plate-making machine (ctp) into plate press roller mechanism

A technology of plate making machine and pressure roller, which is applied in printing plate preparation and printing, etc. It can solve the problems of difficulty in ensuring the consistency of the pressure roller, difficulty in adjustment by the user, difficulty in adjustment of the pressure roller mechanism, etc., so as to improve the stability of plate feeding and improve the work efficiency. Efficiency and convenience for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

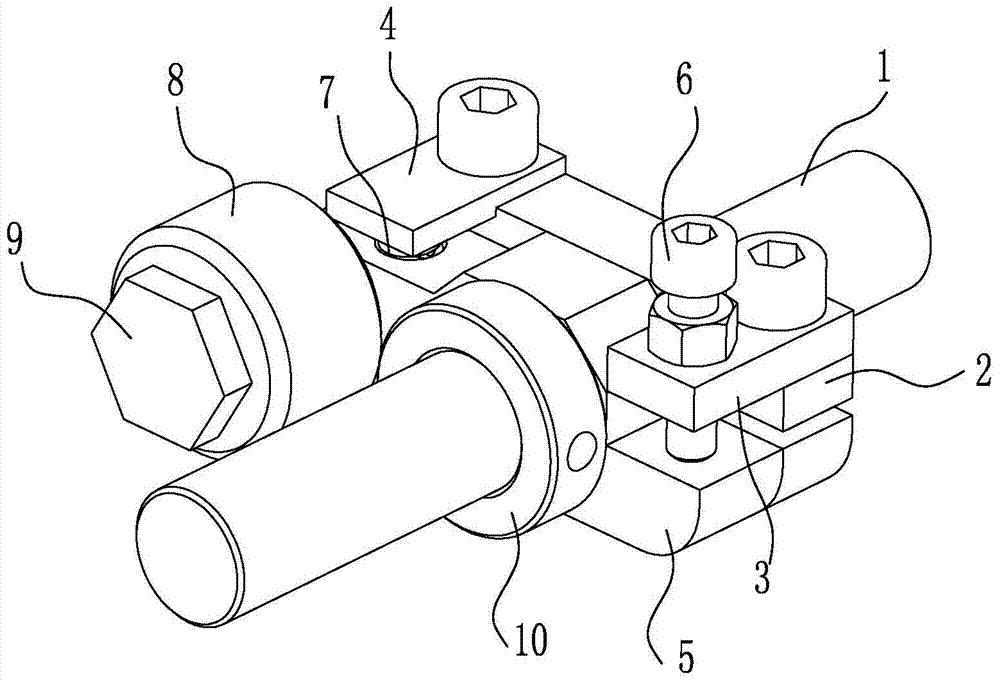

[0010] Such as figure 1 As shown, the plate-feeding pinch wheel mechanism of a direct plate-making machine (CTP) includes a fixed block 2 fixedly installed on a support shaft 1, and a limit block 3 on one side of the support shaft 1 is installed on the fixed block 2 and The pressure plate 4 located on the other side of the support shaft, a rocker arm 5 is also rotatably installed on the support shaft 1, the first end of the rocker arm 5 is located below the limit block 3, and the limit block 3 An adjustment bolt 6 whose lower end is pushed against the upper surface of the first end of the rocker arm 5 is installed on the top, the second end of the rocker arm 5 is located below the pressure plate 4, and the first end of the pressure plate 4 and the rocker arm 5 A compression spring 7 is arranged between the upper surfaces of the two ends, and a pressure roller device is installed on the second end of the rocker arm 5 .

[0011] The pressure wheel device includes a pressure whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com