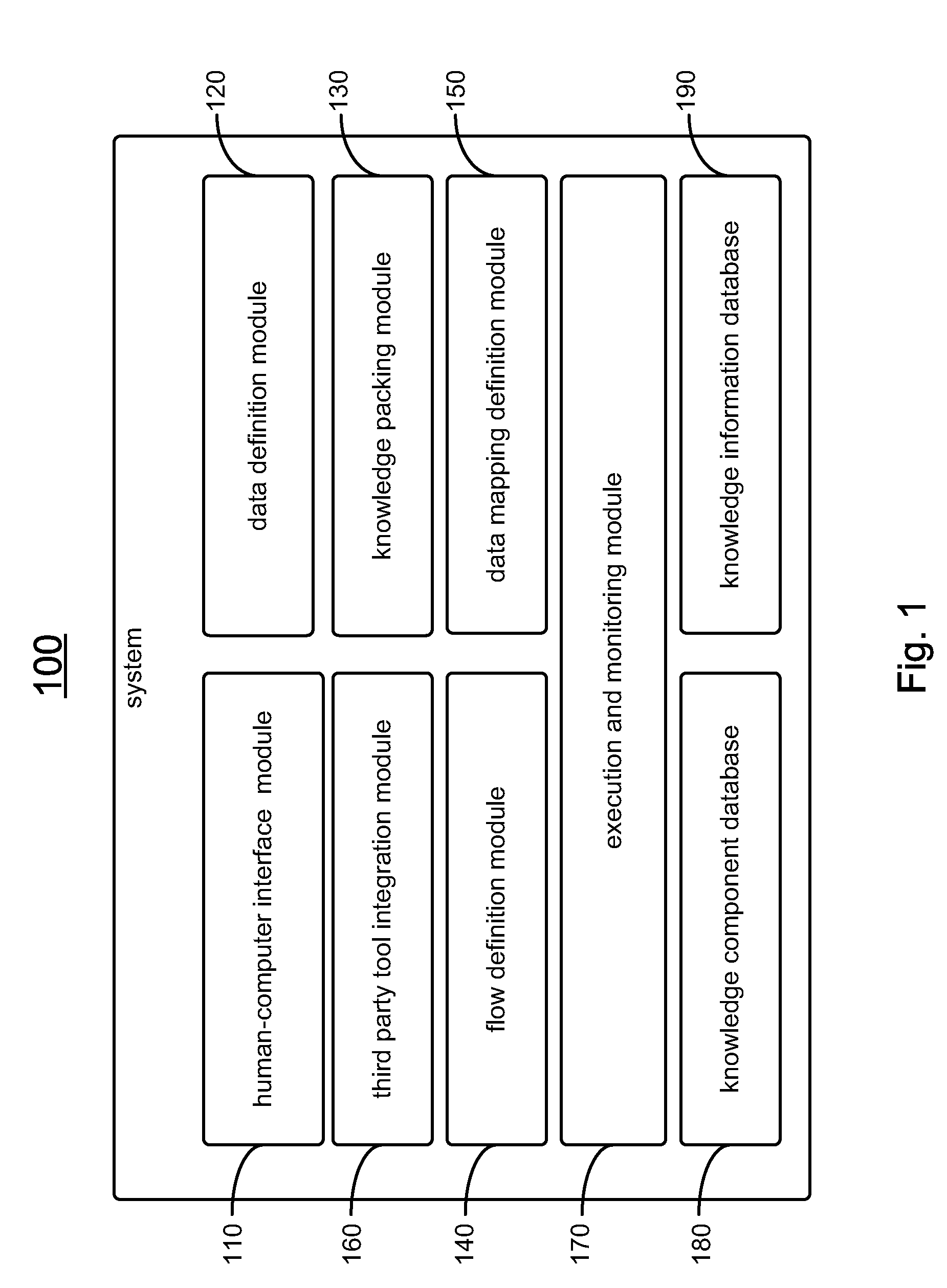

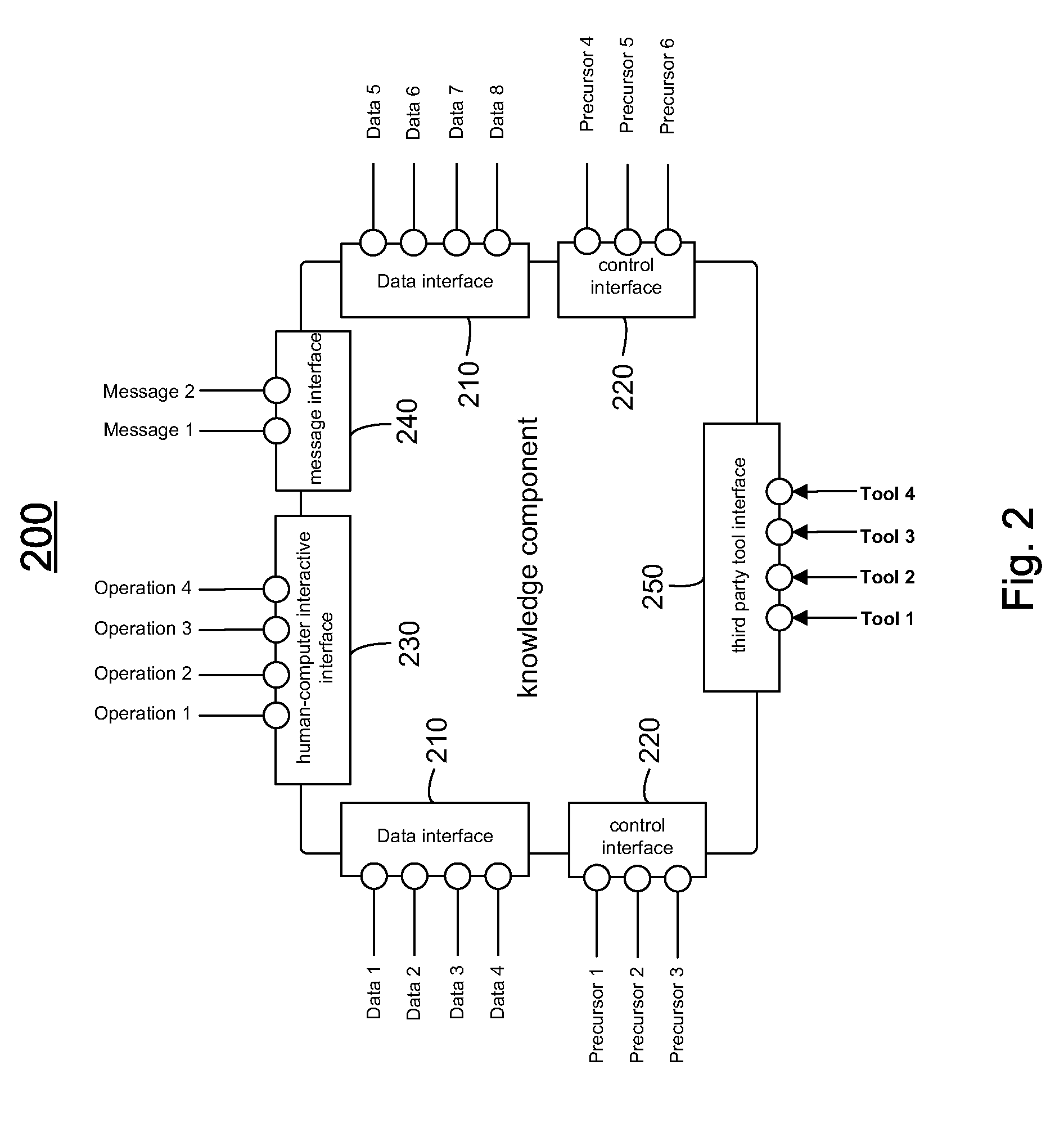

Method and System of Knowledge Component Based Engineering Design

ActiveUS20100121800A1High flexible module designDesign efficiency is usually very lowConfiguration CADSpecial data processing applicationsEngineering design processStandard form

The present invention relates to an engineering design method and a system of implementing same. In one embodiment, the method includes a construction process of knowledge components and a design process based on the knowledge components. The knowledge components pack universal modules in the standard forms. Accordingly, the knowledge components are independent from design layouts or design processes of products, and reusable in different projects and platforms. The design process integrates a variety of software platforms via an uniform environment and calls the knowledge components to complete the engineering designs. Further, the design process defines a data relation and an execution relation of the knowledge components and establishes a relationship between the knowledge components without programming. The universal module comprises at least operations, methods, rules and / or flows of an engineering design process and engineering analysis process.

