Patents

Literature

85 results about "Site engineer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Site engineers act as day-to-day managers on a construction site, and the main source of technical advice and quality control for everyone working on it. The role also involves levelling and surveying a site, checking drawings and quantities and ensuring the accuracy of calculations.

System, method, and apparatus for portable design, deployment, test, and optimization of a communication network

InactiveUS6971063B1Rapid positioningData processing applicationsDigital computer detailsHand heldHand Held Computer

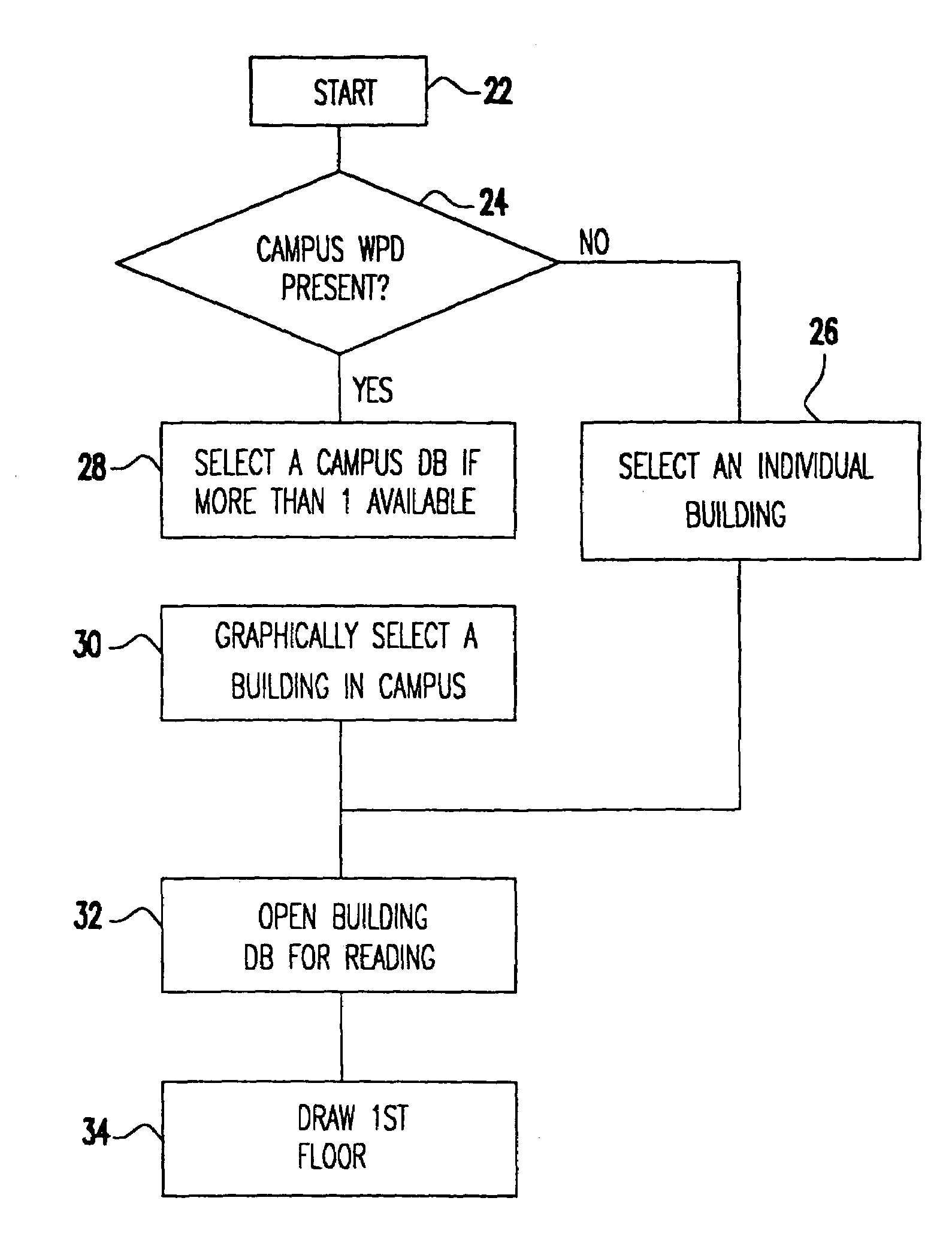

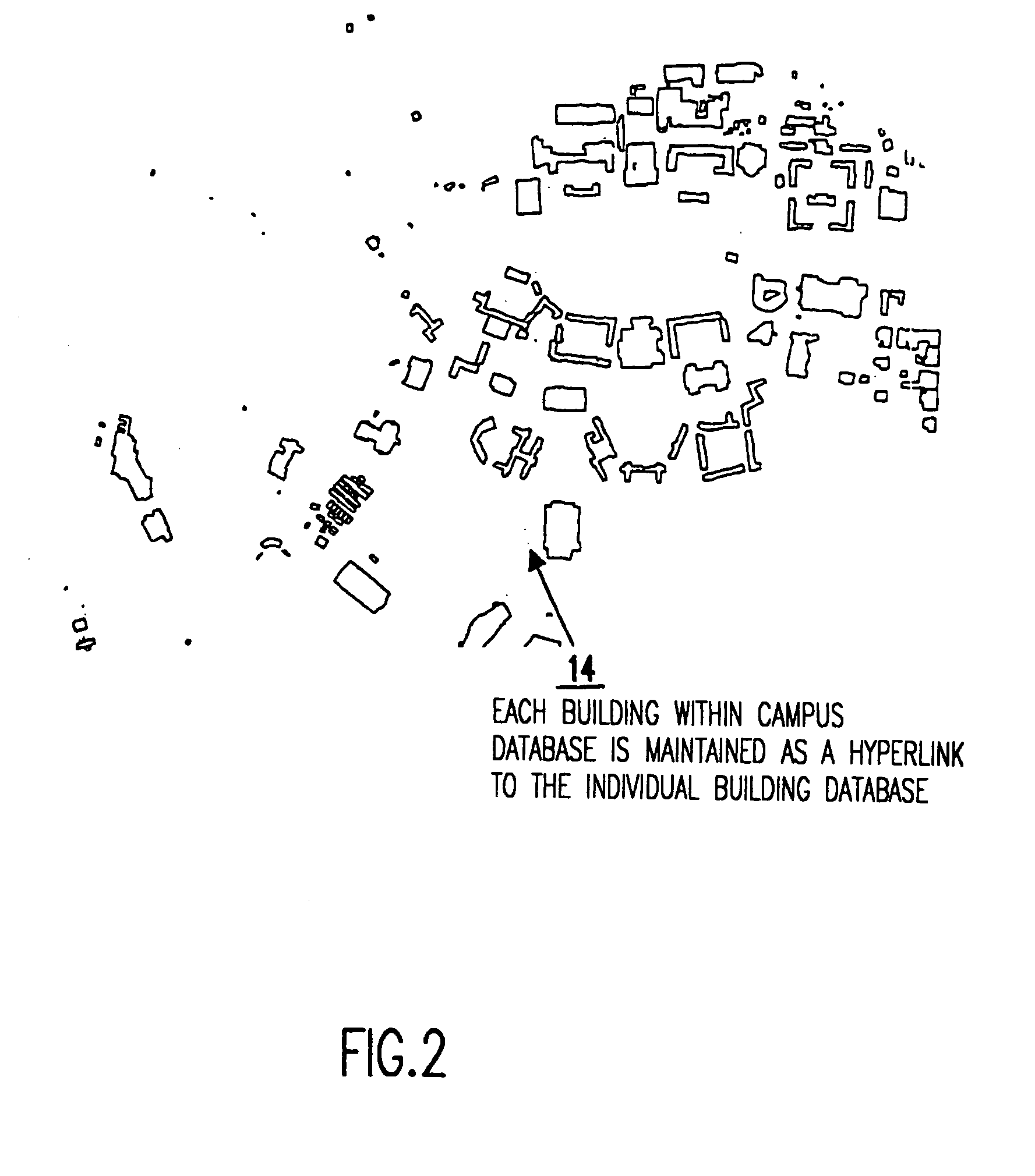

A system and method which employ one or more portable hand held computers and one or more servers, allows a field engineer to complete the entire design, deployment, test, optimization, and maintenance cycle required to implement successful communications networks. The engineer may take the portable hand held computer into the field, and make alterations to the components, position of the components, orientation of the components, etc. based on on-site inspection. As these alterations to the computerized model are made, predictions for the effects these changes will have on the communications network are displayed to the engineer. Measurements may also be made using equipment connected to or contained in the portable hand held computer, and these measurements may be used to optimize performance criteria. Information can be transmitted to and from the portable hand held computer and the server to allow for complex processing to be performed.

Owner:EXTREME NETWORKS INC

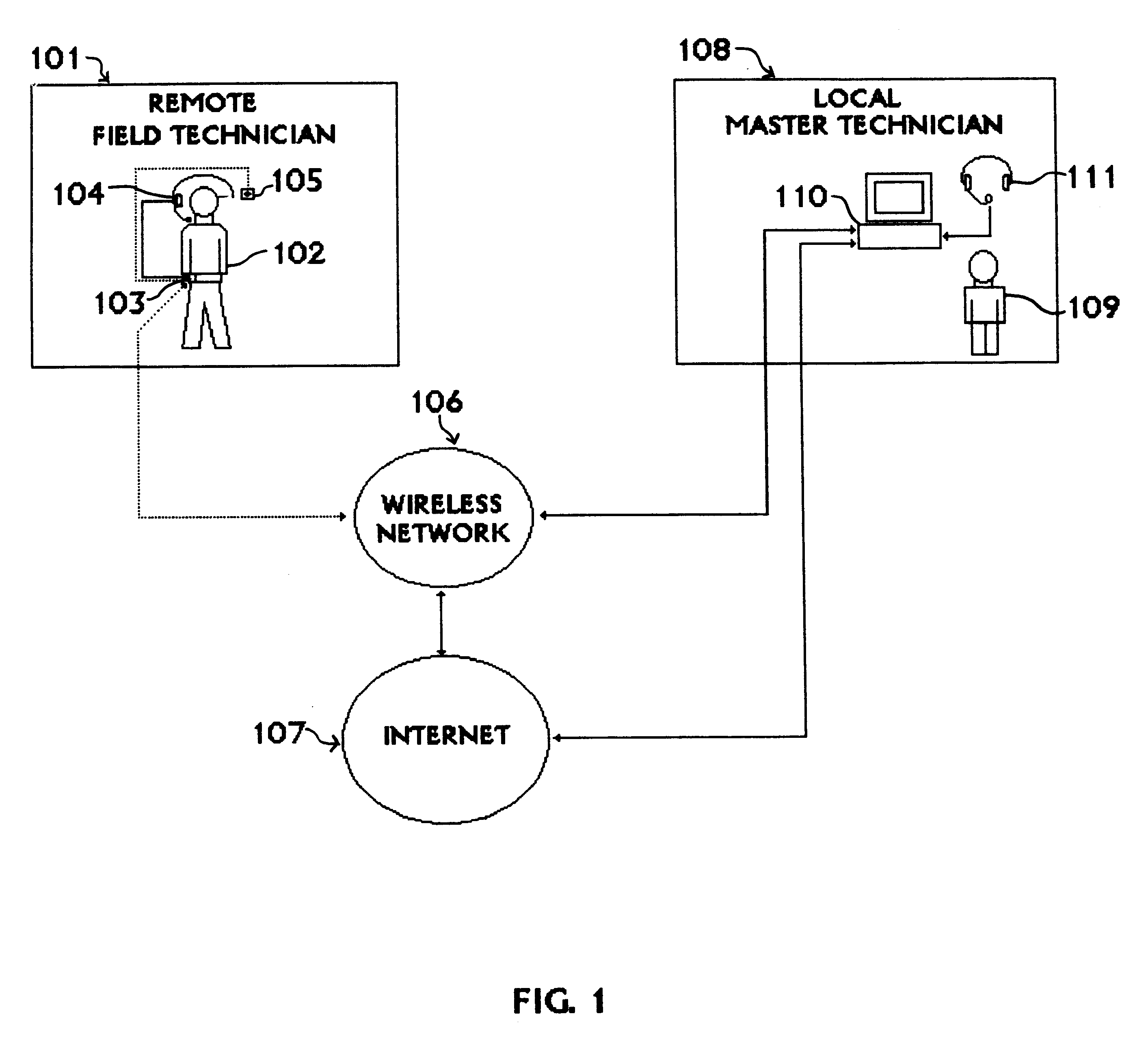

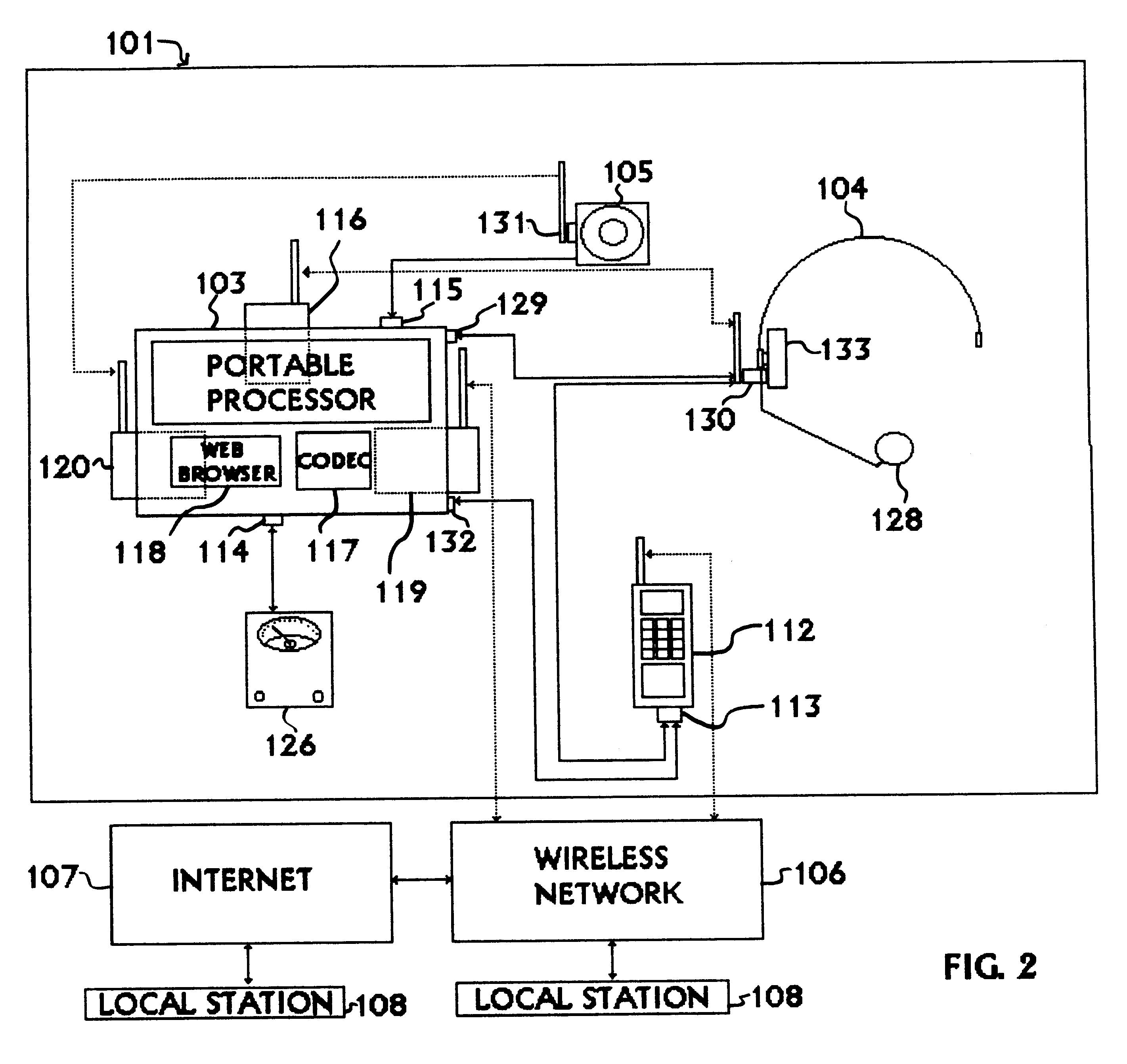

Wireless video audio data remote system

InactiveUS6317039B1Frequency-division multiplex detailsTime-division multiplexRemote systemEngineering

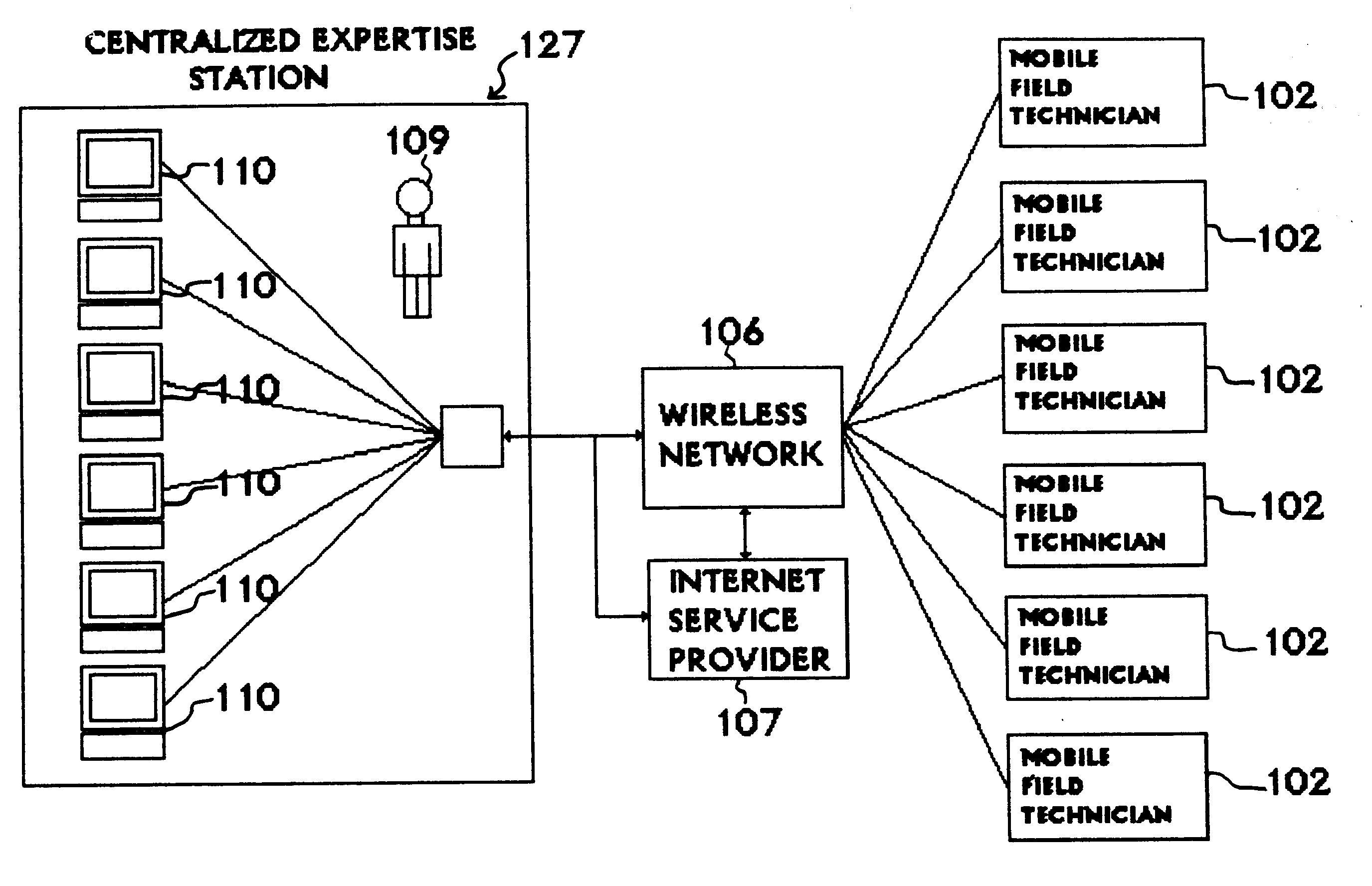

A method and system for remote assistance and review of a technician or multiple technicians, in real time, working with equipment of various complexity. A technician or multiple technicians at a remote location are coupled by a wireless means to an advisor at a local station, so that the advisor may view and hear the same stimuli as the technician, that the advisor and technician may communicate. The technician has limited training or otherwise in need of support, and may be a field engineer, technician or maintenance personnel. The advisor has extensive training and able to provide technical support, and generally has extended and specialized knowledge with regard to the remote apparatus, and may be a technical expert on the remote apparatus. The technician may comprise an individual or group with technical training and knowledge, but lacking managerial or other authority, while the advisor comprises an individual or group with such authority. The technician communicates with the advisor by visual cues or ordinary speech, while the advisor views and listens to the remote apparatus. The advisor gives advise to the technician for manipulating or repairing the remote apparatus. Alternatively, an intermediate advisor may advise the technician and be advised by a higher-level advisor.

Owner:WIRELESS REMOTE SYST

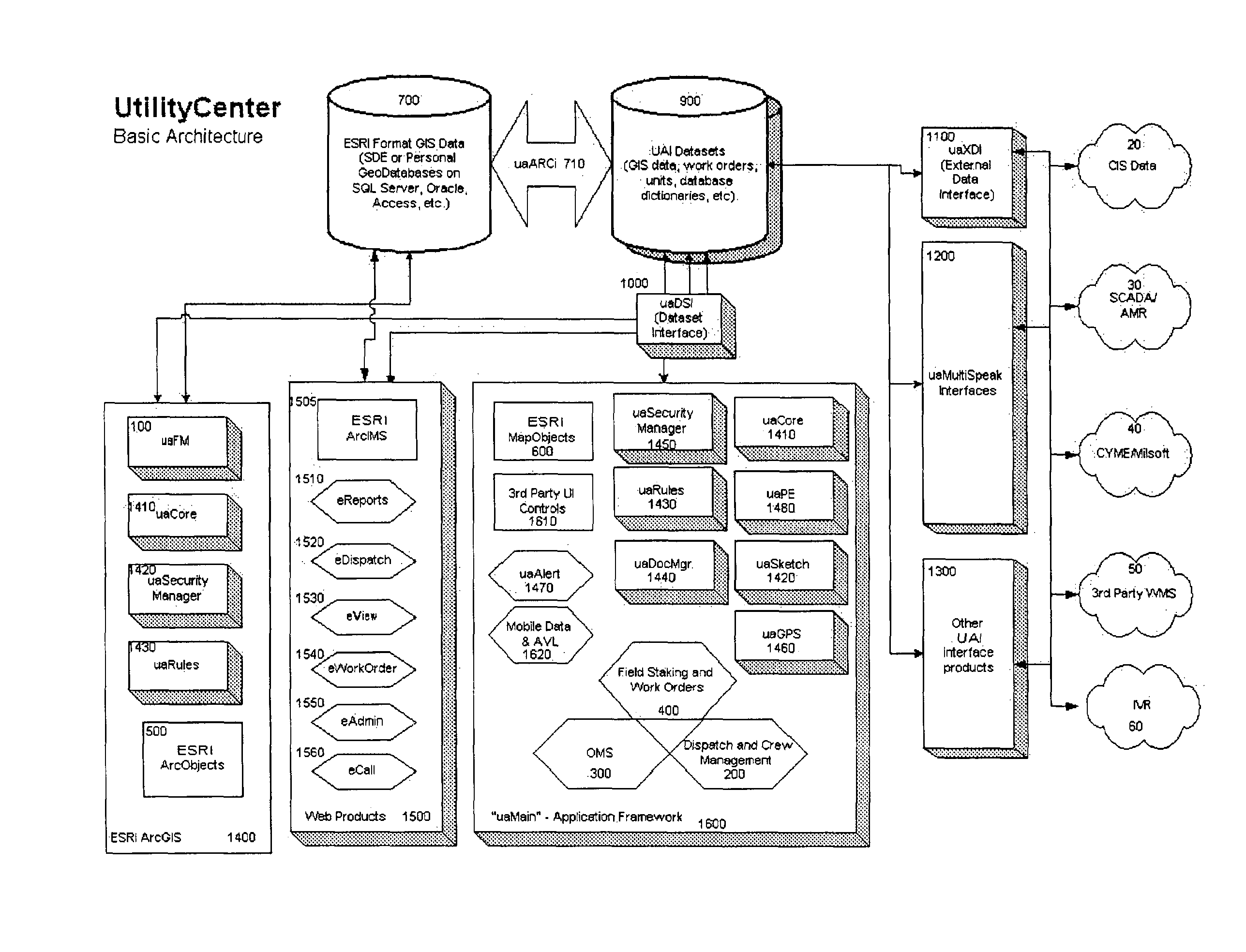

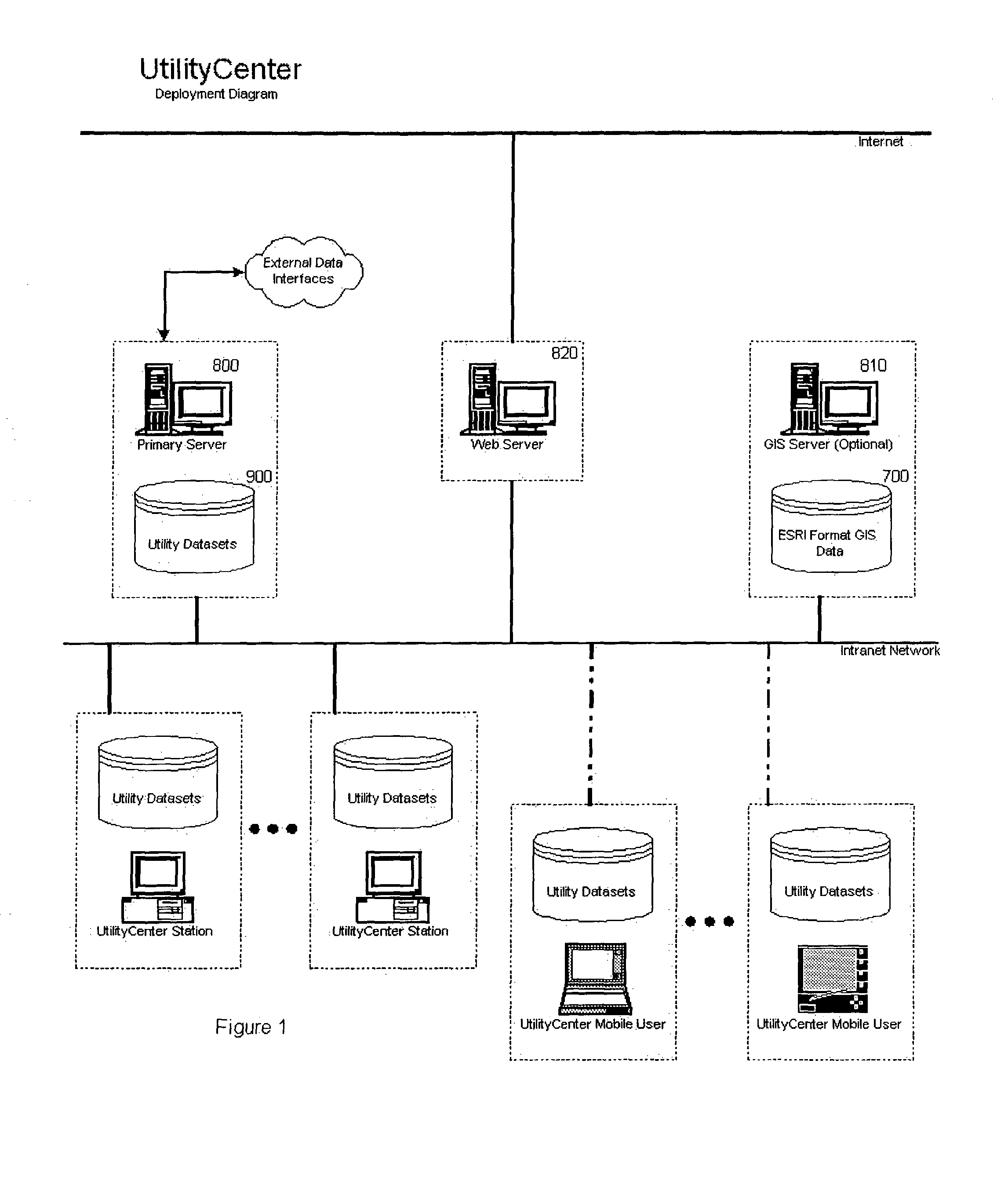

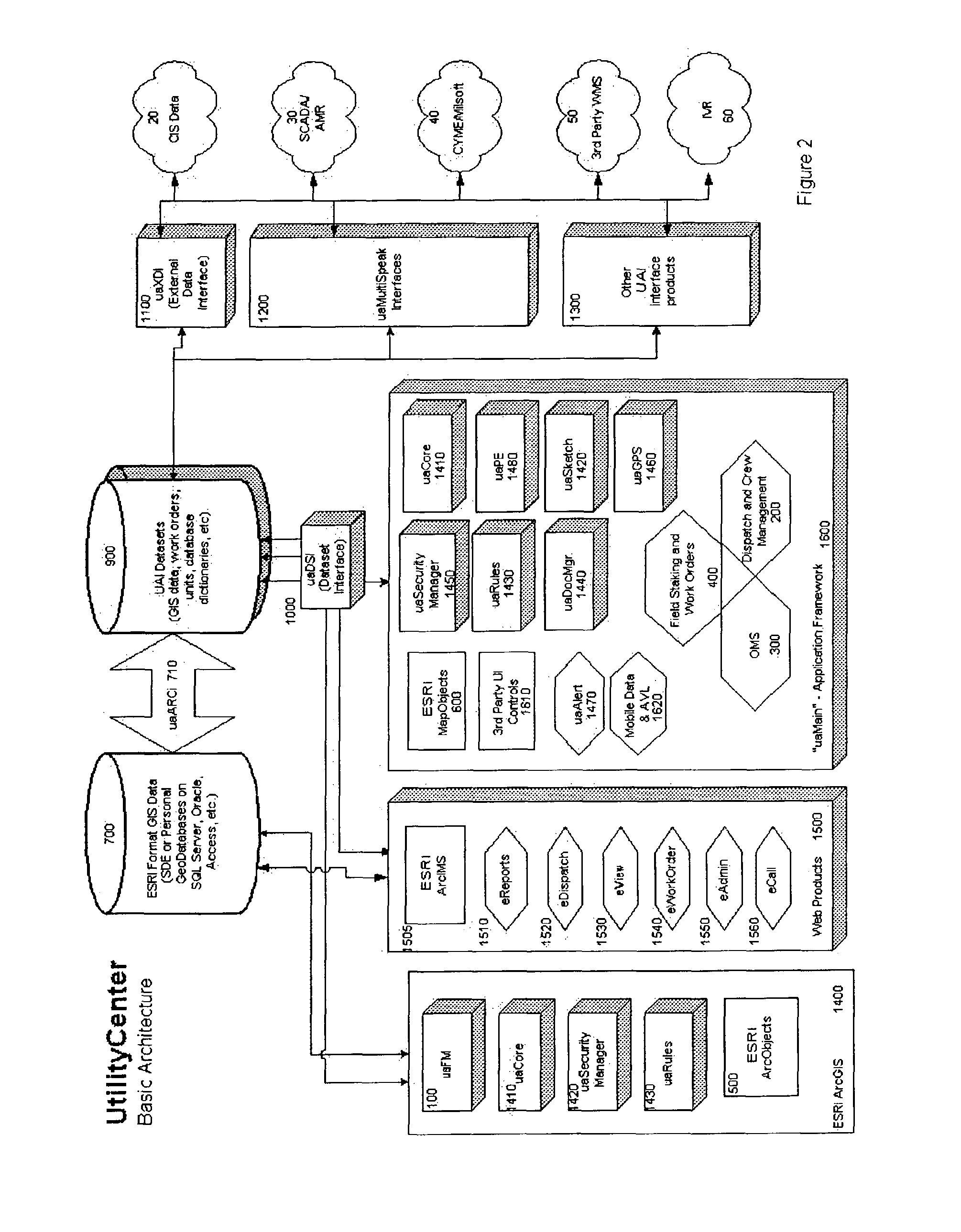

Automated utility supply management system integrating data sources including geographic information systems (GIS) data

InactiveUS7739138B2Accurate field collectionAccurate verificationMultiprogramming arrangementsResourcesData OriginData acquisition

An automated management system for managing data, outage repair, load switching, job workflow and crew dispatching, crew workflow, installation, maintenance and restoration of utility services by integrating geographic information systems (GIS) data with many other data sources so as to gather, transform, manipulate, analyze, and produce desired information for continuously supplying utility and relevant services. The data sources include customer information systems (CIS) and billing data, interactive voice recognition (IVR) call management data, supervisory control and data acquisition (SCADA), mobile crew management (MCM) data, automatic meter reading (AMR) data, automated vehicle location (AVL) data, engineering analysis data supported by 3rd party software packages (such as load monitoring and balancing), etc. In particular, the system allows an on-site engineer to retrieve data (ex. field maps, work orders, codes) or enter, via a portable device, inspection data (ex. such as poles or underground facilities, code violations).

