Machine bench performance matching method and system of semiconductor manufacturing equipment

A technology for manufacturing equipment and semiconductors, which is applied in semiconductor/solid-state device manufacturing, comprehensive factory control, and comprehensive factory control. It can solve problems such as inability to guarantee product quality consistency, high maintenance costs, and low maintenance efficiency, so as to reduce maintenance costs. , Improve work efficiency and simplify the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

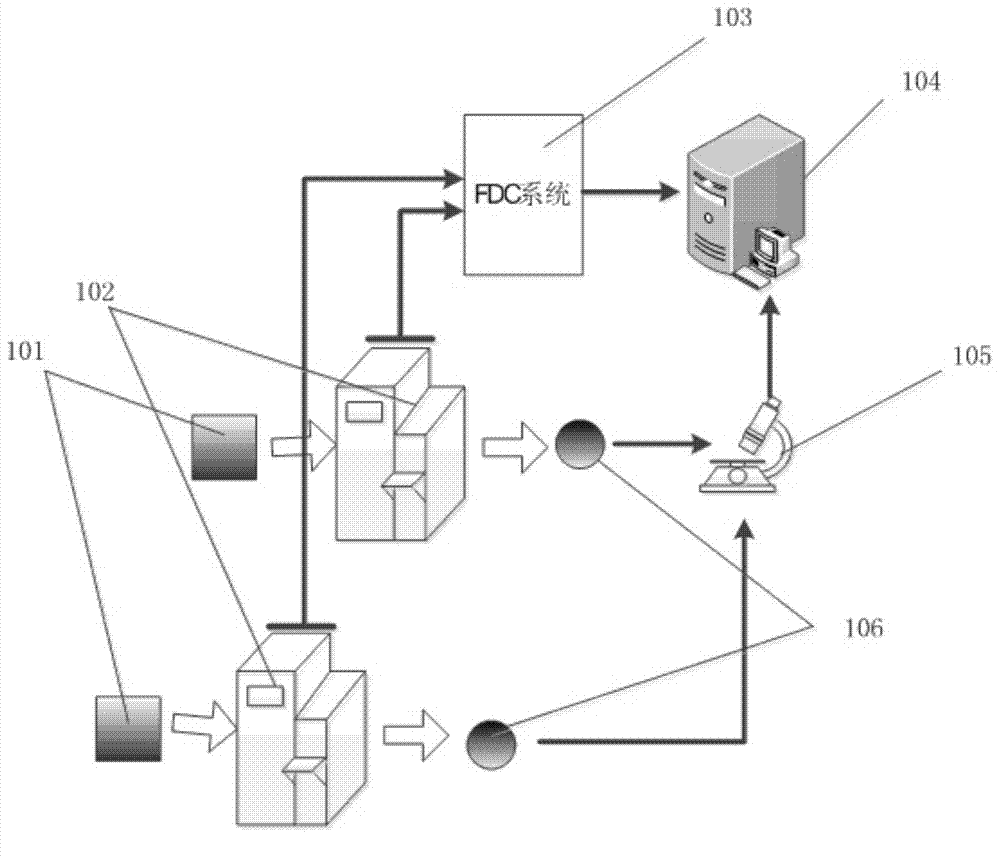

[0024] Please refer to Fig. 1, which is a block diagram of the machine performance matching system for semiconductor manufacturing equipment of the present invention, as figure 1 As shown, the present invention includes a plurality of processing machines 102, products to be processed (wafer / TFT-LCD) 101, a fault detection and classification system (Fault Detection & Classification System, FDC system) 103, a product quality tester 105, and a data collection engine And processing system 104, sampling inspection product 106.

[0025] Wherein, the processing machine 102 includes a plurality of parallel machines, which perform the same product manufacturing process and process products of the same specification;

[0026] Wherein, the FDC system 103 monitors the production process of all processing machines 102 in the process; and provides all monitored process variable data to the data collection engine and processing system 104;

[0027] Wherein, the product quality tester 105 sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com