High-precision water level measuring device of water level gauge

A high-precision technology for water level measurement, applied in the field of water level meters, can solve the problems of low accuracy of measurement results, and achieve the effects of improved display accuracy, convenient use, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

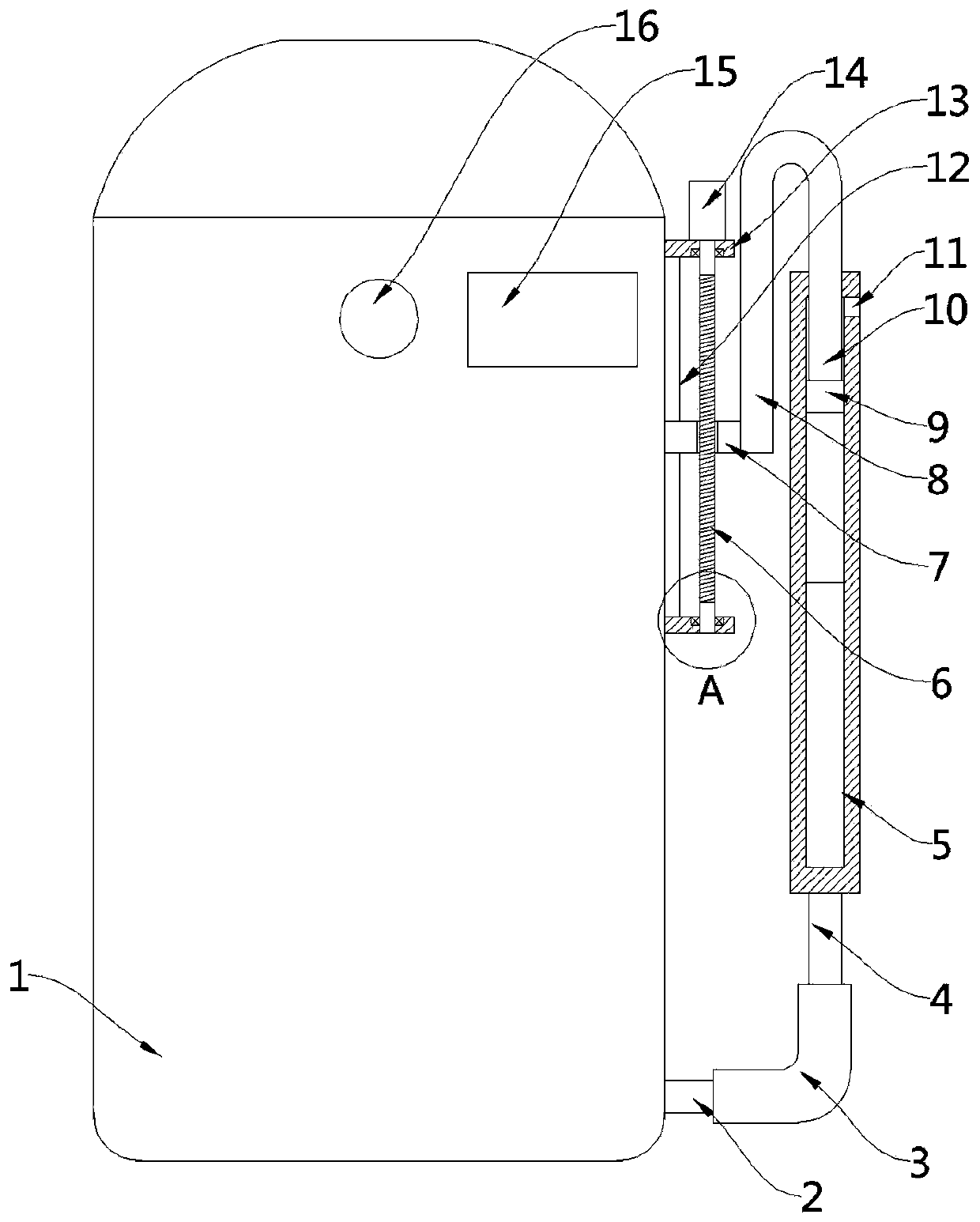

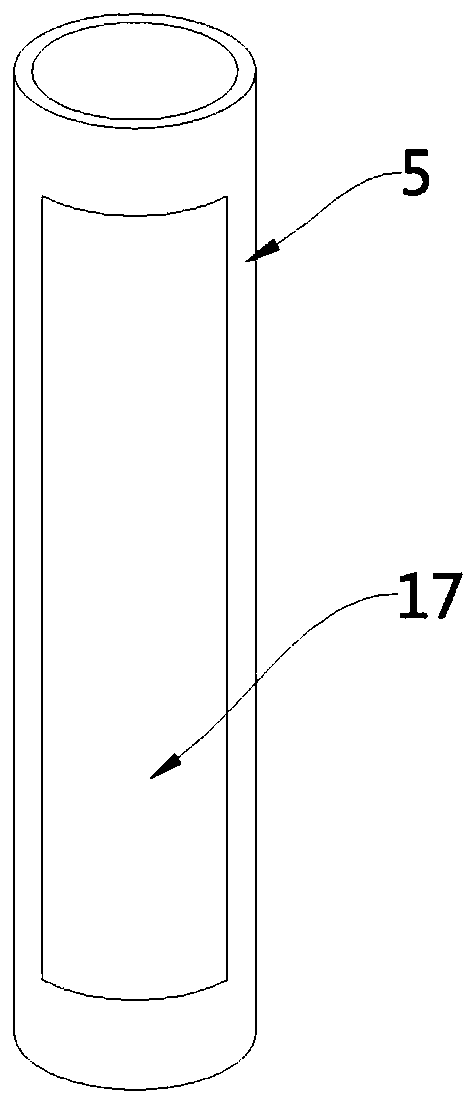

[0023] see Figure 1-2 , this embodiment provides a high-precision water level measuring device for a water level meter, including a display tube 5 arranged on one side of the furnace body 1 and forming a communication structure with the furnace body 1, and an observation tube is provided on the side wall of the display tube 5 A second pressure gauge (not shown) for detecting the internal pressure of the display cylinder 5 is provided outside the display cylinder 5, a display glass 17 is provided at the observation port, and a second pressure gauge (not shown) for detecting the internal pressure of the furnace body 1 is installed on the furnace body 1. The first pressure gauge 16 of the internal pressure and the controller 15 electrically connected with the pressure gauge 16, the pressure compensating assembly is installed on the upper part of the display tube 5, specifically, the pressure compensating assembly includes a movable setting on the display The pressure plate 9 ins...