Owner:UAI +1

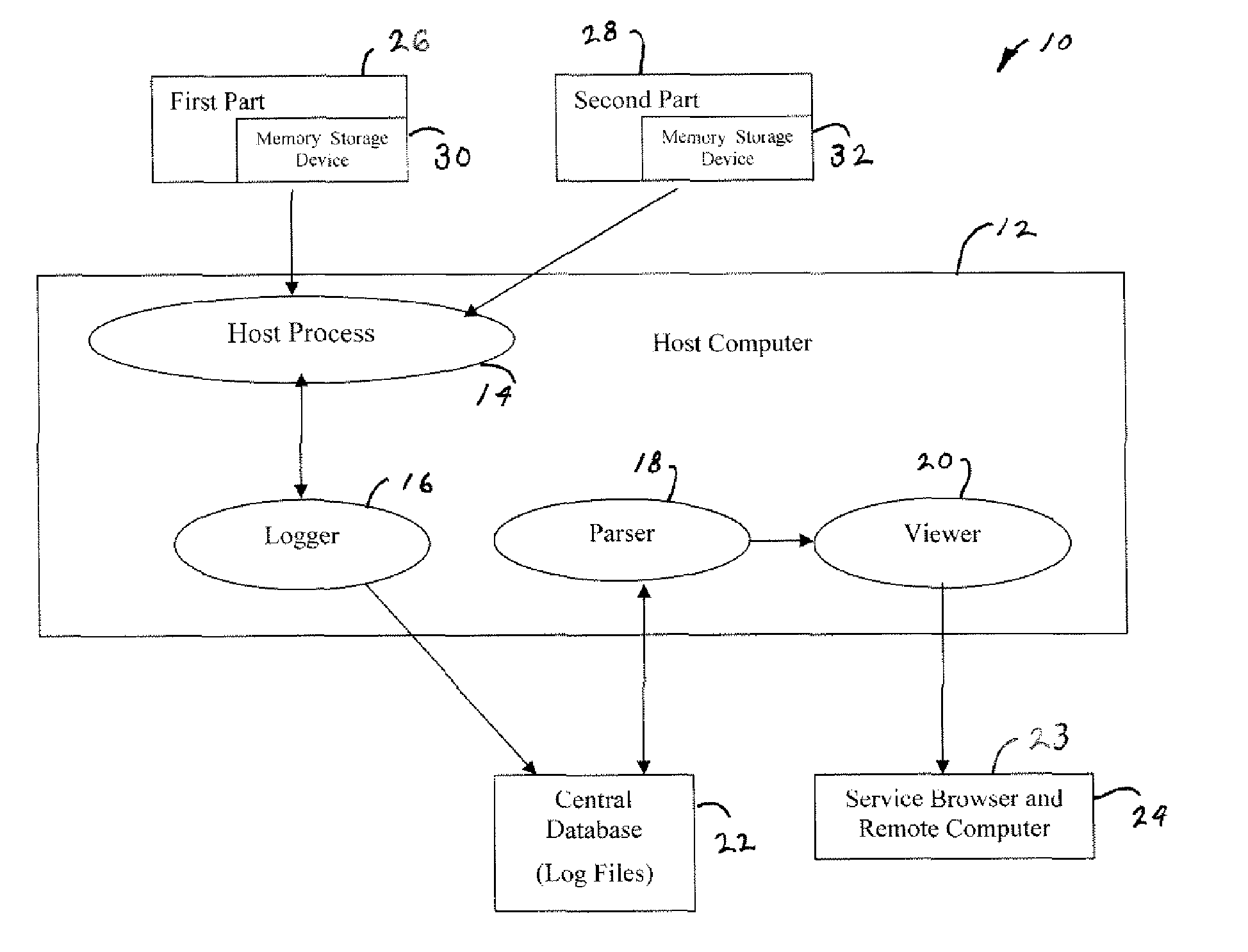

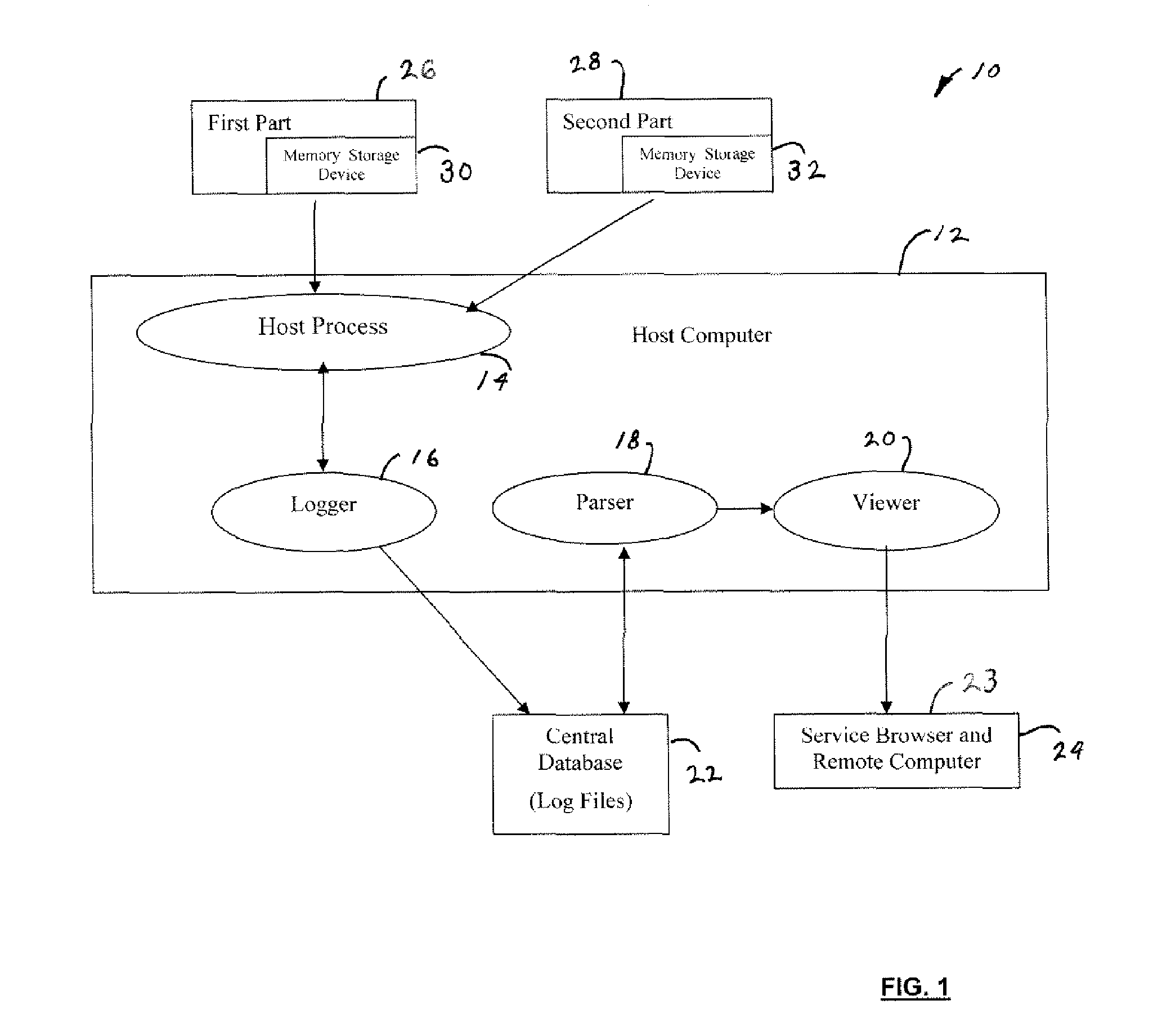

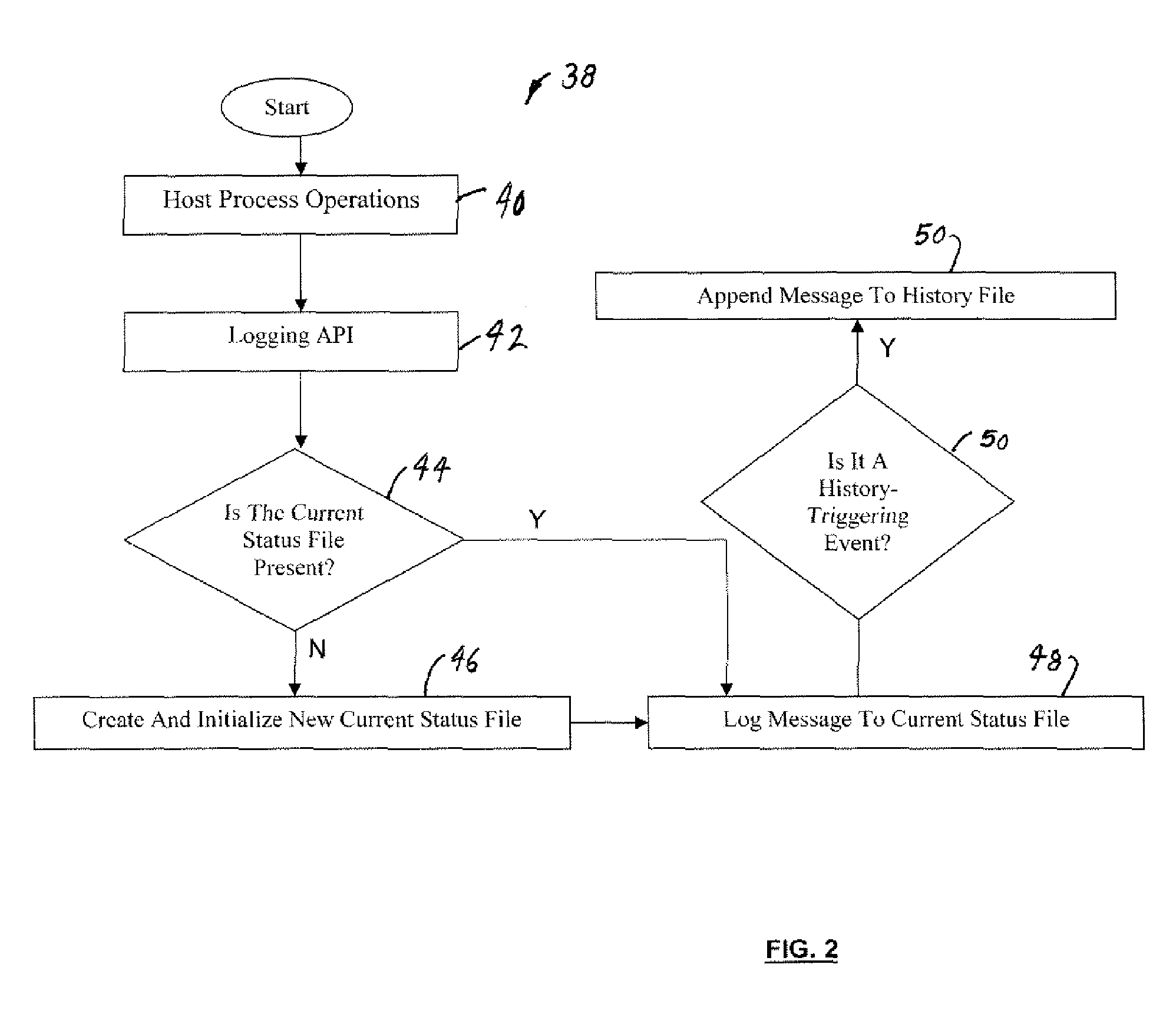

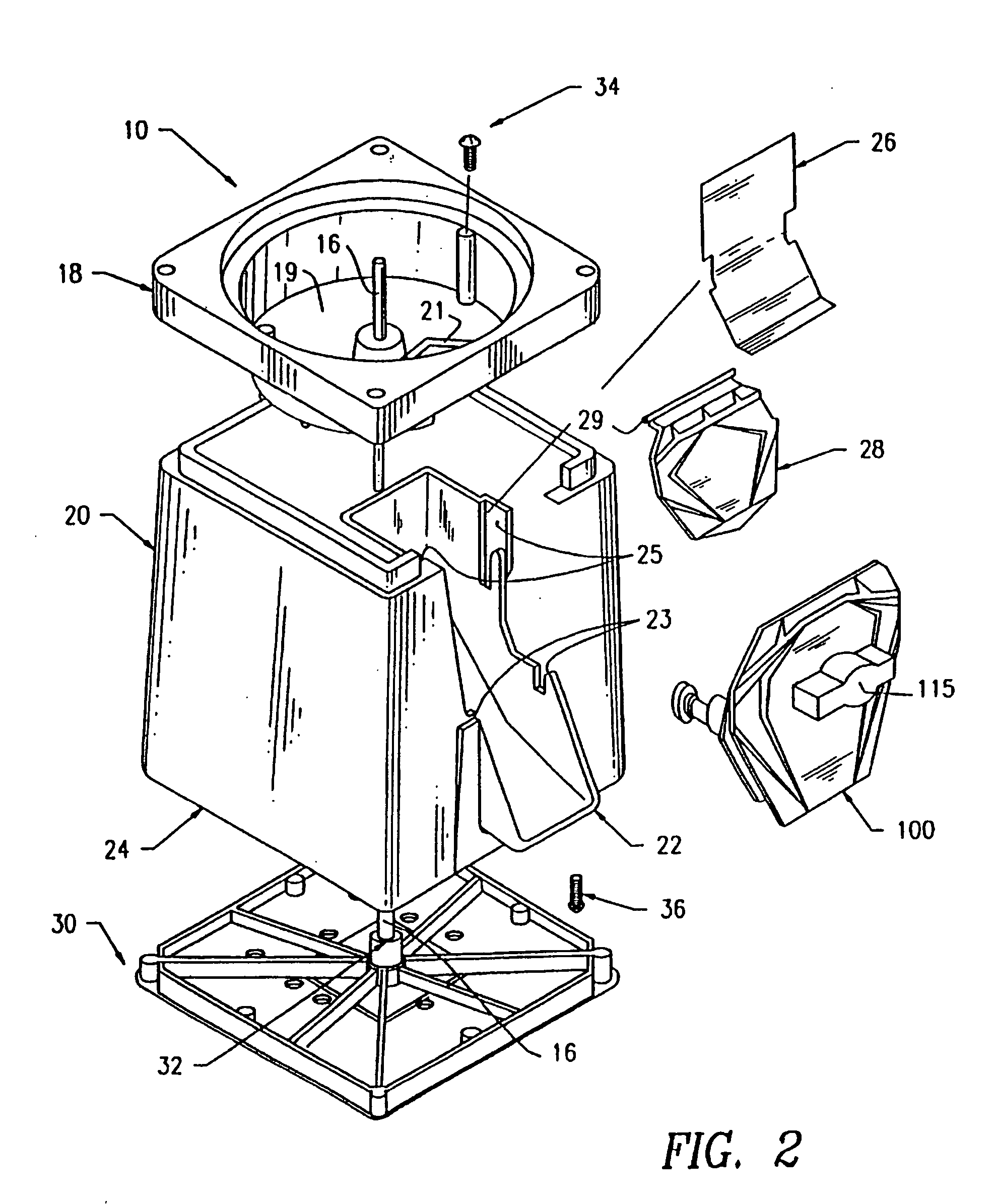

Automated software-based hardware tracking system

InactiveUS20060100972A1Readily availableRaise the possibilitySpecial data processing applicationsTemporal informationFirmware version

A hardware tracking system includes memory storage devices on tracked parts containing unique serial numbers, part numbers, revision numbers, and firmware versions. At power up and after a reset, a host computer or real-time subsystem downloads this information and compares it to the information stored in a central database. Changes in data in a central database log file indicate a replacement or update of the component, which is then used to automatically update the database. Each change causes the generation of a new record having date and time information attached thereto. These records are scanned to determine the system evolution. They are also compared to an error log and diagnostic history information to generate a cause versus effect occurring during troubleshooting. The system also tracks and records the number of times a part is removed and re-inserted, indicating shot-gunning of the system by field engineers.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

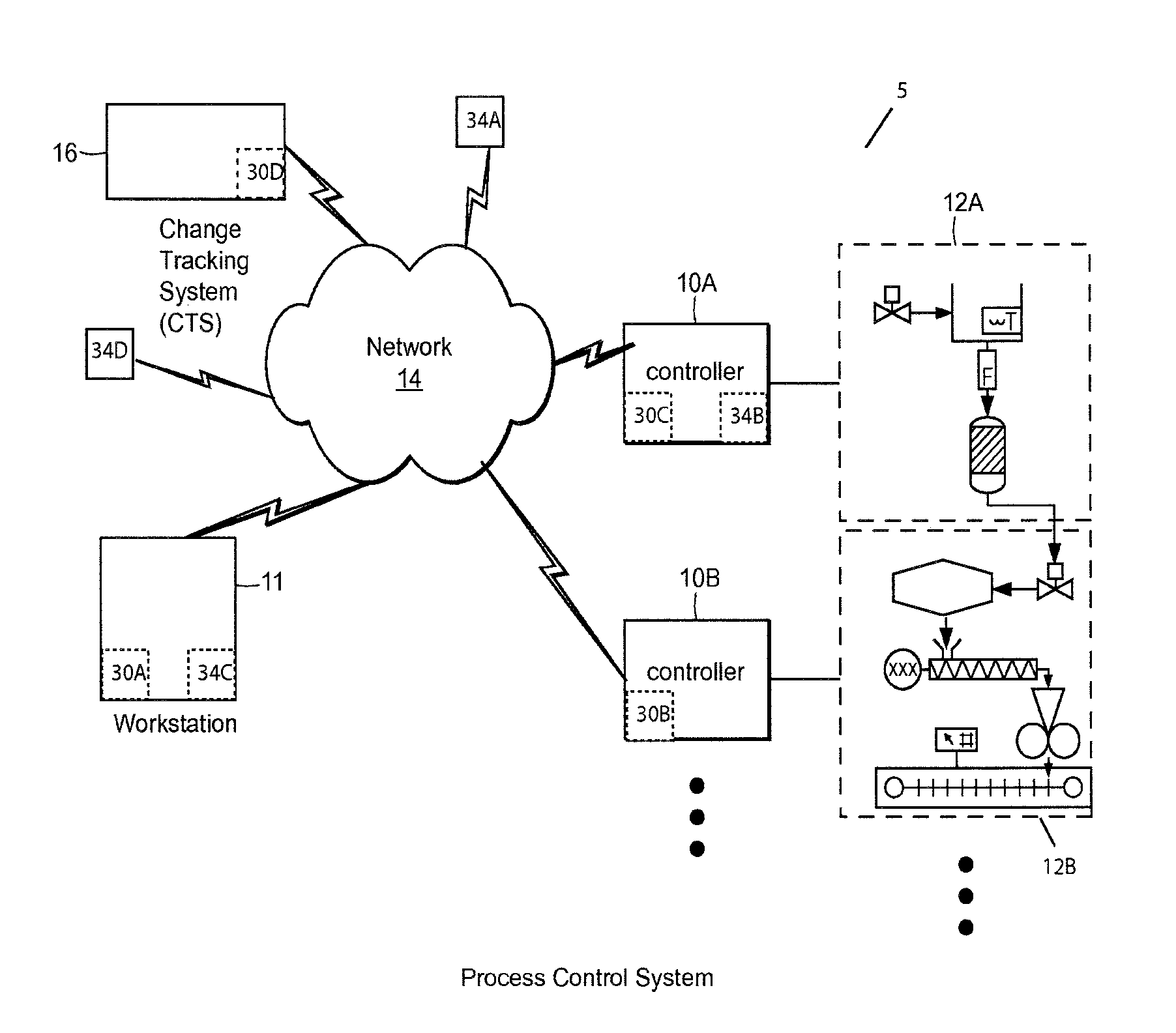

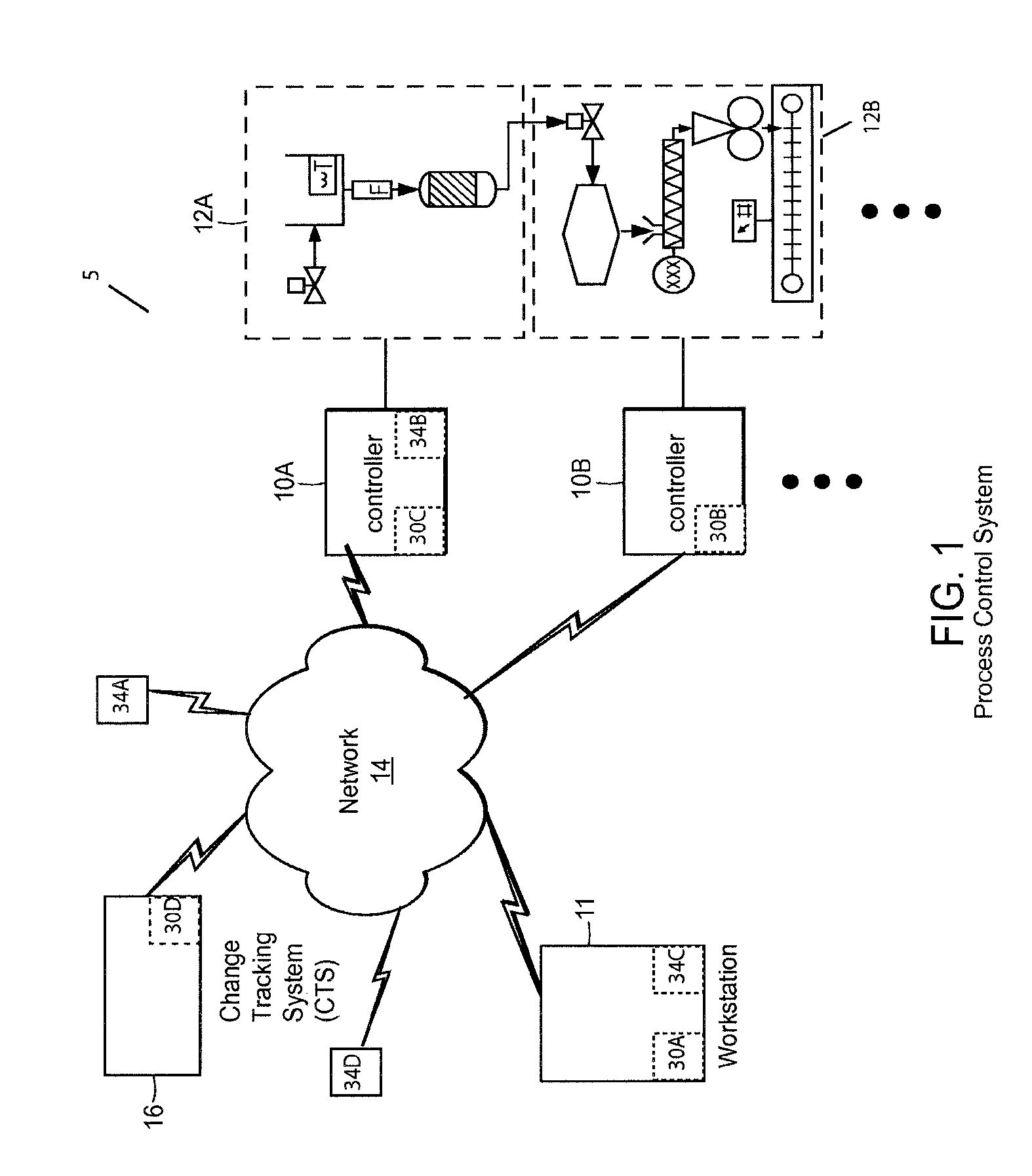

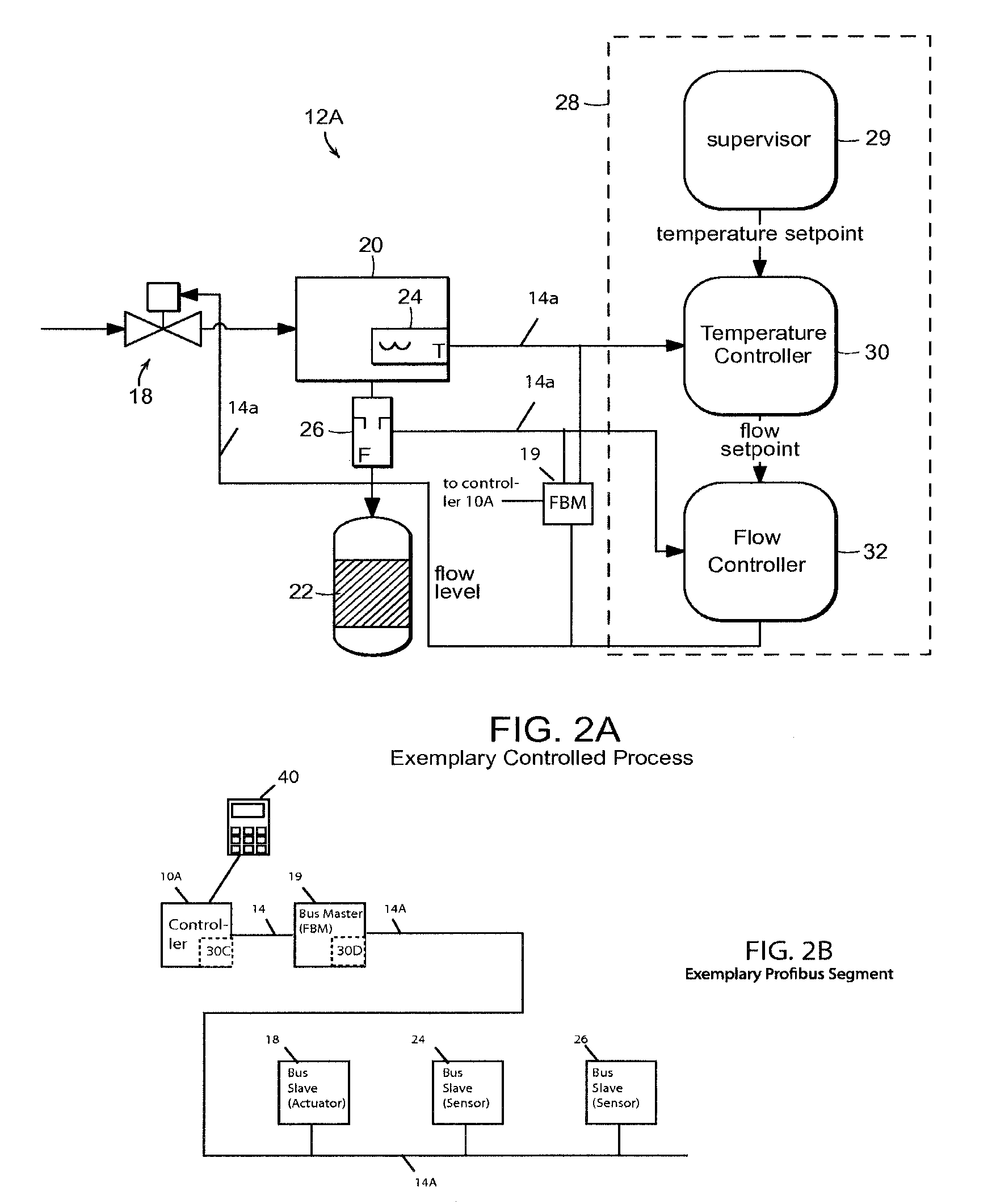

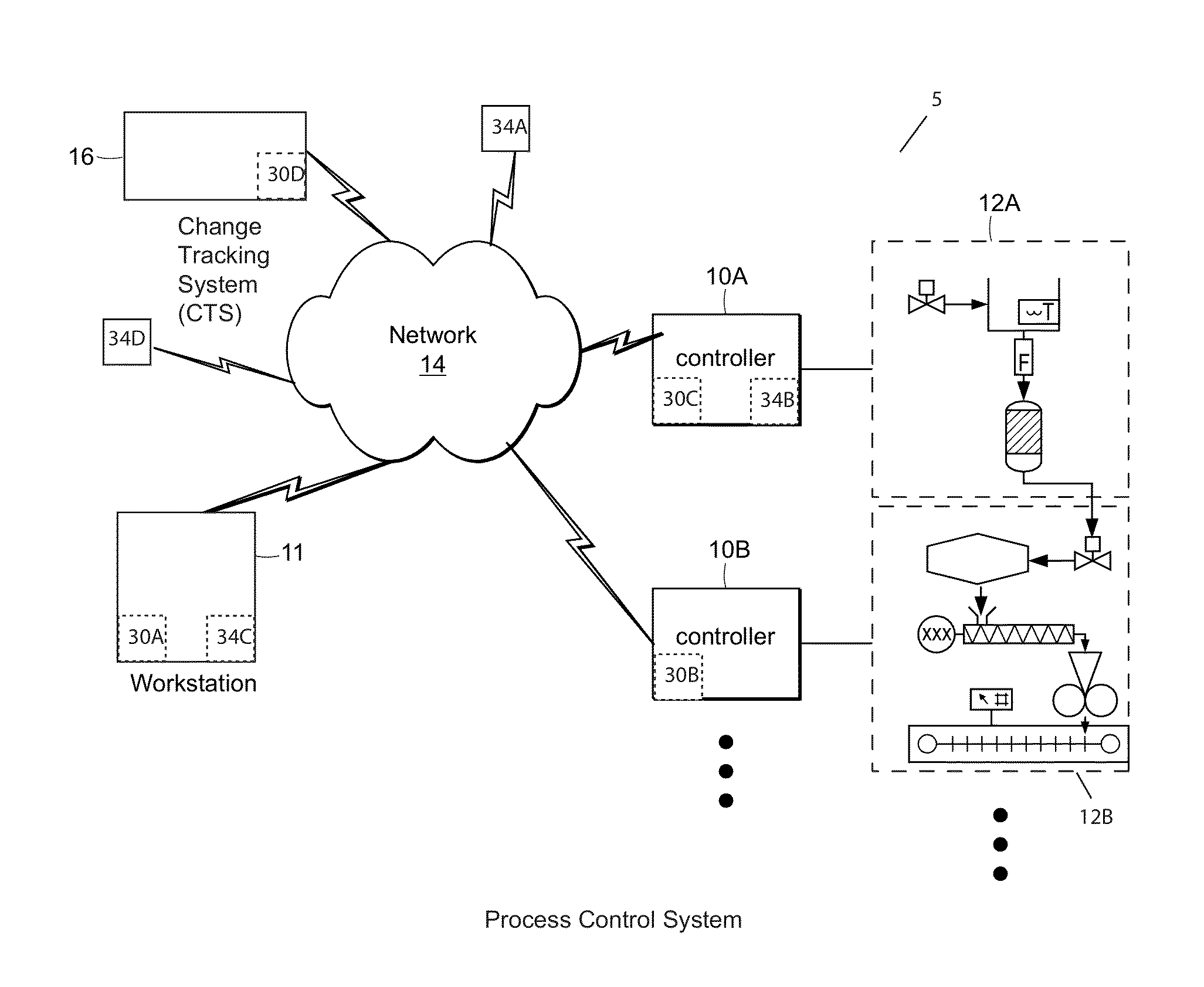

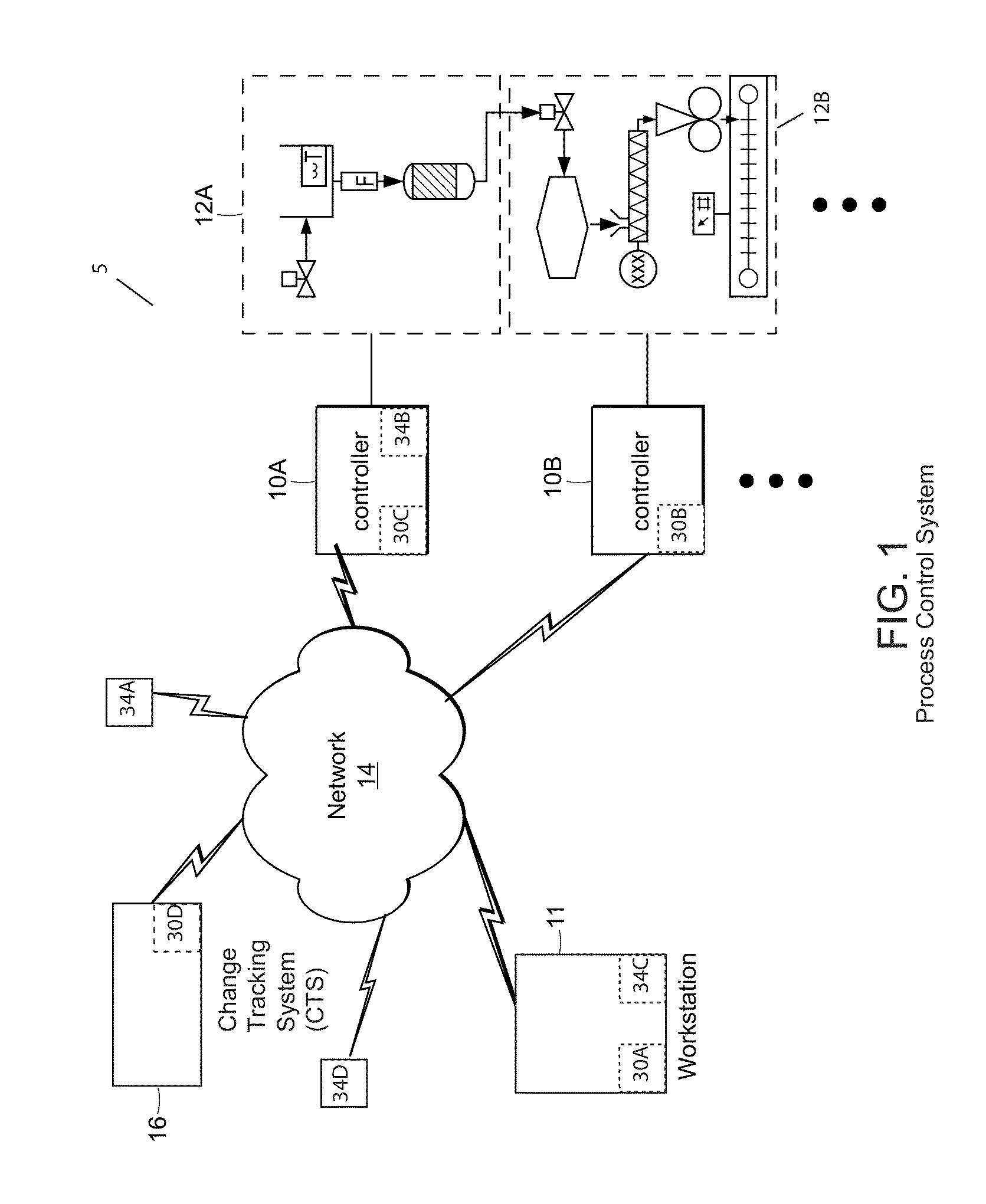

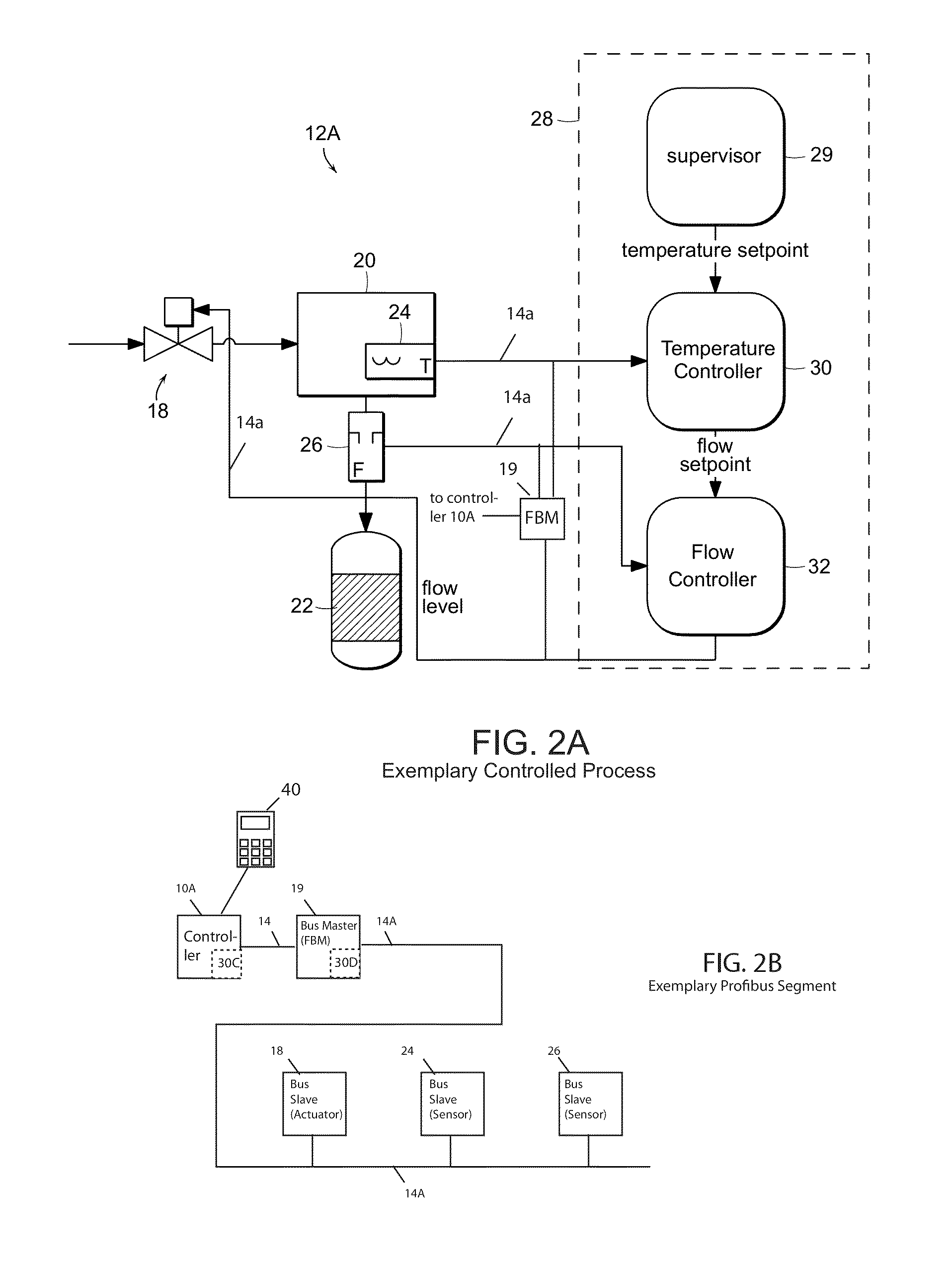

Methods and apparatus for control configuration with enhanced change-tracking

The invention provides, in some aspects, a process, environmental, manufacturing, industrial or other such control system (hereinafter, “control system”) with enhanced, real-time change tracking. The system includes one or more configurable elements (e.g., field devices), a change tracking system that records of changes to those configurable elements (e.g., for compliance reporting, etc.) and a change detection system that responds to detected changes in configuration of those element(s) by inferring an identity of a person and / or device responsible for a change, the time of the change, and / or the reason for the change. This is unlike prior art systems, in which that such information must be specified, e.g., in a data entry form filled-in by the field engineer, operator or other who is making the change.

