Numerical control machine tool remote real-time cooperation fault diagnosis and maintenance system

A fault diagnosis and remote diagnosis technology, applied in the direction of instruments, etc., can solve the problems of lack of safety, lack of intuition, lack of cooperation, etc., to achieve the effect of ensuring safe transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

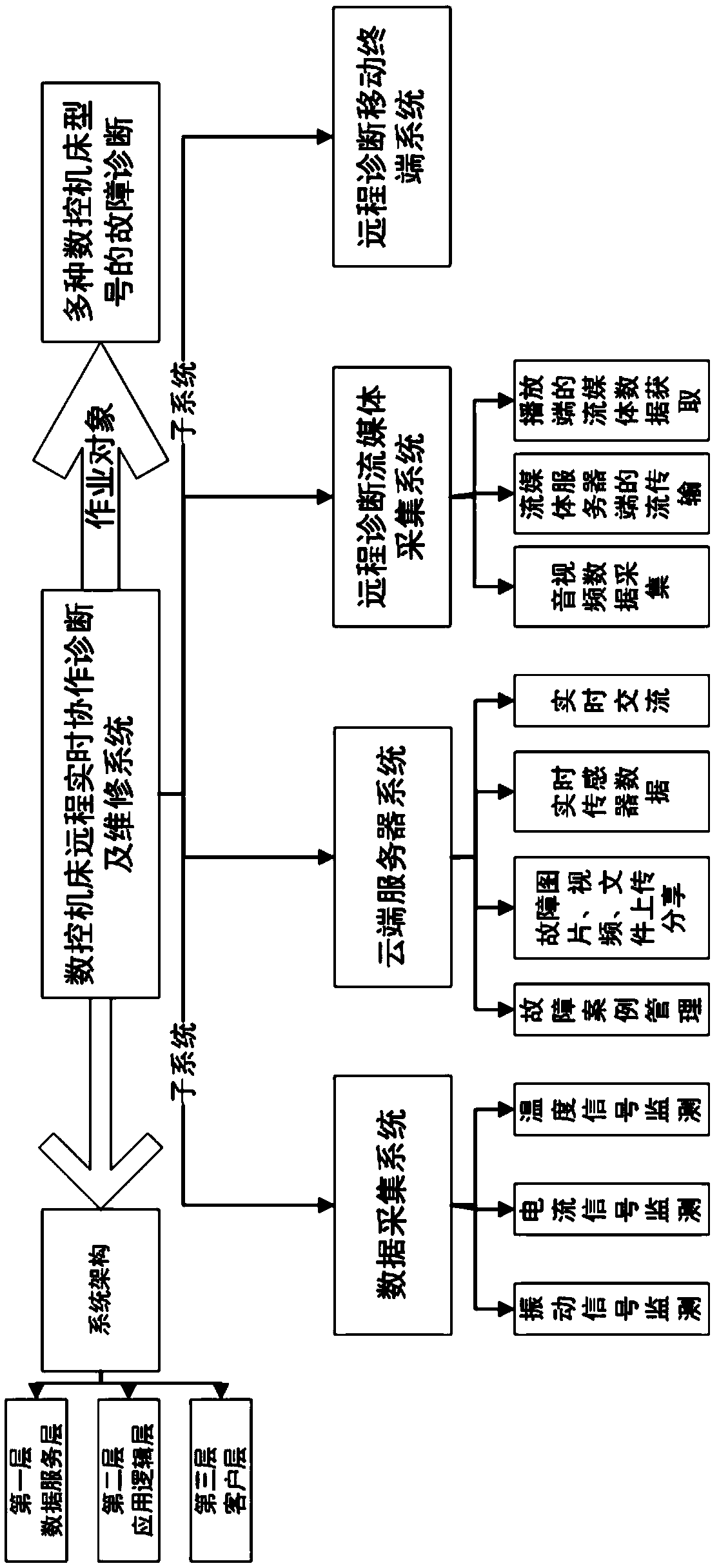

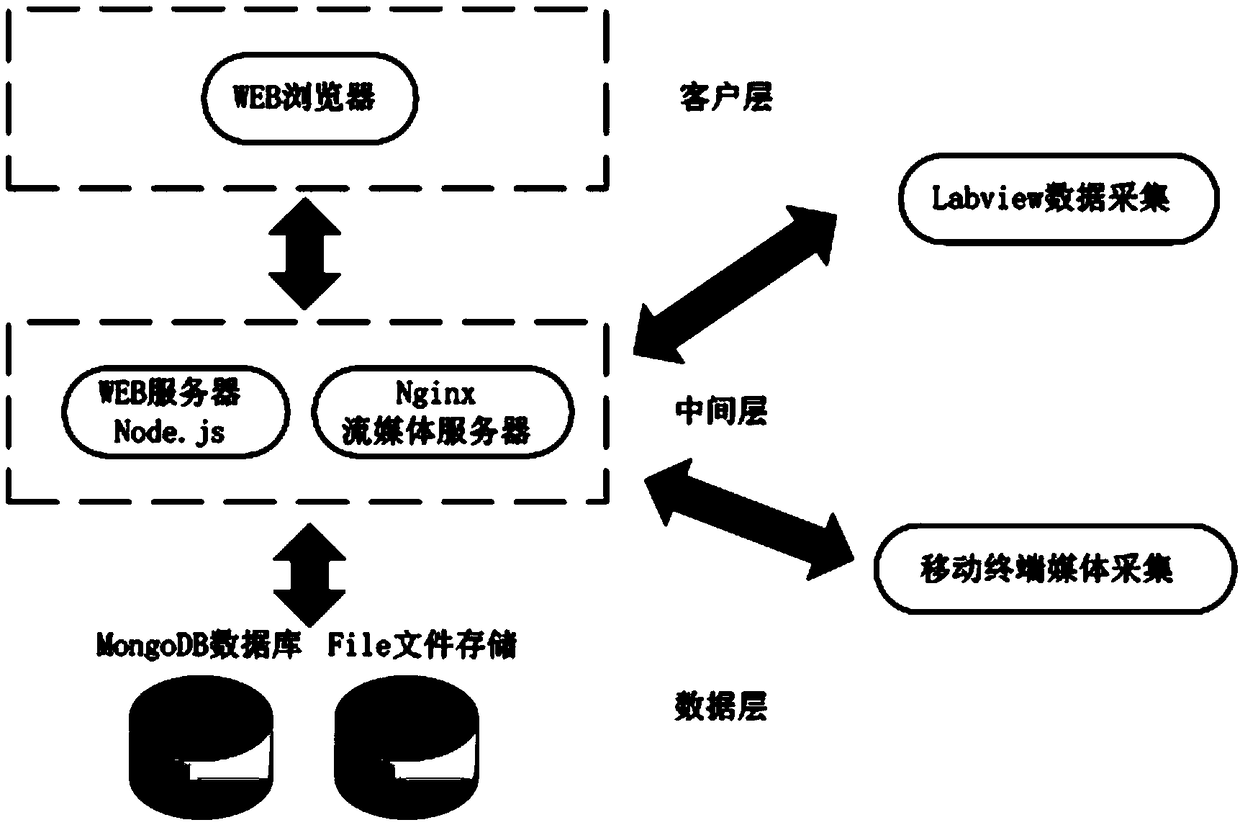

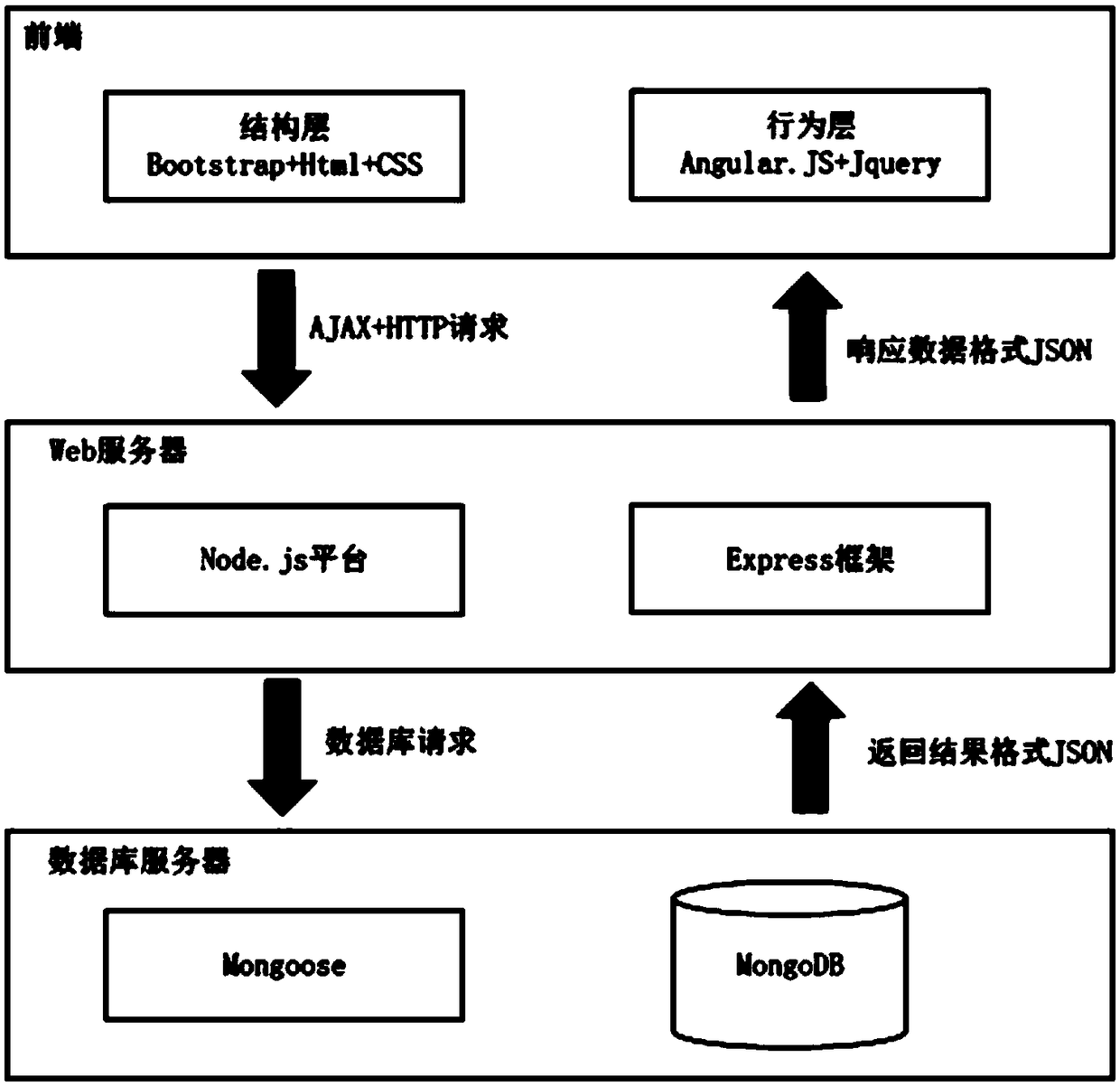

[0030] figure 1It is the functional frame diagram of the remote real-time collaborative fault diagnosis and maintenance system of CNC machine tools of the present invention. The main operation object of the present invention is the fault diagnosis and maintenance of various CNC machine tool models. The system adopts a three-layer system architecture, and the first layer is the data service layer , which mainly provides fault case data, storage and modification of sensor historical data, and user-related data storage; the second layer is the application logic layer, also known as the middle layer, responsible for data processing between cloud servers, remote sensors, and fault diagnosis browsers and transmission; the third layer is the client layer. This system does not need to install the client program remotely, and can communicate with the on-site maintenance engineer and diagnose the machine tool remotely by directly inputting the address in the browser. Specifically, in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com