Method for determining thin-walled structure high-rigidity connecting area load transfer

A thin-walled structure and connection area technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unreasonable load distribution results, inability to transmit bending moments and torques, and difficulty in setting weights. Achieve the effect of obvious practical value and significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

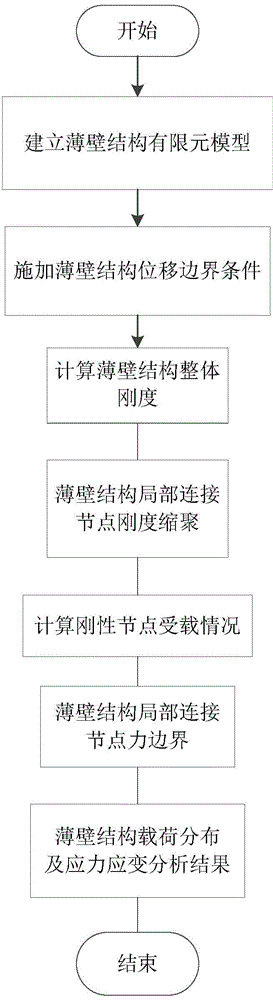

[0042] Describe the present invention below in conjunction with specific embodiment:

[0043] This embodiment is the thin-walled structure of the aircraft wing mounted with the engine. For the thin-walled structure of the aircraft class, since the rigidity of the engine, landing gear and missile is usually much greater than the rigidity of the thin-walled structure of the wing, rigidity assumptions can be made, and these Rigid body loads are transferred to the thin-walled primary structure.

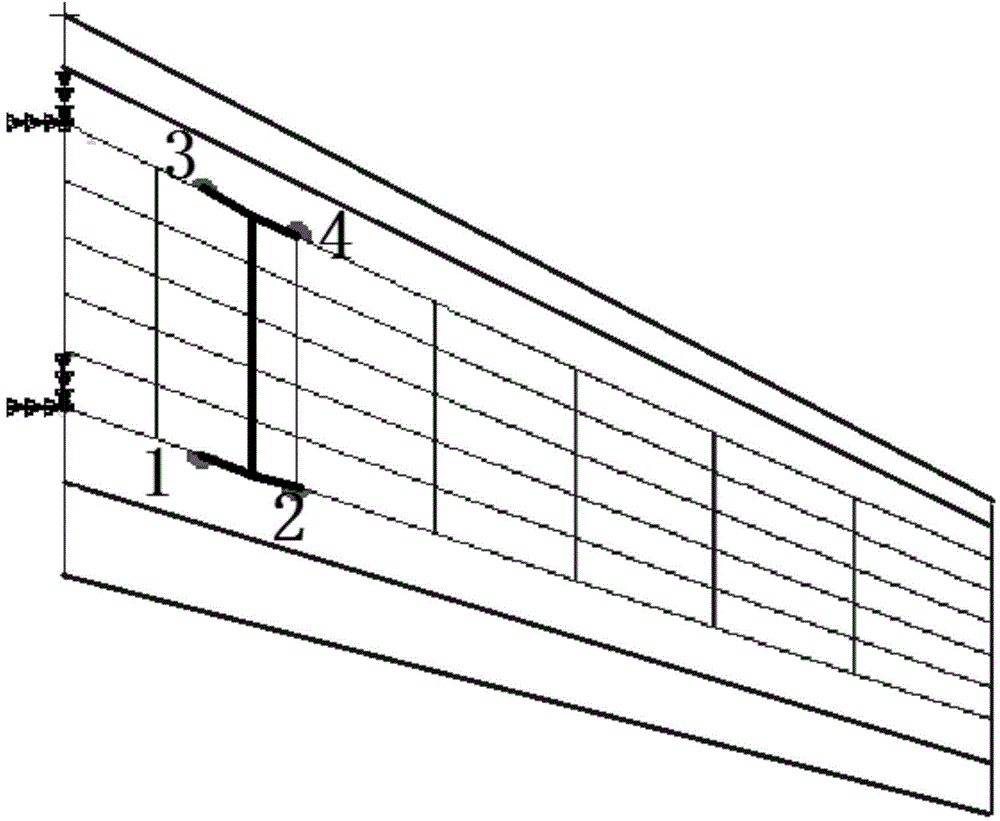

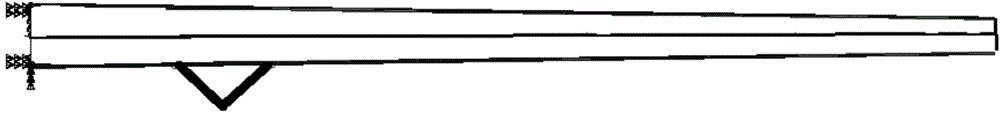

[0044] The CAD data of the wing is established by CATIA software. The wing is mainly composed of upper and lower skins, front and rear spar webs and rib webs. The main parameters of the wing are as follows: the span length is 1.196m, the root chord length is 0.814m, the wingtip chord length is 0.457m, the leading edge sweep angle is 30°, the trailing edge sweep angle is 15.8°, no twist angle, Mongolia The skin thickness is 0.002m, the wing rib thickness is 0.0015m, and the beam web thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com