Owner:SYSWARE TECH CO LTD

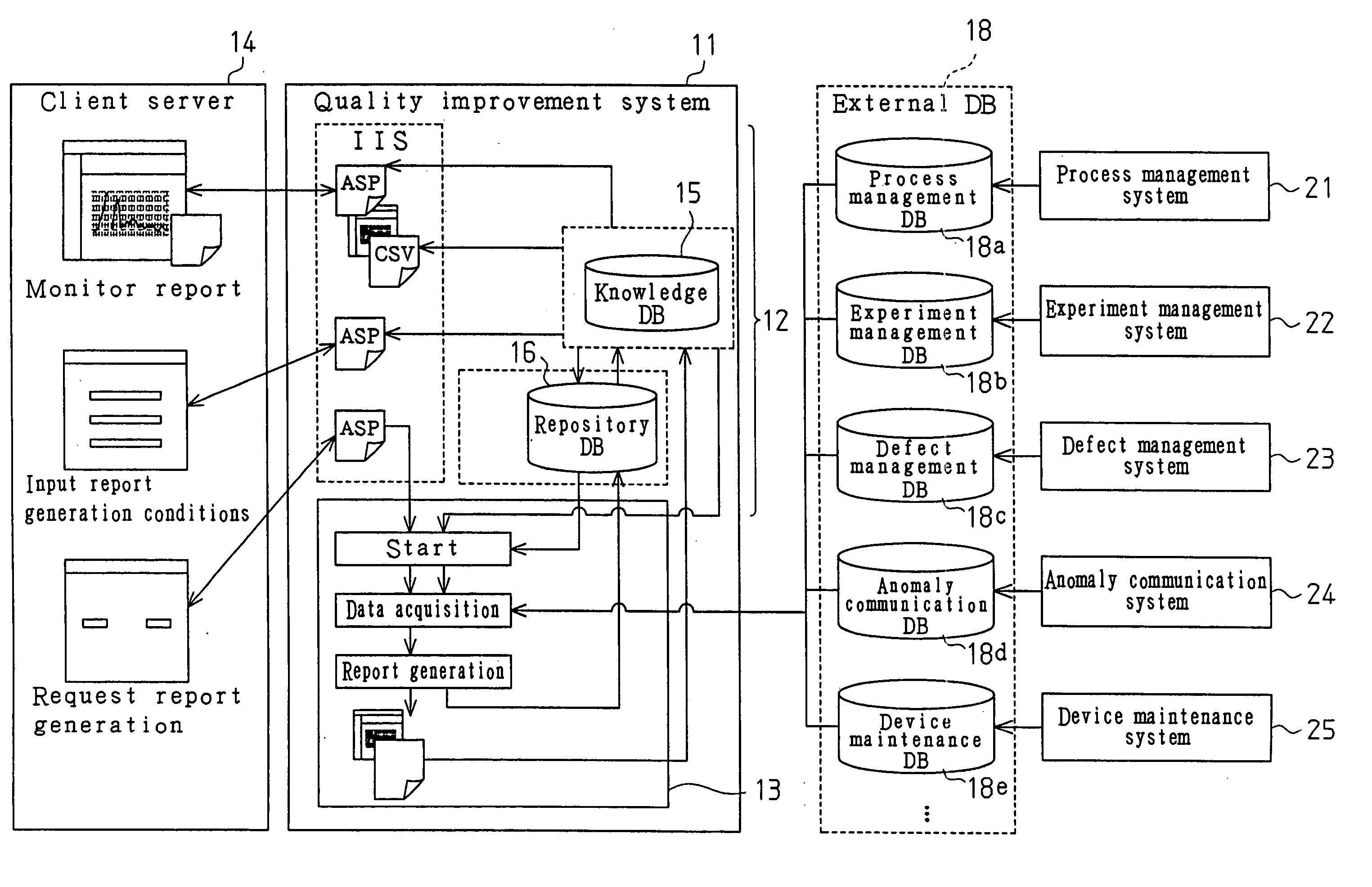

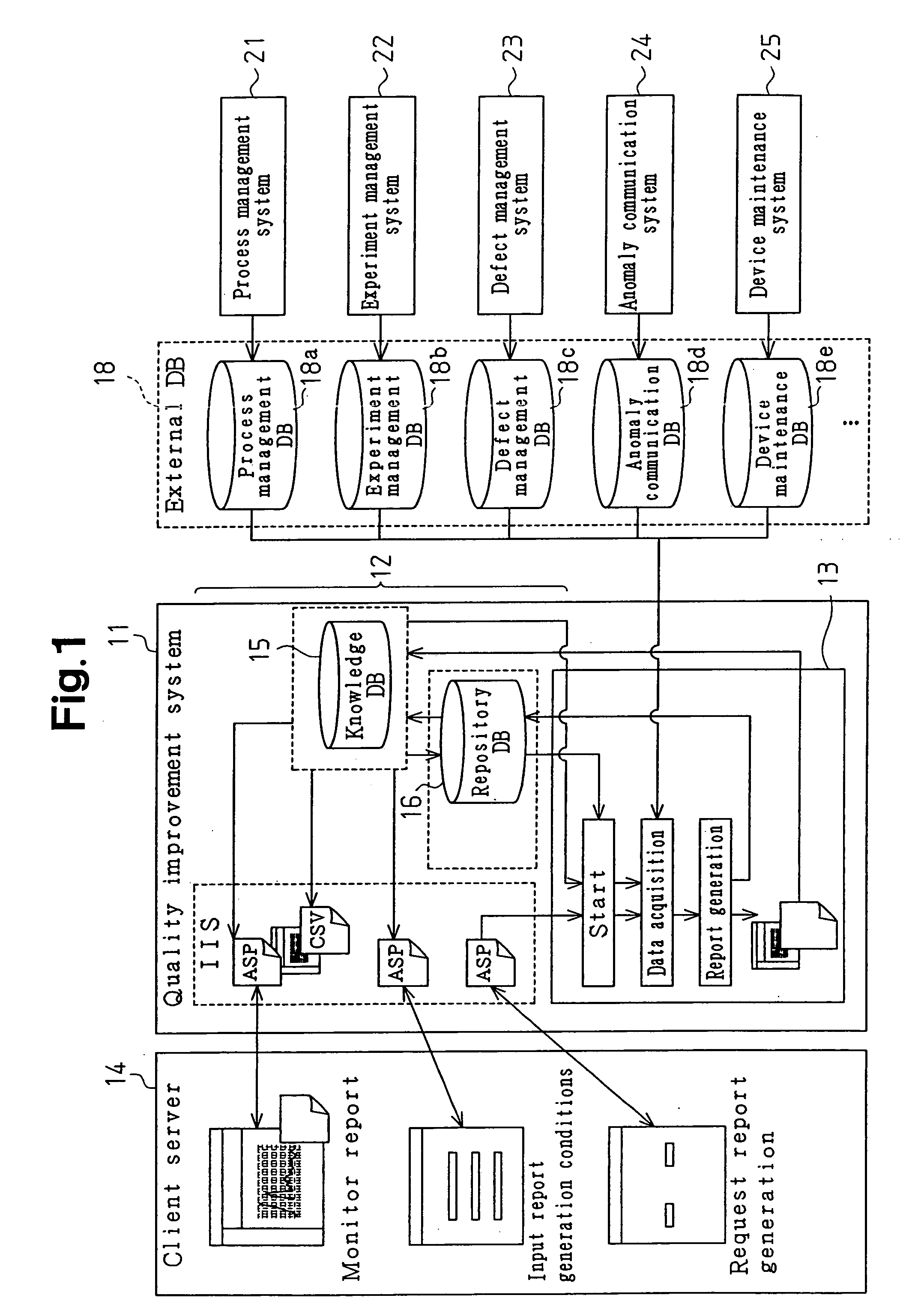

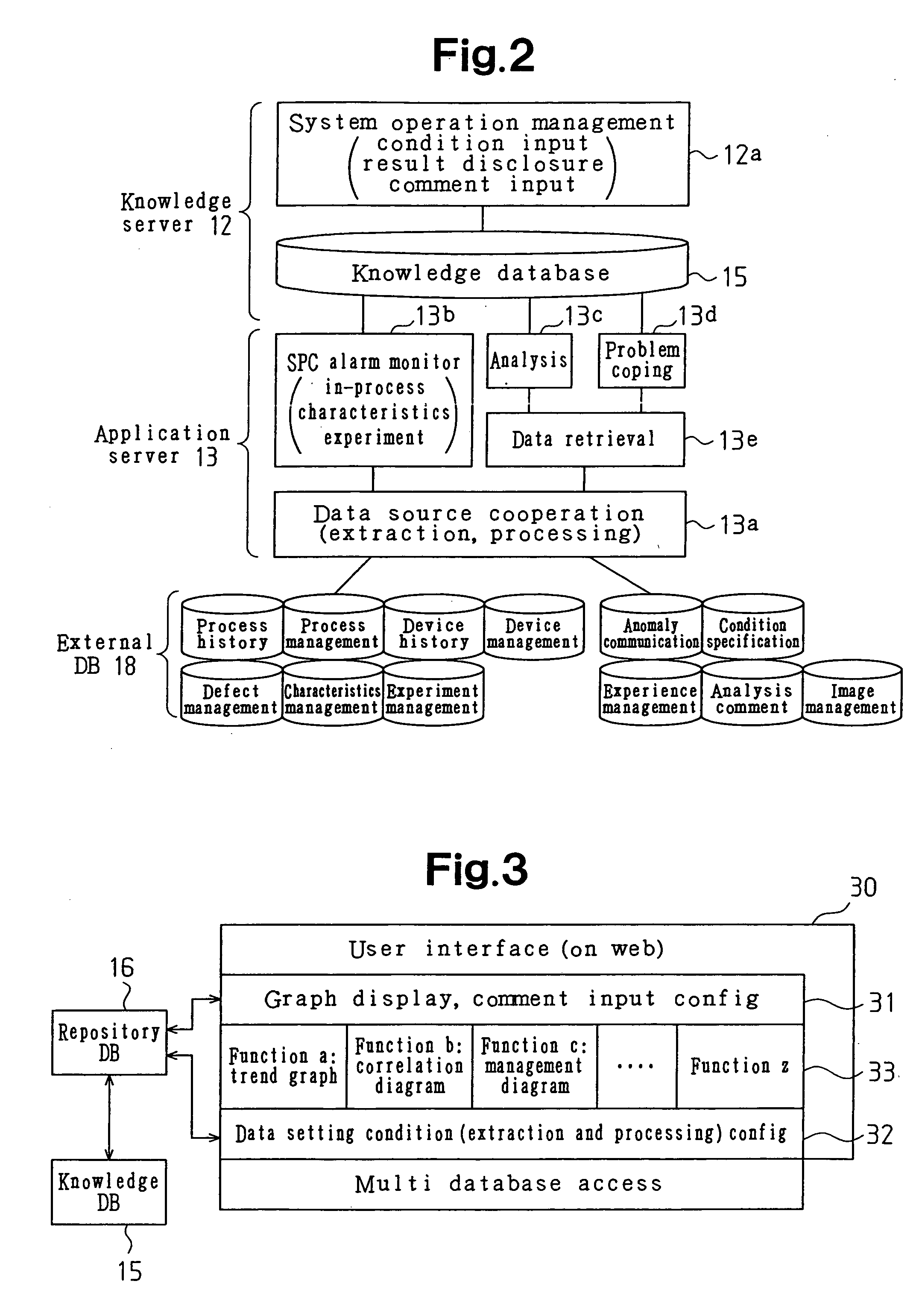

Quality improvement system

InactiveUS20050136559A1Quality improvementDigital computer detailsNuclear monitoringComputer scienceSemiconductor

A quality improvement system, which automatically performs engineering analysis and problem coping to improve the quality of semiconductor products. The quality improvement system is connected to a plurality of external databases, which store semiconductor product quality information acquired in a plurality of manufacturing processes, and a client server, which is operated by an engineer. The quality improvement system receives quality information from the external databases, receives engineer comments from the client server and associates the quality information and comments and stores them in a knowledge database.

