Electric screw driver with adjustable output torque

An electric screwdriver, output torque technology, used in screwdrivers, power tools, wrenches, etc., can solve the problems of motor damage, consuming operator's physical strength, and severe motor vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

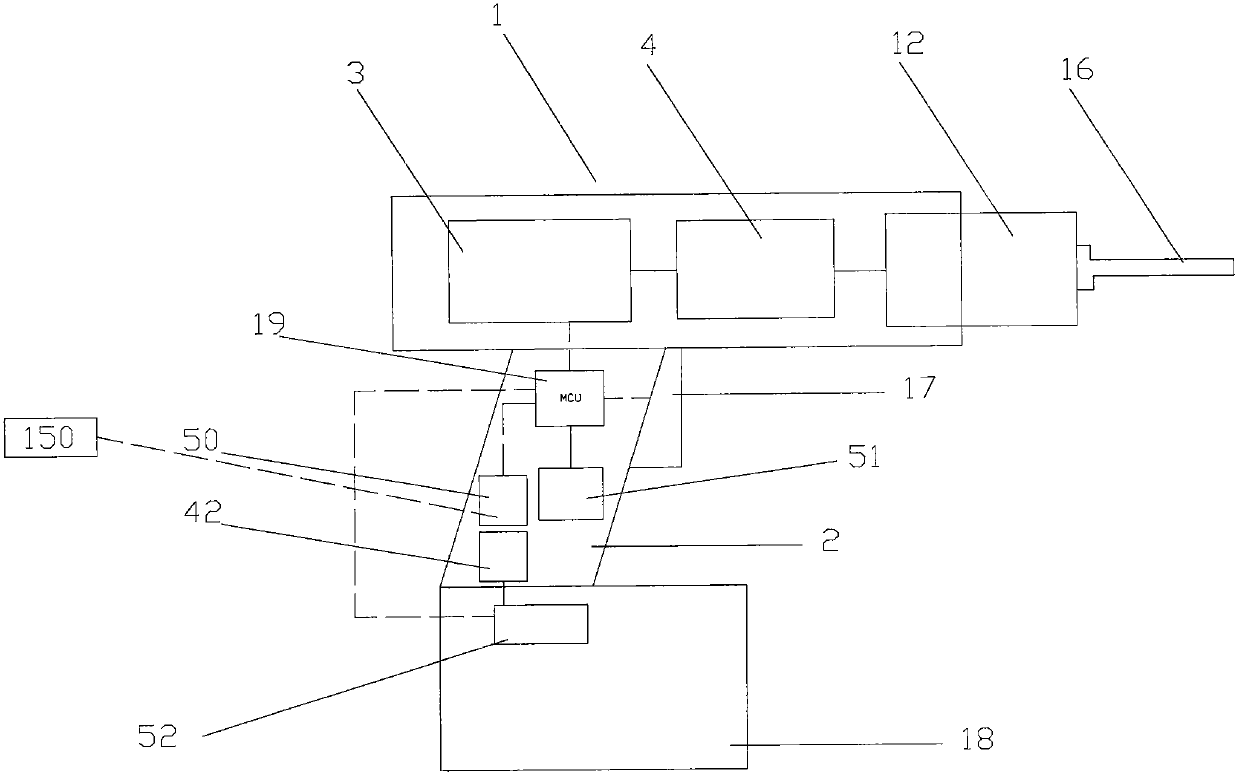

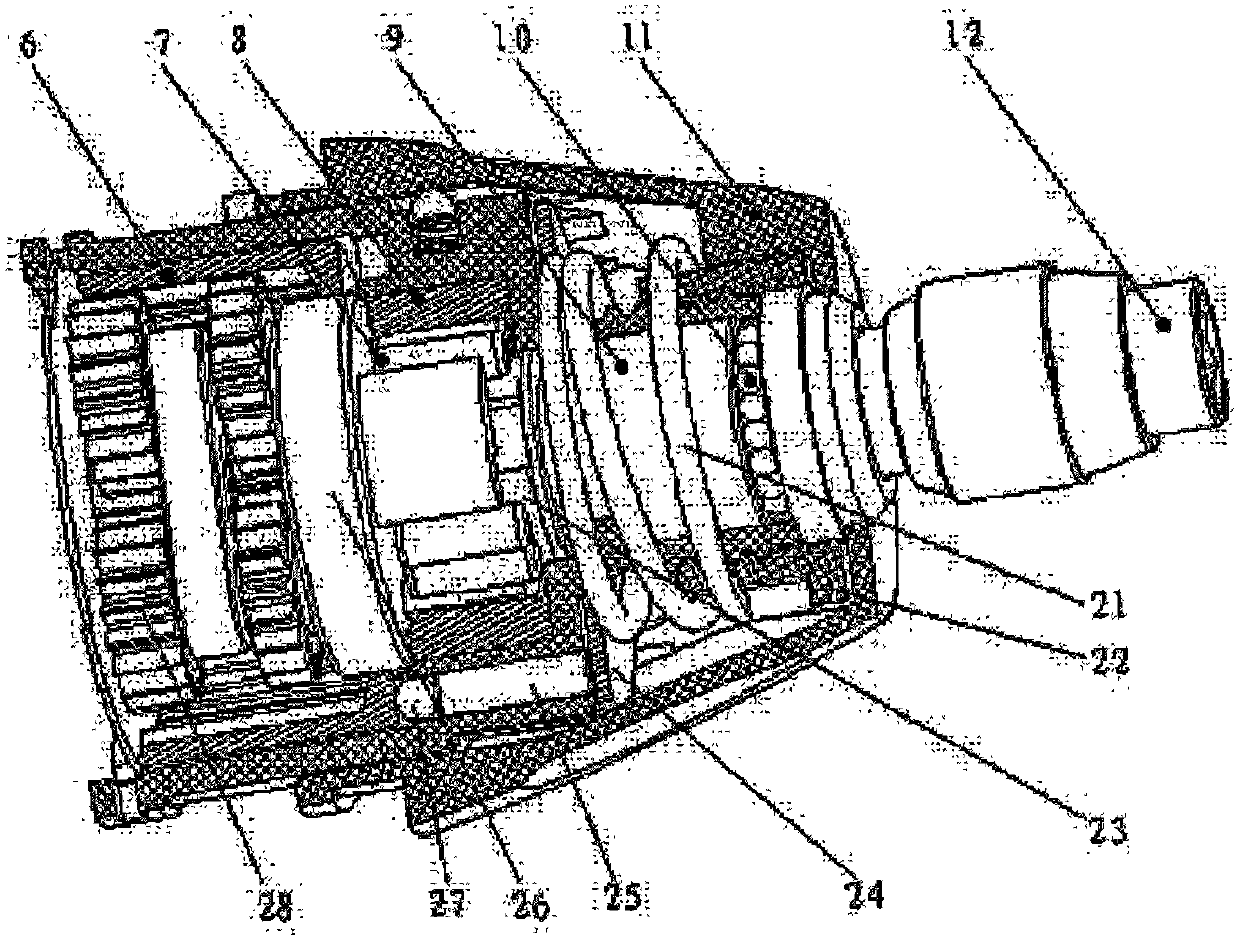

[0013] Such as figure 1 As shown, the present invention provides an electric screwdriver, which has a housing 1 and a handle 2. A motor 3 is installed in the housing 1. An output shaft 12 is provided at the front end of the housing 1. The output shaft 12 is connected to the motor 3 through a transmission mechanism 4. The front end of the output shaft 12 is provided with a screwdriver bit socket, and different types of screwdriver bits 16 can be installed in the screwdriver bit socket.

[0014] The handle 2 is provided with a control unit 19, a transmitting / receiving device 50 for signal sending / receiving, a storage unit 51, a charging socket 52, a switch 17 connected to the motor 3 through the control unit 19, and a battery pack under the handle 2 18 connected to the charging socket 42, the handle 2 below is provided with battery pack 18, the motor 3 is controlled to start and stop by switch 17, and the battery pack 18 can be charged by charging socket 12 connected with extern...

Embodiment 2

[0019] On the basis of Example 1, such as figure 1 As shown, the electric screwdriver of the present invention has a control unit 19, the switch 17 inputs the signal of opening or closing to the control unit 19, and has a storage unit 51, which stores data related to the operation of the electric screwdriver in the storage unit 51, and has pre-authorized information or data, the control unit 19 can read and store data from the storage unit 51 .

[0020] With an external, legally authorized operator's key 150, schematically represented in the drawings, the key 150 has transmitting / receiving means, and preferably a wireless and remote-action interface, as typical optical infrared interface or radio. Communicate with the transmitting / receiving device 50 of the electric screwdriver through the above interface, and the transmitting / receiving device 50 of the electric screwdriver is connected with the control unit 19 .

[0021] The control unit 19 sends out the authorization code ...