Owner:SCHNEIDER ELECTRIC SYST USA INC

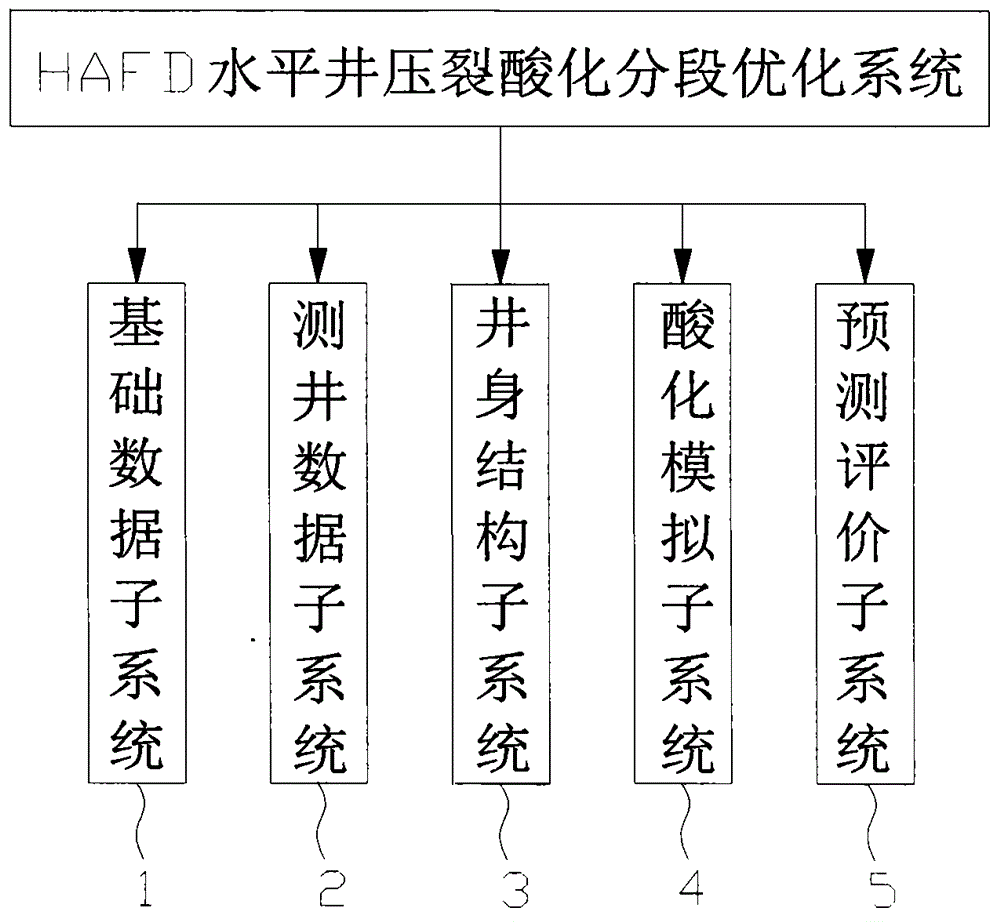

HAFD segmented optimization method and system

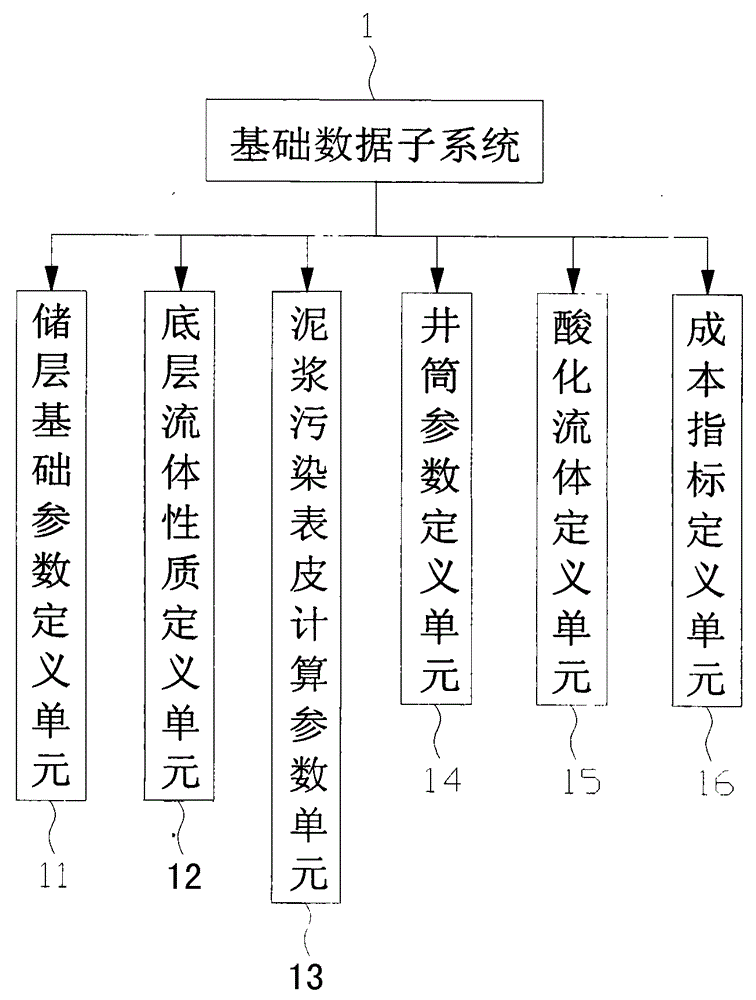

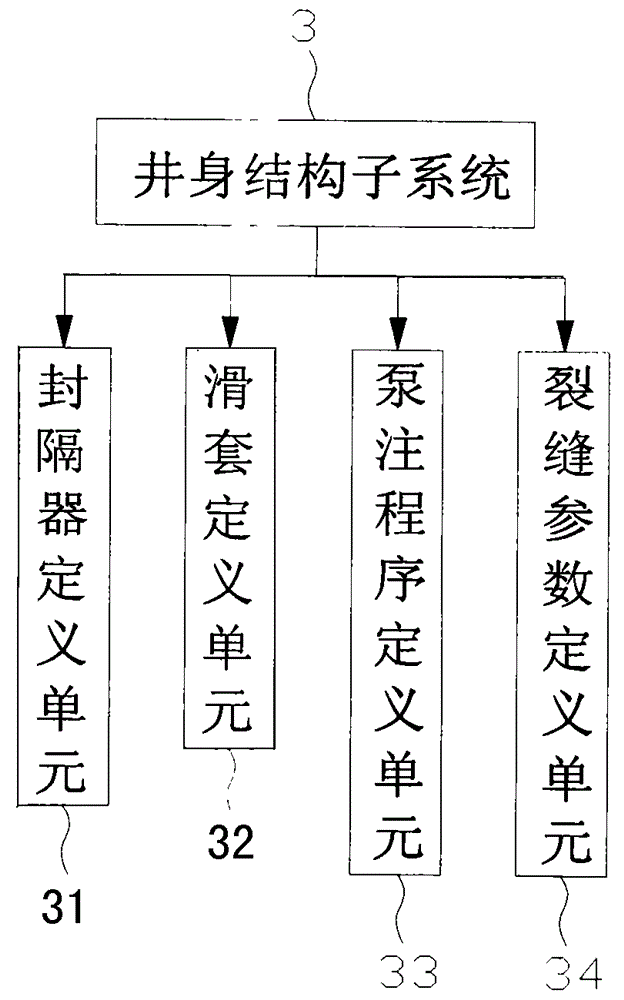

The invention relates to an HAFD (Horizontal-well Acid Fracturing) segmented optimization method and system. The optimization method comprises the following optimization flow: simulating a horizontal well segmented matrix acidization, predicting acidizing capacity for forming the horizontal well segmented matrix, predicting the capacity of the segmented acid fracturing horizontal well, optimizing segmented acidizing and acid fracturing for the horizontal well, realizing digitalization of well logging drawings, and combining the segmented matrix acidizing technology with the acid fracturing technology. The optimization system comprises a basic data subsystem, a log data subsystem, a well bore configuration definition subsystem, an acidizing simulation subsystem and a prediction evaluation subsystem. The optimization method disclosed by the invention is ingenious and reasonable in conception, simple in steps, and capable of avoiding the problems that the carbonatite reaction kinetic model is complicated and difficult to apply and estimating the acid absorption content of the stratum segment more accurately. The optimization system disclosed by the invention is simple and reasonable in structure, and capable of realizing integrated design process of the parameter design of the acidizing and acid fracturing technologies, effect prediction and economic evaluation, and brings convenience for field engineers to carry out optimization design on the acidizing scheme.

Owner:BEIJING GOODLUCK PETROLEUM TECH CO LTD

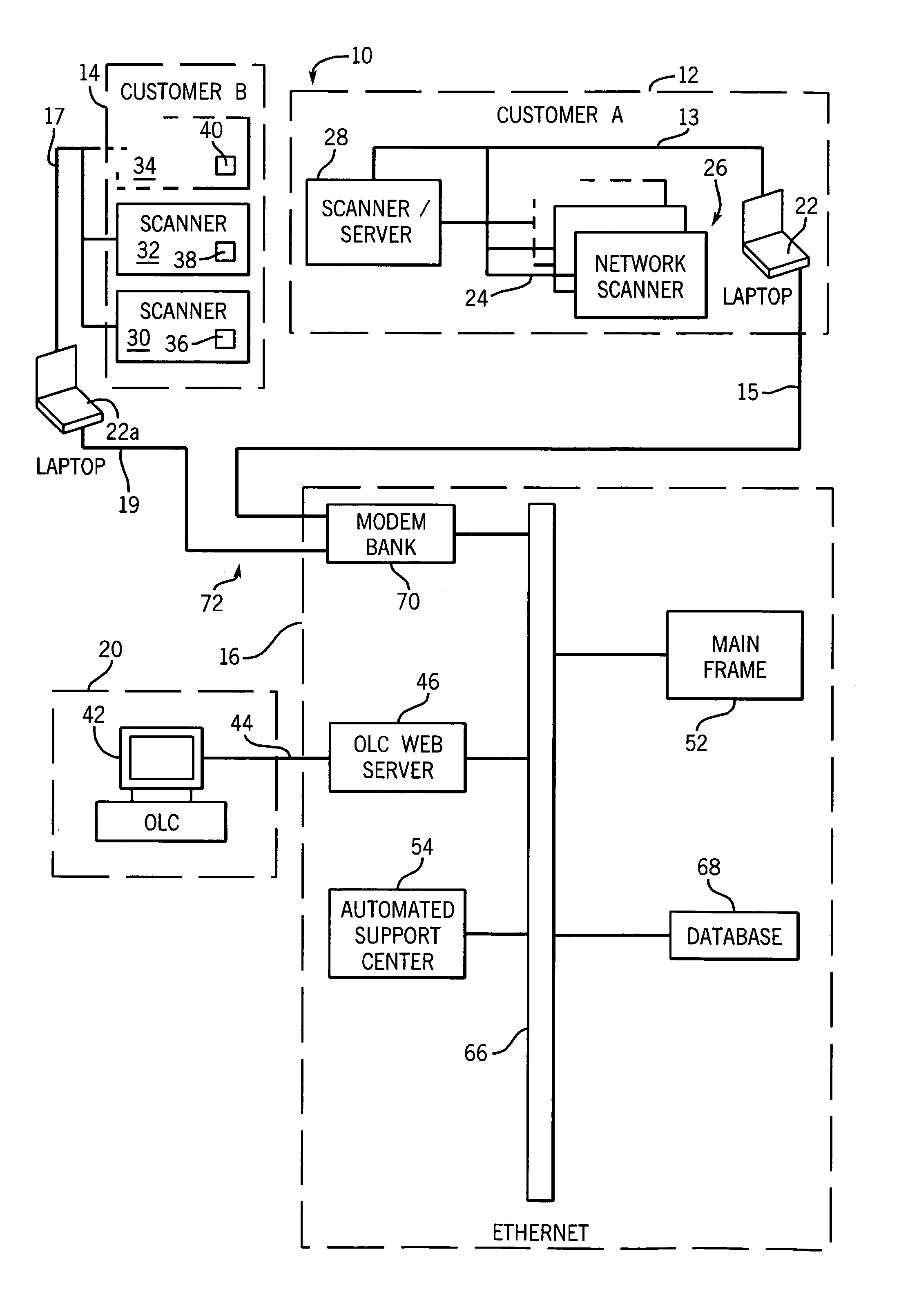

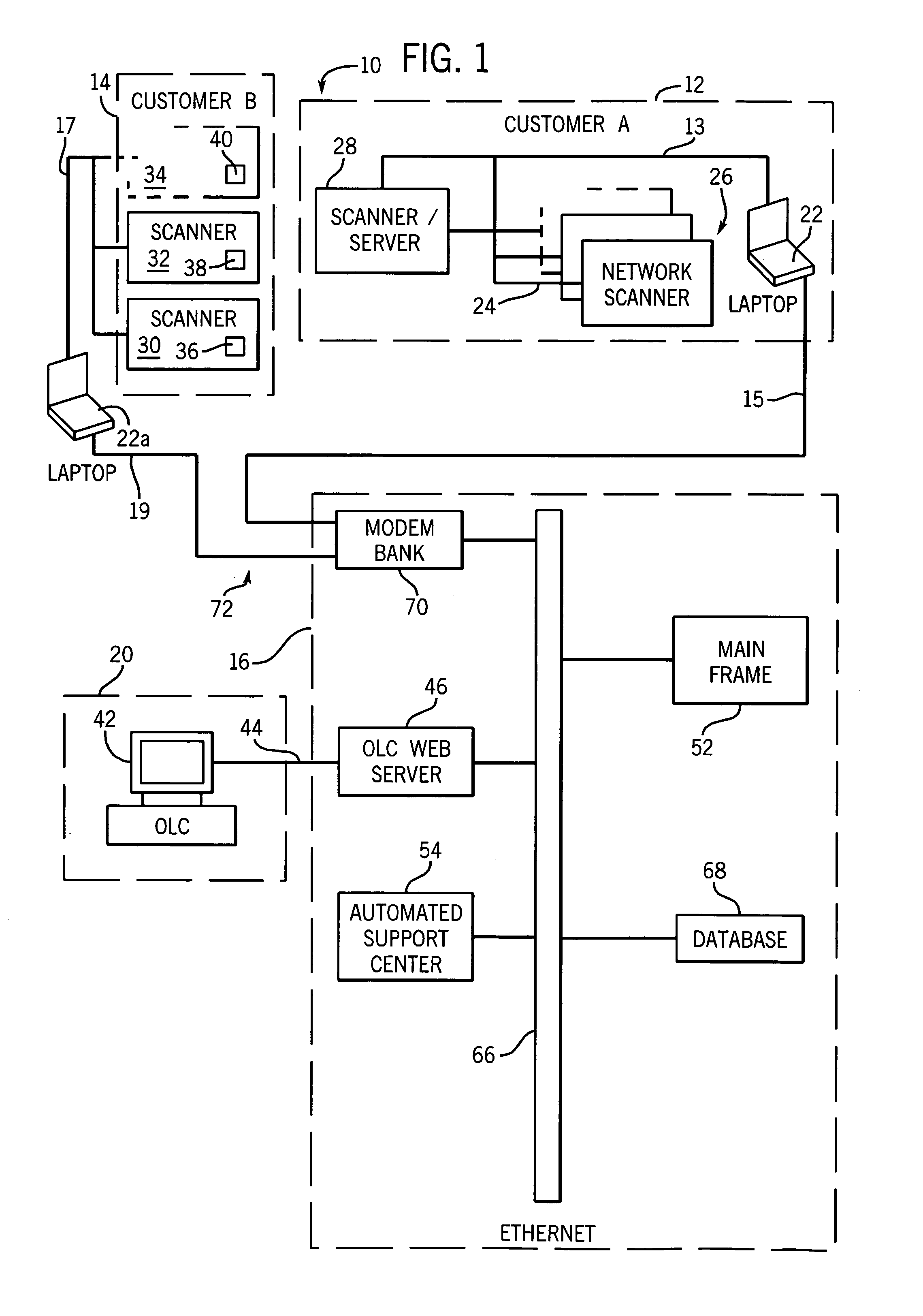

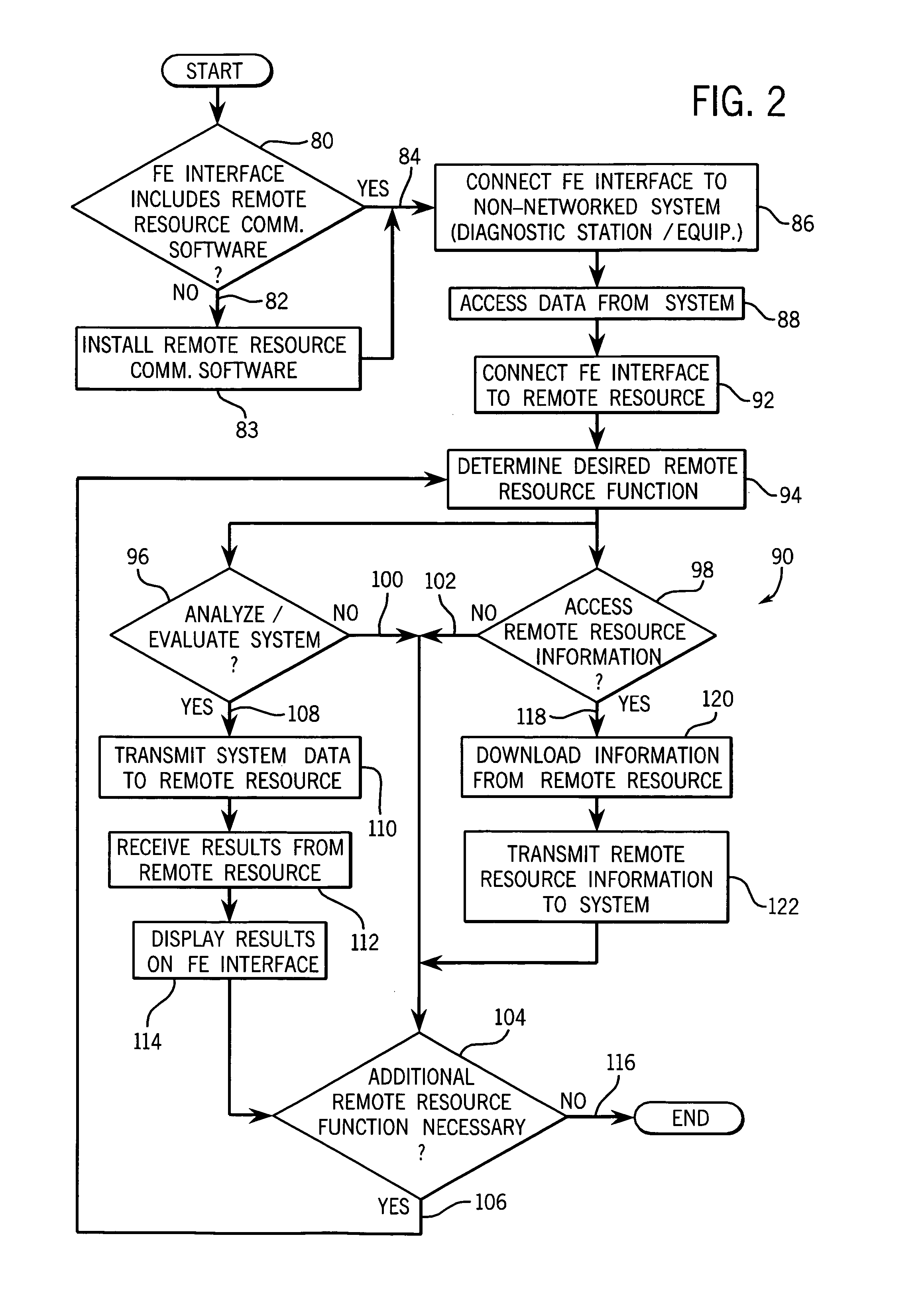

System and method for remote servicing of in-field product

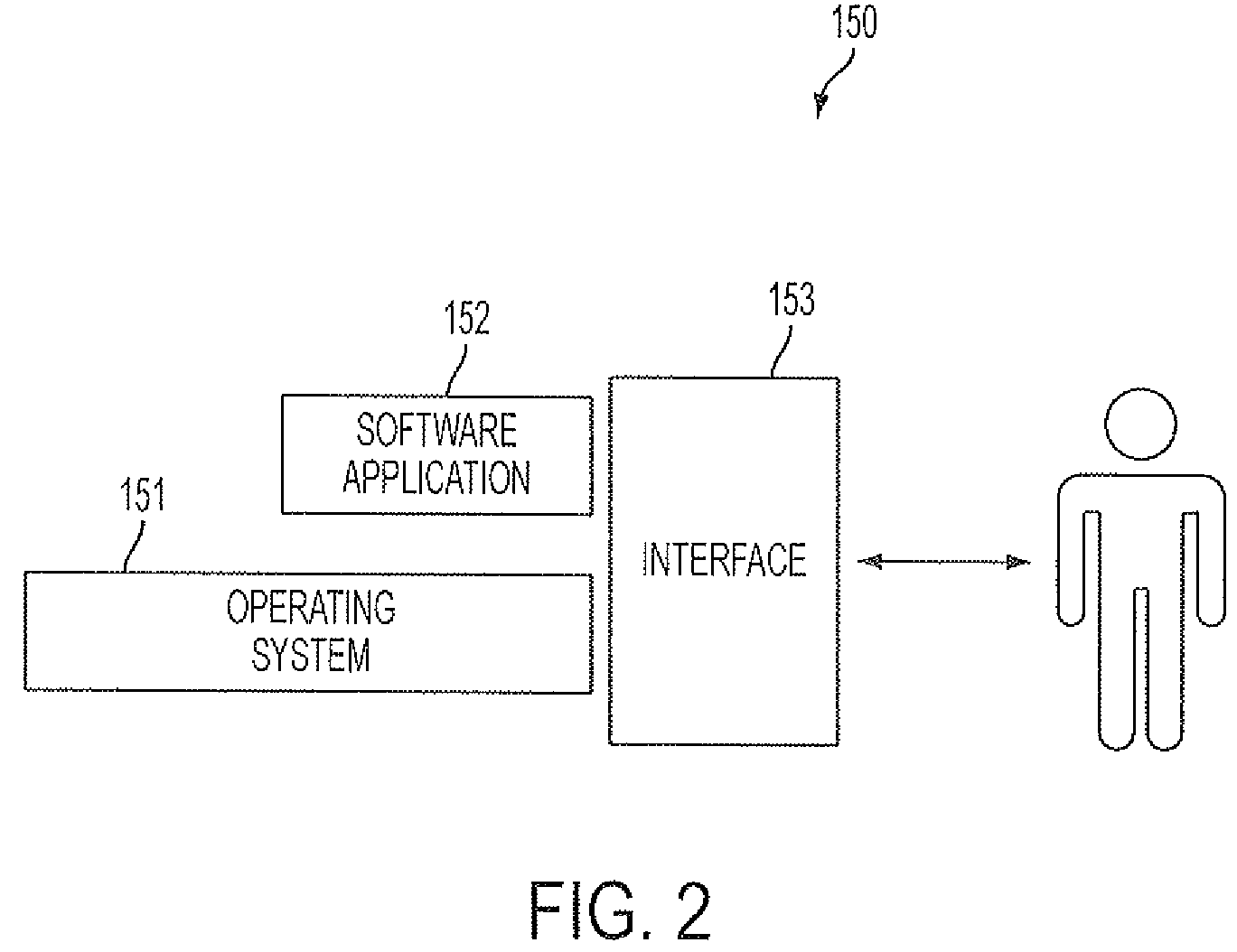

InactiveUS7383358B1Not readyLocal control/monitoringMultiple digital computer combinationsEngineeringSite engineer

A system and method for remote servicing of an in-field product at a customer site. The remote servicing system includes a portable service interface, typically a laptop computer, which is utilized to connect a remote servicing on-line center with the in-field produce, such as a medical image scanner. The portable service interface includes software not resident with the in-field product to permit such servicing functions as diagnostic evaluations of the in-field product, as well as downloading configuration files, original source files, protocols and other software from the on-line center through the portable service interface at the customer site. The field engineer or other operator is able to provide service functions to in-field products that are not networked or are not readily networked with the on-line center and that do not have the on-line center connecting software resident on the portable service interface.

Owner:GE MEDICAL TECH SERVICES

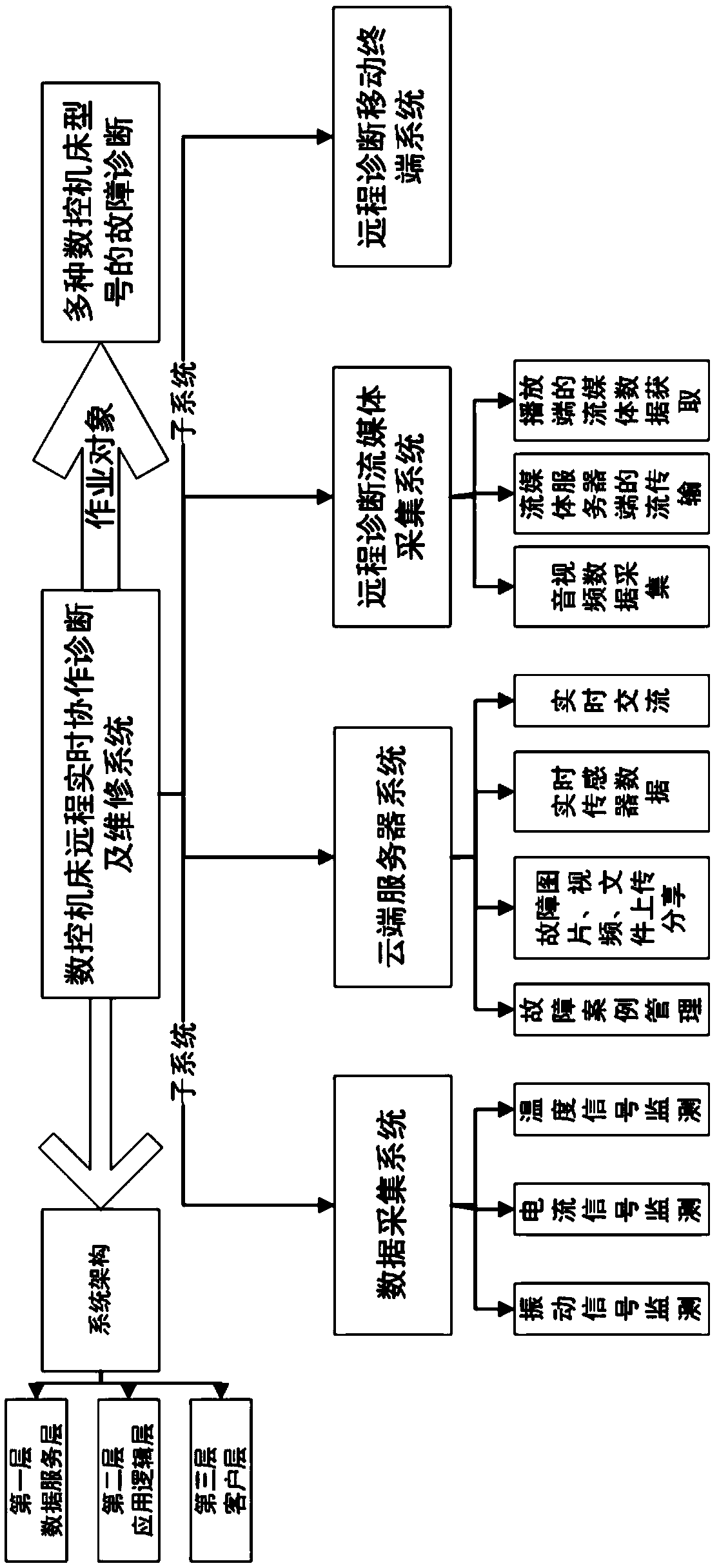

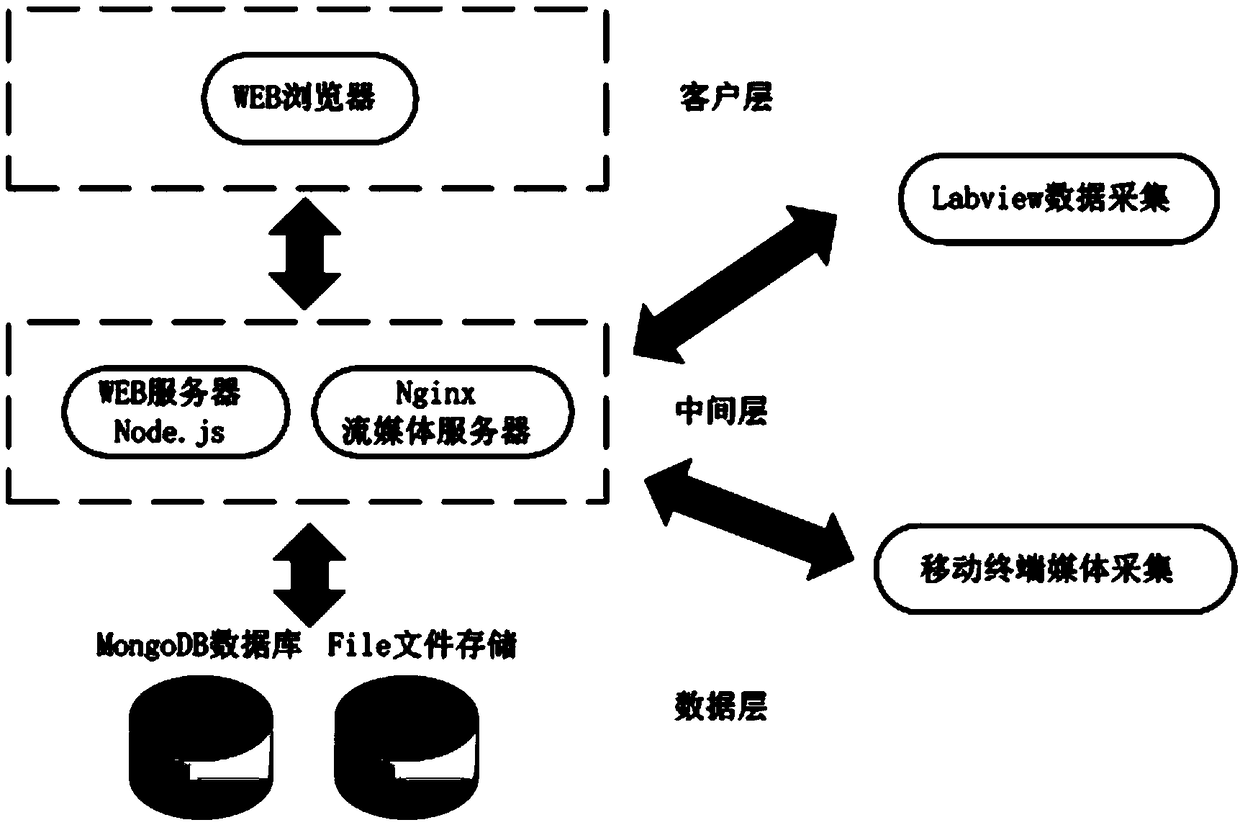

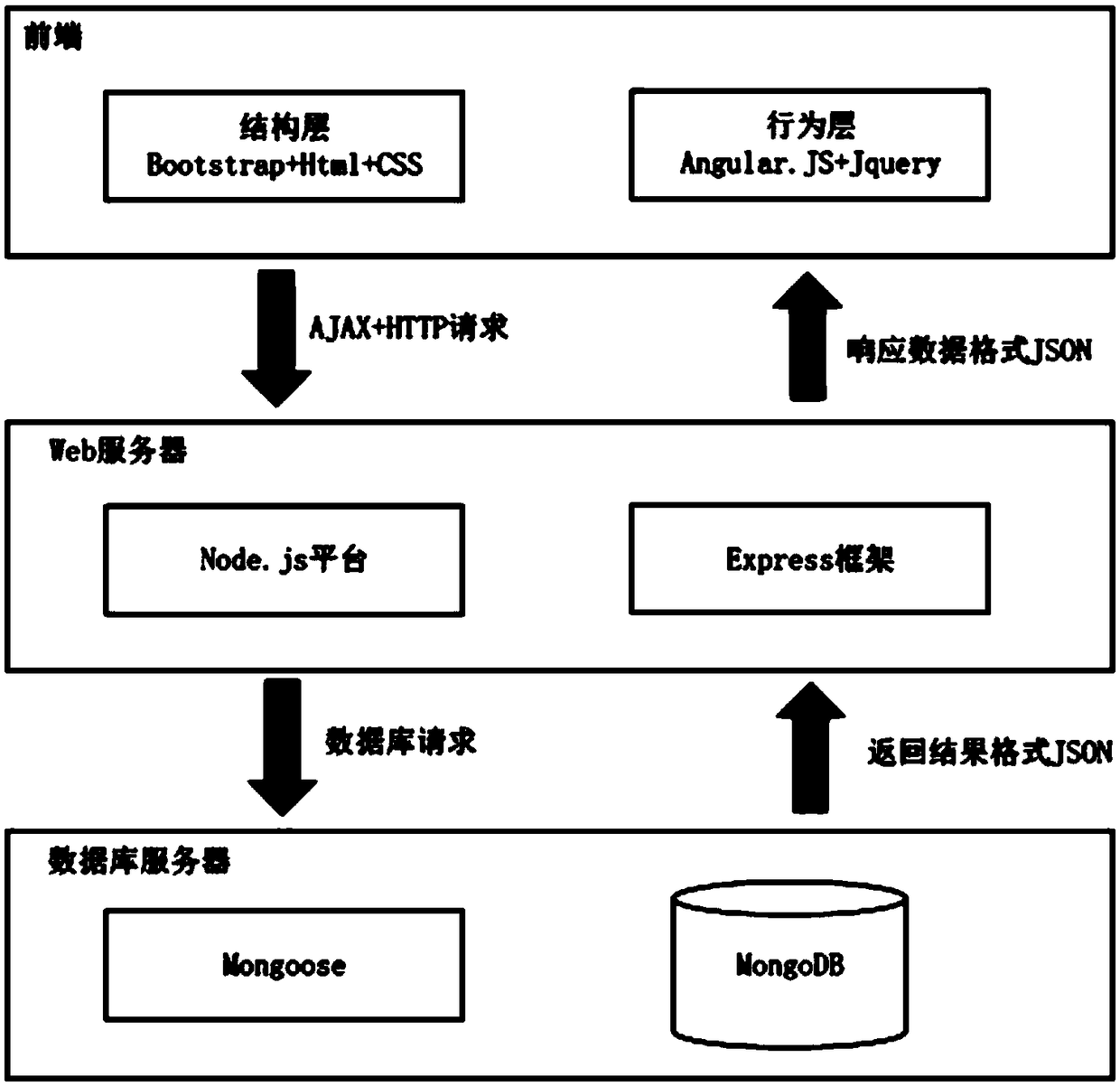

Numerical control machine tool remote real-time cooperation fault diagnosis and maintenance system

The invention relates to a numerical control machine tool remote real-time cooperation fault diagnosis and maintenance system. According to the system, a LabVIEW virtual instrument technology, a Node.js background server technology, a streaming media technology and an iOS mobile terminal technology are utilized to establish a remote fault diagnosis system, data collection, transmission and processing are integrated on one shared platform, the work of a fault diagnosis expert gets rid of limitations of spatial positions and conditions, collected data is sent to a remote cloud server in real time through a network, and then the data is stored and distributed through the cloud server. For real-time cooperation, a cooperation exchange platform is set up, and real-time online text exchange andpicture and file sharing between a field engineer and the remote expert are supported. Meanwhile, mobile equipment is utilized to collect fault field pictures, videos and other multimedia data and send the data to the cloud server during field engineering so that the remote expert can view all types of multimedia data in real time. Besides, the system adopts an HTTPS encryption technology, so thatsecure transmission of the data is guaranteed.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

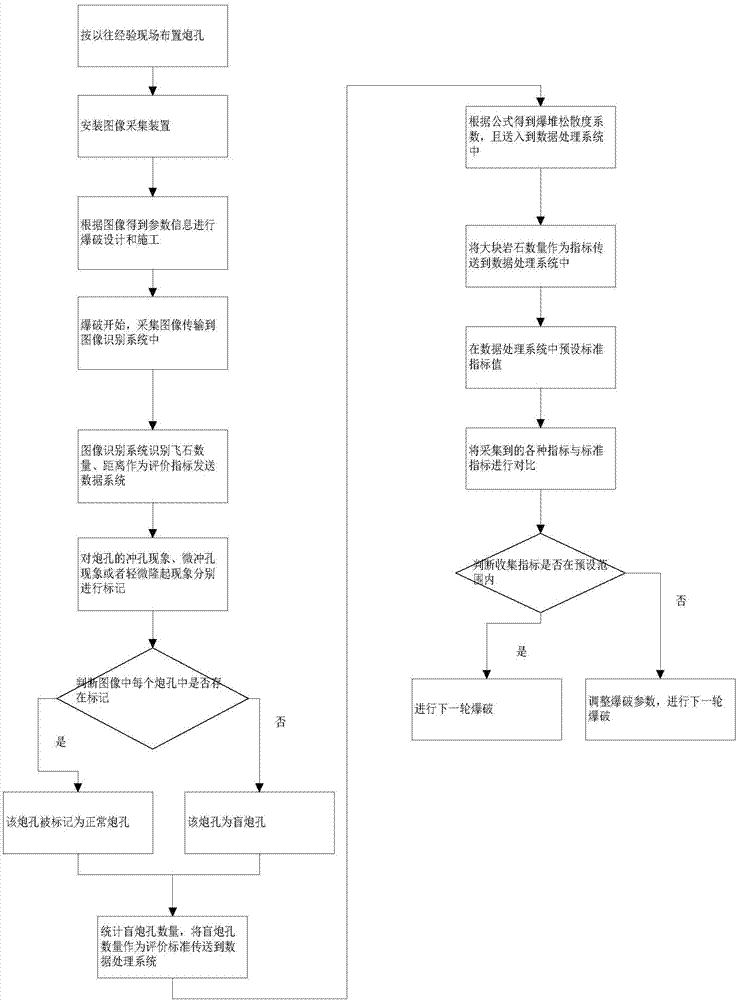

Open-pit mine demolition effect evaluating method

Provided is an open-pit mine demolition effect evaluating method. The method adopts the following steps that an image capture device is installed on a safety platform of a demolition bench; on-site images are captured by the image capture device to obtain actual on-site required parameters, and demolition construction is conducted by a staff member based on an actual distance; the number and the distance of slungshots, the shatter value coefficient of demolition muck pile, the size and the number of massive rocks and the number of blind holes are identified from the images collected by an image identification system as evaluating index values; the number and the distance of the slungshots, the shatter value coefficient of the demolition muck pile, the size and the number of the massive rocks and the number of blind holes are preset as standard index values in a data processing system; the index values collected are compared with the corresponding standard index values by the data processing system; evaluating index values above the standard index values are analyzed, demolition parameters are adjusted, and the next round of a demolition is conducted. The method has the advantages that the method is accurate, open-pit mine demolition effects such as the number of the slungshots, blind shot judgement and demolition muck pile information are evaluated quantitatively, operation is convenient and easy, the method is safe and reliable, and the work amount of an on-site engineer is reduced.

