Heavy-duty isothermal forging press with four corner leveling function

A technology of isothermal forging and four-corner leveling, applied in the field of warm forging presses, can solve the problems of low leveling accuracy and production efficiency, long leveling response time, loss of main tonnage of the press, etc., to avoid the loss of main tonnage, The effect of reducing production costs and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

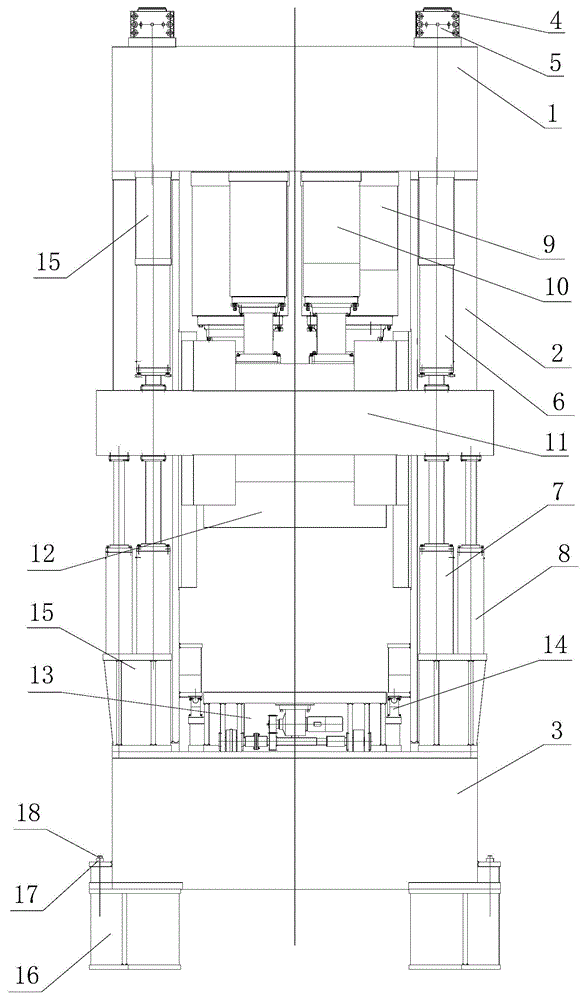

[0012] see figure 1 , a heavy-duty isothermal forging press with four-corner leveling function, including an upper beam 1, a lower beam 3, and a column 2 located between the upper beam and the lower beam, and the upper beam, lower beam, and column pass through a tie rod 4 and a lock nut 5 It is connected as an integral force-bearing frame body, and the body is fixed on the base 16 through a connecting rod 18 and a lock nut 17 . The upper beam is fixed to the bottom of the main cylinder 9 and the side cylinder 10, the piston ends of the main cylinder and the side cylinder are fixed to the slider 11, the lower plane of the slider is fixed to the upper backing plate 12, and a mobile workbench is installed on the lower beam 13. The upper four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com