Owner:FUJITSU SEMICON LTD

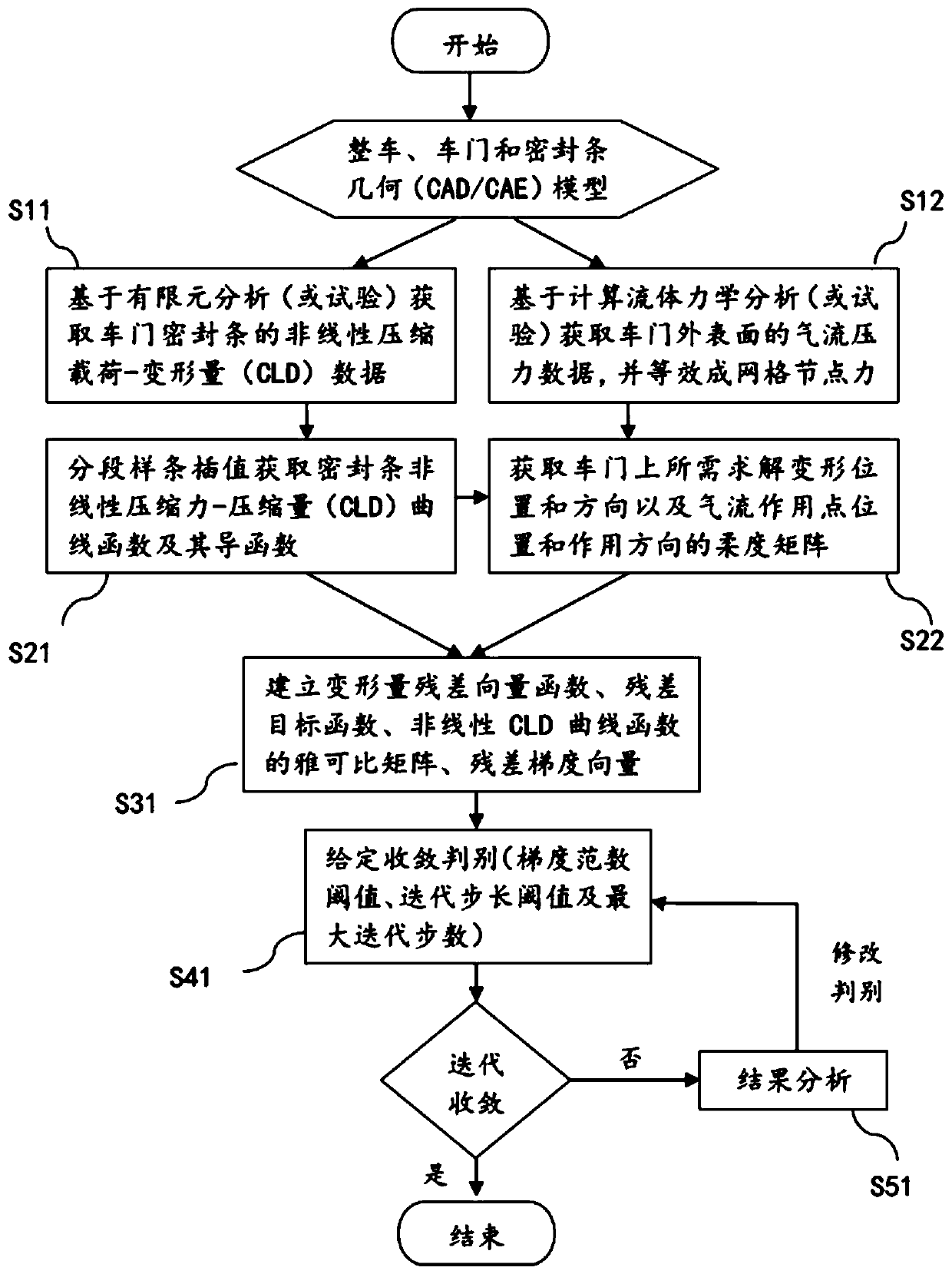

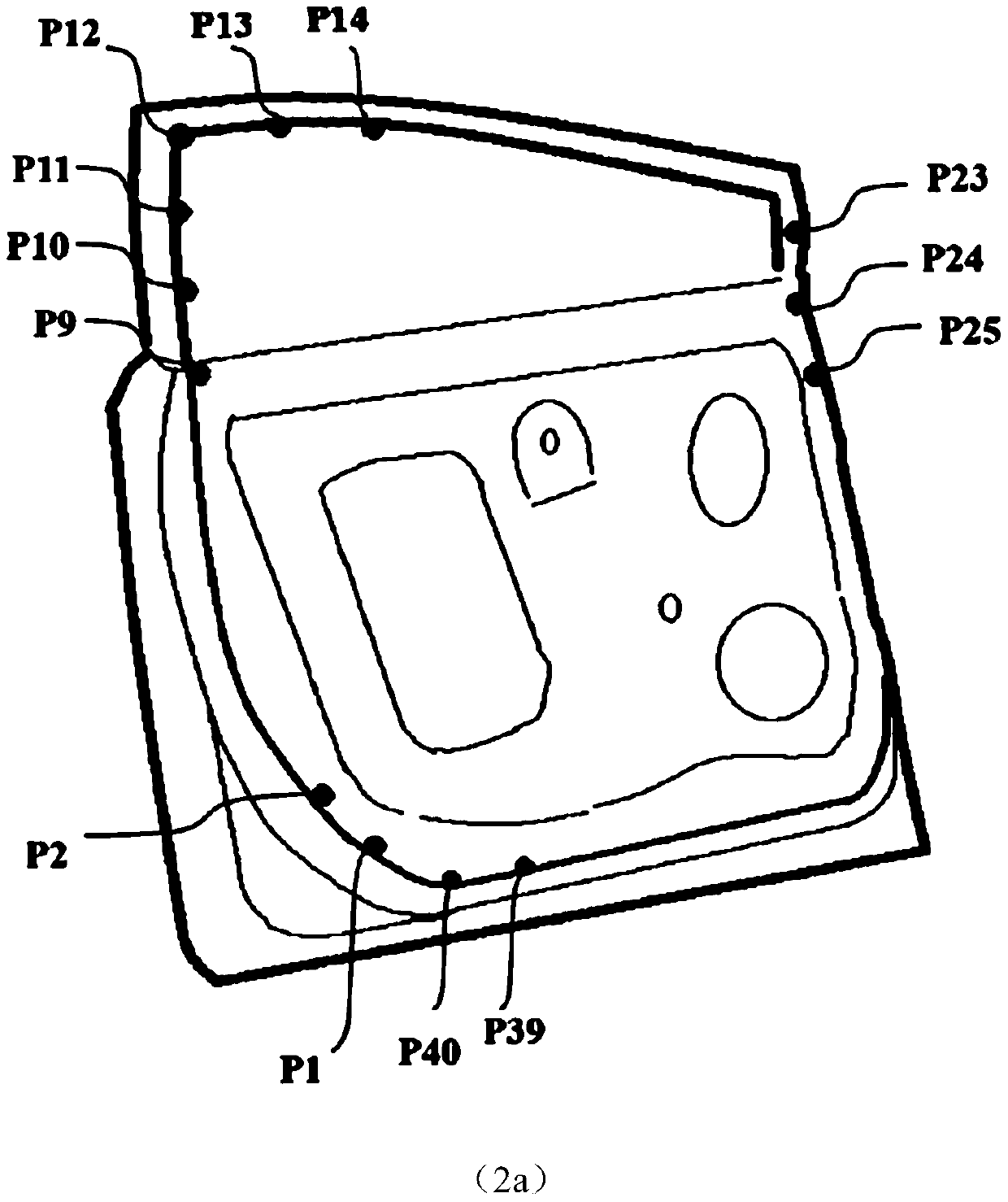

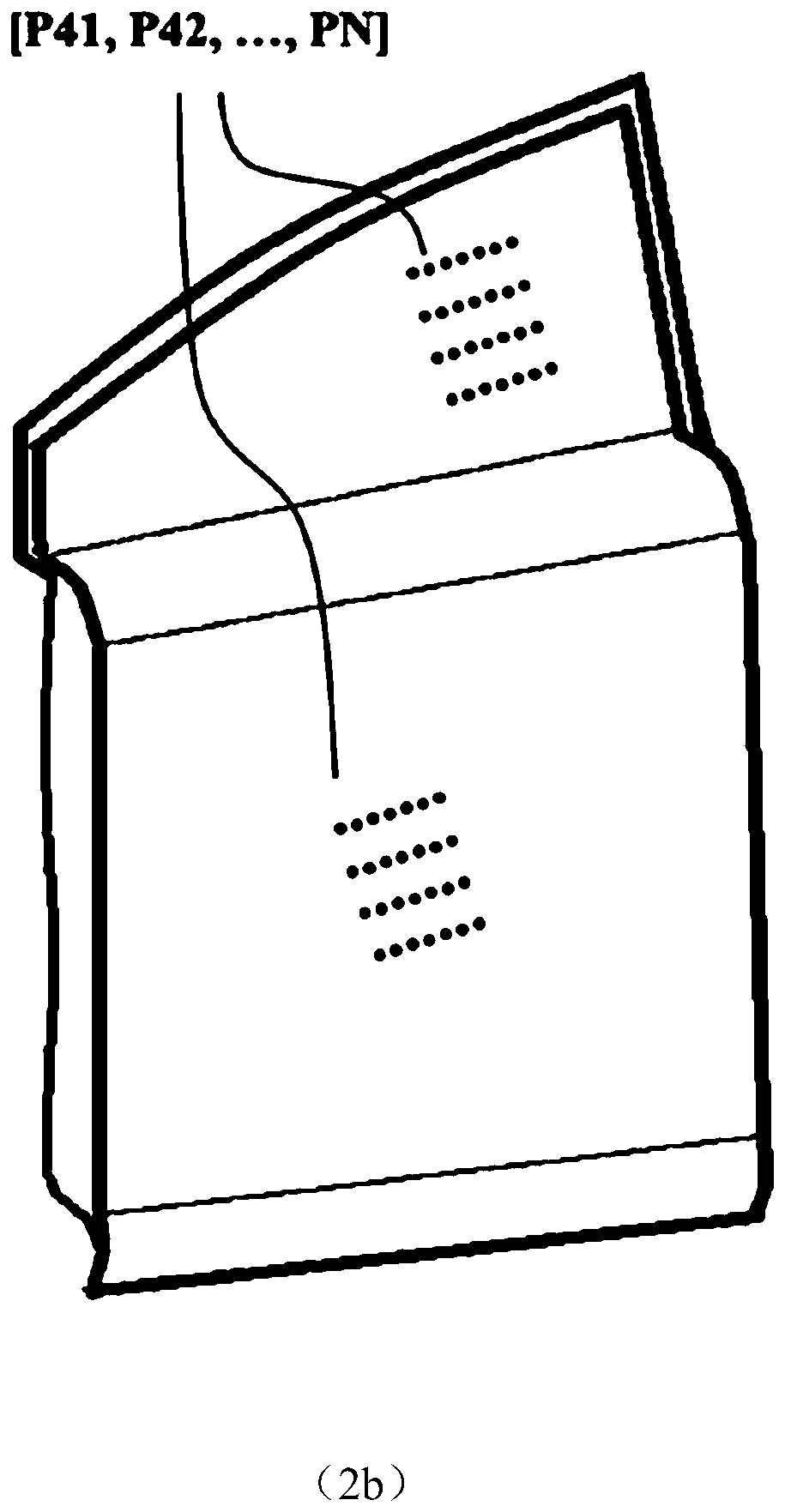

Vehicle door deformation acquisition method considering nonlinear compression characteristics of sealing strip

ActiveCN110502788AImprove accuracyHigh engineering practical valueSpecial data processing applicationsState of artElement analysis

The invention relates to a vehicle door deformation acquisition method considering nonlinear compression characteristics of a sealing strip. Nonlinear compression load-deformation data in the compression process of the vehicle door sealing strip are obtained based on finite element analysis; a nonlinear compression load-deformation function relationship of the sealing strip is obtained through segmented spline interpolation; airflow pressure data of the outer surface of an automobile door are obtained based on computational fluid mechanics analysis, a flexibility matrix of the position and direction of deformation needing to be solved on the automobile door and the position and direction of an airflow force acting point is obtained based on finite element analysis, and the automobile doordeformation amount is iteratively solved through a numerical analysis method. According to the method, a rapid calculation and evaluation means is provided for engineering analysis of vehicle door deformation, a numerical analysis method and basis are provided for compression evaluation and acoustic optimization of the sealing strip. Compared with the prior art, the method has the advantages of being simple in calculation process step, convenient to program, good in universality, high in engineering practical value and the like.