Owner:GEZHOUBA YIPULI XINJIANG BLASTING ENG CO LTD +1

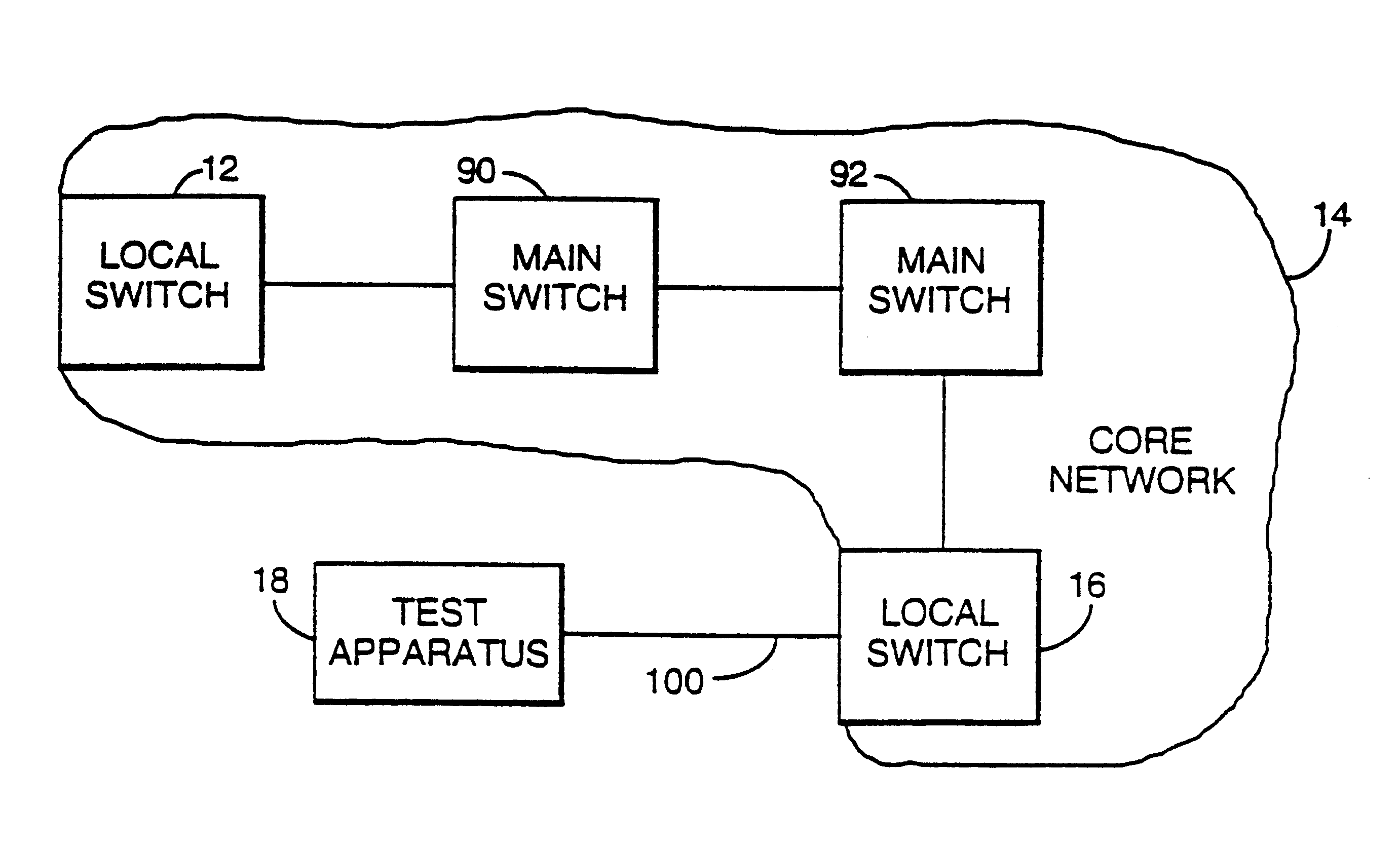

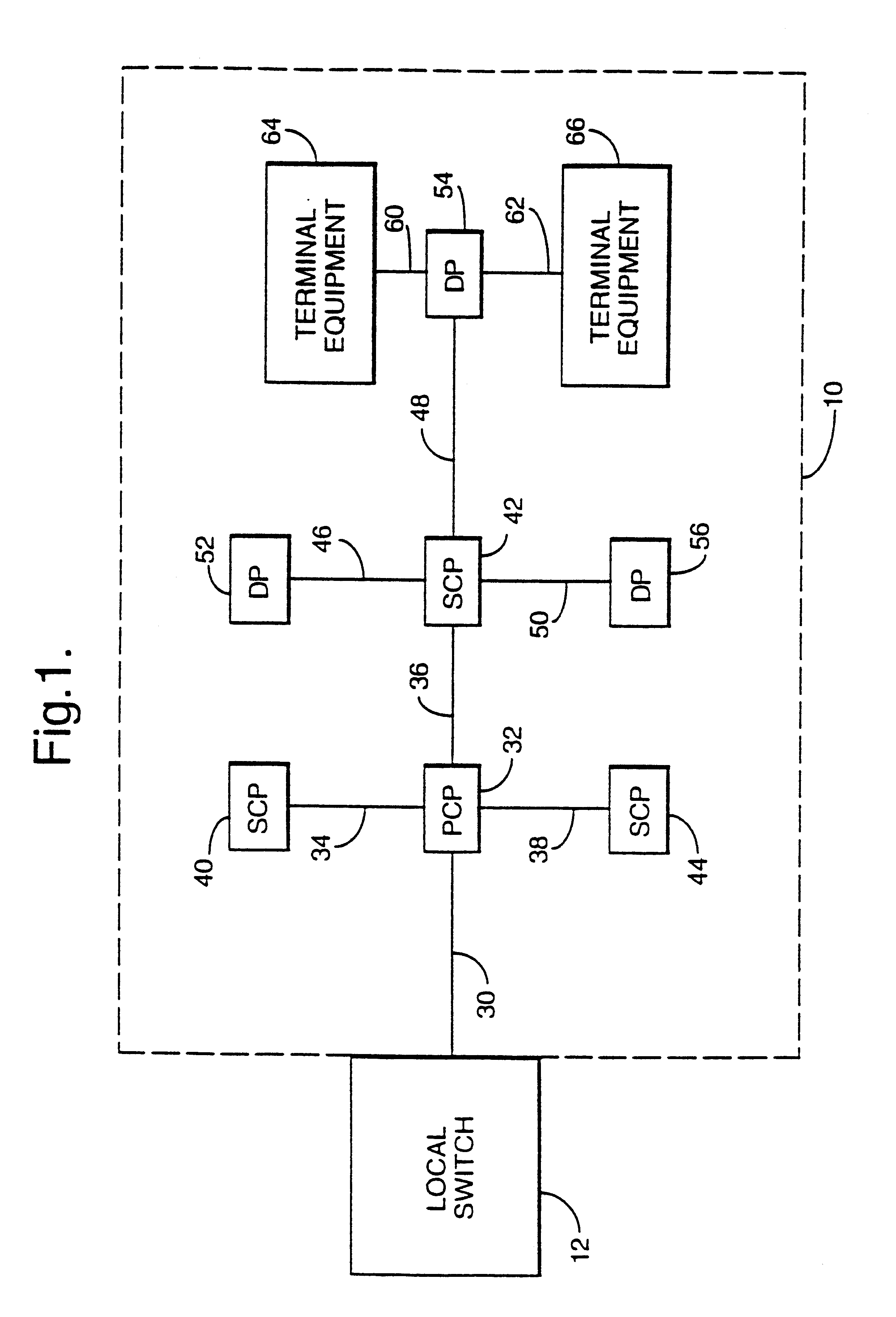

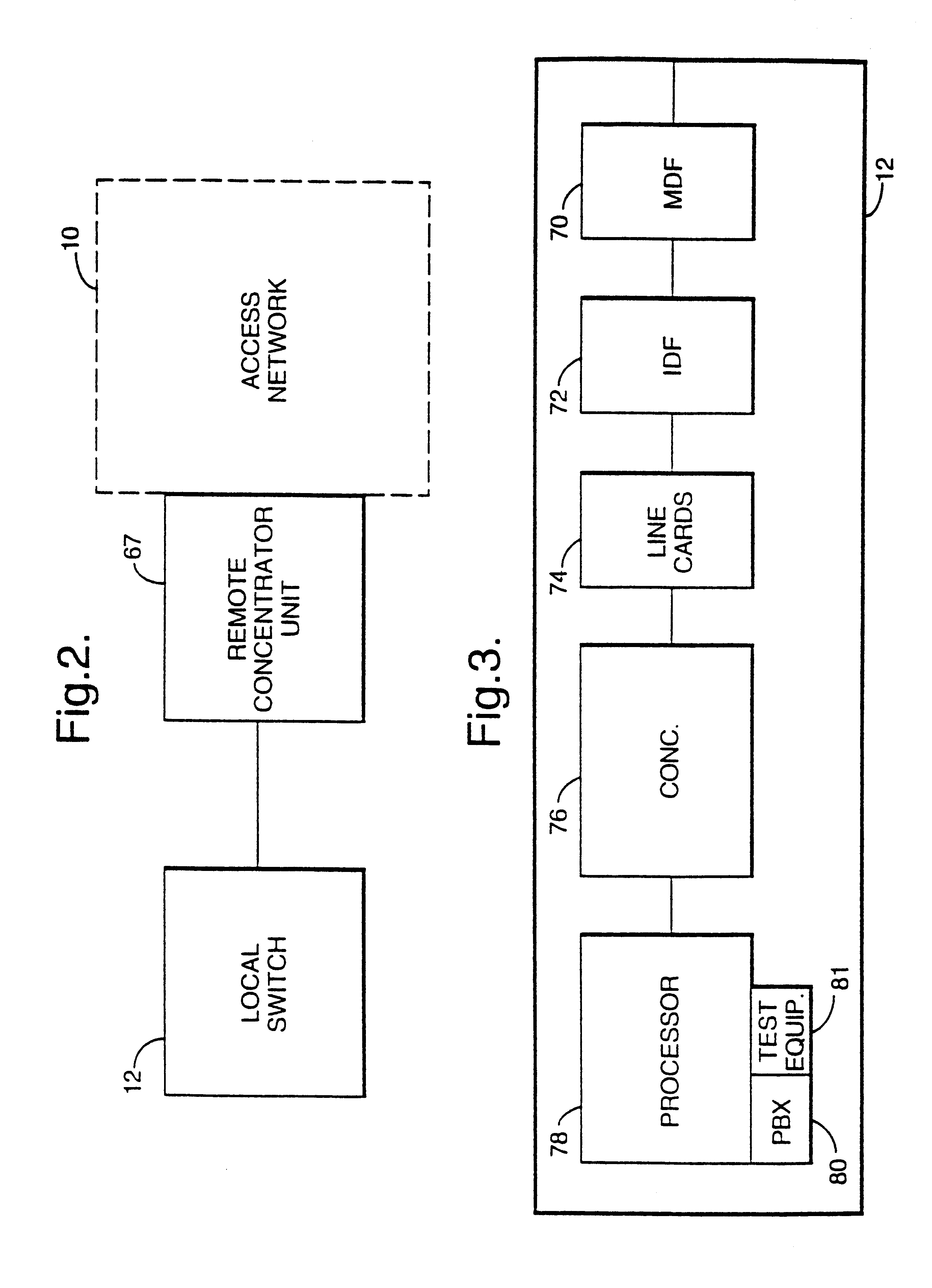

Line testing in a telecommunications network

InactiveUS6385299B1Interconnection arrangementsFrequency-division multiplex detailsTelecommunications linkTelecommunications network

A centralized test apparatus is provided for a telecommunications network which includes local switches and a core network. Each local switch is connected through terminating lines to terminating equipment such as telephone handsets. The test apparatus enables a field engineer to obtain the identity of a terminating line from one of the local switches. When a field engineer dials the number of the test apparatus, the test apparatus retrieves the calling line identity on answering the call. It then transmits the calling line identity in speech form back to the calling line. After transmitting the calling line identity, the test apparatus offers a menu of further services which comprise a ring back service and the provision of a test tone on a specified telephone line.

Owner:BRITISH TELECOMM PLC

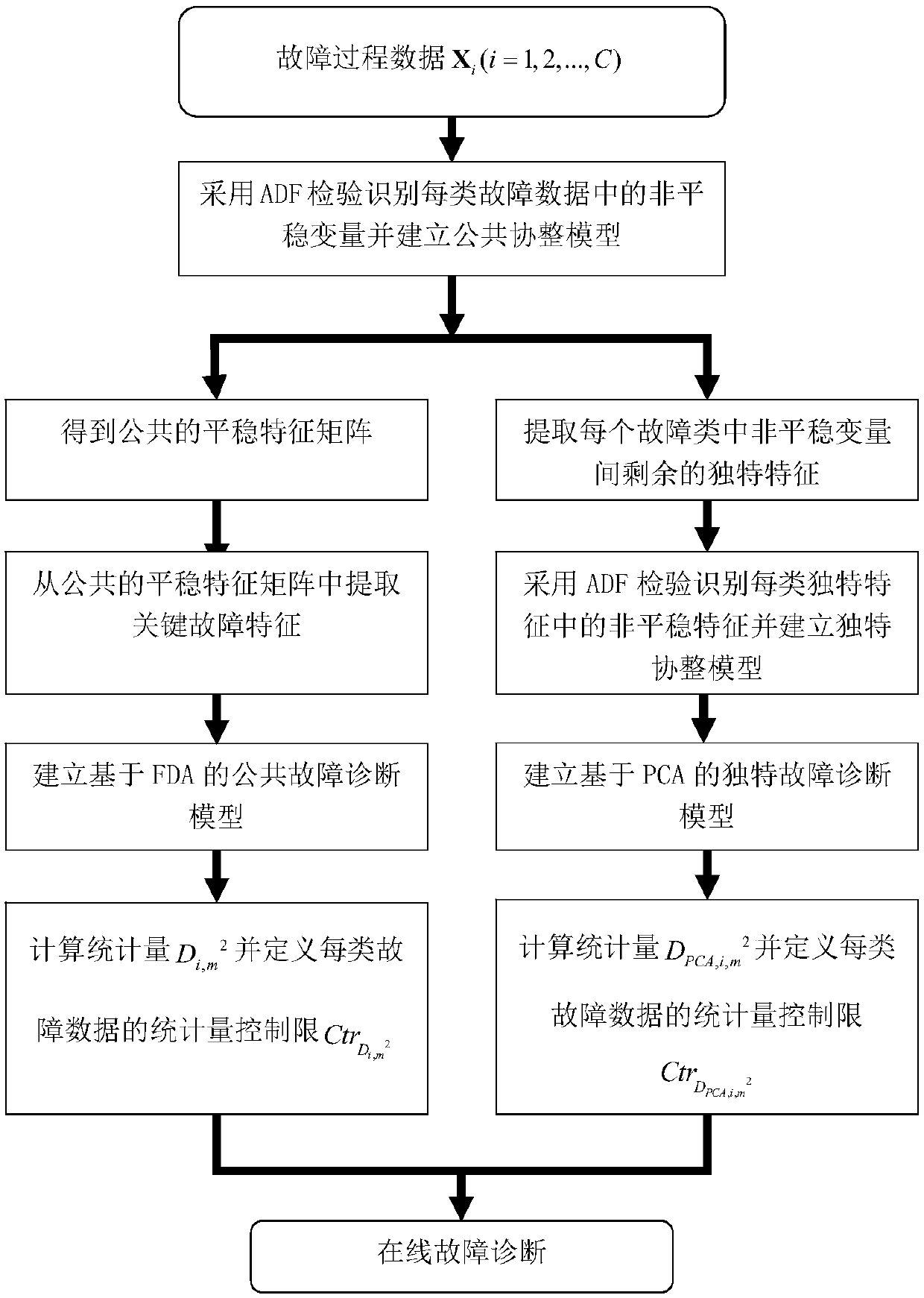

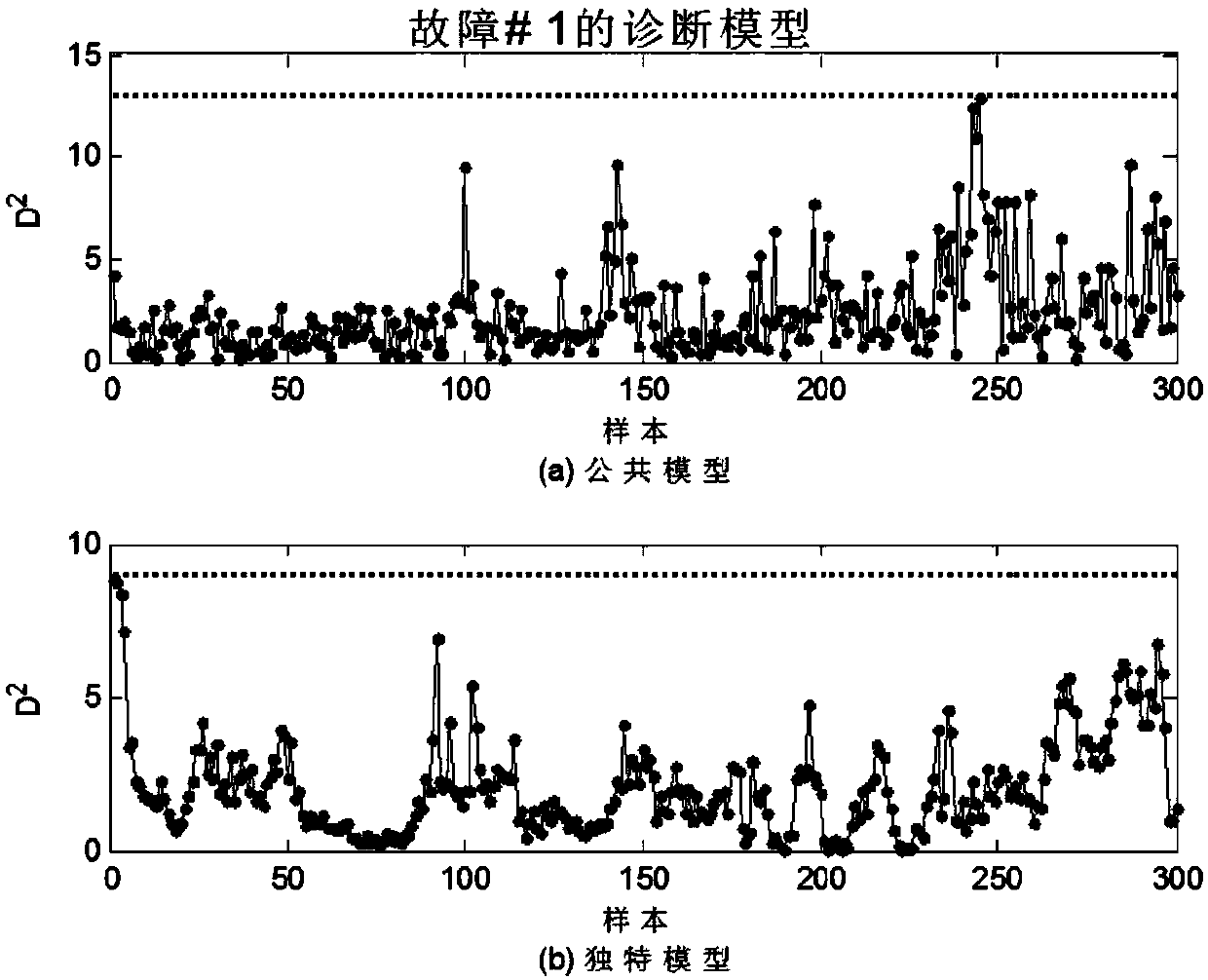

Online fault diagnosis method for non-stationary fault characteristics of million-kilowatt ultra-supercritical unit

The present invention discloses an online fault diagnosis method for non-stationary fault characteristics of a million-kilowatt supercritical unit. The method disclosed by the present invention aims at the non-stationary and complex and changeable characteristics of the fault process of a million-kilowatt supercritical unit, and combines the co-integration analysis and the variable selection baseddual model for fault diagnosis. According to the method disclosed by the present invention, the non-stationary characteristics of the fault process of large coal-fired units are overcome, potential information contained in the faults is fully exploited, a dual diagnostic model is established to supplement each other, the problem of the difficulty in online diagnosis in the complex and non-stationary fault process is effectively solved, the performance of online diagnosis in the non-stationary fault process is greatly improved, and the on-site engineers can accurately repair the faults in a facilitated manner, so that the safe and reliable operation of the million-kilowatt ultra-supercritical generator unit is ensured, and production efficiency is improved.