Embodiment 3

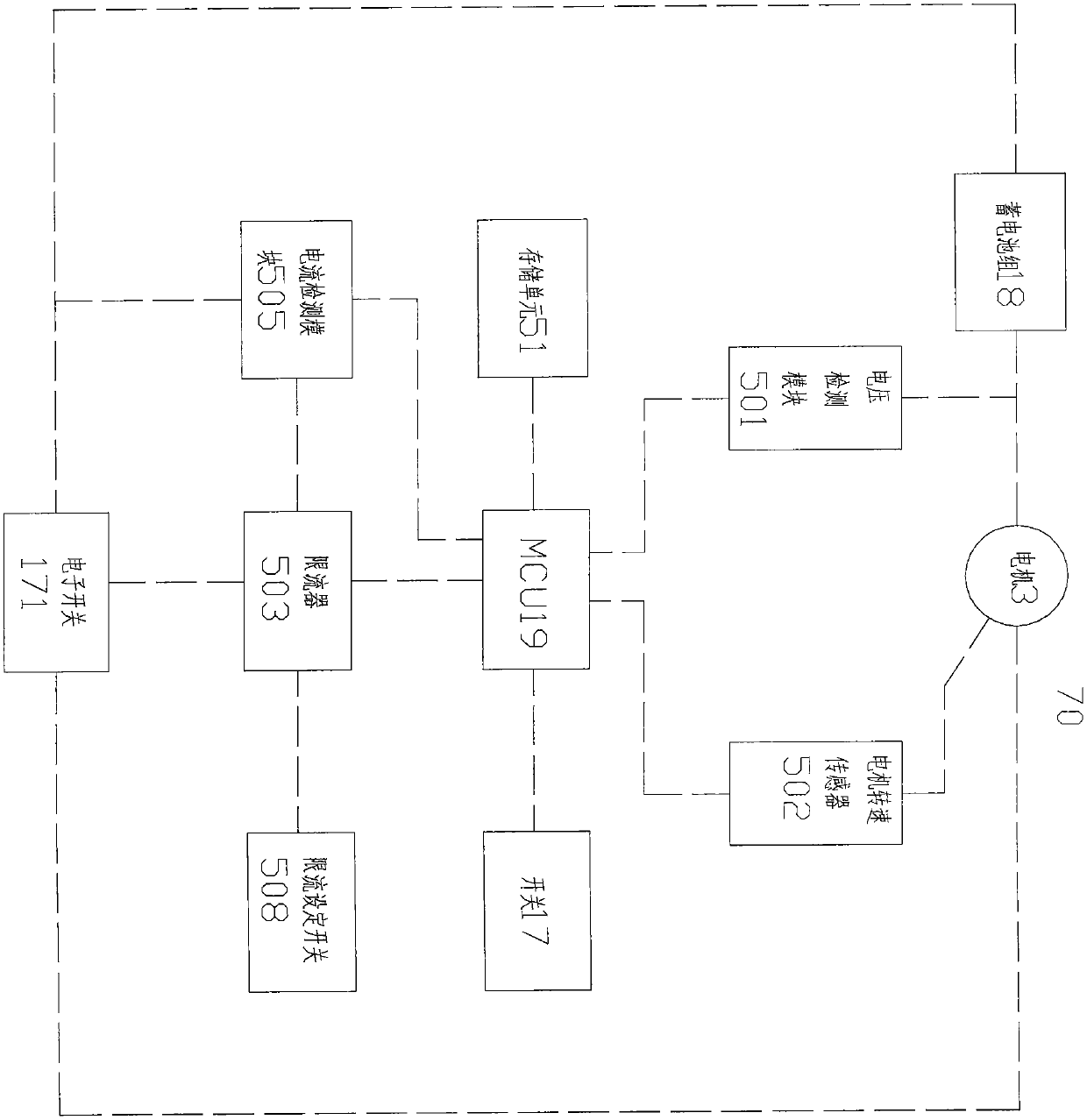

[0024] On the basis of Embodiments 1 and 2, in order to further accurately adjust the torque output value of the electric screwdriver, the control circuit of the electric screwdriver of the present invention is further optimized.

[0025] Such as image 3 As shown, the control circuit 70 has a control unit 19 , an electronic switch 171 , a switch 17 , a storage unit 50 , a current limit setting switch 508 , a current limiter 503 , a current detection module 505 , a voltage detection module 501 , and a motor speed sensor 502 .

[0026] The motor 3 is connected to the battery pack 18 through the electronic switch 171 , and the electronic switch 171 is connected to the control unit 19 through the current limiter 503 .

[0027] Since the motor speed N is related to the motor voltage and the motor current I, and when the load increases, the motor current I also increases accordingly. To maintain the motor speed N, the corresponding motor voltage needs to be increased. Therefore, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com