Patents

Literature

70results about How to "Achieve the purpose of adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

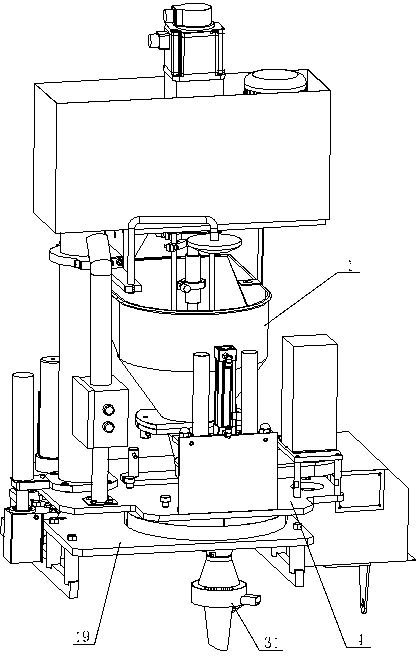

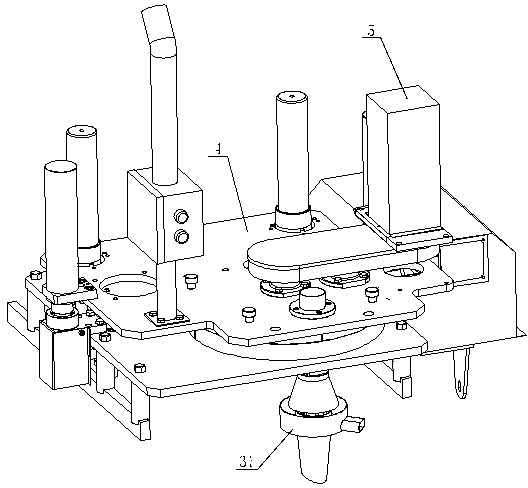

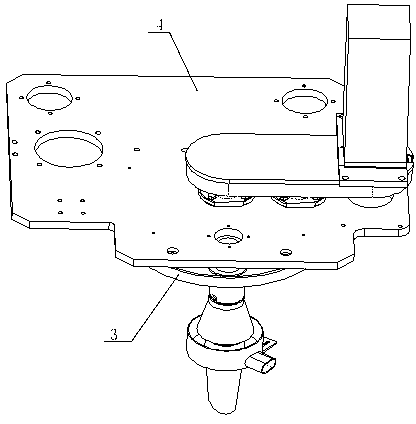

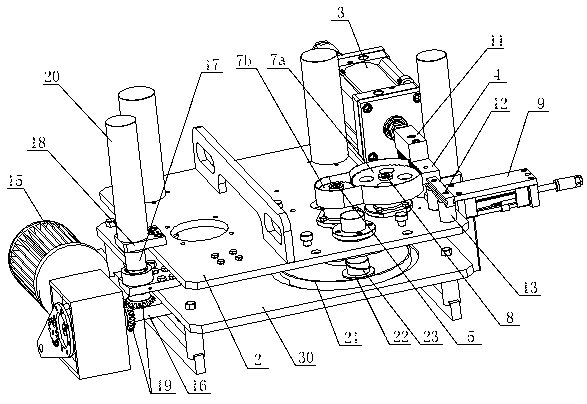