Owner:ZHEJIANG UNIV

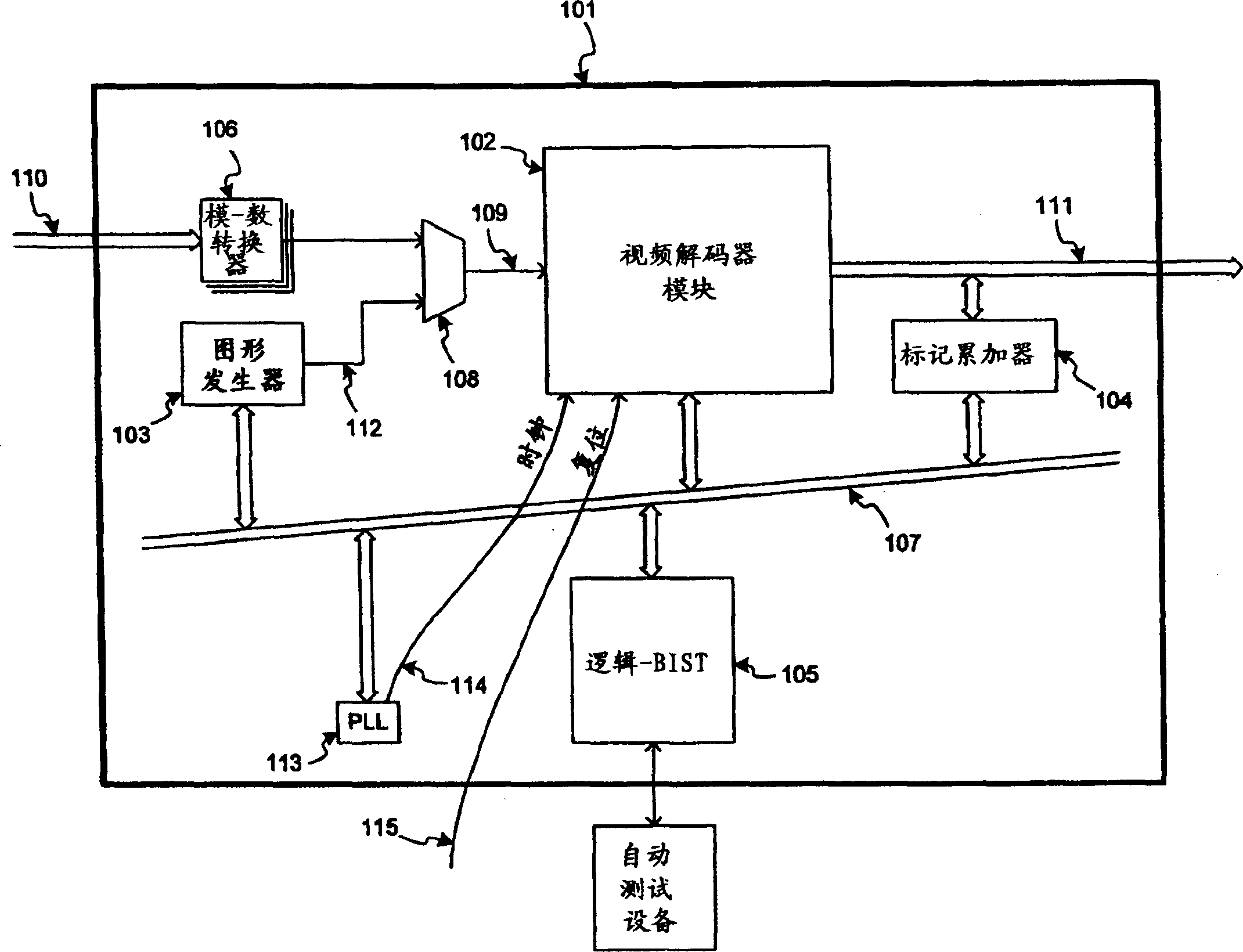

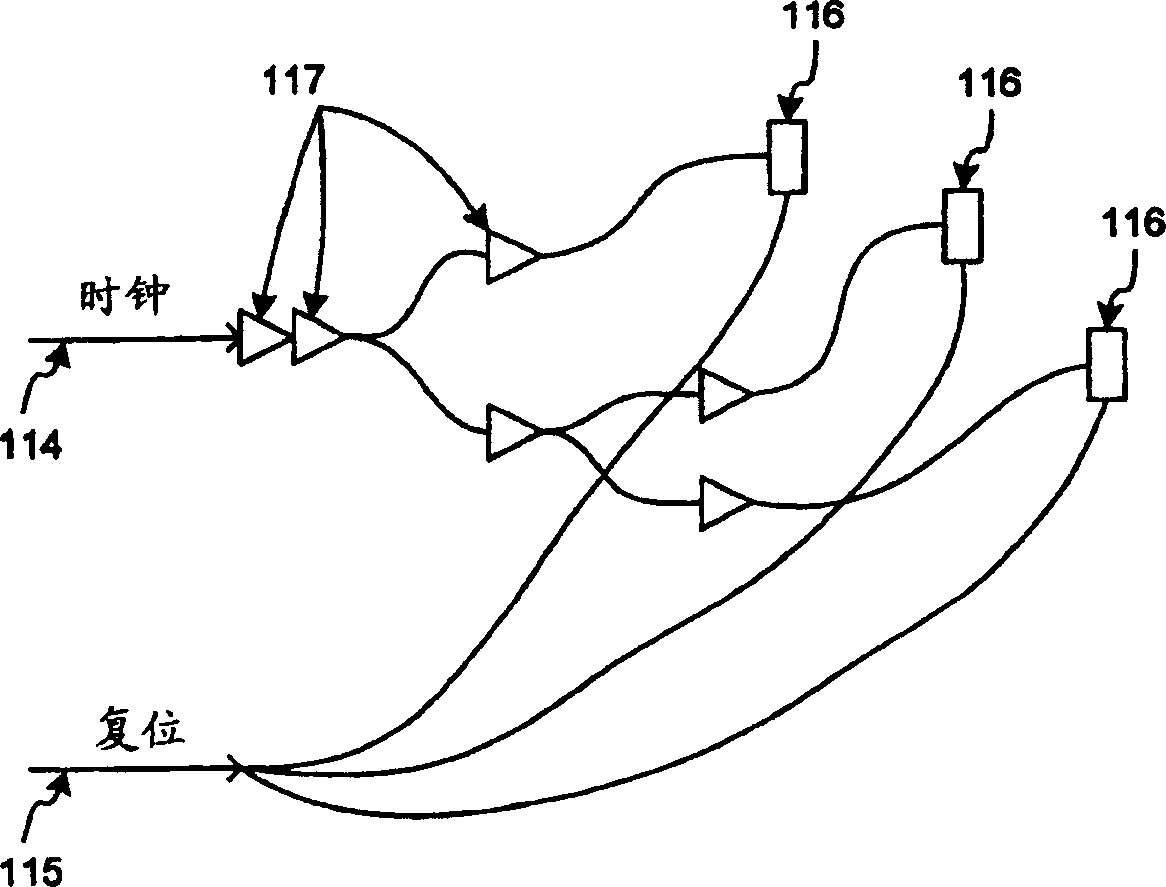

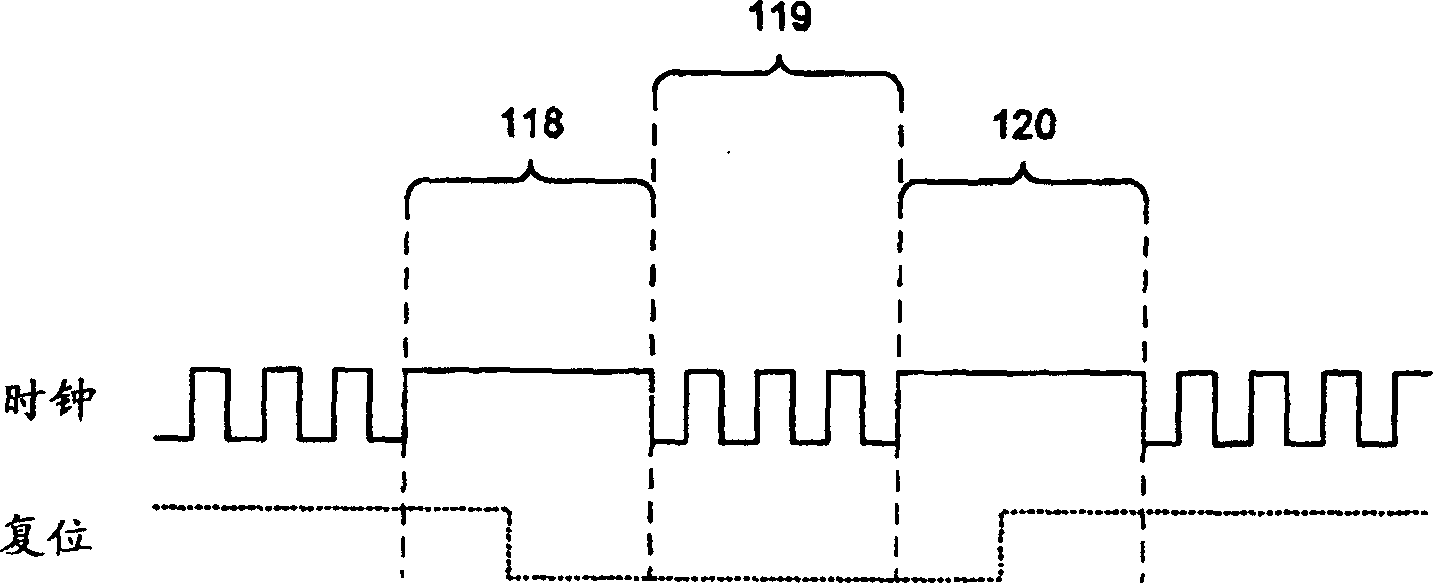

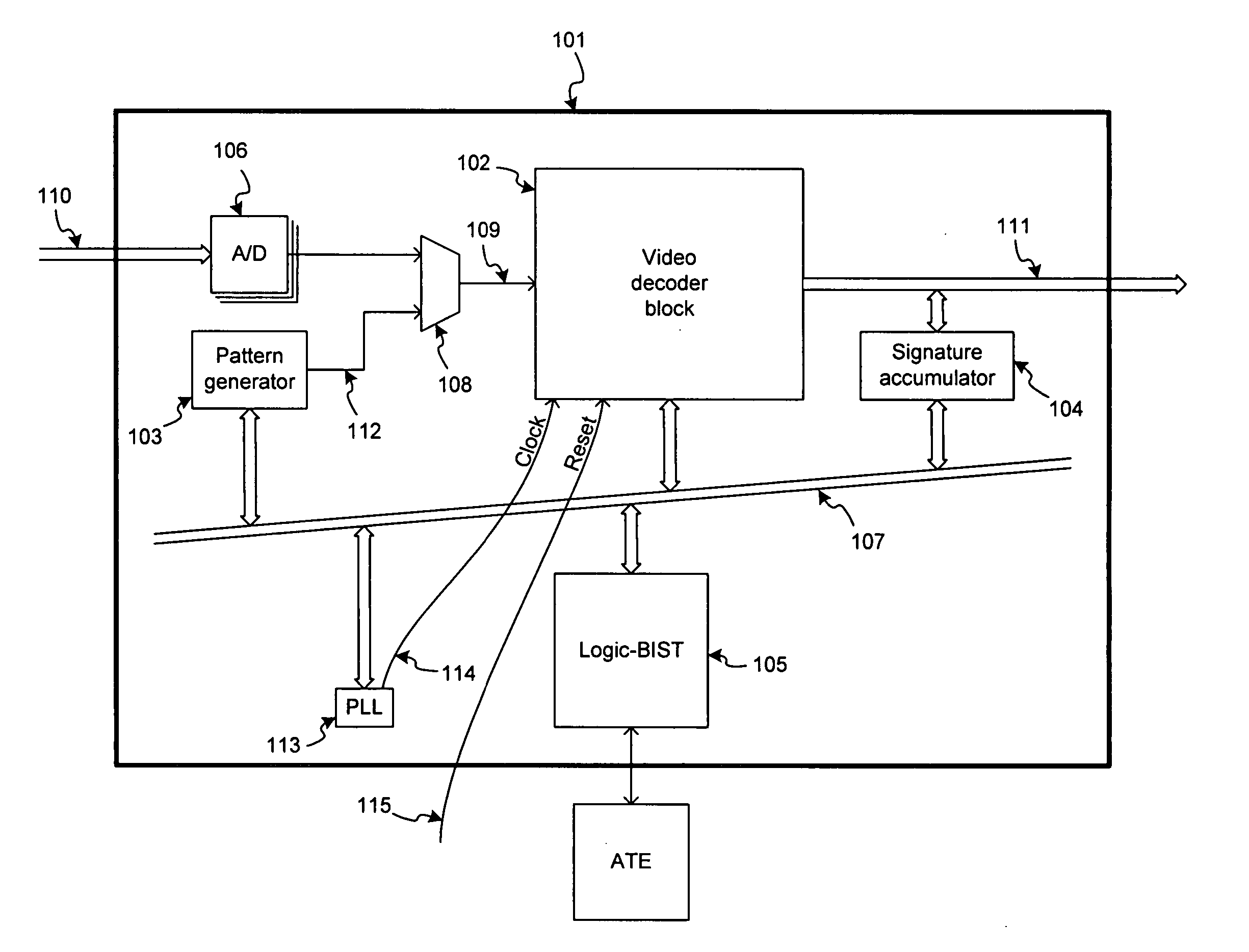

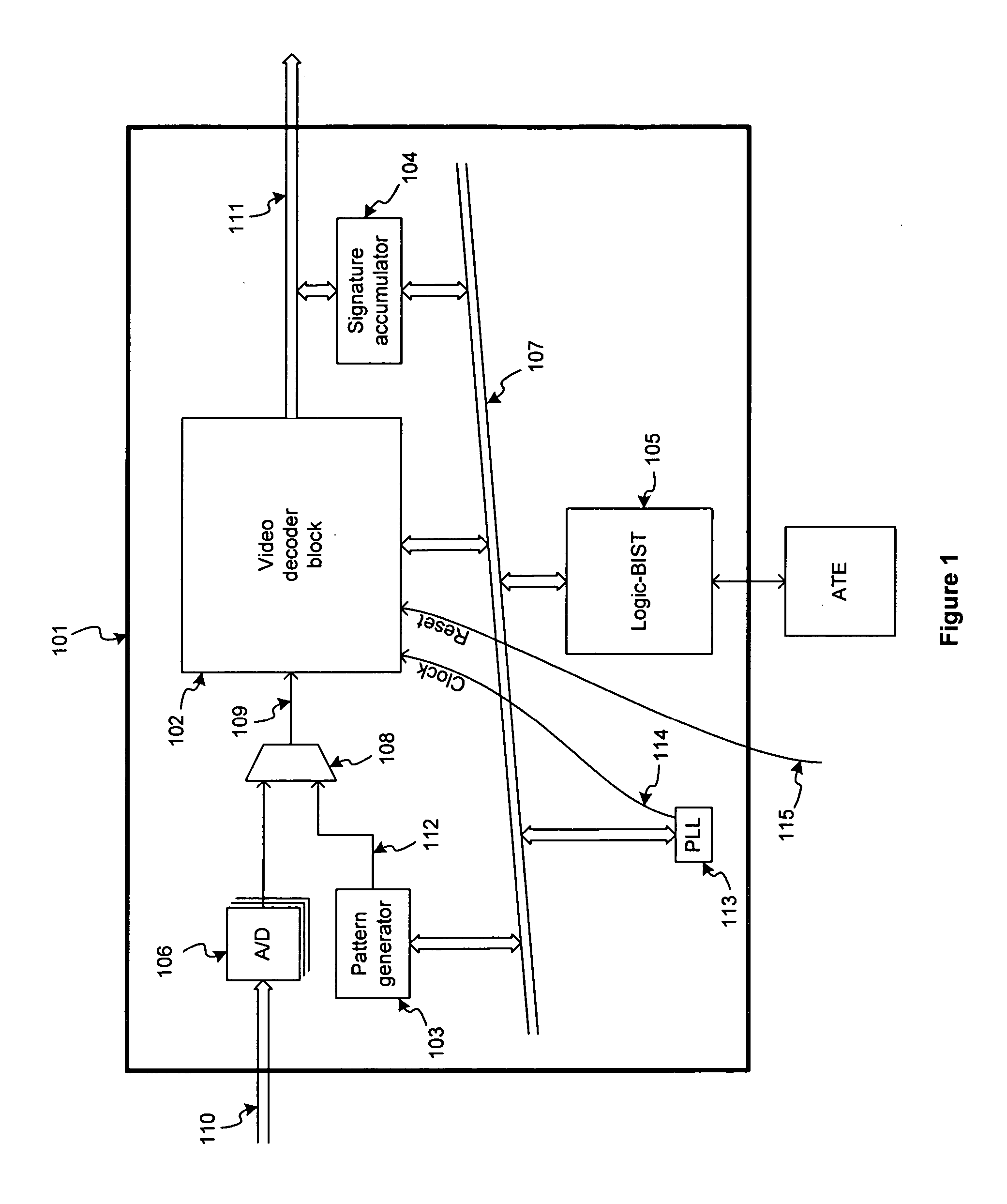

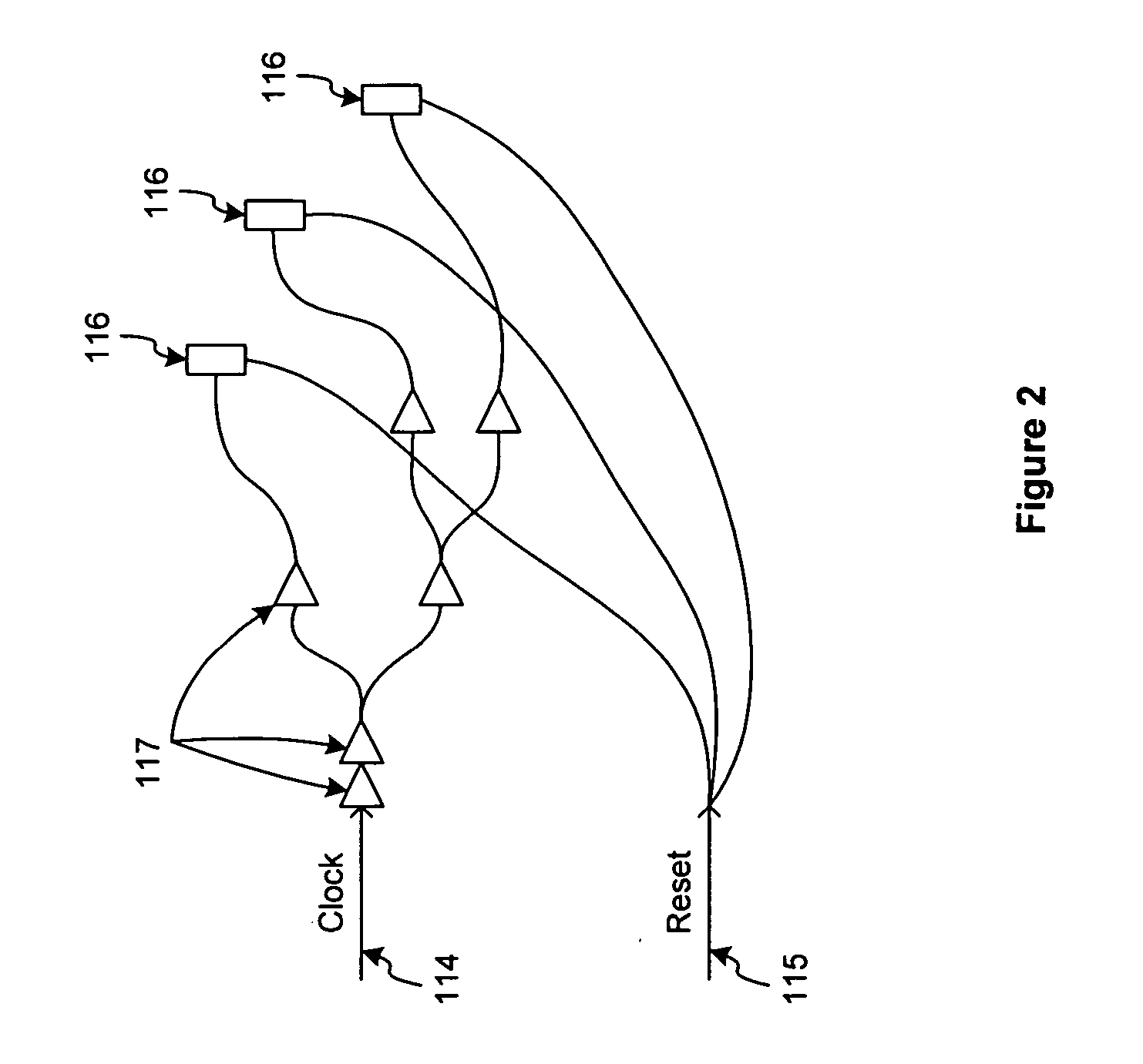

Automatic fault-testing of logic blocks using internal at-speed logic-bist

System and method for automatic fault-testing of a logic block and the interfaces of macros with logic gates inside a chip, using an at-speed logic-BIST internal to the chip. Following an initialization of internal storage elements, a set of test signals are generated and processed by the logic block. The output of the logic block is accumulated into a signature and compared to a reference signature to detect faults. Testing can be performed on an ATE (Automatic Test Equipment) using a simple test vector, or can be performed by a field engineer on the actual board comprising the chip.

Owner:TAMIRAS PER PTE LTD LLC

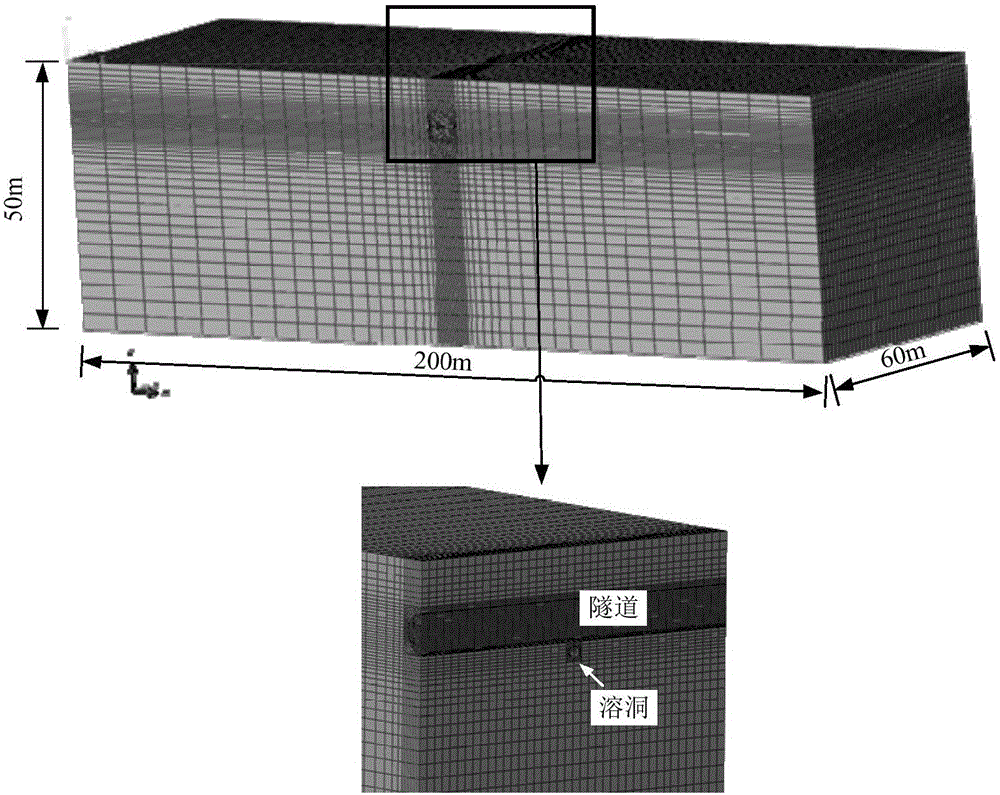

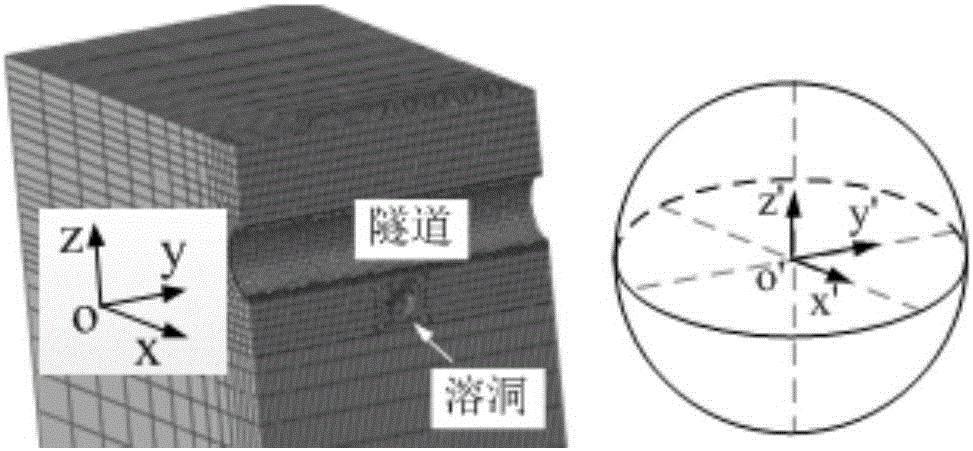

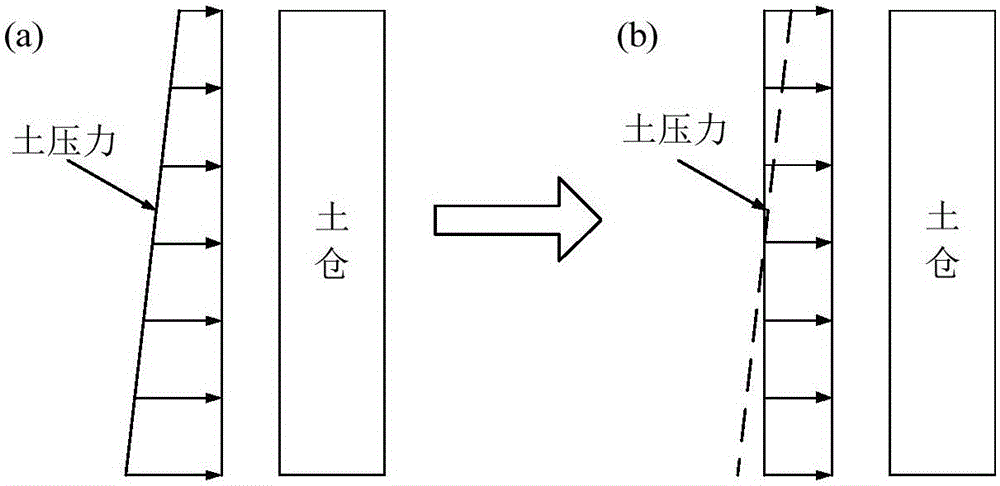

Method for determining safe vertical distance between shield and karst cave in sand karst stratum

ActiveCN106372297AThe safety distance expression is simple and clearEasy to operateDesign optimisation/simulationSpecial data processing applicationsKarstElement modeling

The invention provides a method for determining a safe vertical distance between the shield and karst cave in the sand karst stratum. The method comprises the following steps: firstly, surveying the field geology of a project; secondly, establishing a finite element analytical model by utilizing three-dimensional finite element modeling software for simulating a karst cave, the excavation face balance, the stratum loss, a lining and slag cart and the shield tunnel construction excavation; thirdly, calculating the vertical displacement of shield tunnel excavation on the karst cave under different working conditions; and fourthly, making a normalized relational graph of the karst cave roof sedimentation and the distance between the karst cave and the tunnel. The method sufficiently takes shield tail volume loss into consideration when the karst cave is positioned under a tunnel during shield tunnel construction, and calculates a safe vertical distance formula for the tunnel excavation influenced karst cave by analyzing the normalized relation among karst cave roof sedimentation, vertical distance between the karst cave and the tunnel and the diameter of the karst cave; and the formula is simple and clear, is beneficial to quick and intuitive judgment of a field engineer, and can be used for improving the construction efficiency.

Owner:SHANGHAI JIAO TONG UNIV

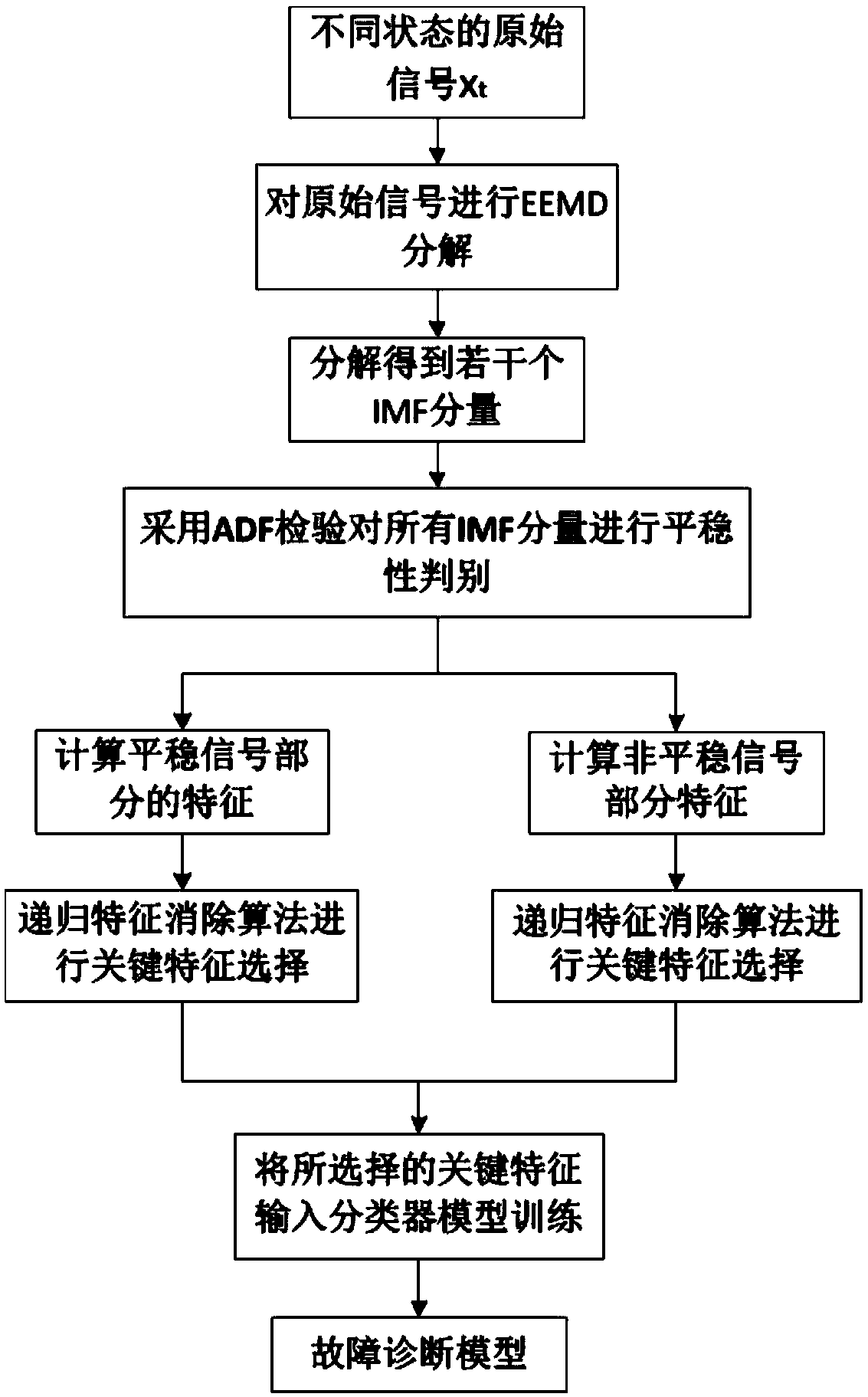

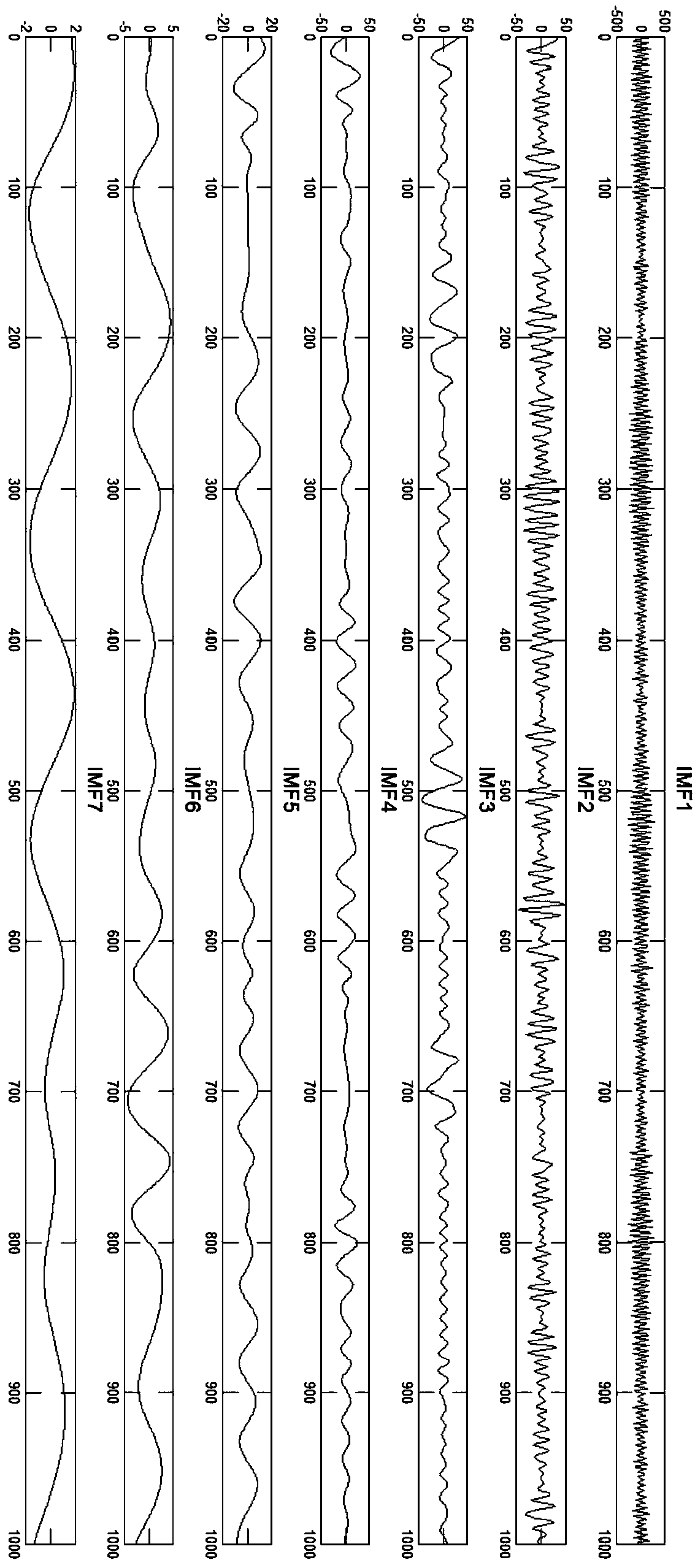

Steam turbine host fault diagnosis method based on feature selection of stationary and non-stationary vibration signals

ActiveCN109297713AOvercome the modal aliasing problemAvoid interferenceEngine testingCharacter and pattern recognitionFeature vectorControl engineering

The invention discloses a steam turbine host fault diagnosis method based on feature selection of stationary and non-stationary vibration signals. For a steam turbine in a thermal power steam turbineunit, the method combines use of ensemble empirical mode decomposition (EEMD) and a recursive feature elimination method to decompose and extract key features of the stationary and non-stationary signals in detail, and uses the same for fault diagnosis of steam turbine vibration signals. According to the method, the characteristics of non-stationarity, massive noise inclusion and the like of the steam turbine vibration signals are fully considered, potential information contained in fault data is fully exploited, features are respectively extracted for the stationary and non-stationary data, and the problem that non-stationary data features are liable to be masked is overcome. At the same time, the key features are extracted, dimension quantity of feature vectors is decreased, redundancy of data is reduced, accuracy of fault diagnosis of the steam turbine vibration signals is improved, accurate repair of an on-site engineer on a fault is facilitated, thus safe and reliable running of generator steam turbine equipment is guaranteed, and production benefits are improved.

Owner:ZHEJIANG UNIV

Automatic fault-testing of logic blocks using internal at-speed logic-BIST

System and method for automatic fault-testing of a logic block and the interfaces of macros with logic gates inside a chip, using an at-speed logic-BIST internal to the chip. Following an initialization of internal storage elements, a set of test signals are generated and processed by the logic block. The output of the logic block is accumulated into a signature and compared to a reference signature to detect faults. Testing can be performed on an ATE (Automatic Test Equipment) using a simple test vector, or can be performed by a field engineer on the actual board comprising the chip.

Owner:TAMIRAS PER PTE LTD LLC

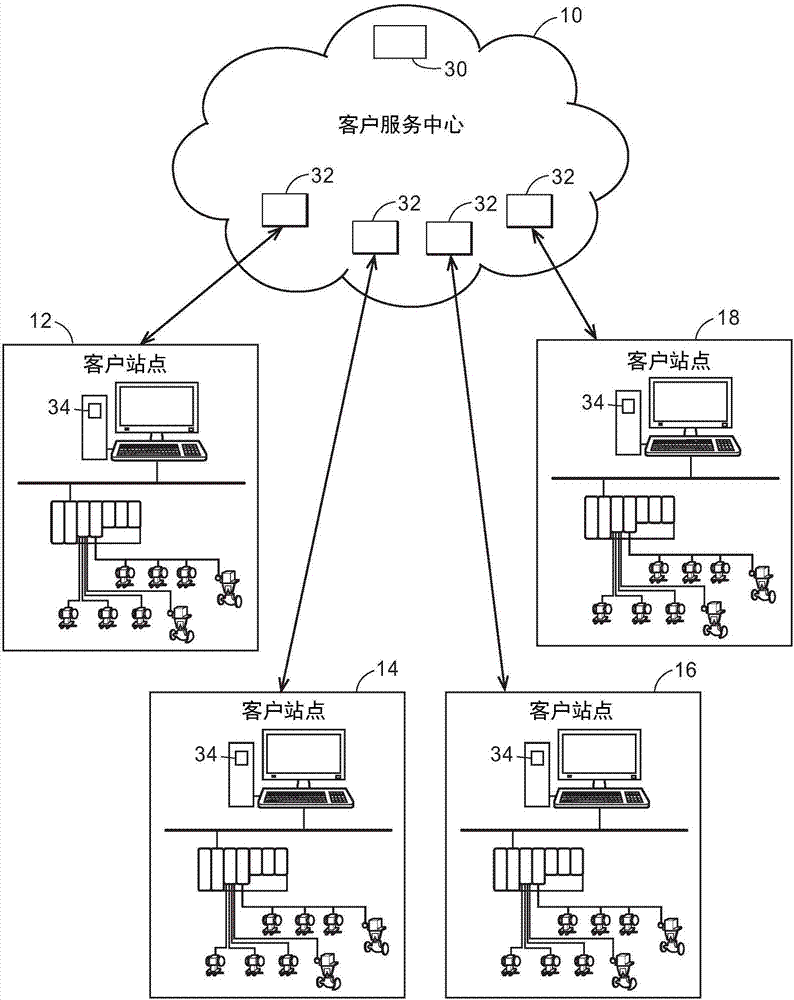

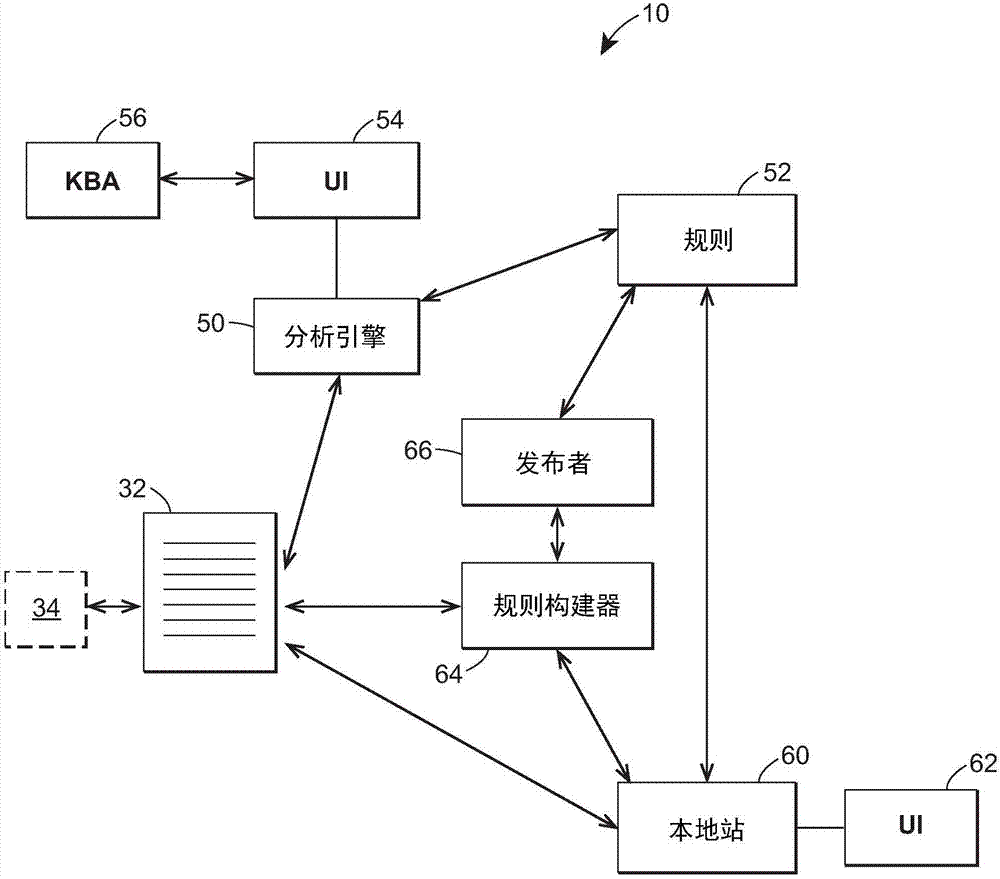

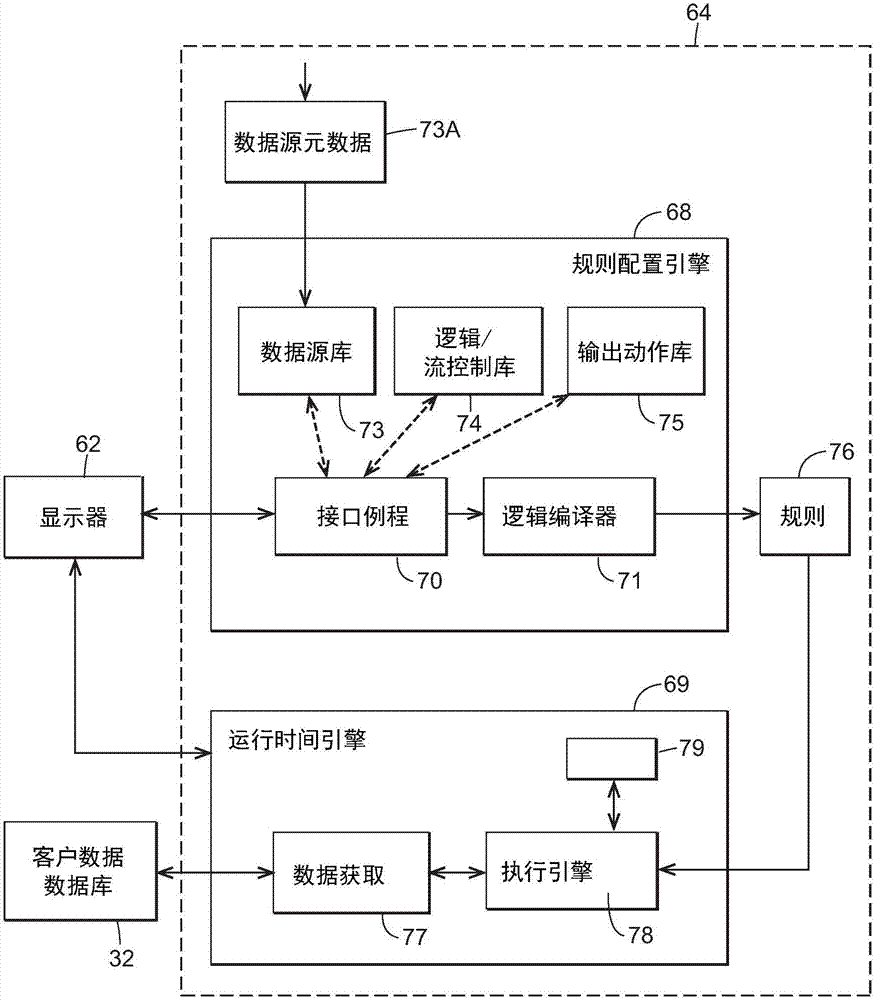

Rule builder in a process control network

ActiveCN107085415ATesting/monitoring control systemsVisual/graphical programmingProcess control networkSupporting system

An analytic rule generation application is integrated into an electronic customer technical support system to enable those using the customer technical support center systems to build custom analytic rules, on demand, for use in diagnosing and detecting issues at customer process plant sites, without having to submit a request to a developer and wait for one or more new rules to be provided in future releases of the customer technical support system. The analytic rule builder can be used by local offices and local technology groups if need be, or can be used by personnel at customer sites. The custom analytic rules created using the rule builder application can be shared among the engineers using the electronic customer technical support system to empower local engineers to immediately use newly created rules. Still further, the analytic rule builder can be used in an online support system within a process plant, where on-site engineers can build custom analytic rules to monitor certain data streams or events in the plant control system and to trigger actions upon the detection of predetermined events or conditions.

Owner:FISHER-ROSEMOUNT SYST INC

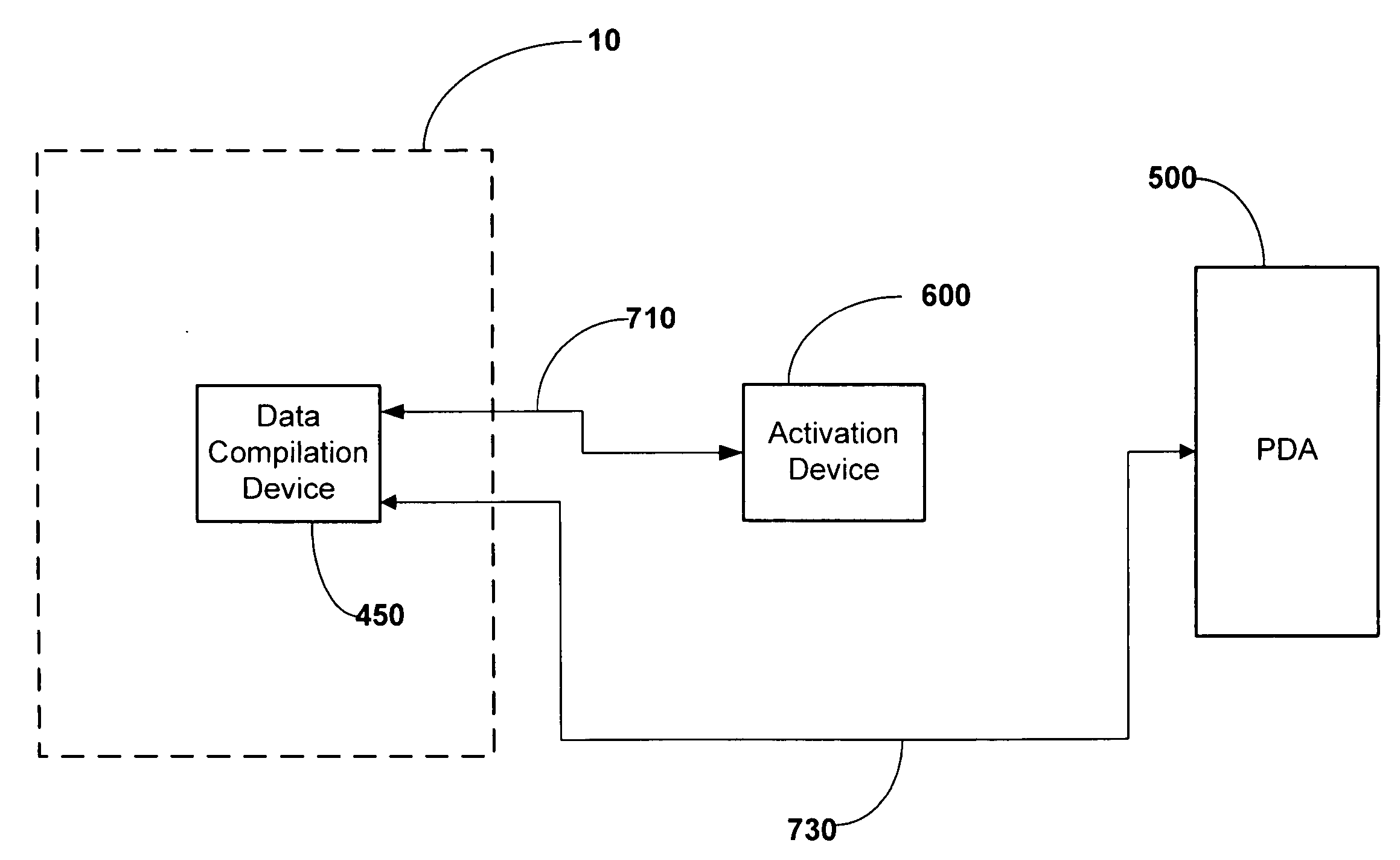

Information management system

InactiveUS20060200271A1Extended shelf lifeEasy to manageAcutation objectsSpecial data processing applicationsBiological activationComputer science

A system for information management has a compilation device collecting information particular to a vending device located therein, a PDA useable for receipt, manipulation or inputting information into the compilation device. An activation device triggers the compilation device to prepare it to export or import information to or from the PDA. The compilation device has a power source and activation sensor for activation of thereof and in a dormant state prior to such activation, thereby conserving the energy stored within the power source, and allowing the data compilation device to remain as small as possible. The PDA has operating software which is able to synchronize multiple PDAs to a computer server and is also capable of having route management software for use by field engineers.