Owner:TONGJI UNIV

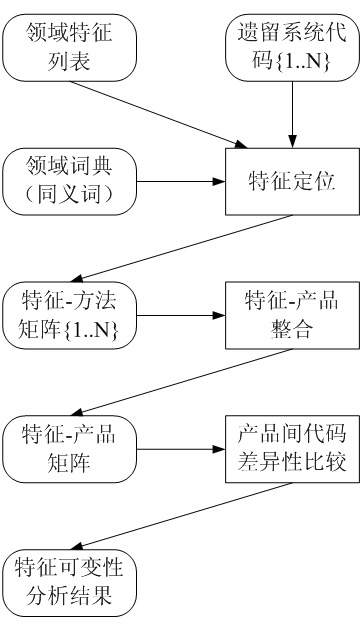

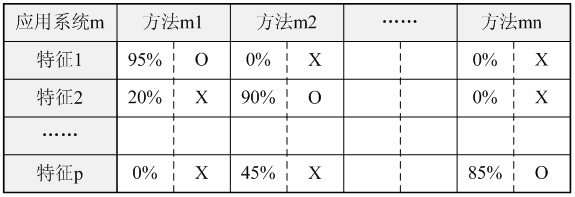

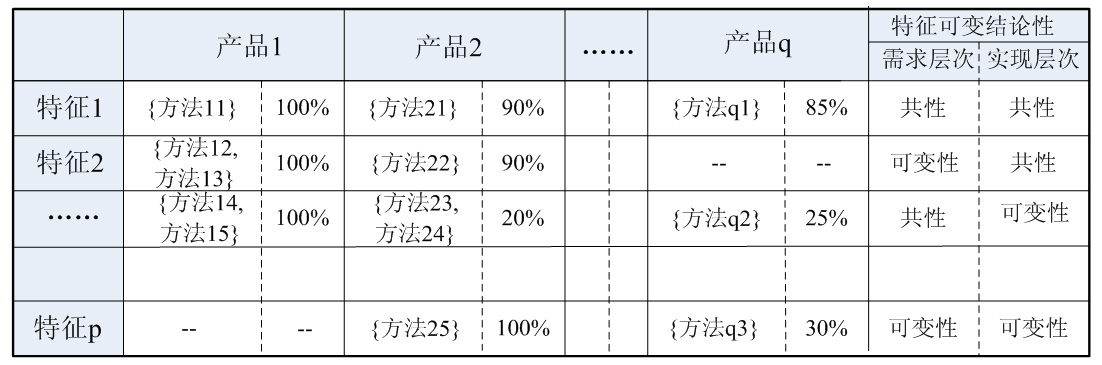

Reverse engineering analysis method of feature variability in software product line development

InactiveCN101894038AAccurate Requirements Variability KnowledgeComprehensive demand variability knowledgeProgram controlMemory systemsProduction lineReverse analysis

The invention belongs to the software development technical field, in particular relating to a reverse engineering analysis method of feature variability in software product line development. In the method, legacy system codes and a domain feature list are taken as input, and a variability analysis result for domain features is acquired through reverse analysis to show variability description on a demand layer and an implementation layer. The reverse engineering analysis method comprises the following steps: establishing a feature-classification matrix set by adopting a feature localization technology; carrying out feature-product integration, and establishing a feature-product matrix to obtain the variability on the demand layer; and comparing the difference of the legacy codes for each feature to obtain the variability on the implementation layer. The reverse engineering analysis method combines domain knowledge in the codes with knowledge in the forward process together to obtain more accurate and comprehensive variability conclusions; and meanwhile variability analysis on the feature implementation layer brings benefits for design and implementation activities of a product line.

