Independent sound insulation room

A sound-proof room and sound-proof layer technology, applied in the direction of sound-proof, insulating layer, sound-generating equipment, etc., can solve the contradiction between sound-proof quality control and sound-proof room weight and volume control, sound-proof room has no environmental sound effect simulation, and affects the safety of use, etc. Achieve the effects of improving sound energy consumption efficiency, excellent sound absorption effect, and improving sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

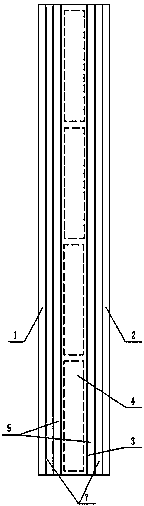

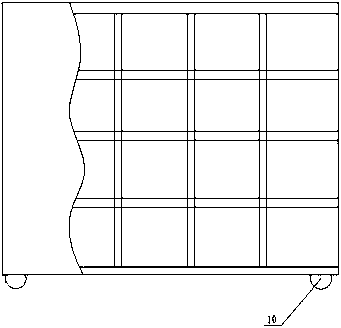

[0027] A separate soundproof room, such as figure 1 with figure 2 As shown, it includes a first multimedia screen 1, a skeleton layer and a second multimedia screen 2; the first multimedia screen 1 and the second multimedia screen 2 can be selected as LED screens or LCD screens, and the first multi-media screen The media screen 1 is installed on the outer surface of the skeleton layer; the skeleton layer includes: the dragon skeleton body 3, including the bottom joist, the top joist and the damping joist in the prior art. On the top, perimeter and bottom of the soundproof room, pay attention to reserve the door installation opening when installing the keel. The sound insulation layer comprises the bone body sound insulation layer between the keel skeleton bodies 3 and the bone surface sound insulation layer 5 inside and outside the keel skeleton body; the bone surface sound insulation layer 5 can be selected as sound-absorbing cotton or sound-insulation felt for adhesion. T...

Embodiment 2

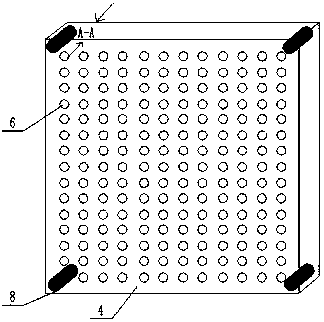

[0036] On the basis of Example 1, in order to improve the sound-absorbing effect of the sound-absorbing panel, the sound-absorbing panel can be designed in the following form, such as figure 2 As shown, the sound inlets 6 on both sides of the sound-absorbing panel 4 are symmetrically and evenly distributed, and a metal film with holes is arranged between the symmetrical sound-inlets 6 on both sides of the sound-absorbing panel 4 , so as to ensure that the sound-absorbing channels 11 are parallel. The distances between adjacent sound inlets 6 are equal, so that the distances between the sound-absorbing holes 11 are the same. Since the sound energy entering the adjacent channels is basically the same, the sound energy causes the sound-absorbing channels to vibrate, and the vibration frequencies of the adjacent sound-absorbing channels are almost the same. The distance between the sound-absorbing channels is relatively close, and the vibration can cause the air outside the chann...

Embodiment 3

[0038] On the basis of Example 1, in order to expand the application scenarios of the soundproof room, the soundproof room can be modified.

[0039] Further, including light-transmitting glass, install the side or top surface between the keel frame bodies, cancel the installation of sound-absorbing panels there, and change to installing hollow sound-insulating glass to transmit light.

[0040] Further, it also includes an exhaust mechanism, which can be an exhaust fan or an air conditioner, and is installed between the keel frames, and the installation of the sound-absorbing panels there is canceled, or only a partial area is installed, and the remaining area is used to install the air exchange port of the exhaust mechanism.

[0041] Furthermore, the first multimedia screen and the second multimedia screen are connected with a terminal control, and the terminal control is a computer, which can switch the content played on the screen. Generally, the first multimedia screen can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com