Owner:NOVA RESOLUTION INDS

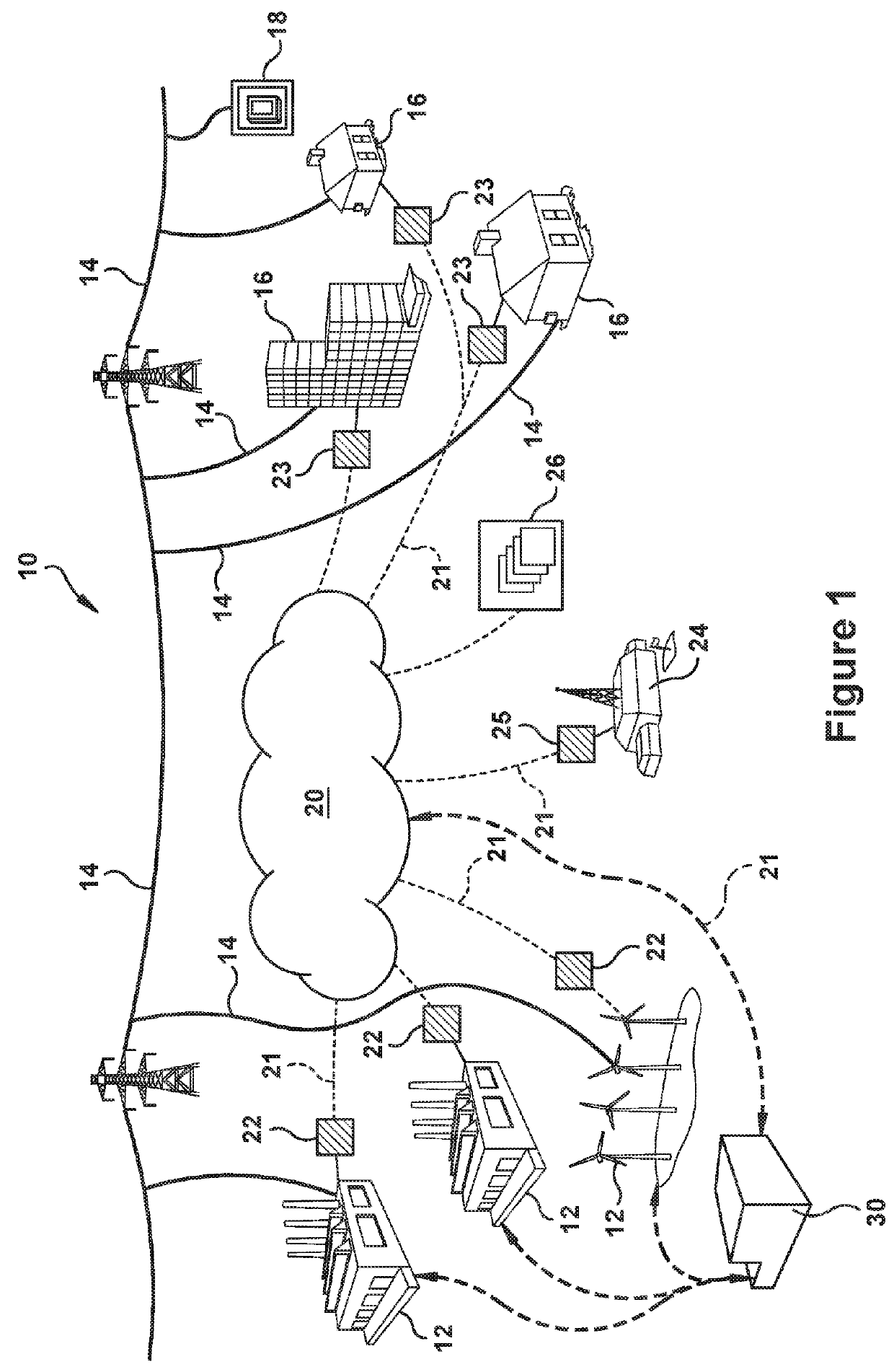

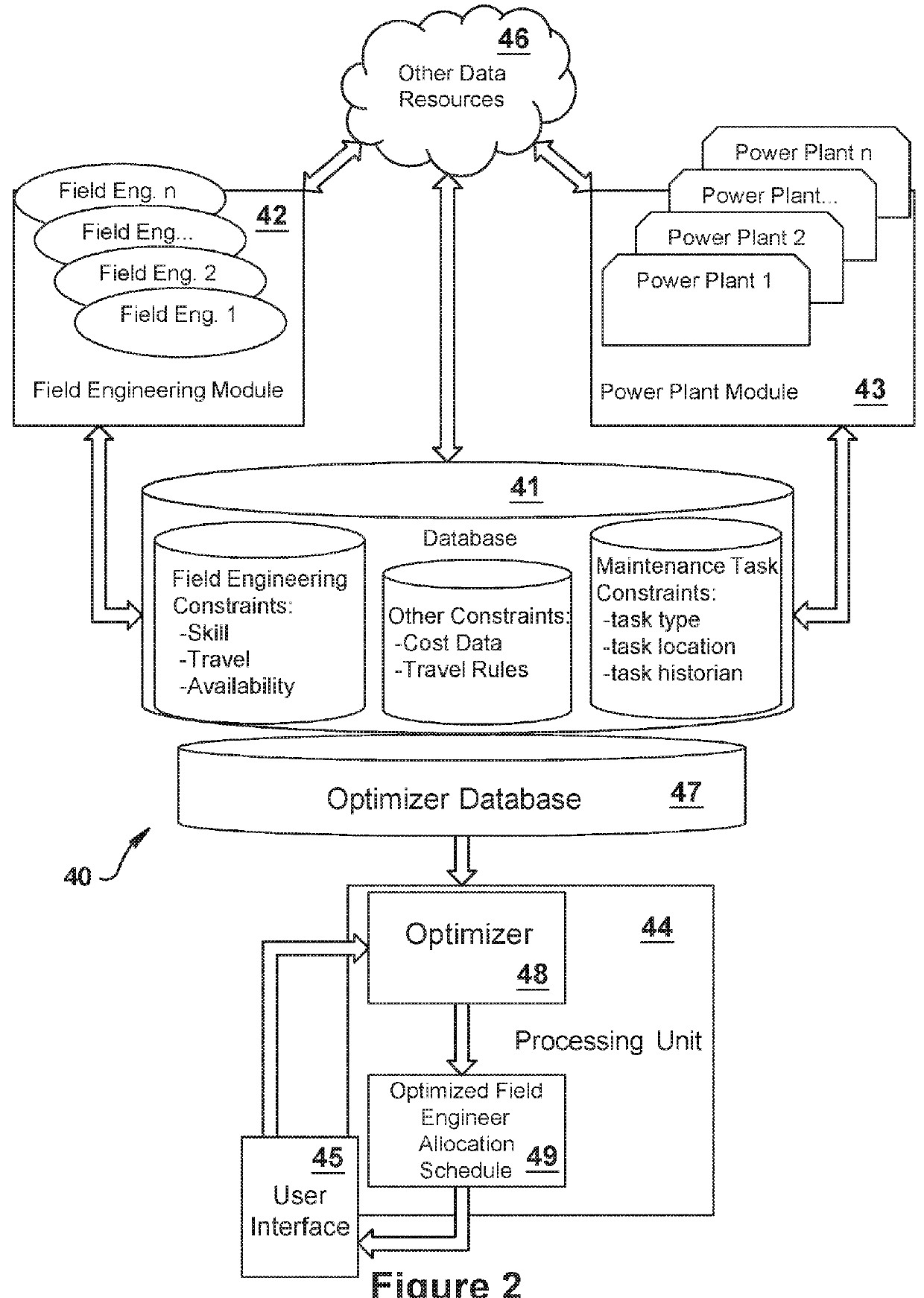

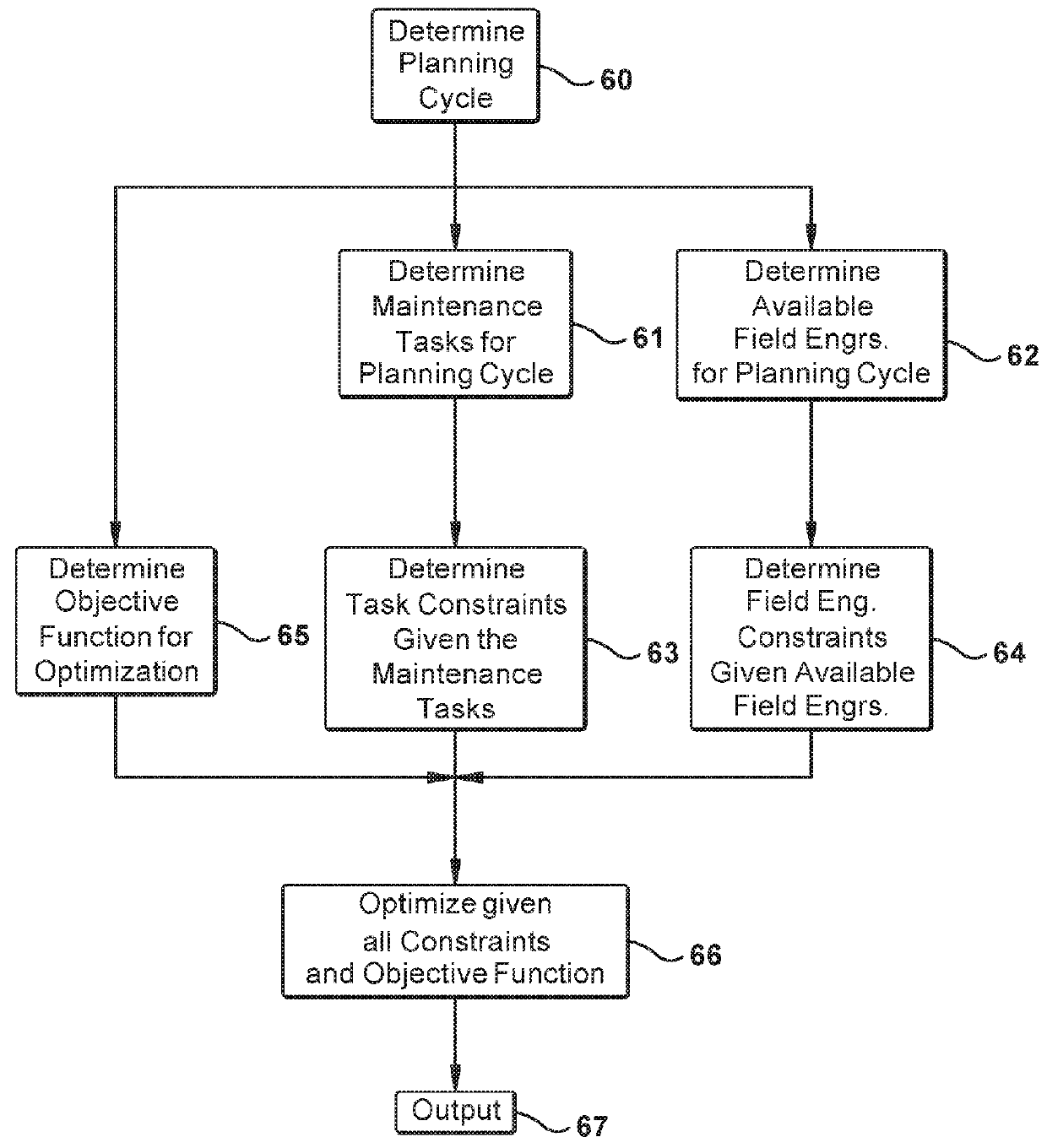

Methods and systems related to allocating field engineering resources for power plant maintenance

A system for allocating field engineers to perform maintenance tasks according to a generated allocation schedule, the maintenance tasks occurring during a planning cycle at customer power plants dispersed within a territory. The system may include a database that stores data related to field engineer and task constraints. The system may further include a computing device configured to: receive an input defining an objective function; using the database, determine an occurring group of the maintenance tasks during the planning cycle; using the database, determine an available group of the field engineers during the planning cycle; using the database, import the task constraints that correspond to the occurring group of maintenance tasks; using the database, import the field engineer constraints that correspond the available group of the field engineers; given the imported task and field engineer constraints, generate an optimized version of the allocation schedule pursuant to the objective function.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for control configuration with enhanced change-tracking

The invention provides, in some aspects, a process, environmental, manufacturing, industrial or other such control system (hereinafter, “control system”) with enhanced, real-time change tracking. The system includes one or more configurable elements (e.g., field devices), a change tracking system that records of changes to those configurable elements (e.g., for compliance reporting, etc.) and a change detection system that responds to detected changes in configuration of those element(s) by inferring an identity of a person and / or device responsible for a change, the time of the change, and / or the reason for the change. This is unlike prior art systems, in which that such information must be specified, e.g., in a data entry form filled-in by the field engineer, operator or other who is making the change.

Owner:SCHNEIDER ELECTRIC SYST USA INC

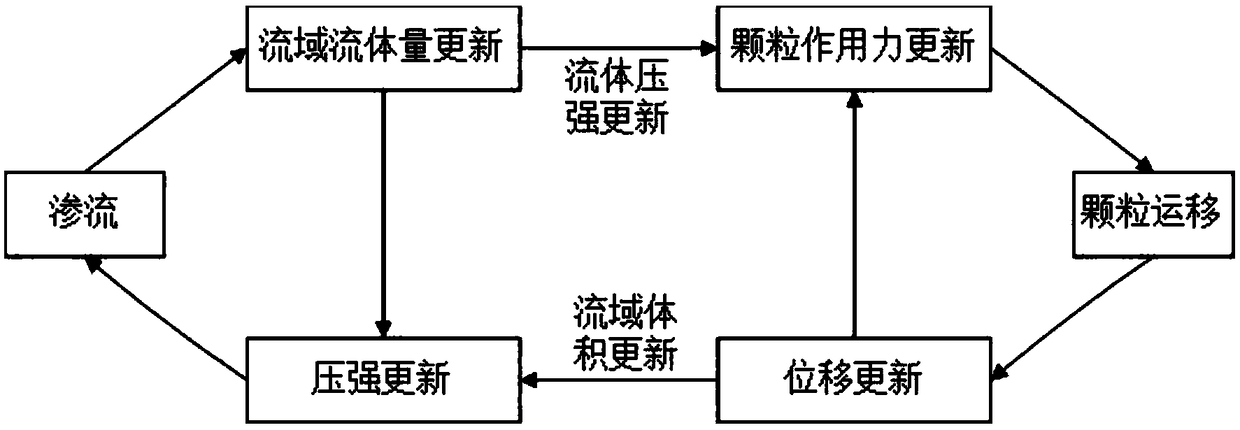

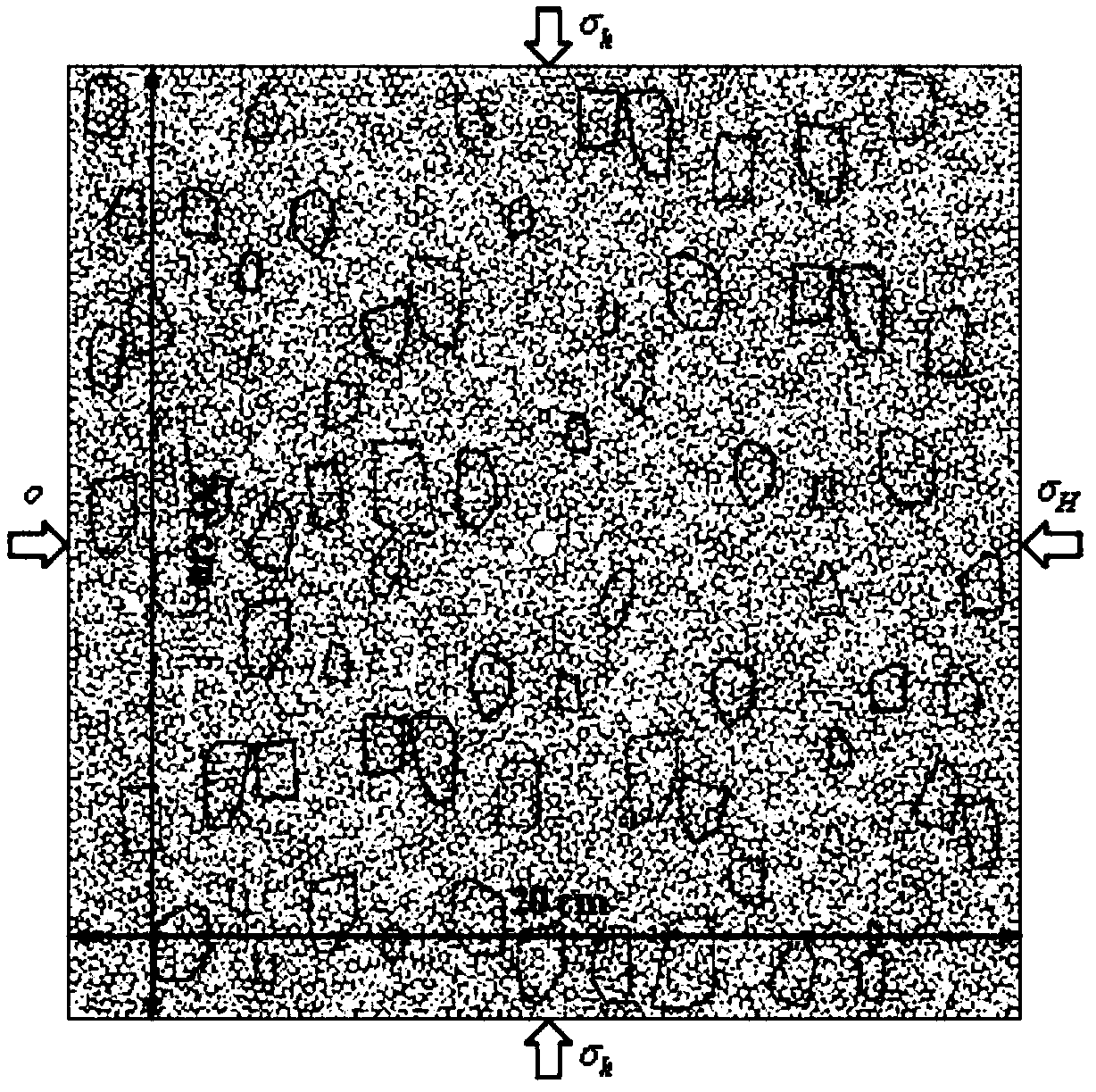

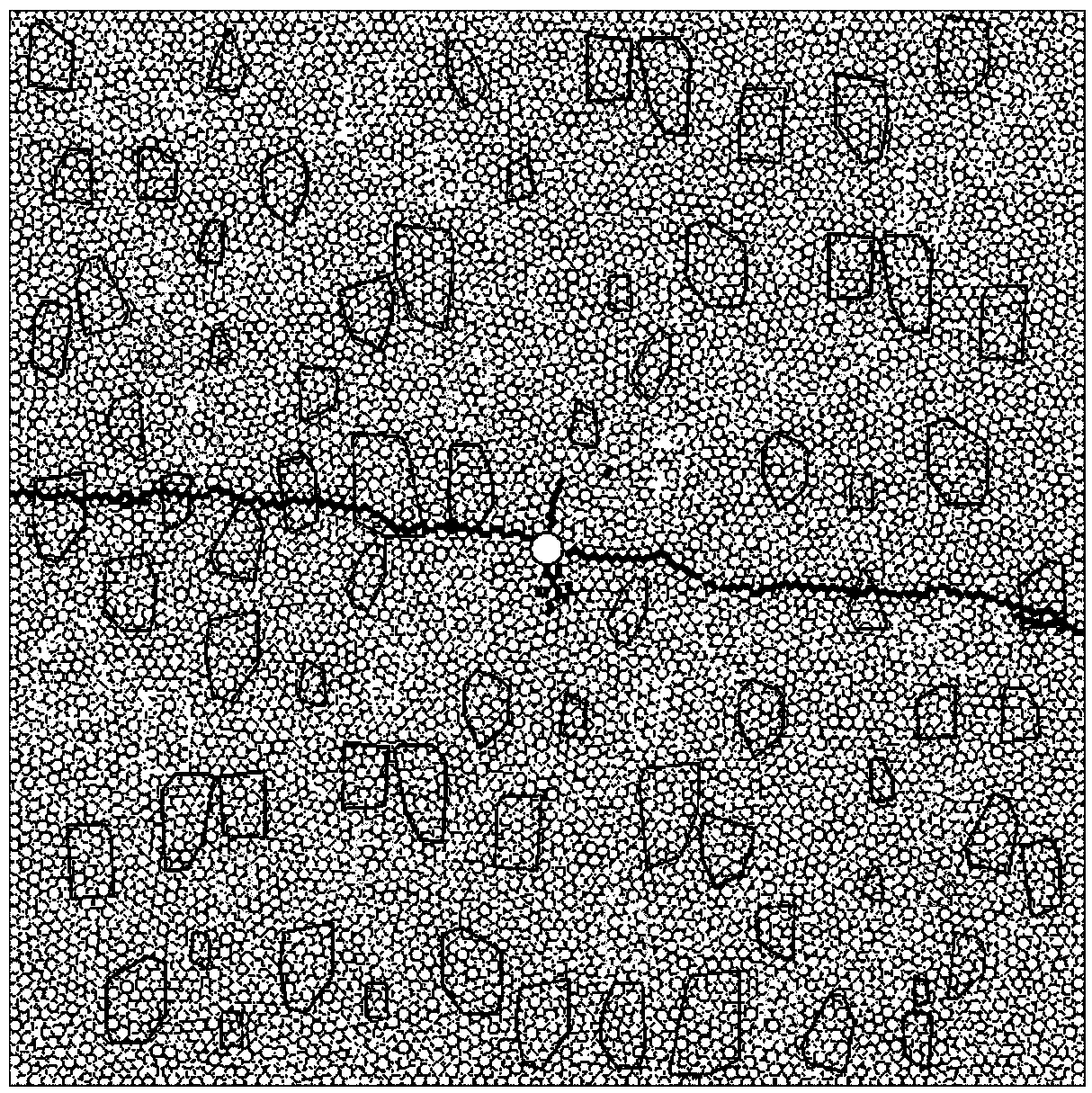

Glutenite hydrofracture simulation method based on discrete element

ActiveCN109374867AAccurate captureAccurately reproduce interactionsEarth material testingDiscrete element methodHydraulic fracturing

The invention relates to a glutinite hydrofracture simulation method based on a discrete element. The method comprises the following steps of: S1, constructing a wall and a well bore, generating particles according to a size grading curve, and performing initial balance calculation, S2, dividing the particles into a matrix and gravel by a cutting method, endowing the matrix and the gravel with different cementing parameters, S3, adding a seepage field and endowing a corresponding flow parameter, S4, applying confining pressure on the external wall based on a servo system, setting a fluid injection speed, S5, monitoring cementing states of the particles in real time, and judging whether micro cracks are generated according to the cementing states, and S6, continuing simulation till penetration of hydraulic cracks occurs. The glutinite hydrofracture simulation method based on the discrete element can characterize crack initiation and expansion mechanisms of the hydraulic cracks preciselyfrom a microscale, and accurately capture a macro distribution morphology of the hydraulic cracks, so that the understanding of a field engineer on an expansion rule of the hydraulic cracks of a glutinite reservoir is enhanced; and a fracture design is improved.

Owner:QINGDAO UNIV OF SCI & TECH

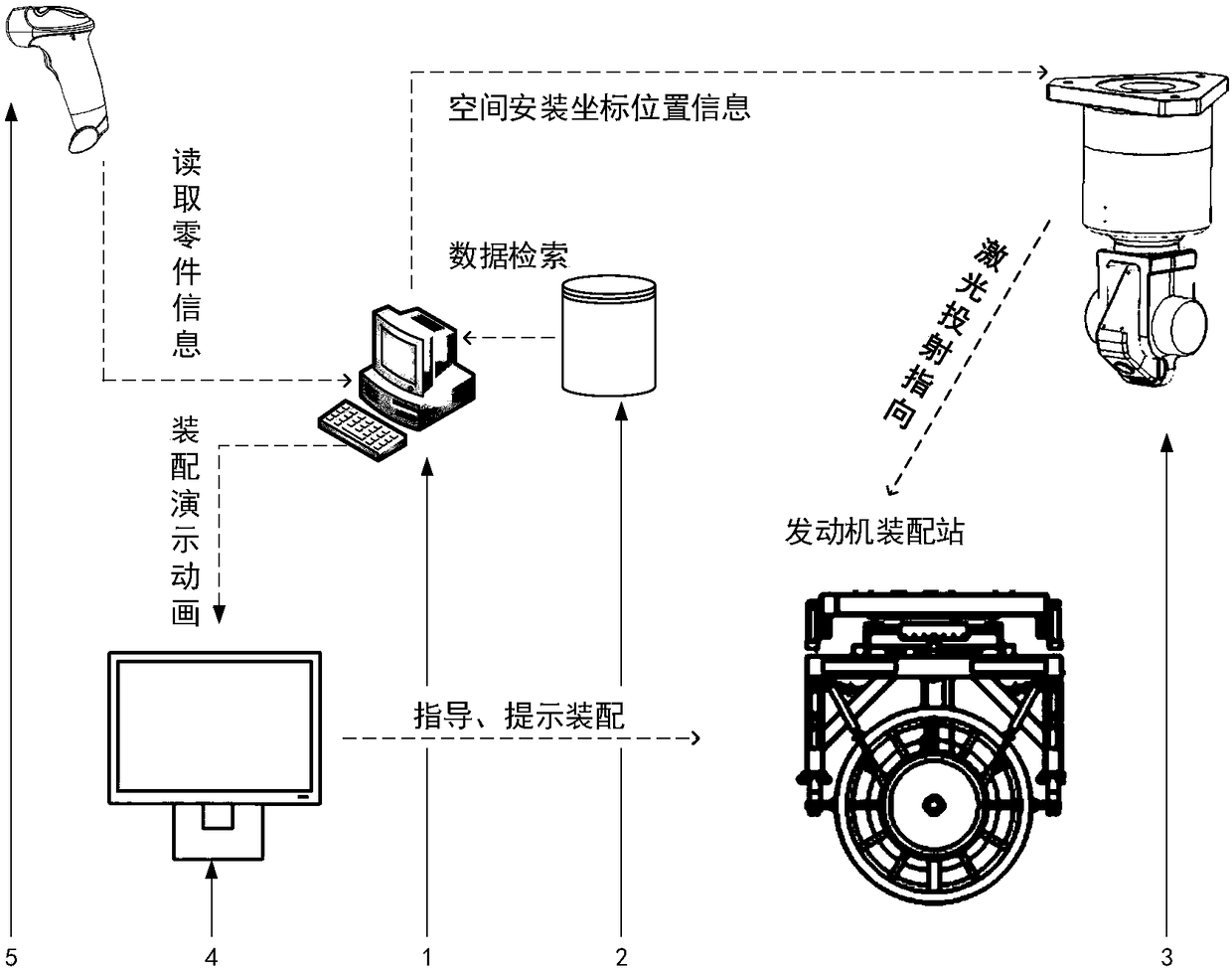

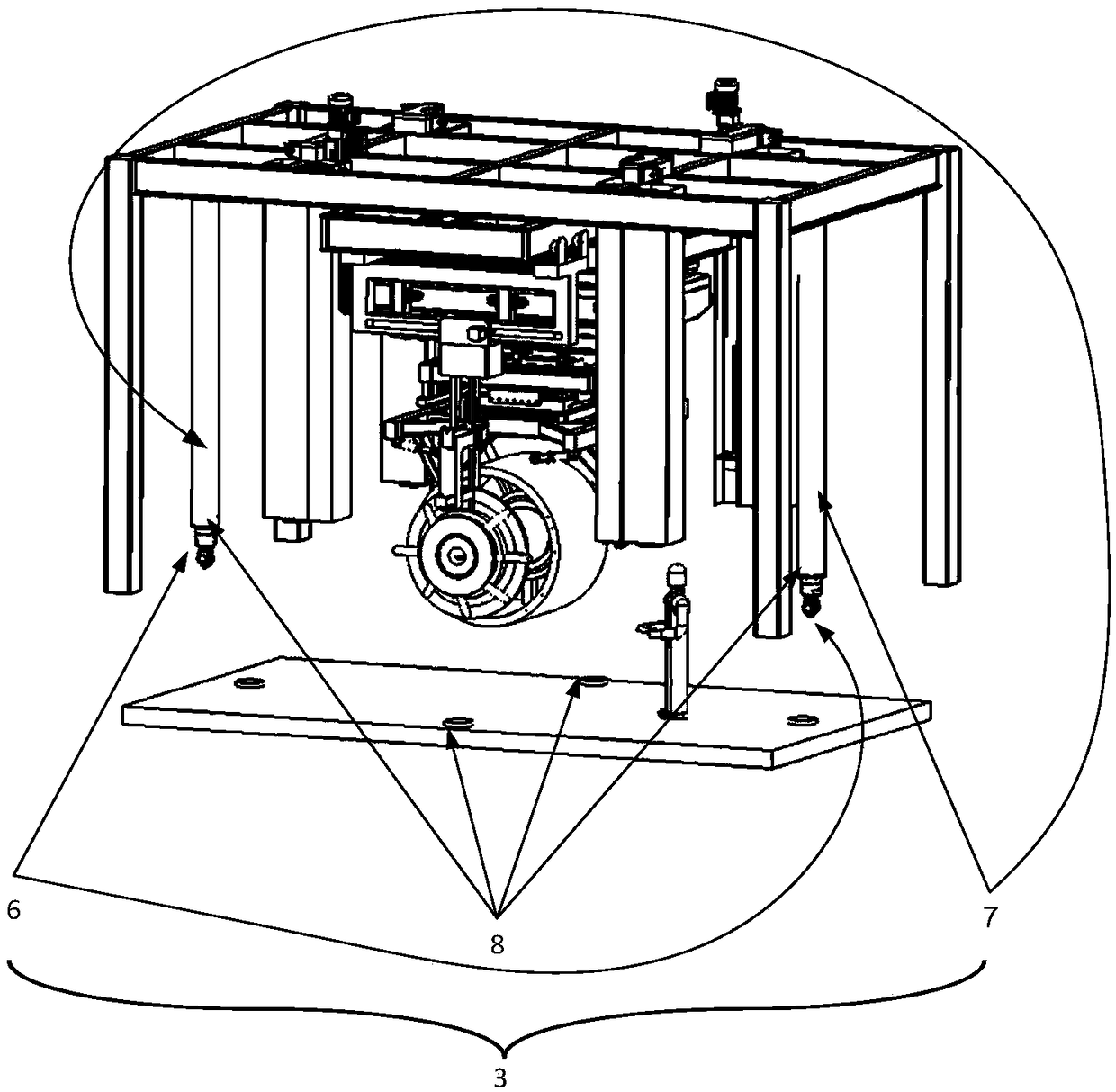

Digitized assembling supporting system and method of aero-engine parts

ActiveCN108229615AImprove assembly efficiencyReduce workloadData processing applicationsCo-operative working arrangementsAviationEngineering

The invention discloses a digitized assembling supporting system and method of aero-engine parts. The system comprises a central computer control unit, a part assembling process database, an assembling station laser-assisted orientation device, an assembling station digitalized display platform and an approach part code scanning system; after reading the code information of approach parts recognized by the code scanning system, the central computer control unit extracts corresponding parts assembling data from the part assembling process database, and respectively transmits to the laser-assisted orientation system and the digitalized display platform; the digitalized display platform repeatedly plays the assembling process procedure and assembling process simulation animation of the partsto be assembled, so as to remind on-site engineers; a laser projector projects a pointed laser beam to the installation position of the parts to be assembled on the engine assembling body; the on-siteengineers executes the on-site assembling tasks of the parts. The digitized assembling supporting system and method of aero-engine parts, the overall assembling efficiency of the aero-engine can be remarkably improved while the installation positions of the parts can be rapidly and accurately positioned.