Owner:FUDAN UNIV

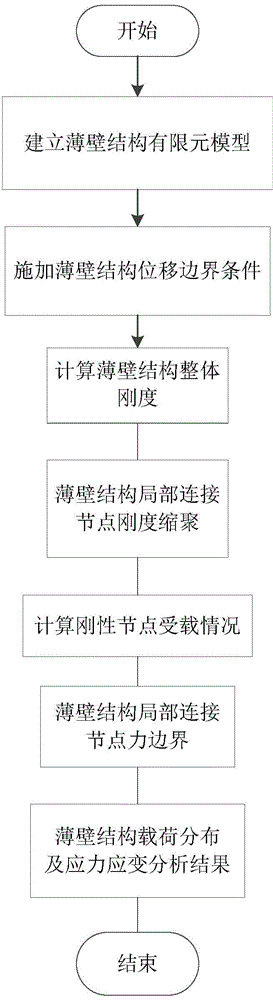

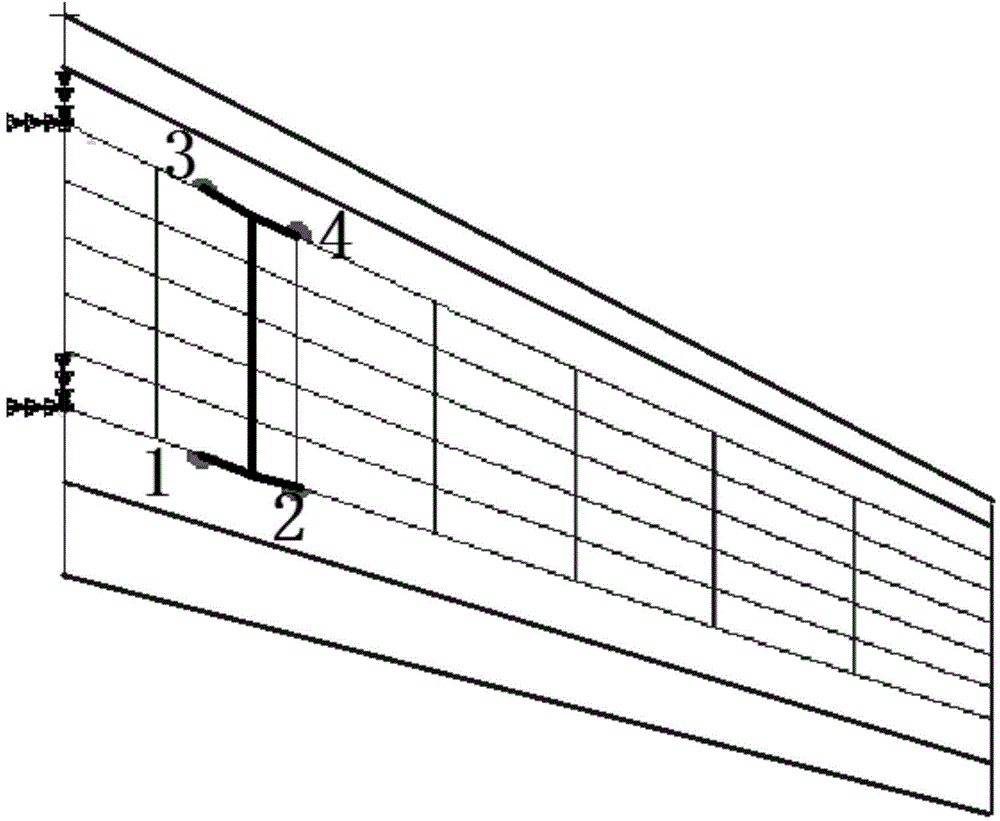

Method for determining thin-walled structure high-rigidity connecting area load transfer

InactiveCN104598693AAccurate Pinch StiffnessAvoid unreasonable setting processing methodsSpecial data processing applicationsLoad distributionEngineering analysis

The invention provides a method for determining thin-walled structure high-rigidity connecting area load transfer, wherein the rigidity property of a thin-walled structure is condensed into a connecting area through a rigidity matrix condensation technology, so that the condensing rigidity of the connecting area is obtained accurately, and the unreasonable setting process to weighting average constraint element local rigidity weight by people is avoided. After the condensed rigidity property is obtained, load distribution can be performed according to the bearing capacity of joint rigidity through a load rigidity distribution principle, so that a reasonable and effective high precise load transfer result is obtained; the obvious practical value and significance in aeronautic and astronautic thin-walled structure engineering analysis are available.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