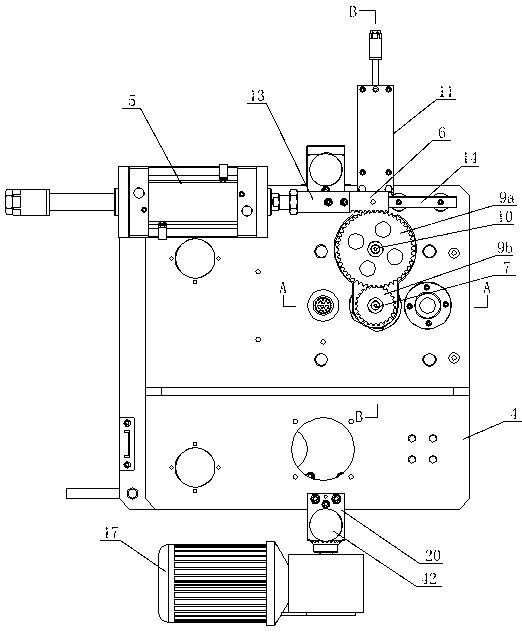

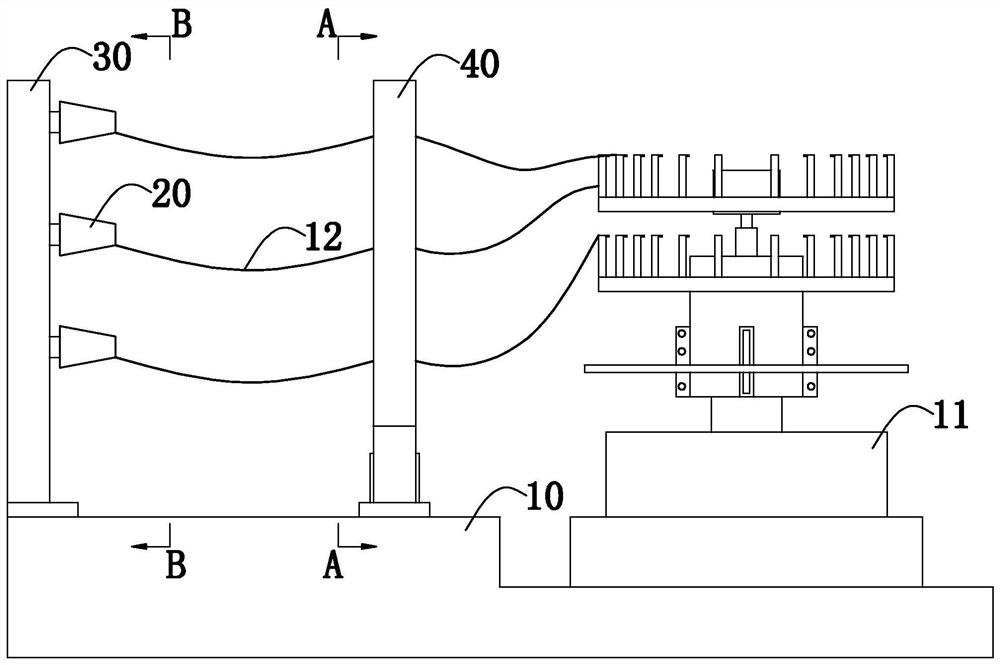

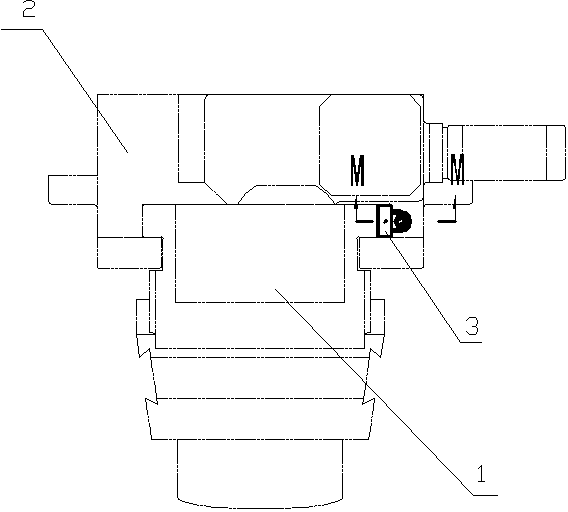

Filling machine

ActiveCN103193002AAchieve the purpose of adjustmentAchieve regulationLiquid materialDrive shaftElectric machinery