Owner:TSINGHUA UNIV

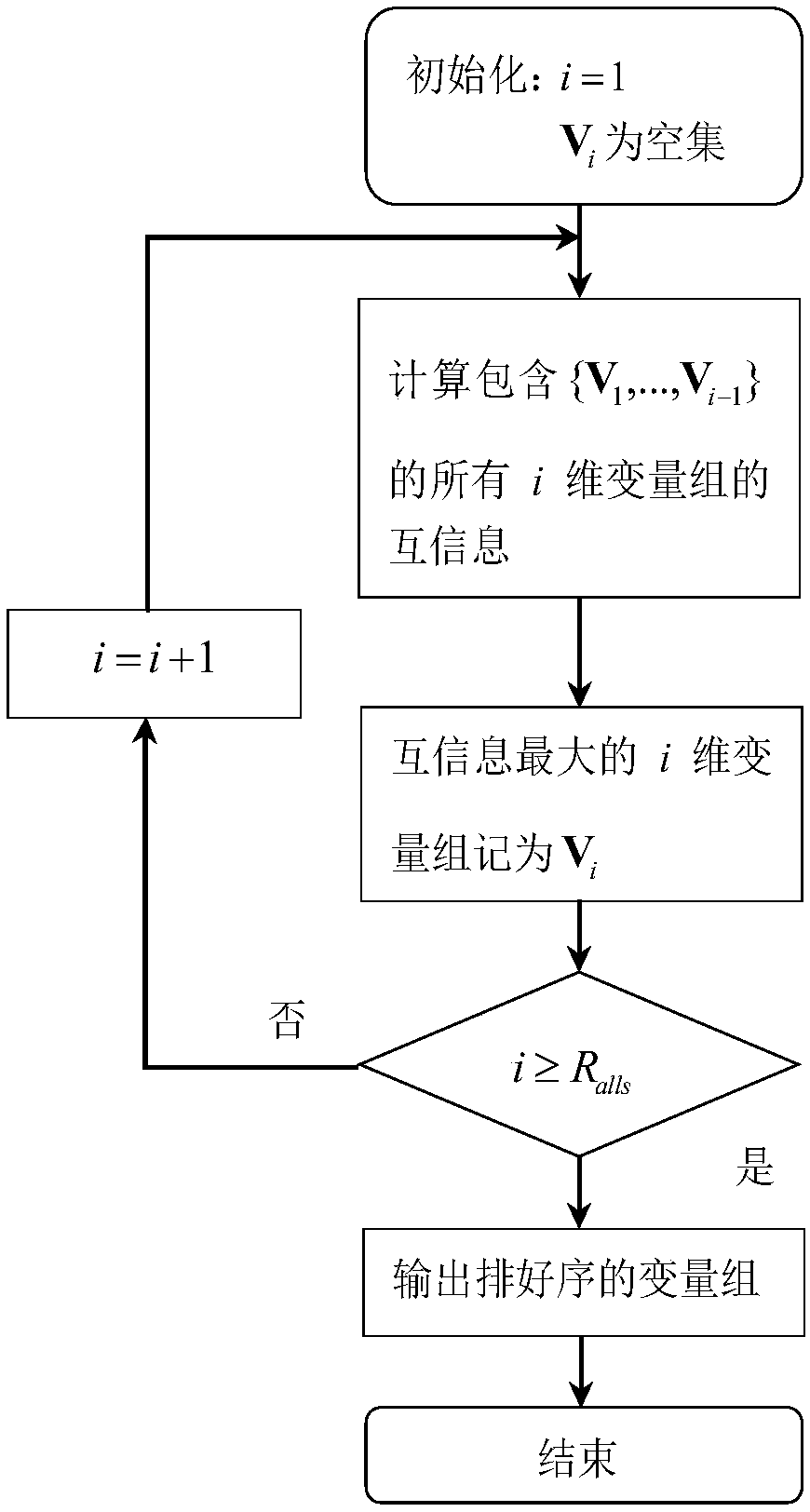

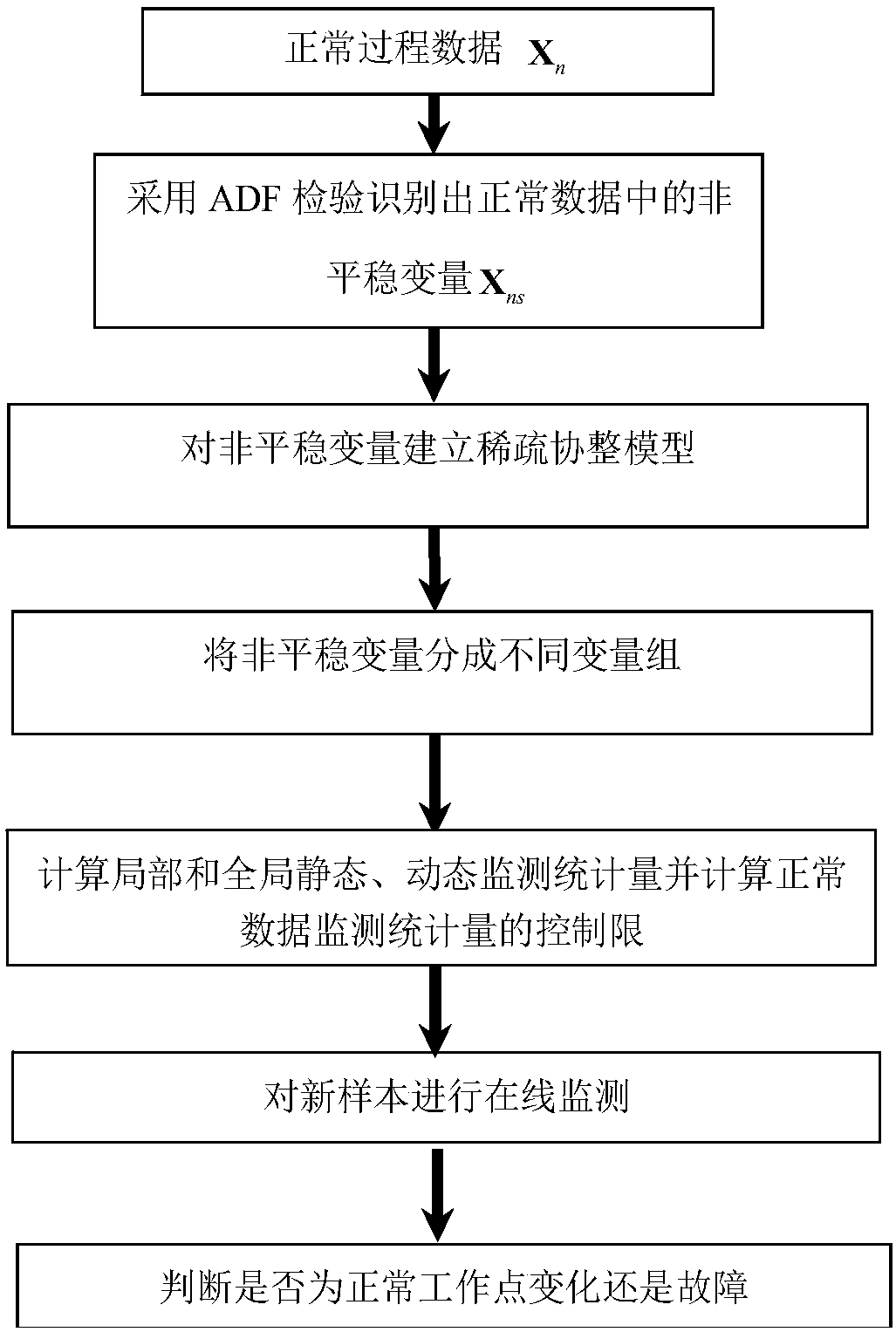

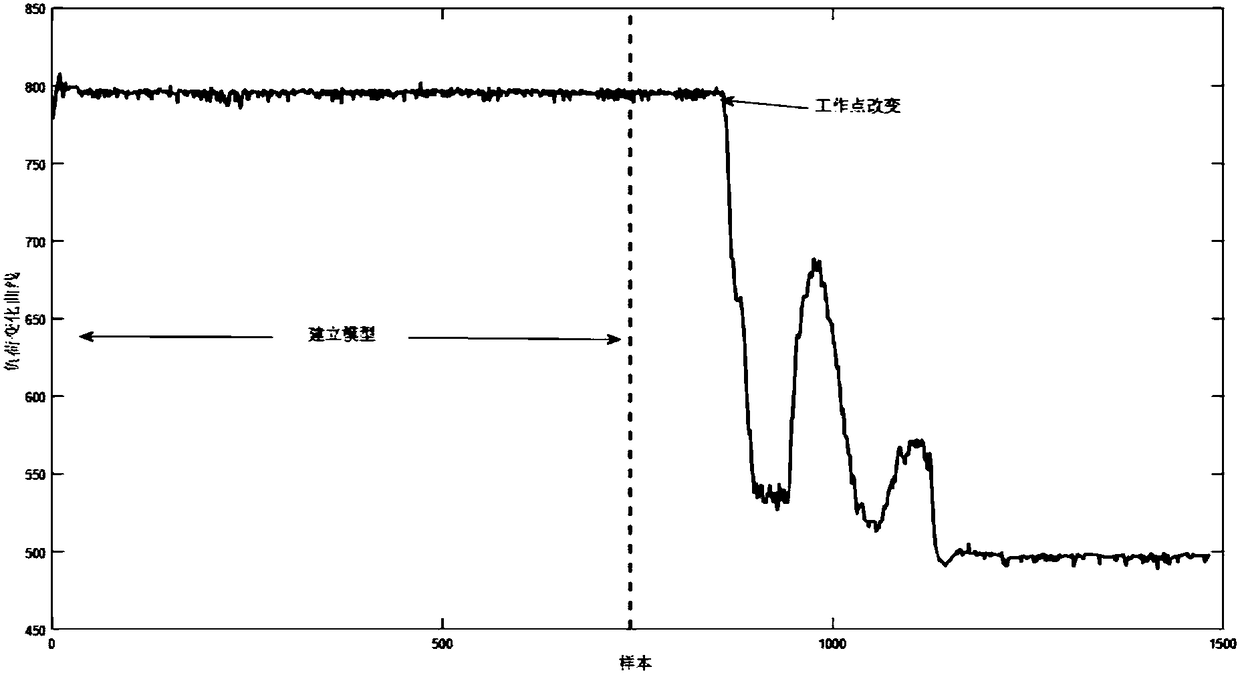

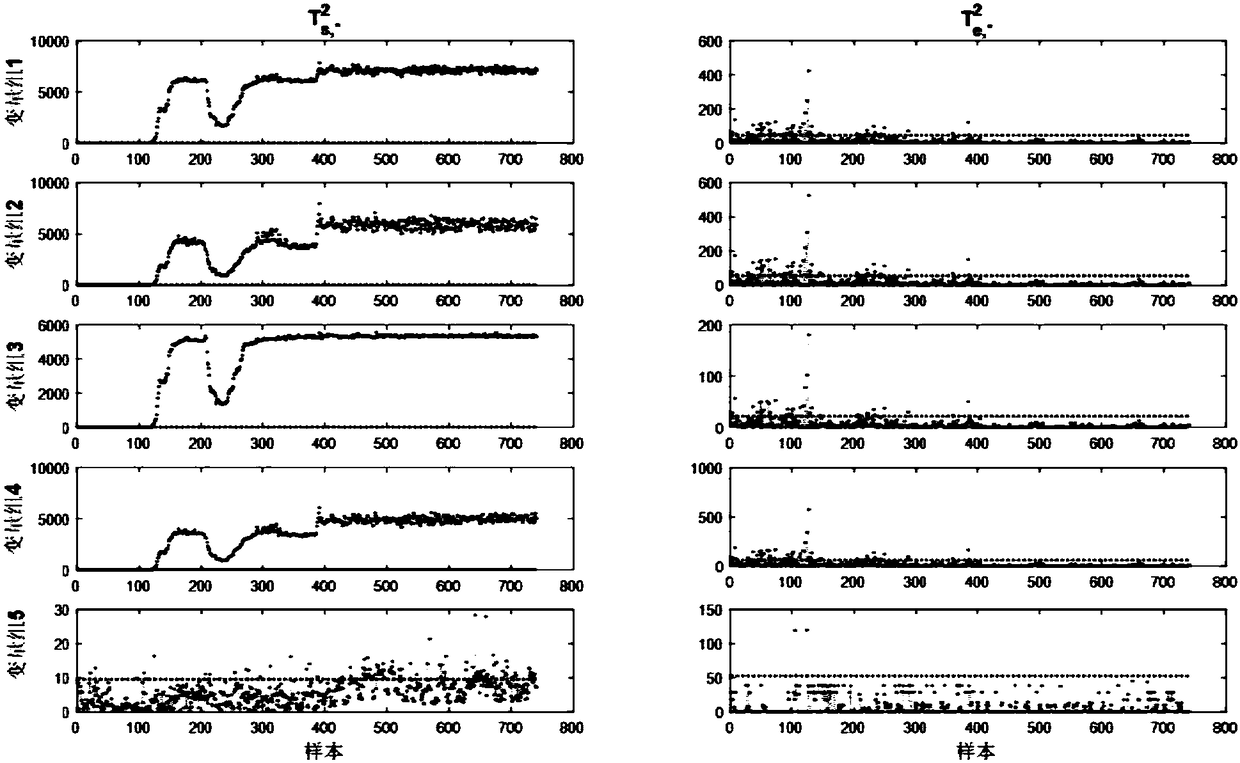

Dynamic distributed monitoring method for varying-condition operation of million-kilowatt ultra supercritical set

ActiveCN108490908ARealize identificationReduce complexityElectric testing/monitoringNormal conditionsCons

The invention discloses a dynamic distributed monitoring method for varying-condition operation of a million-kilowatt ultra supercritical set. Aimed at a typical large-scale non-stationary process ofthe million-kilowatt ultra supercritical set, sparse con-integration analysis and a dynamic feature extraction method are combined for fault detection as well as recognition of condition change. Via the method, components of the large-scale process can be divided into different variable groups automatically, static and dynamic process information is extracted from each variable group, the static process information is modeled and monitored, and the dynamic process information is also modeled and monitored. The process information is dug deeply, and normal condition change of the process can beeffectively distinguished from a real process fault. The method can be used to solve the problem in monitoring the process of the large-scale non-stationary dynamic system, namely the million-kilowatt ultra supercritical set, improve the process monitoring performance, help an onsite engineer master operation state of the set accurately, ensure the safety of the million-kilowatt ultra supercritical set, and improve the production benefit.

Owner:ZHEJIANG UNIV

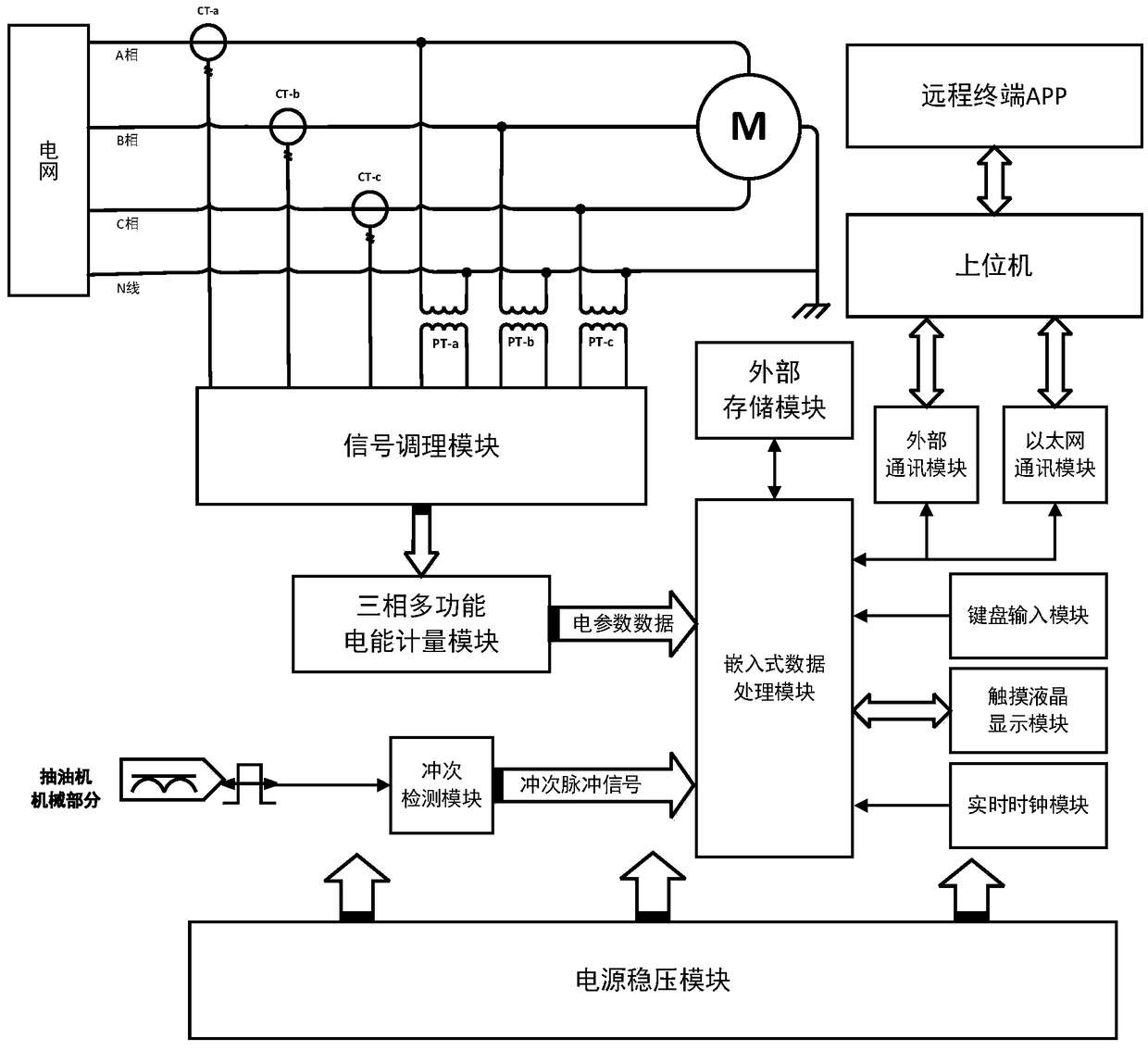

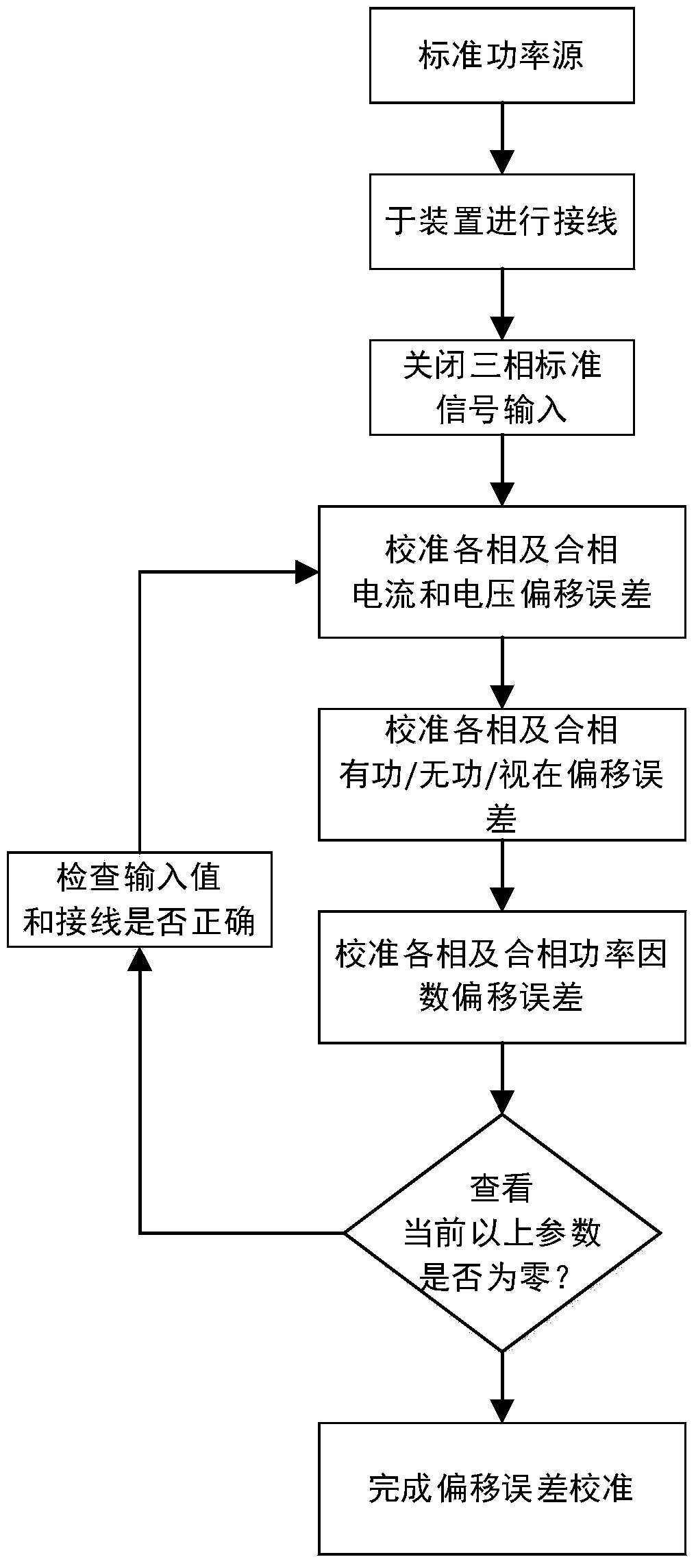

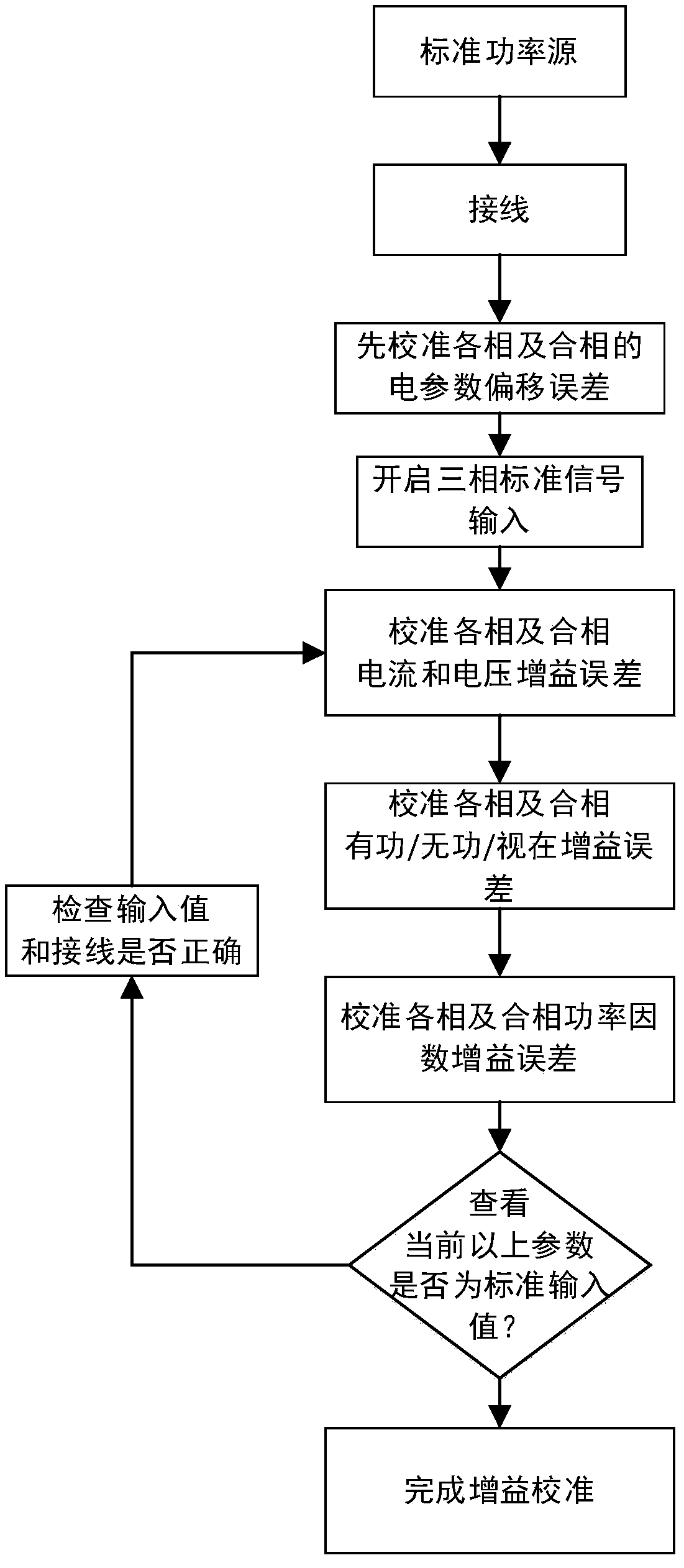

Intelligent monitoring device and method for monitoring efficiency of oil pumping system in real time based on electric parameters

The invention discloses an intelligent monitoring device and a method for the monitoring efficiency of an oil pumping system in real time based on electric parameters. Actual demands of oil field production is fully considered, important data, key variables and parameters, such as product volume, power consumption, pump efficiency, system efficiency, power outage well logging, motor various electrical parameters, and the like, in multiple oil pumping well production processes is provided, all important parameters in the running process of an oil pumping machine can be comprehensively detected,beside, the calculation mode of the multiple parameters can be selected by a user according to demands, evaluating standard is diversified, field engineers can be effectively assisted in comprehensive evaluation and the diagnosis of the operating state of an oil well.

Owner:NORTHEASTERN UNIV

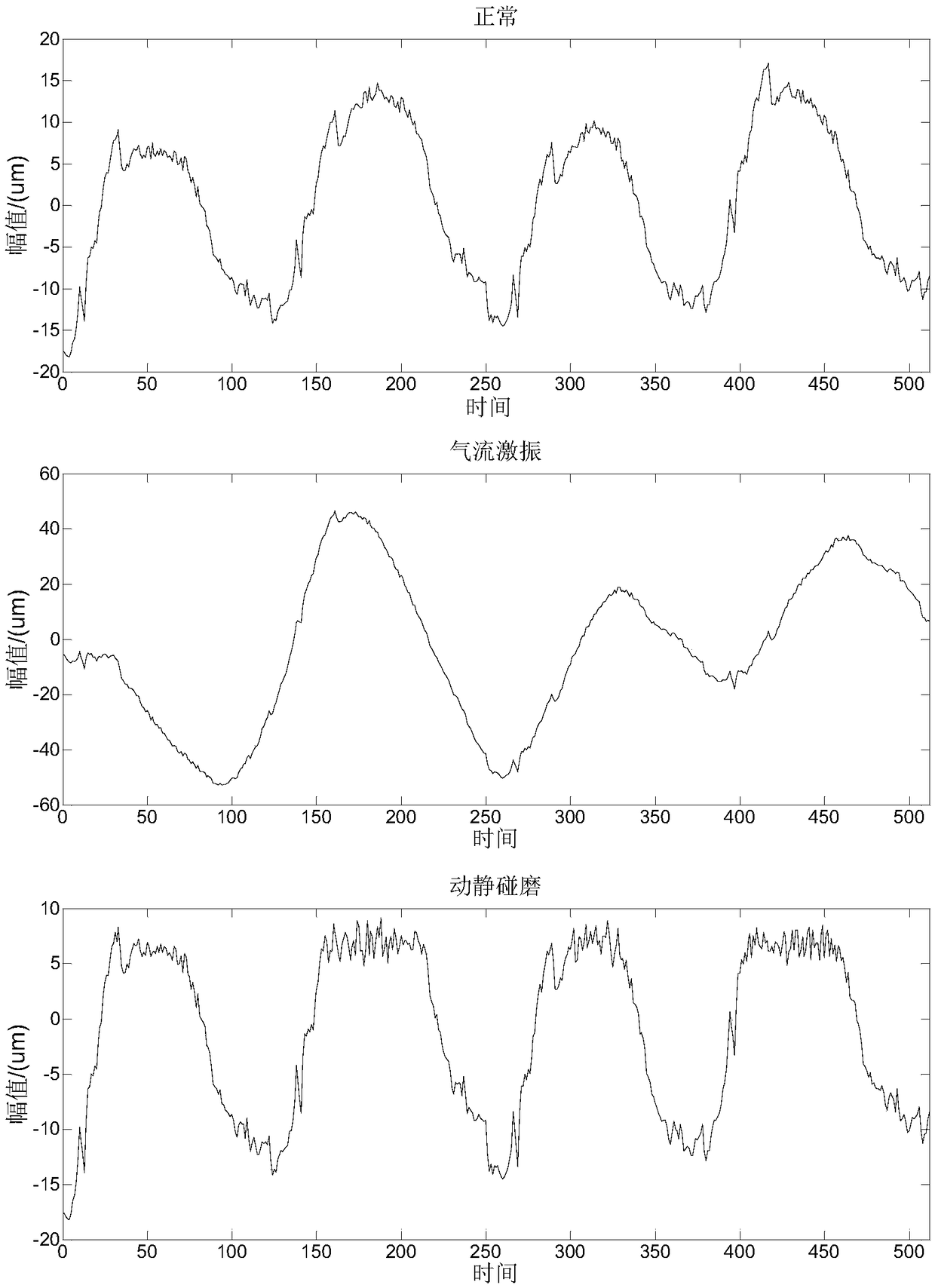

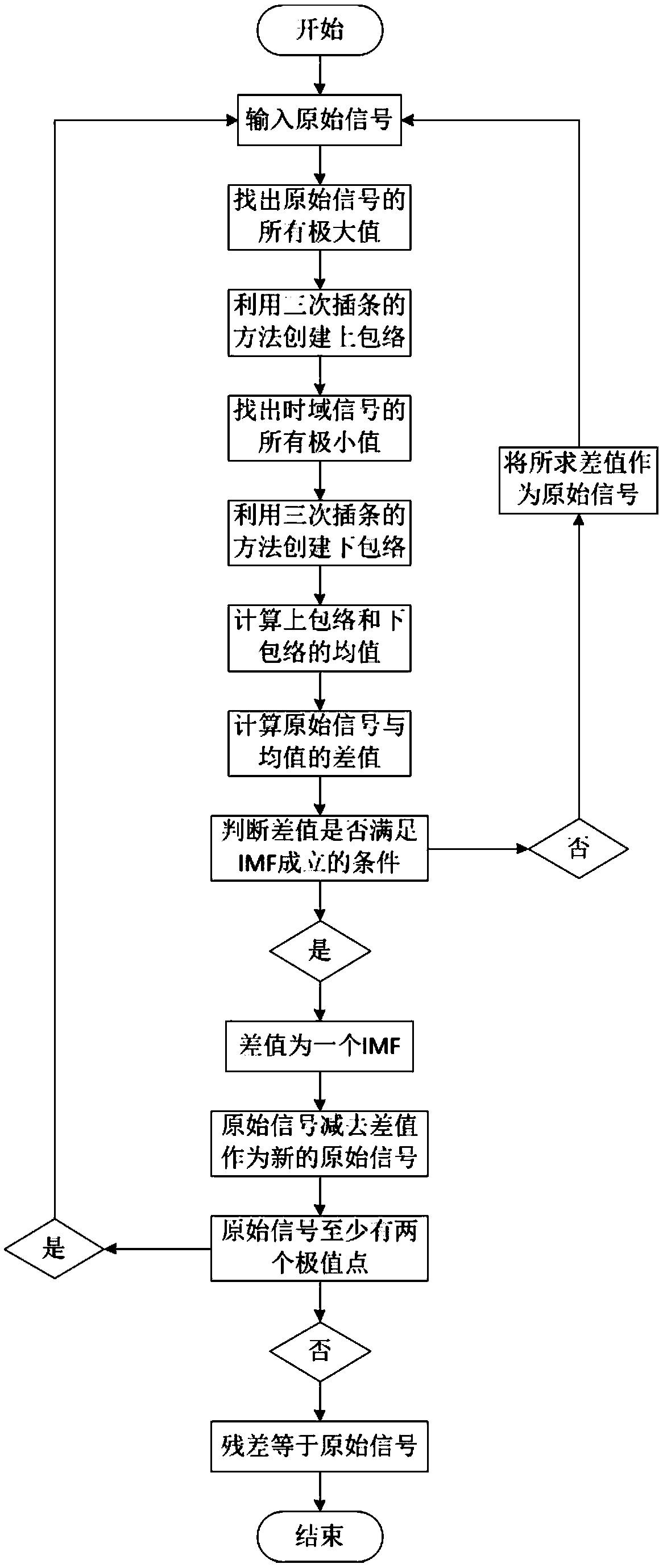

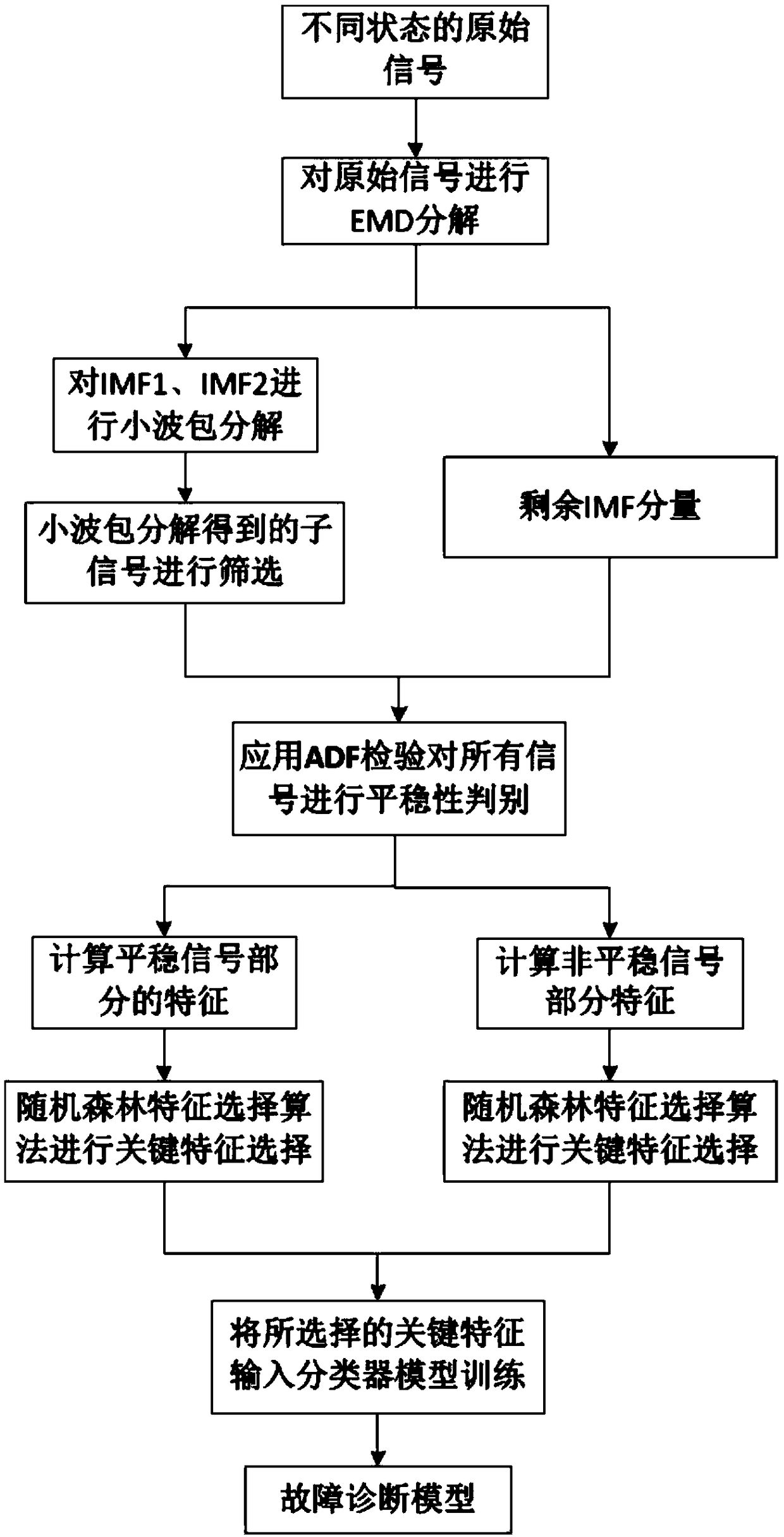

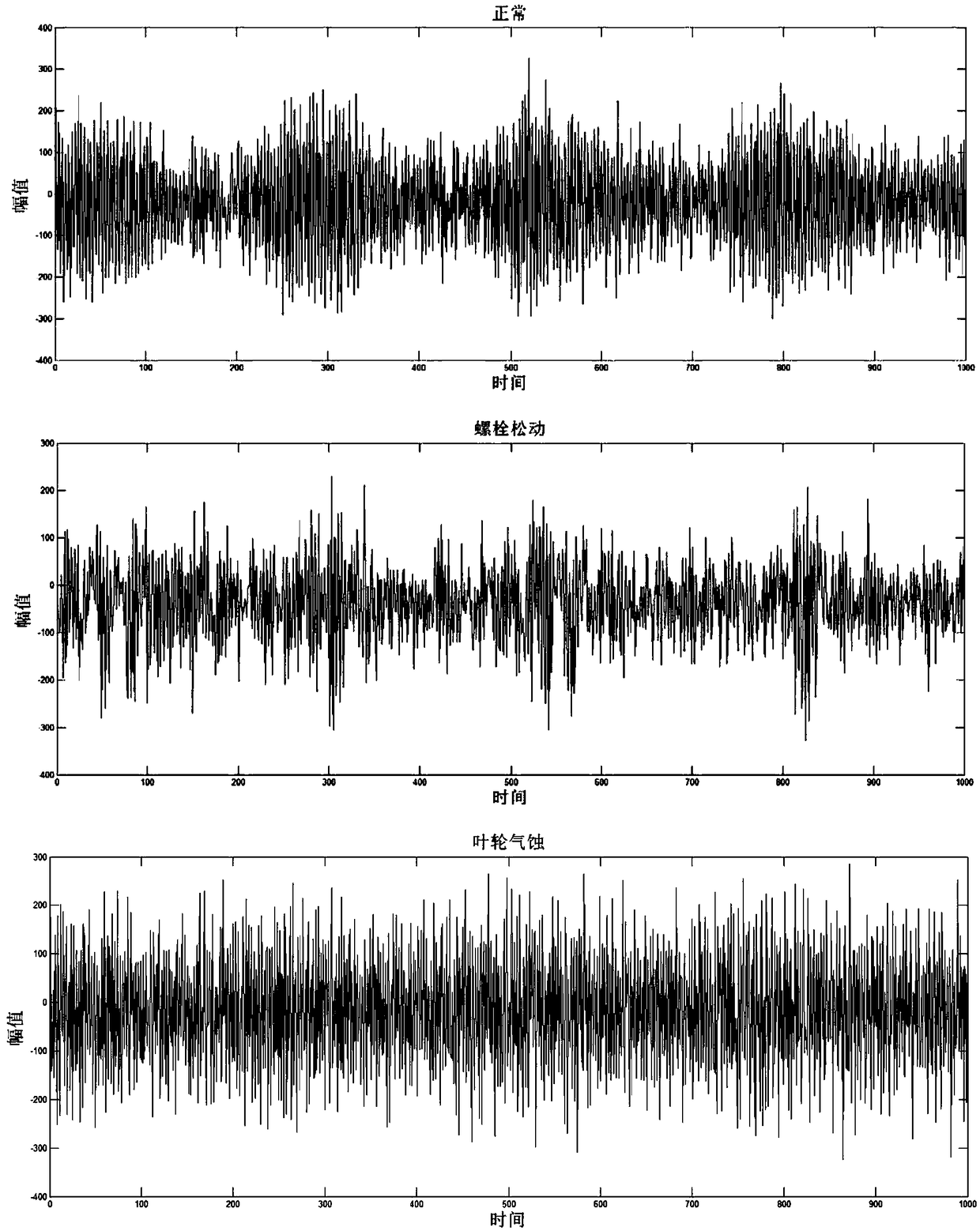

Intelligent power plant pump machine fault diagnosis method based on vibration signal stationary non-stationarity discrimination and feature discrimination

ActiveCN109241915AAvoid interferenceGuaranteed safe operationCharacter and pattern recognitionGeneration processFeature vector

The invention discloses an intelligent power plant pump machine fault diagnosis method based on vibration signal stationary non-stationarity discrimination and feature discrimination. The method mainly aims at the pump equipment in the thermal power generating unit, and decomposes the original signal to obtain a plurality of eigenmode components through the empirical mode decomposition, and overcomes the mode aliasing problem of the EMD decomposition by using the wavelet decomposition. At the same time, the stationarity of the decomposed sub-signal is discriminated, and the stationary part andthe non-stationary part are respectively calculated. In the aspect of feature computation, the first and second frequency-doubling features are added because the frequency spectrum of the pump vibration signal changes obviously when it is abnormal. In addition, the selection of key features reduces the dimension of eigenvectors, reduces the redundancy of data, improves the accuracy of fault diagnosis of vibration signals of pumps in thermal power generating units, and helps engineers to repair the faults accurately, so as to ensure the safe and reliable operation of power generation process and improve the production efficiency.