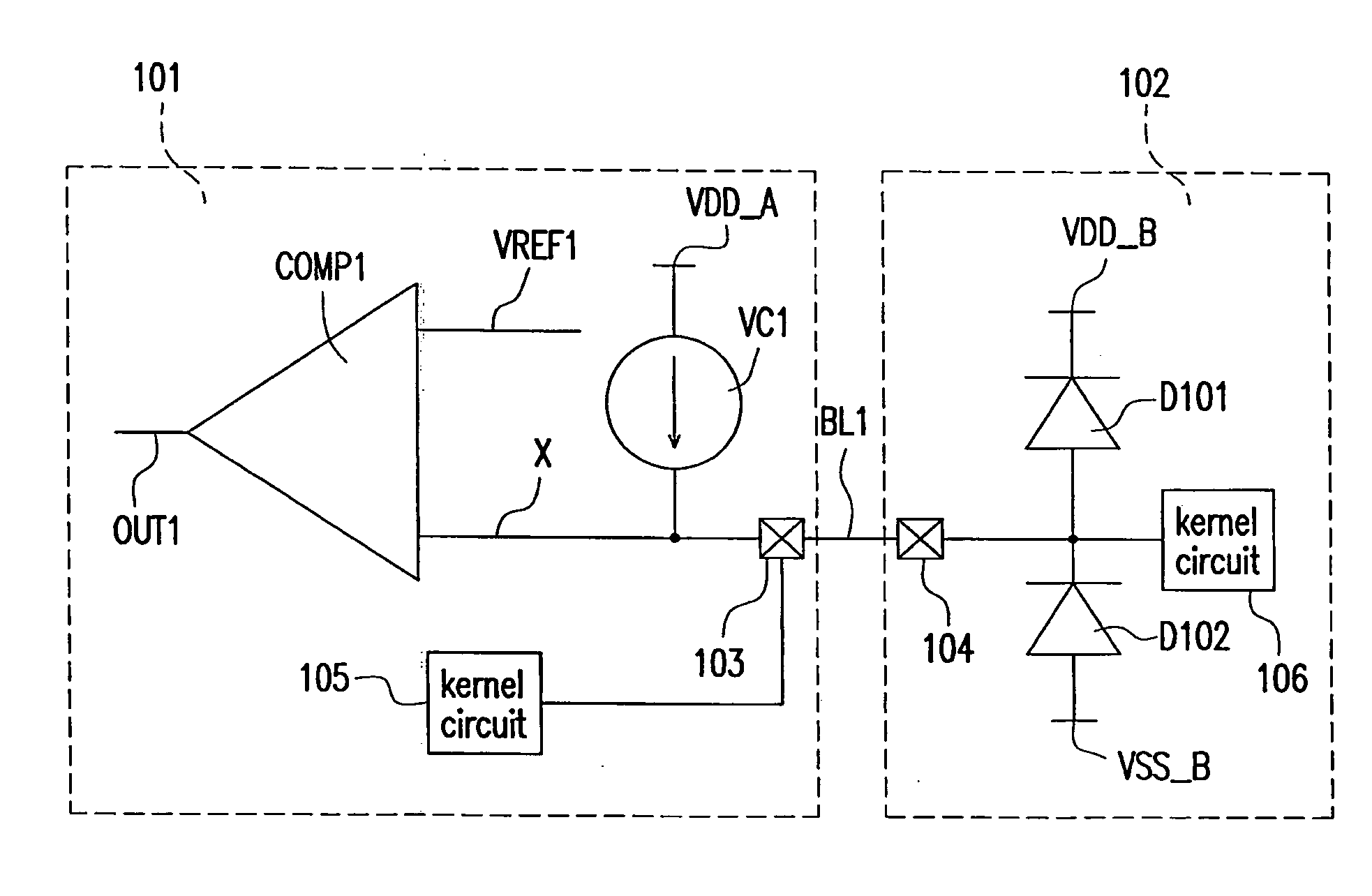

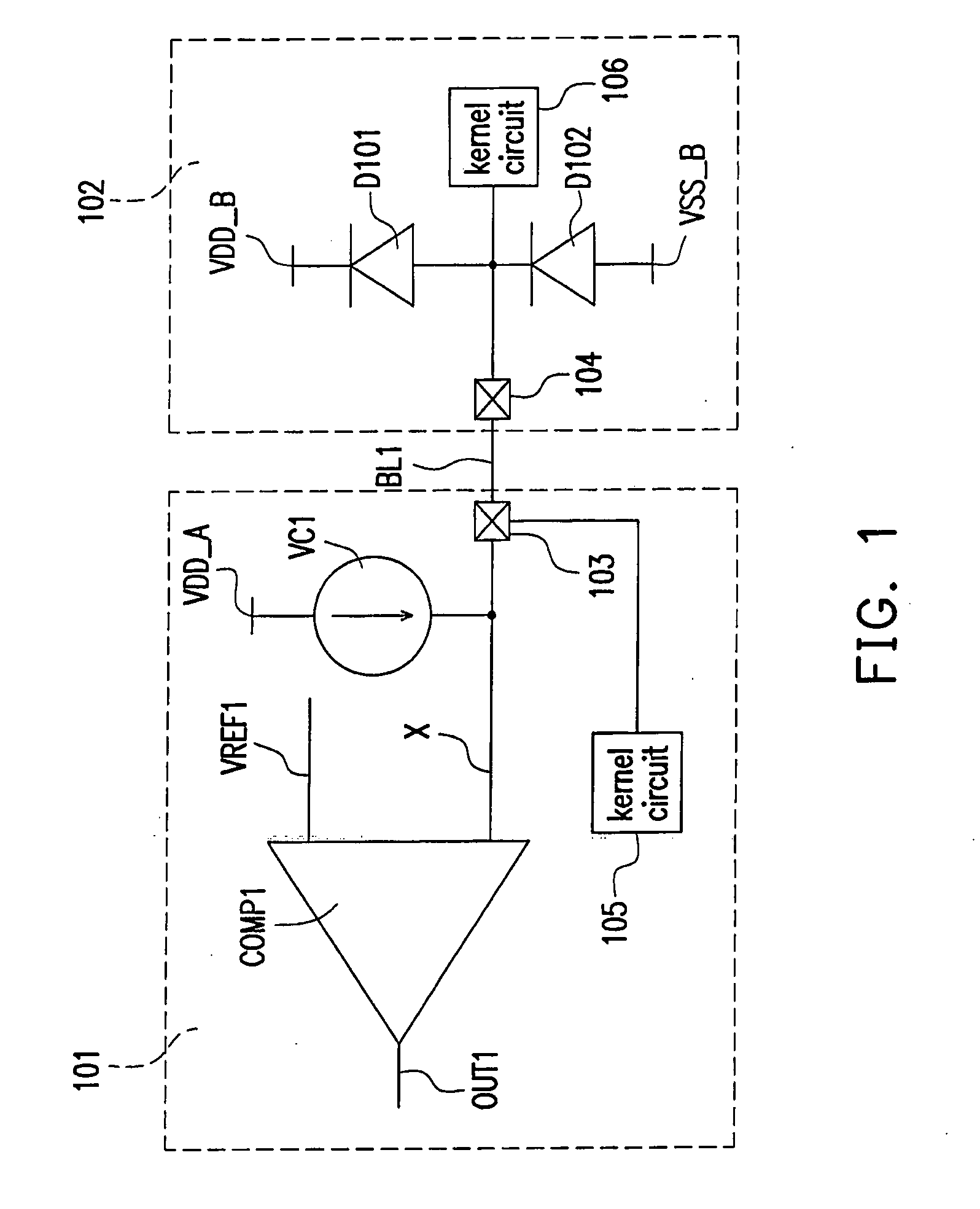

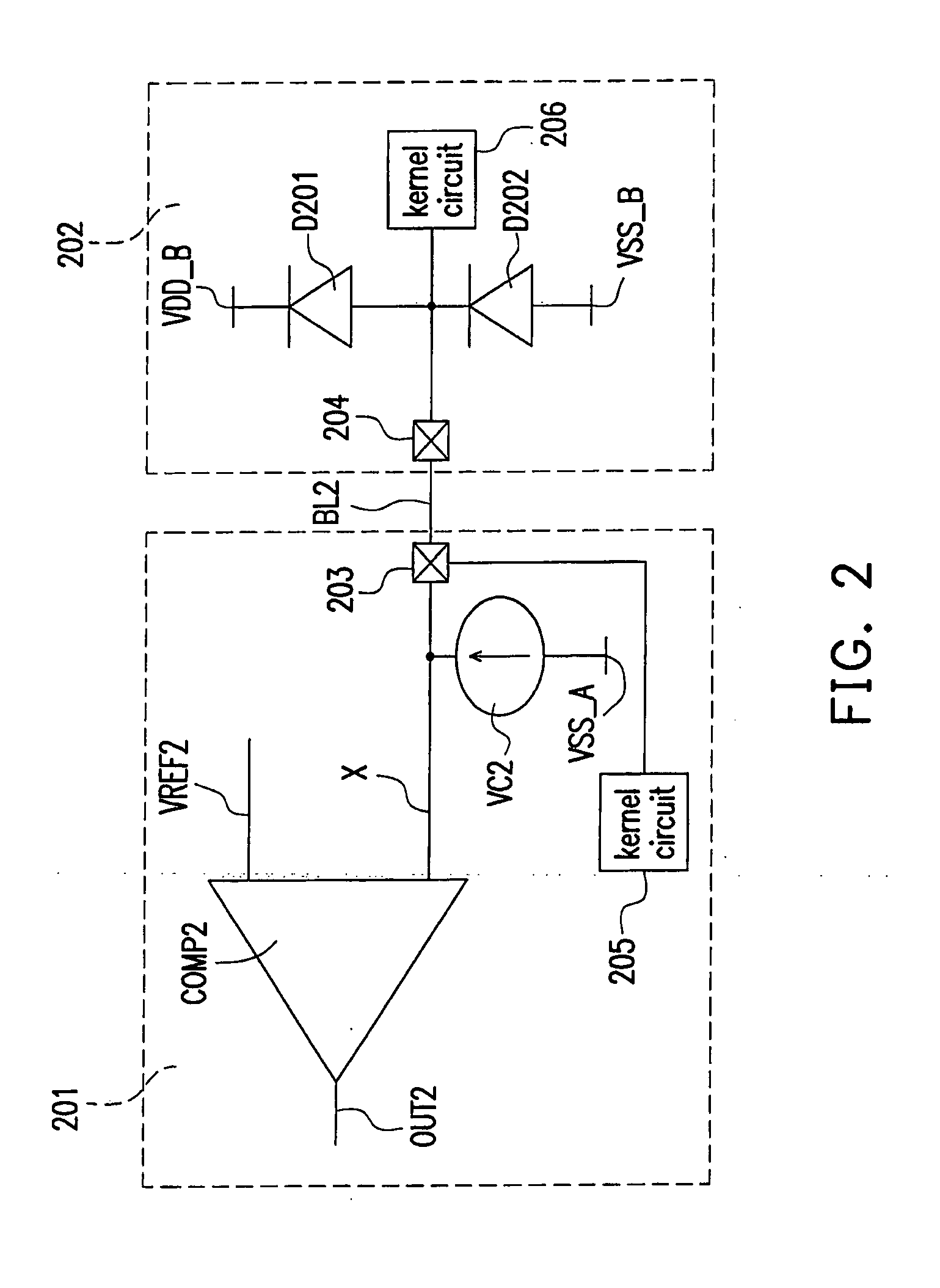

Connection testing apparatus and method and chip using the same

ActiveUS20090079457A1Reduce testing costsDegree of improvementSemiconductor/solid-state device detailsSolid-state devicesVoltage variationTest fixture

