Mesh generation method of modeling structural steel knifing pass rolling process

A rolling process and grid generation technology, applied in the pre-processing field of finite element engineering analysis, can solve problems such as rough two-dimensional grid division and unavailable grid division, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

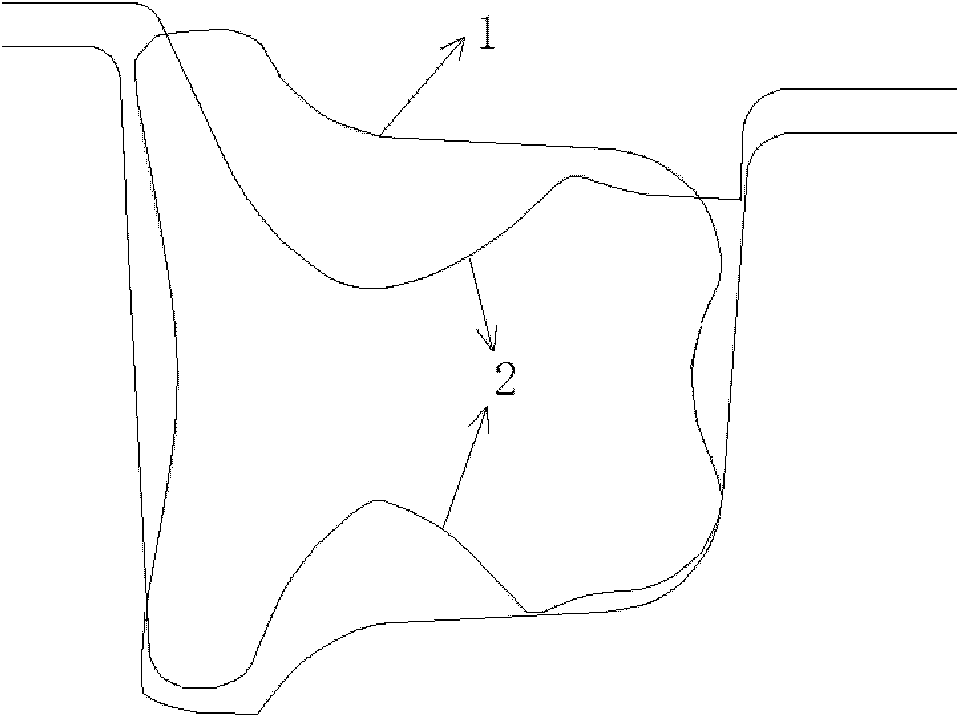

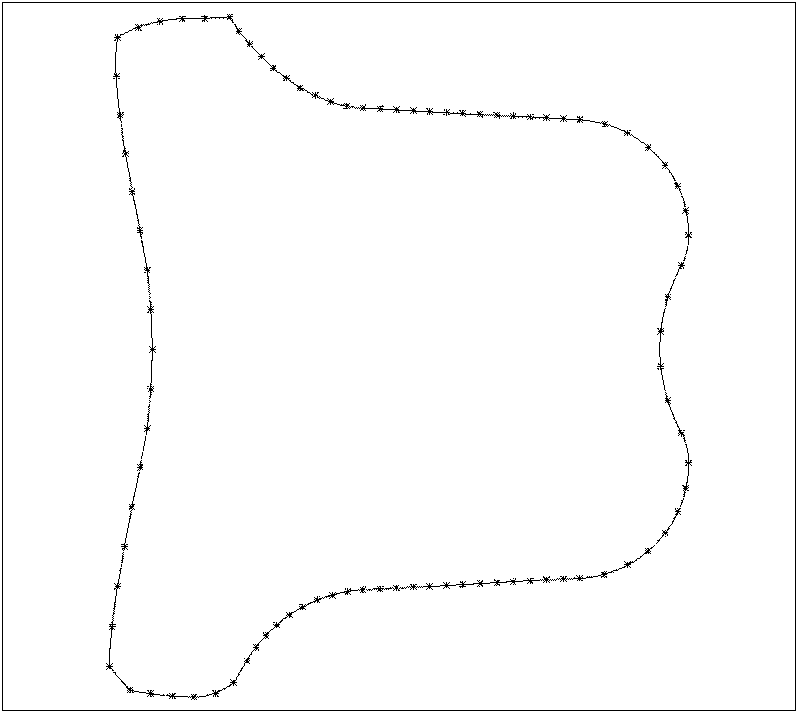

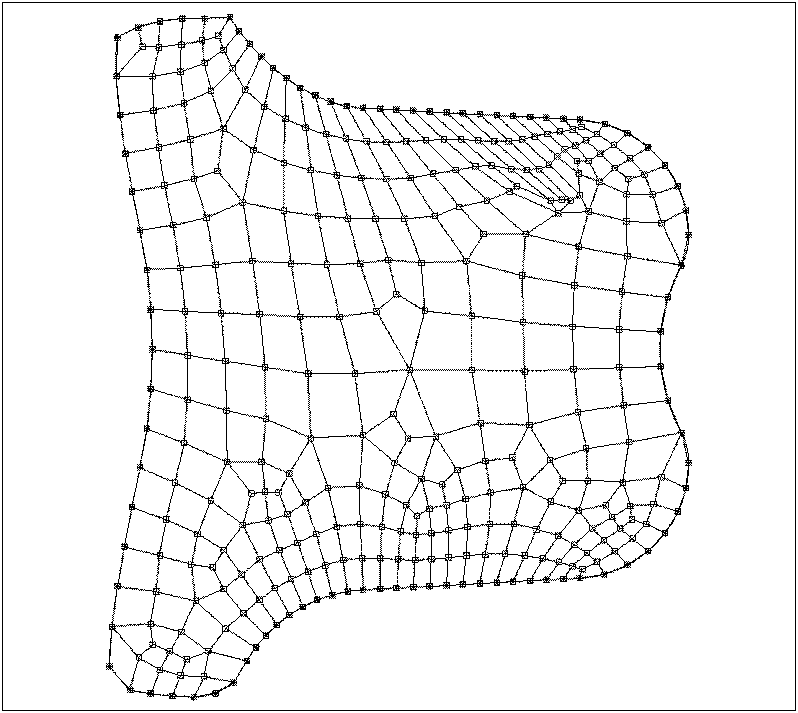

[0040] See Figure 1 to Figure 5 , is the finite element mesh division of the rolled piece during the rough rolling and deep hole rolling process of the rail:

[0041] 1) First obtain the two-dimensional initial shape of the billet for the required simulation pass, and ensure that the curve is closed;

[0042] 2) Set the seed point on the contour boundary in the two-dimensional plane of the blank. The seed point is dense in the part with large deformation, and one seed point is set every 6mm. The seed point is sparse in the part with small deformation, and one seed point is set every 13mm. In the middle, the transition zone is used to obtain the transition of dense and dense grids, and a seed point is set about every 10mm;

[0043] 3) The grid division in the two-dimensional plane adopts the MSC.Mentat automatic grid calculation method, which generates one unit at a time, and gradually generates a global grid from the boundary of the region to the interior, and the generated ...

Embodiment 2

[0047] See Figure 6 ~ Figure 10 , the finite element mesh division of the rolled piece in the process of rough rolling and deep hole cutting of bulbous flat steel:

[0048] 1) First obtain the two-dimensional initial shape of the billet for the required simulation pass, and ensure that the curve is closed;

[0049] 2) Set the seed point on the contour boundary in the two-dimensional plane of the blank. The seed point is dense in the part with large deformation, and one seed point is set every 4mm. The seed point is sparse in the part with small deformation, and one seed point is set every 10mm. In the middle of the transition zone to obtain the transition of dense grid, set a seed point about every 7mm;

[0050] 3) The grid division in the two-dimensional plane adopts the MSC.Mentat automatic grid calculation method, which generates one unit at a time, and gradually generates a global grid from the boundary of the region to the inside, and the generated grid is generated based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com