Owner:ZHEJIANG UNIV

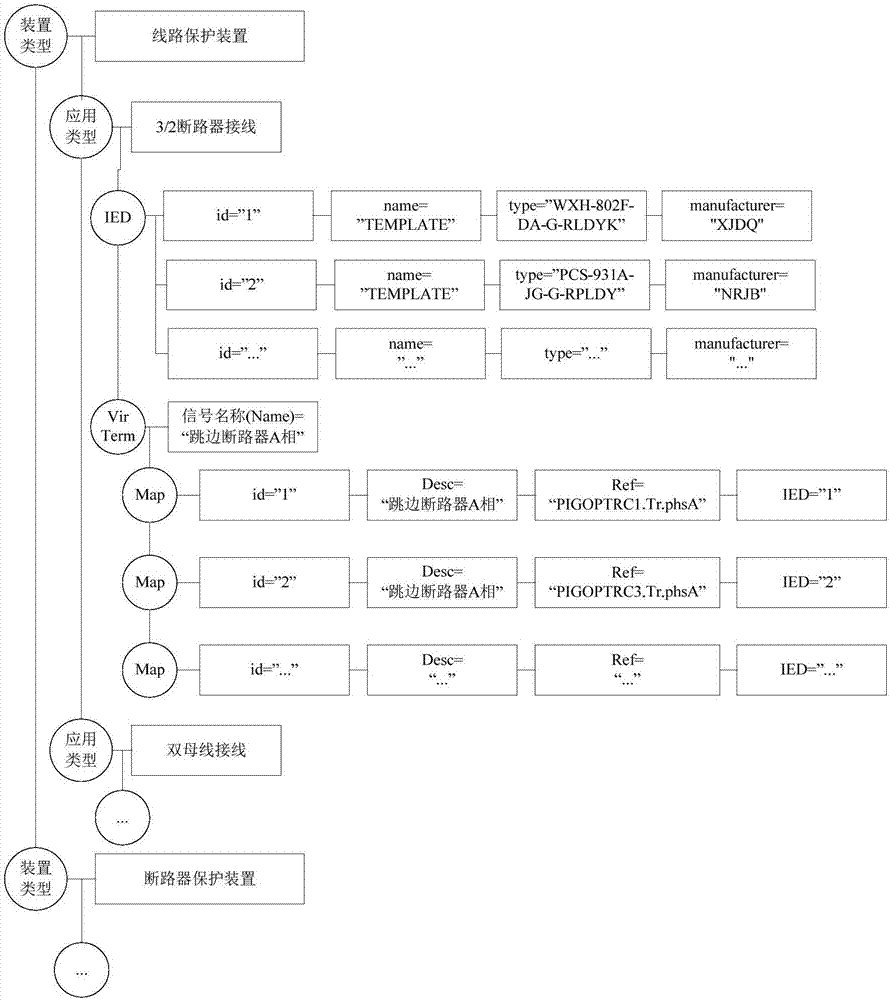

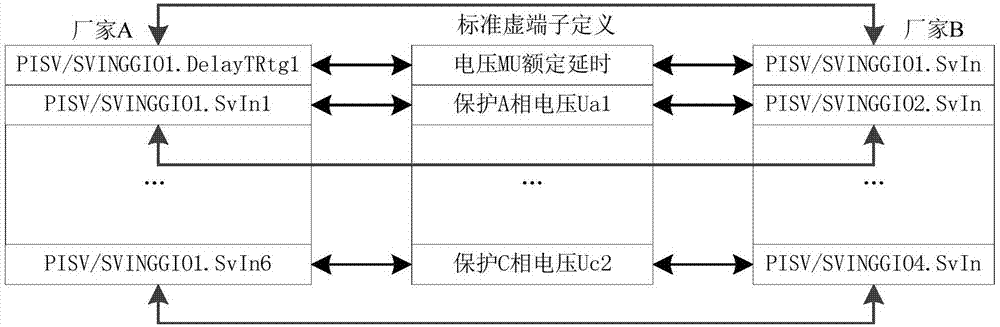

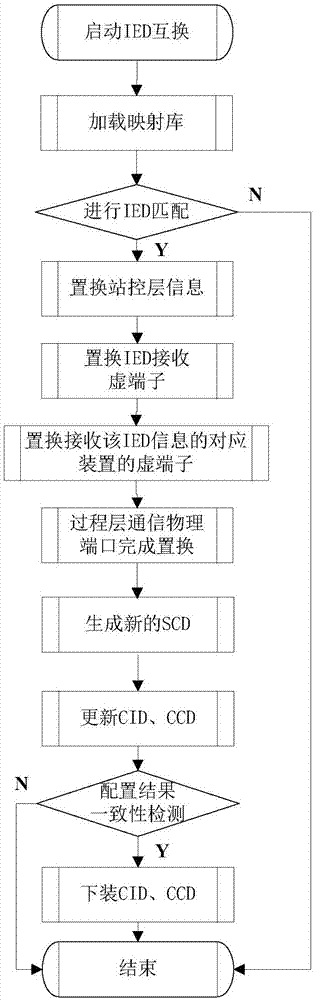

Intelligent substation IED interchange method and device

ActiveCN106991482AReduce workloadImprove operation and maintenance efficiencyData processing applicationsVirtual terminalSmart substation

The invention relates to an intelligent substation IED interchange method and device. The method is characterized by constructing a virtual terminal mapping database by collecting ICD models of products passing state grid company relay protection and safety automatic device professional test; and when an intelligent substation is reconstructed and expanded, and a secondary system of the intelligent substation is configured, virtual terminal connection lines can be replaced quickly according to the virtual terminal mapping database. The intelligent substation IED interchange method and device reduce workload of on-site engineers and improve configuration accuracy; the virtual terminal mapping database can be used repeatedly; and when a new product is released, the virtual terminal mapping database is updated synchronously, thereby facilitating operation personnel to carry out corresponding processing and improving operation and maintenance efficiency of an intelligent device.

Owner:XUJI GRP +4

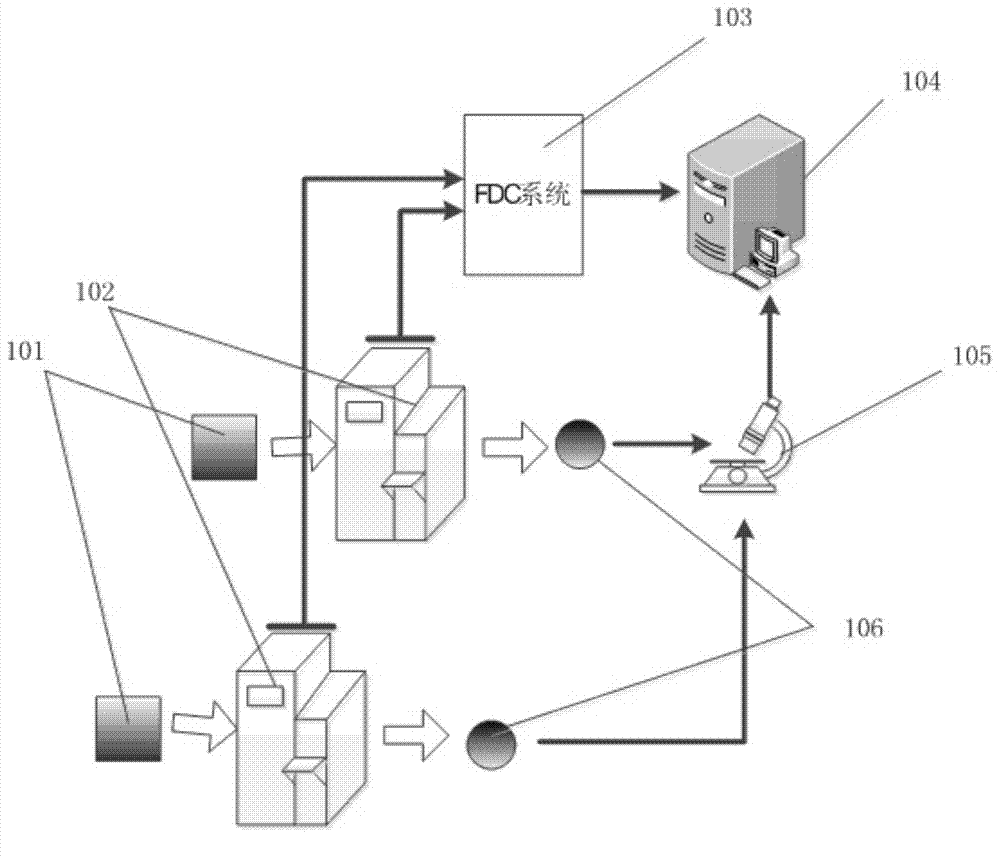

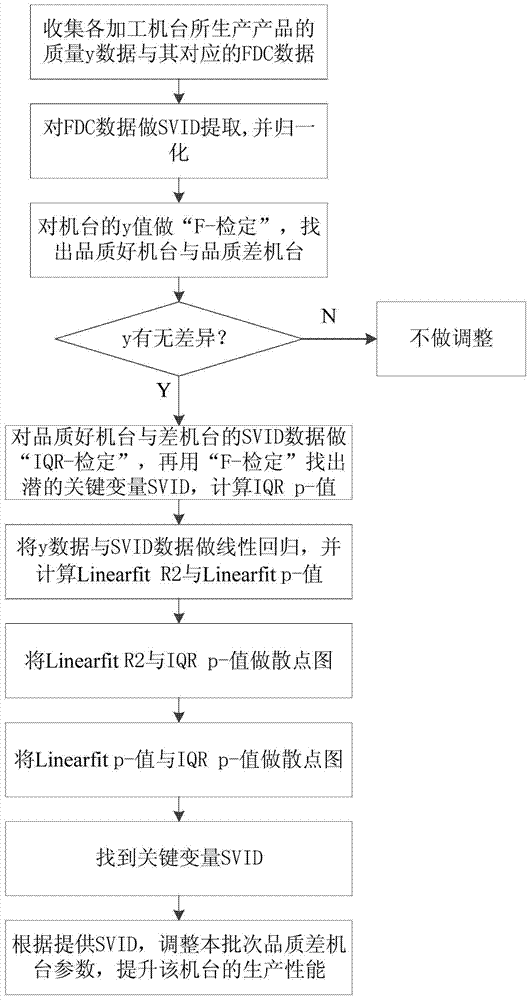

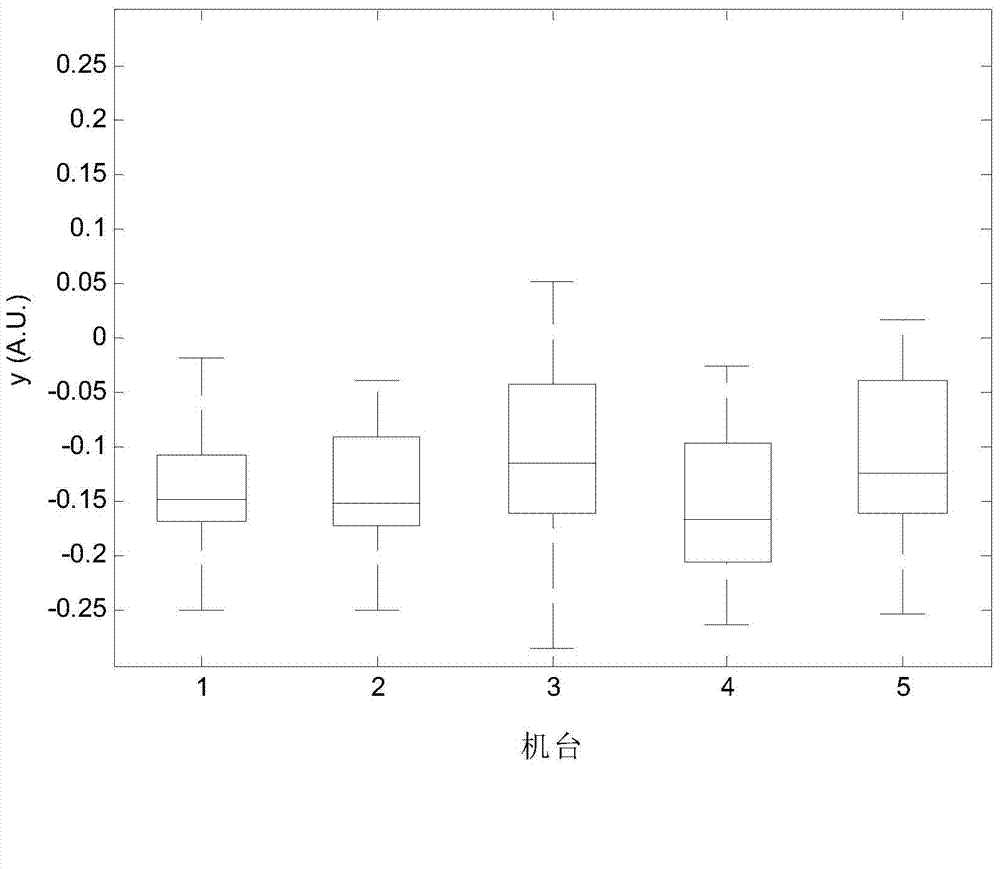

Machine bench performance matching method and system of semiconductor manufacturing equipment

ActiveCN103592913ASimplify the maintenance processReduce maintenance costsSemiconductor/solid-state device manufacturingTotal factory controlManufacturing technologyTest quality

The invention discloses a machine bench performance matching method and system of semiconductor manufacturing equipment. The system comprises a plurality of processing machine benches, a fault detection and classification system, a product quality tester and a data collecting engine and processing system. The processing machine benches execute a same product manufacturing technology and machine products of a same specification. The fault detection and classification system monitors production processes of all the processing machine benches in the technology process. All monitored process variable data are provided for the data collecting engine and processing system. The product quality tester tests quality of the machined products in the technology process in a sampling mode and provides quality data for the data collecting engine and processing system. Through performance matching of the processing machine benches in the same technology process, key process variables of the machine benches affecting and leading poor quality are rapidly found, and a parameter adjustment scheme is provided for a field engineer in the process of maintaining the machine benches, so that the products manufactured by the different machine benches almost are the same in quality.

Owner:江阴百盛电气控制有限公司

Power substation secondary system failure reconnaissance method

ActiveCN103279520AReduce reuseImprove efficiencyData processing applicationsSpecial data processing applicationsComputer moduleSystem maintenance

The invention discloses a power substation secondary system failure reconnaissance method. The power substation secondary system failure reconnaissance method comprises following modules: an information inputting and comparing module, an information real-time transmission module, an engineer data module and a failure simple treatment scheme module, wherein the information inputting and comparing module is used for inputting all kinds of site data to a database of an engineer on site, the site data comprise pictures and variable data of corresponding parameters, the data are compared in a common fault database of a power substation secondary system which is originally built, and the fact that whether failure occurs in the secondary system and the type of the failure are compared. The information real-time transmission module is used for carrying out a real time transmission function, and has the image, character and voice transmission functions. The engineer data module is used for building a database of secondary system maintenance engineers and recording the maintenance aspects at which a corresponding engineer is good, and enabling coordination staff to find an appropriate engineer rapidly and conveniently. The failure simple treatment scheme module is used for establishing the treatment scheme of a common failure, namely, the simple treatment scheme of the common failure is summarized in the simple treatment scheme module, and accessories are provided; a flow chart and simple measures of treatment of the failure are inquired through the method of inputting the name of the failure.

Owner:STATE GRID CORP OF CHINA +1

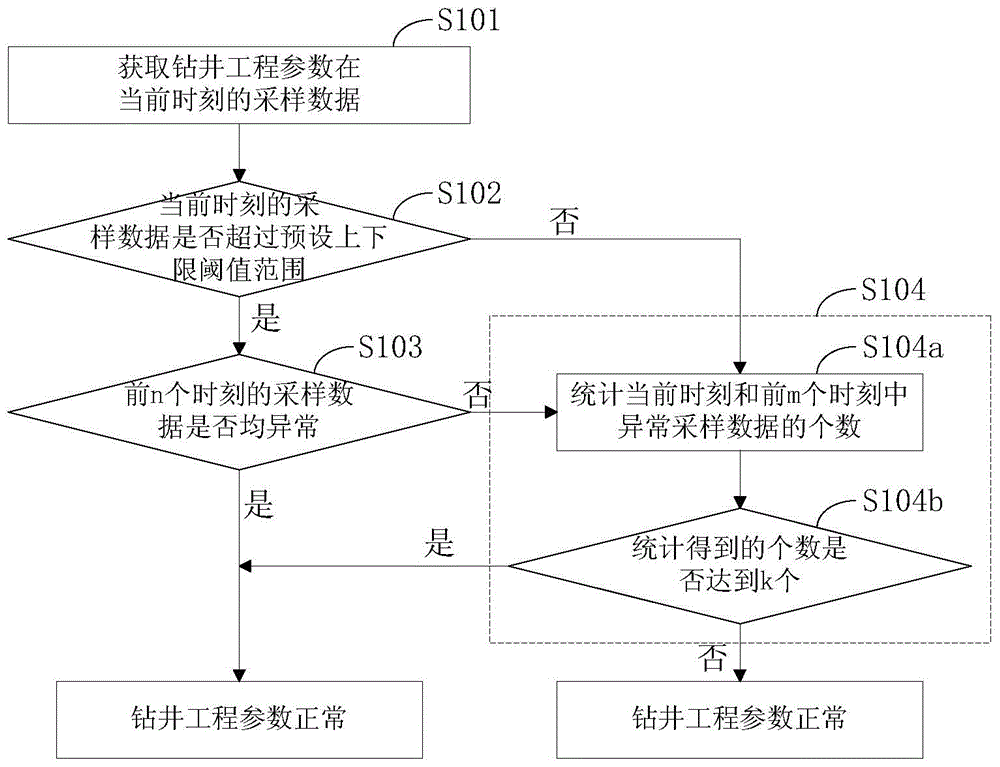

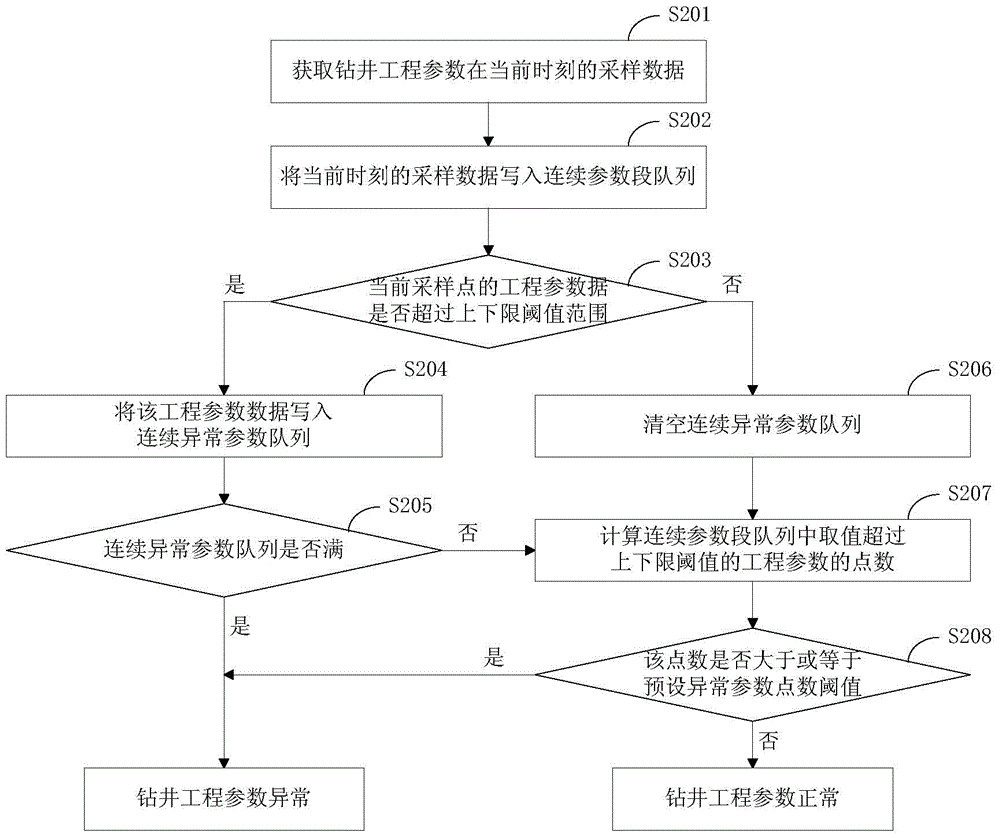

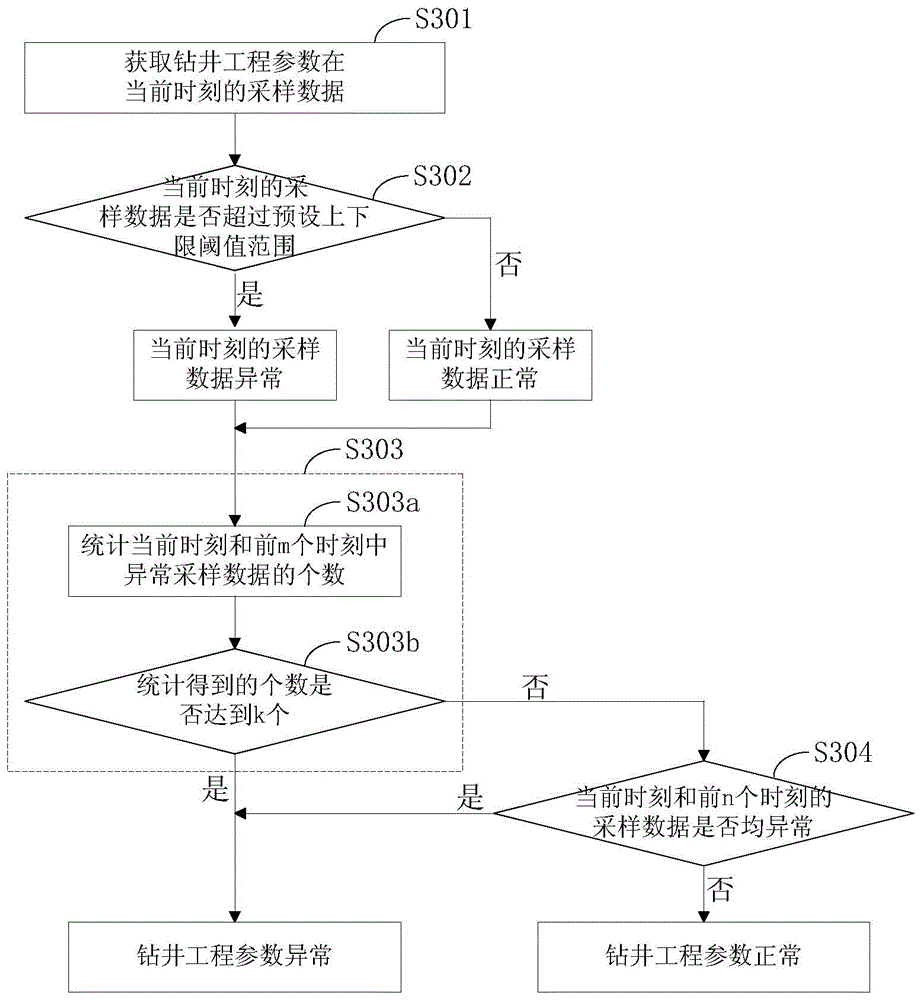

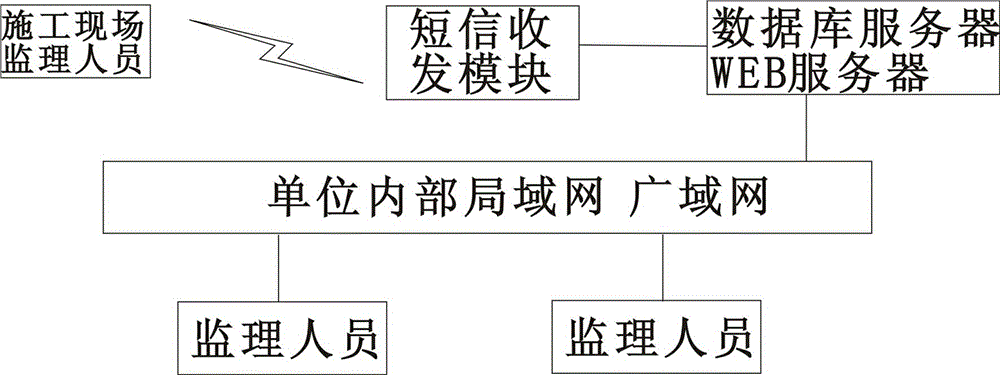

Drilling engineering parameter state detecting method

Owner:CHINA PETROLEUM & CHEM CORP +1

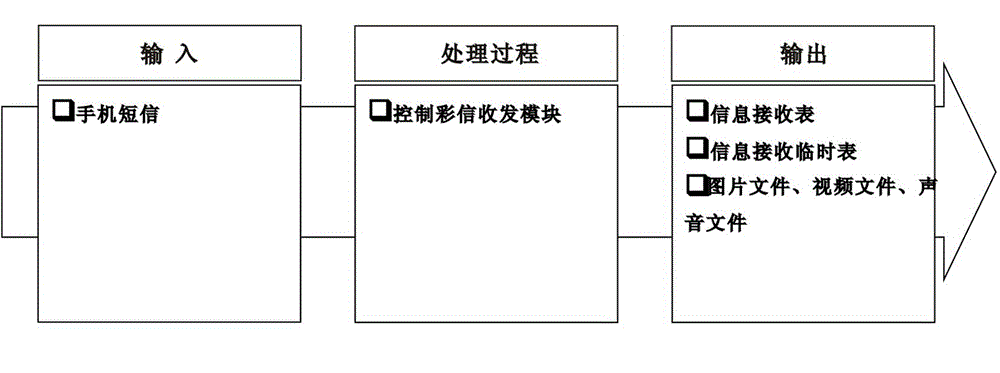

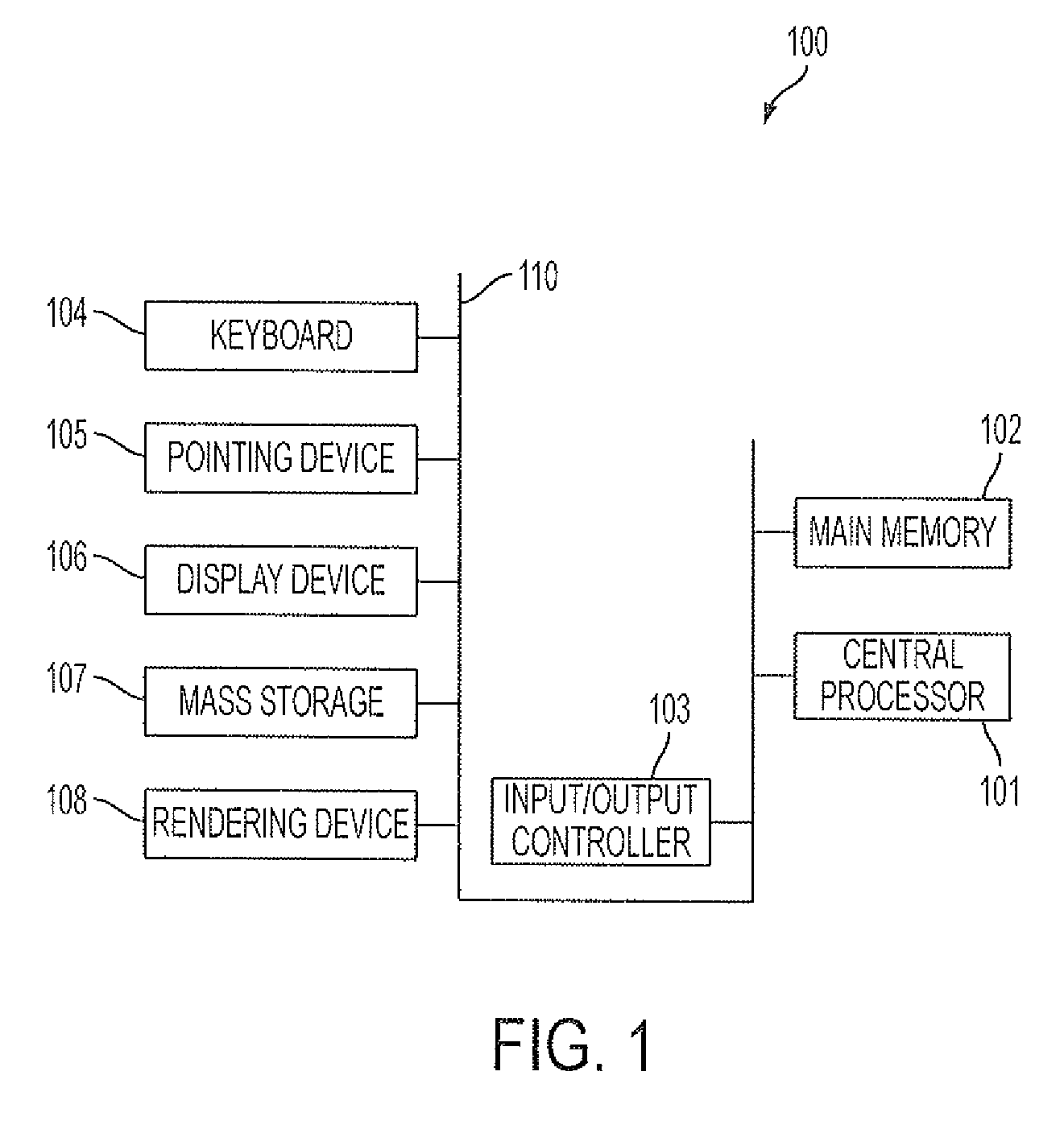

Construction project field management information acquisition and subsequent application processing technology

InactiveCN104636840AImprove collection efficiencyStable supportResourcesSpecial data processing applicationsProject managementComputer science

The invention discloses construction project field management information acquisition and subsequent application processing technology. A construction project field management engineer adopts a mobile phone short message or multimedia message mode to send working information of each construction field in real time to a system center via a public wireless communication network or a self-built local wireless communication network; the system center separates contents and pictures in the short messages or multimedia messages, and a database is built; according to construction project management needs, the system automatically generates working logs; through searching and initial sorting functions, according to certain conditions, compilation of data such as the construction quality and the process are sorted and generated, and a foundation is laid for compiling the quality of the special project and the process; and administrators such as a project management person can query relevant management logs of the field engineer according to authorization and assess the working condition of the engineer. Thus, the field management working level and the efficiency are enhanced.

Owner:吴晓铭

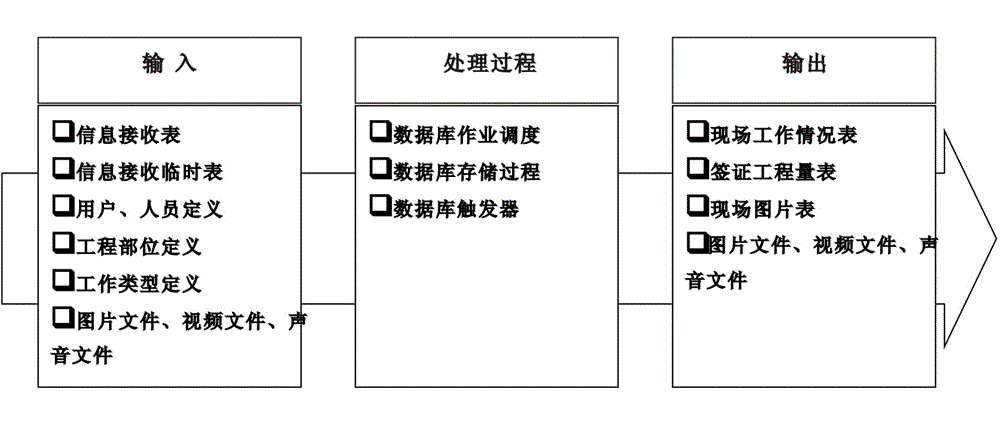

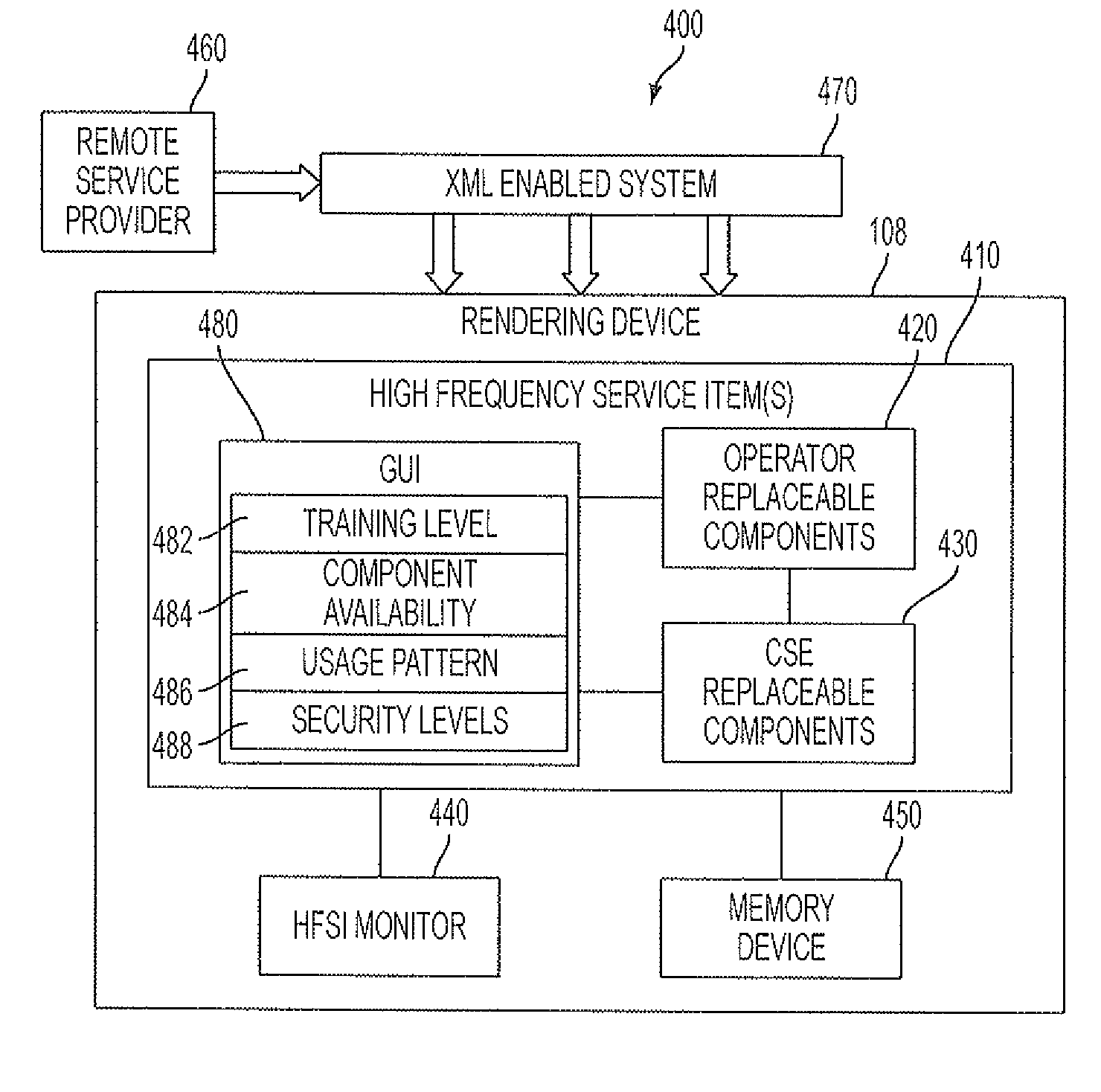

Method and system for managing field convertible customer replaceable components

ActiveUS9488947B2Easy to changeLow costError detection/correctionVolume/mass flow measurementSecurity levelSite engineer

A method and system for managing field convertible operator replaceable components associated with a rendering device. A file that defines a set of operator replaceable components can be created and remotely installed on the device. The replaceable components associated with the device can be easily changed from a designation as a customer service engineer replacement component to an operator replacement component and vice versa. A determination that an operator is allowed to replace the component can be made based on a training level provided to the operator, the component availability, a usage pattern, and / or a security level. Such an approach enables the operator to perform the majority of maintenance on the device without requiring the services of a field engineer.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com