A connection testing apparatus, a connection testing method, and a chip using the same are provided. The method can be used for testing connections between chips, so as to solve the problems that a conventional multi-chip connection test needs a plenty of test patterns, resulting in a long test time and a high test cost, and the condition of a connection failure is hard to be analyzed after a test failure. In the present invention, a voltage variation caused when an ESD element in a chip is conducted and a comparison circuits are used to determine whether a connection is correct. Furthermore, the test apparatus is built in the chip, so that the connection test may be accomplished quickly and efficiently. Once a connection failure occurs, the failed connection pin can also be found, so as to be favorable for engineering analysis and thereby effectively saving the test cost.

Owner:HIMAX DISPLAY INC

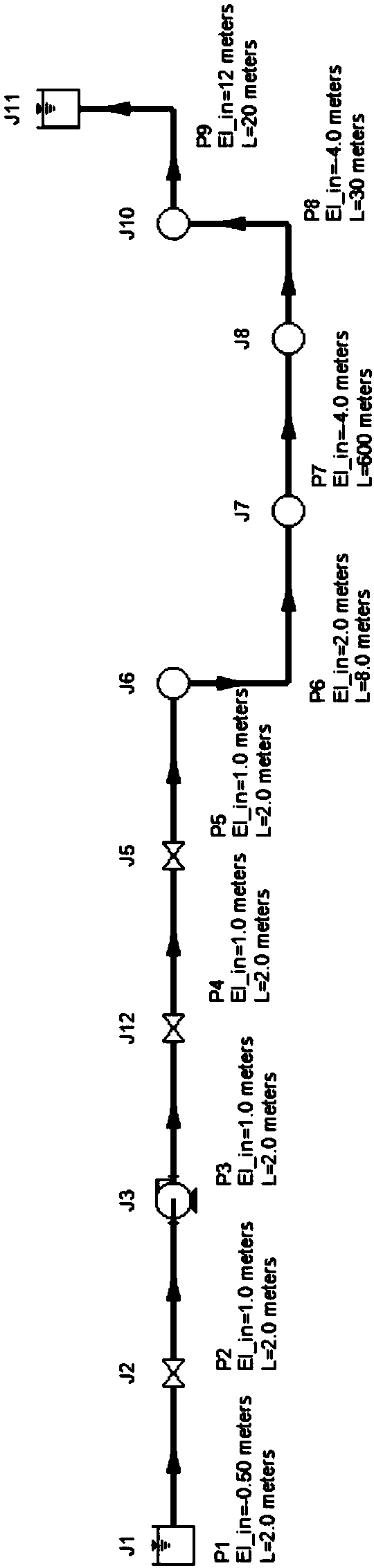

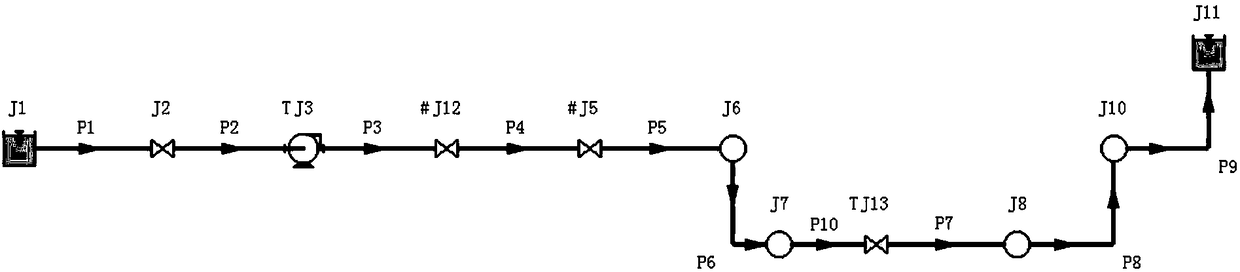

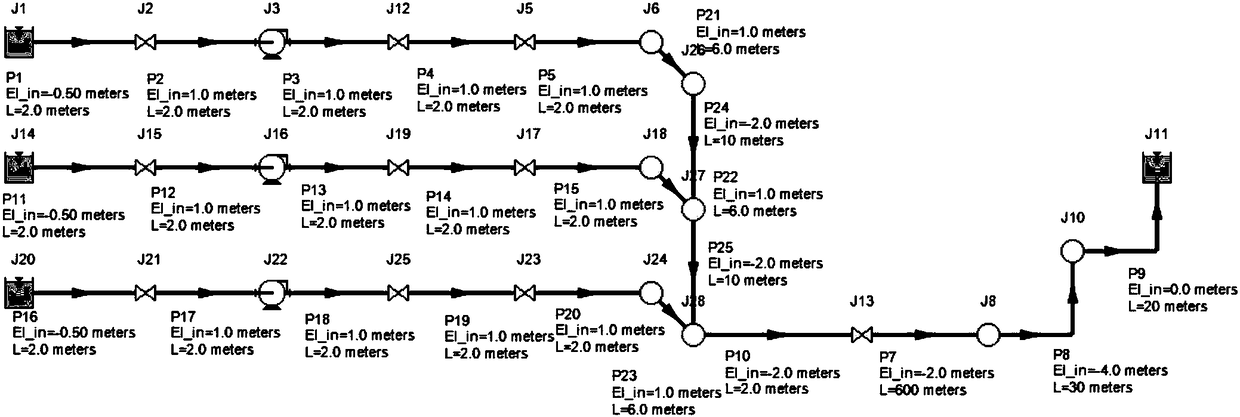

Safety control method for preventing water hammer of synchronous multistage valve positioning large-diameter pipeline system

The invention discloses a safety control method for preventing a water hammer of a synchronous multistage valve positioning large-diameter pipeline system. The water hammer theory is utilized to conduct pre-judging and primary engineering analysis; a system model is built through AFT-Impulse software simulation; single-line simulation analysis or multiline simulation analysis is conducted, and a second-stage interlocking slow-closure type valve and multiple stages of interlocking slow-closure type valve are positioned according to the working condition; and the positioning and closing conditions are verified and corrected according to a calculation report, and specific measures are adopted. According to the safety control method, the large-diameter pipeline system is adopted as a researchobject, the engineering application value of the large-diameter pipeline system is embodied by combining the water hammer theory and AFT software simulation, and finally, a set of feasible preventative measures is established according to the simulated calculation result; and a method for solving the problem of sharp overpressure of a pump-stopping water hammer of a single-pump large-diameter pipeline system is provided, effective control over the water hammer under the situations of pump stopping of the single line in multiple pumps and simultaneous pump stopping of the multiple pumps is achieved, and one-key pump stopping in the accidental state is achieved.

Owner:CHINA TIANCHEN ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com