Spring type multi-gear pressure-limiting valve with pressure adjustable

A pressure-adjustable, spring-type technology, applied in the field of pressure-limiting valves, can solve the problems of changing the maximum pressure in the pot, instability, safety hazards, etc., and achieve the effect of clear action, convenient and stable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

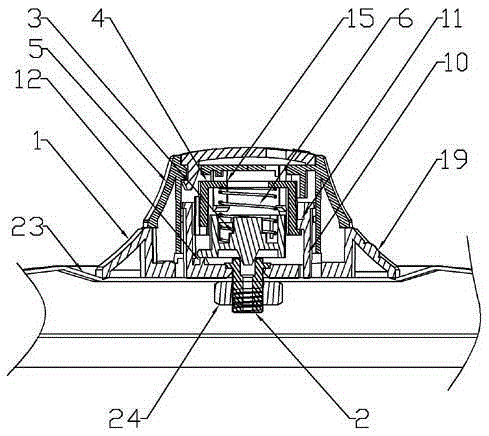

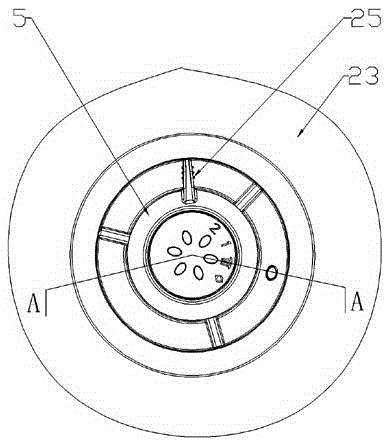

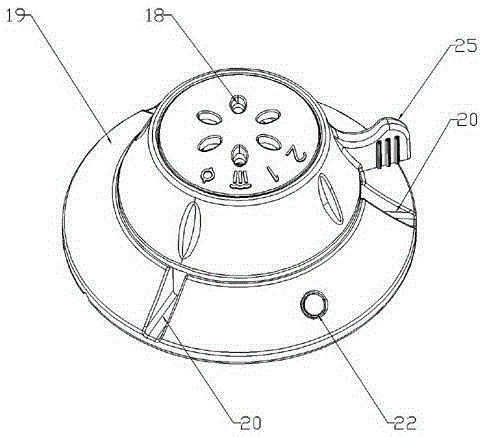

[0027] In this example, if Figure 1 to Figure 7 As shown, in this embodiment, the present invention includes a valve seat 1, an exhaust pipe 2 arranged at the bottom of the valve seat 1, and an exhaust pipe 2 arranged on the valve seat 1 and adapted to the exhaust pipe 2. A pressure regulating mechanism, the pressure regulating mechanism includes a lower valve core 3 adapted to the air outlet of the exhaust pipe 2, an upper valve core 4 arranged above the lower valve core 3, and an upper valve core 4 connected to the upper valve core 4 Connected rotary cover 5, a pressure limiting spring 6 is set between the lower valve core 3 and the upper valve core 4, the upper valve core 4 is sleeved on the lower valve core 3, and the lower valve core 3 is provided with three spool claws 7, and the inner wall of the upper spool 4 is provided with a chute 8 that matches the three spool claws 7, and the outer wall of the upper spool 4 is There are three sets of stepped locking positions 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com