Embodiment 2

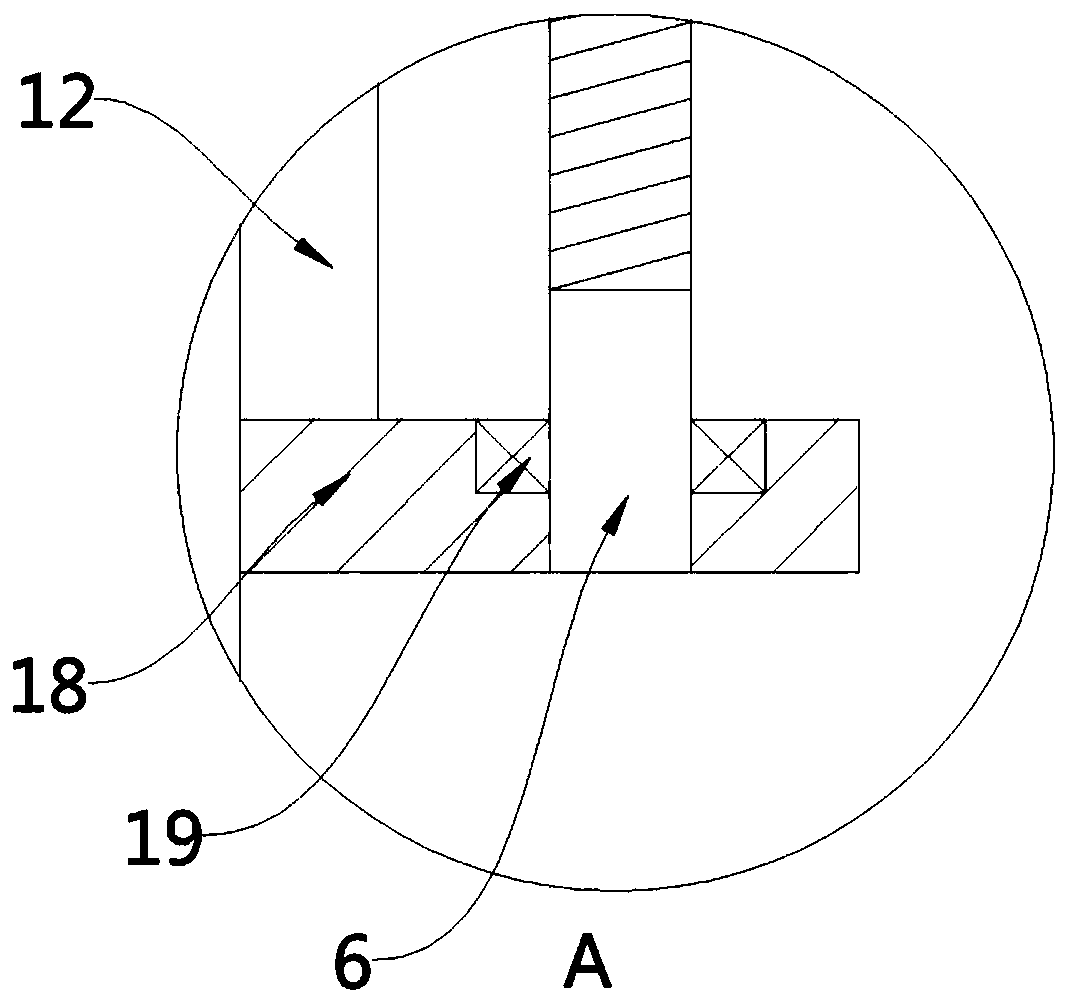

[0036] see figure 1 and image 3, a high-precision water level measuring device for a water level meter. Compared with Embodiment 1, the side wall of the furnace body 1 is also fixedly provided with a second support plate 18, and the drive shaft 6 is far away from the end of the motor 14. It is rotationally matched with the second support plate 18 through a bearing 19 .

[0037] The embodiment of the present invention has the advantages of convenient use and high measurement accuracy. The liquid level of the furnace body 1 can be measured accurately in real time according to the pressure change inside the furnace body 1. The first drive rod 8, The second drive rod 10 and the pressing plate 9 move up and down, thereby increasing or decreasing the pressure inside the display cylinder 5, so that the pressure inside the display cylinder 5 and the furnace body 1 are always equal, ensuring that the liquid level inside the display cylinder 5 is equal to that of the furnace body 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com