The invention discloses a filling machine which comprises a storage hopper, a discharge mechanism, a turnplate, and a drive device for driving the turnplate to rotate. A moving plate is disposed above the turnplate. The drive device comprises a drive motor disposed on the moving plate and a power transmission assembly in drive connection with a power output end of the drive motor. The power transmission assembly is provided with a transmission shaft. The lower end of the transmission shaft sequentially penetrates the axial center of the moving plate and the axial center of the turnplate and is connected with the turnplate through a locknut. The moving plate is connected with a synchronous vertical transmission mechanism. The drive device is disposed on the moving plate which is connected with the synchronous vertical transmission mechanism, the turnplate is connected with the power transmission assembly of the drive device, and accordingly the drive device and the turnplate can move up and down synchronously to adjust the distance between the turnplate and a fixed plate and adjust storage capacity of a measuring cup under the action of the synchronous vertical transmission mechanism.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

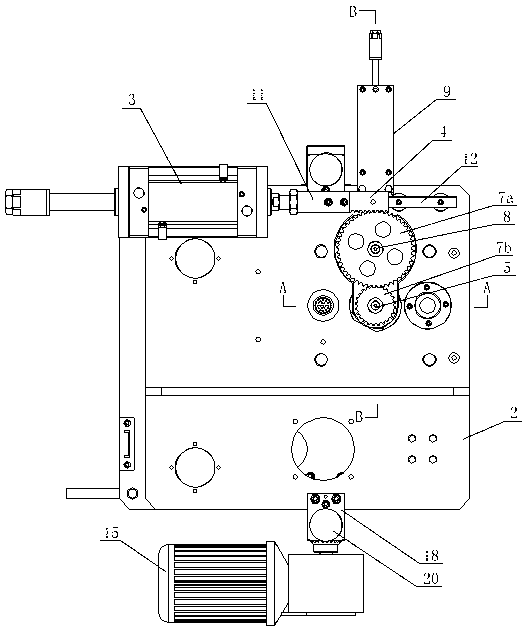

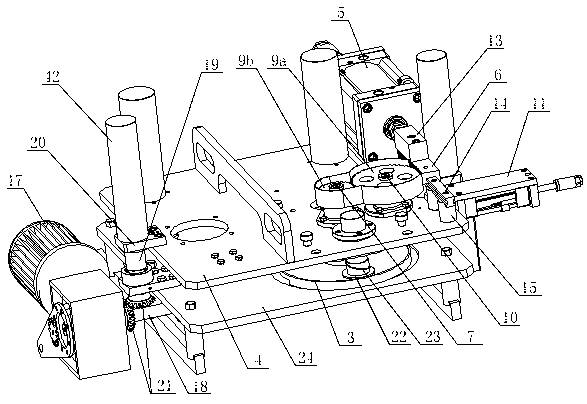

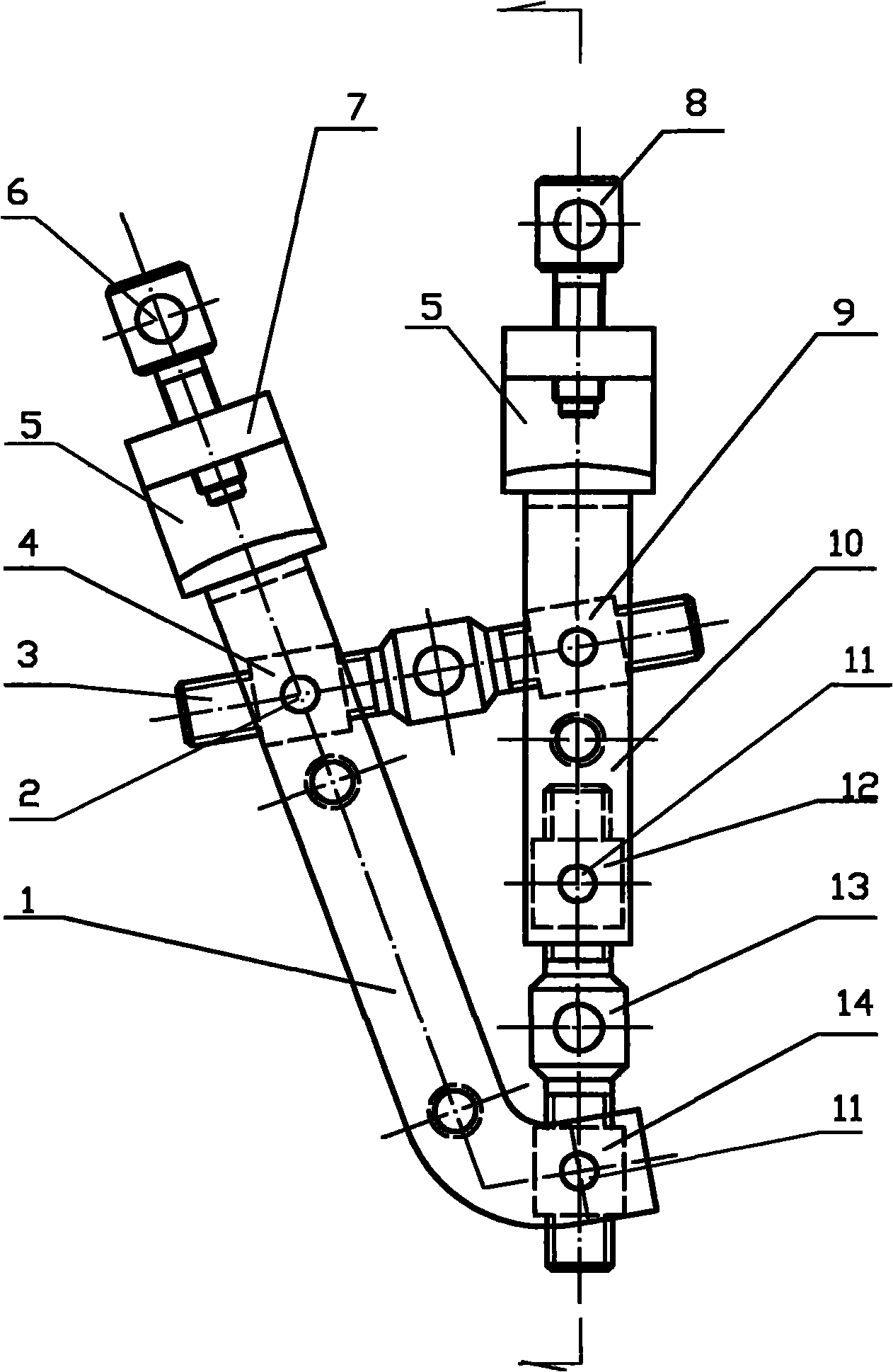

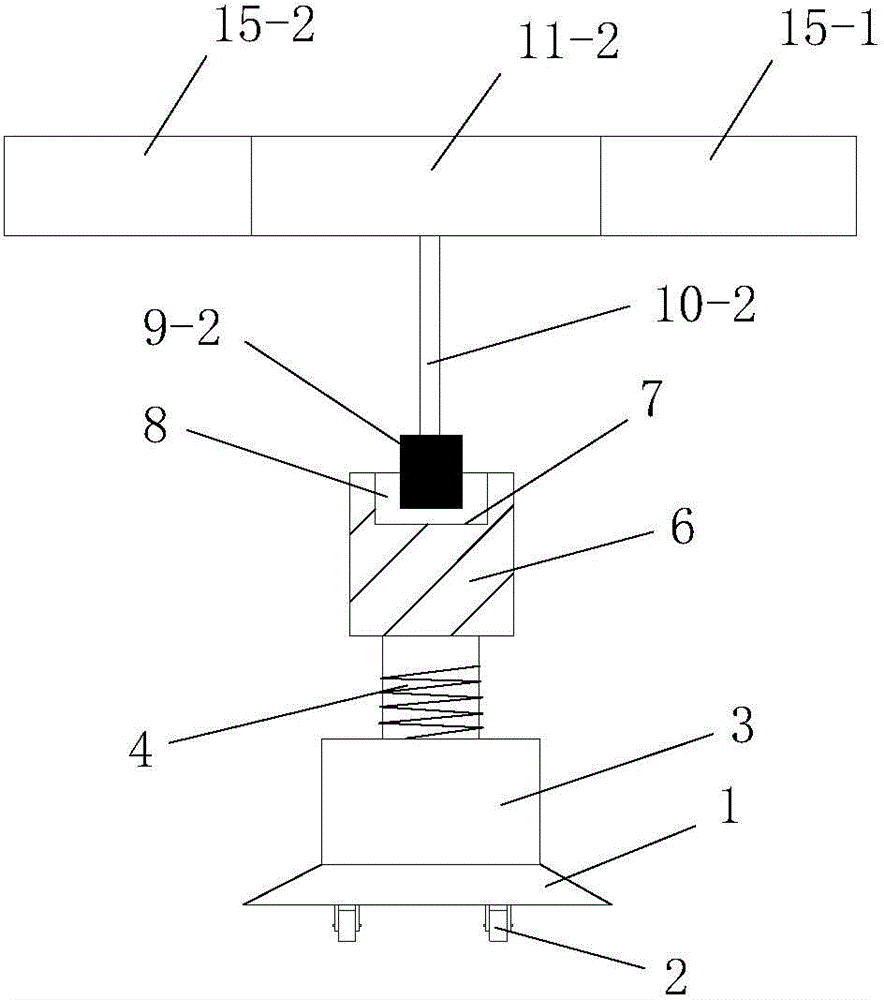

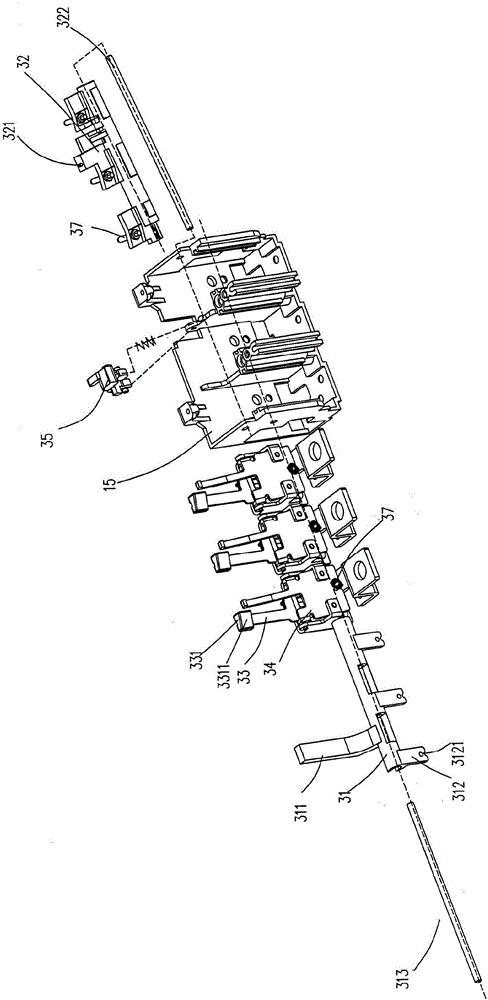

Vertically moving turntable reciprocating type driving mechanism

ActiveCN103253409AAchieve the purpose of adjustmentAchieve regulationLiquid materialPackaging machinesDrive shaftEngineering

The invention discloses a vertically moving turntable reciprocating type driving mechanism which comprises a turntable and a driving device used for driving the turntable to rotate. The driving device comprises a reciprocating type driving cylinder arranged on a moving plate and a rack in driving connection with the reciprocating type driving cylinder, the rack is meshed with a gear transmission set, a rotating shaft is arranged on the gear transmission set, the lower end of the transmission shaft sequentially penetrates through the moving plate and a turntable mandrel to be connected with the turntable through a locking nut, the moving plate is connected with a synchronous vertical transmission mechanism, a fixed disc is correspondingly arranged below the turntable, an adjustable jigger is arranged between the turntable and the fixed table, and the distance between the turntable and the fixed disc is adjusted through the synchronous vertical transmission mechanism. Under the effect of the synchronous vertical transmission mechanism, the vertically moving turntable reciprocating type driving mechanism can achieve synchronously integral and vertical movement of the driving device and the turntable so as to achieve adjustment of the distance between the turntable and the fixed disc and achieve the aim of adjustment of material storage amount of the jigger.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

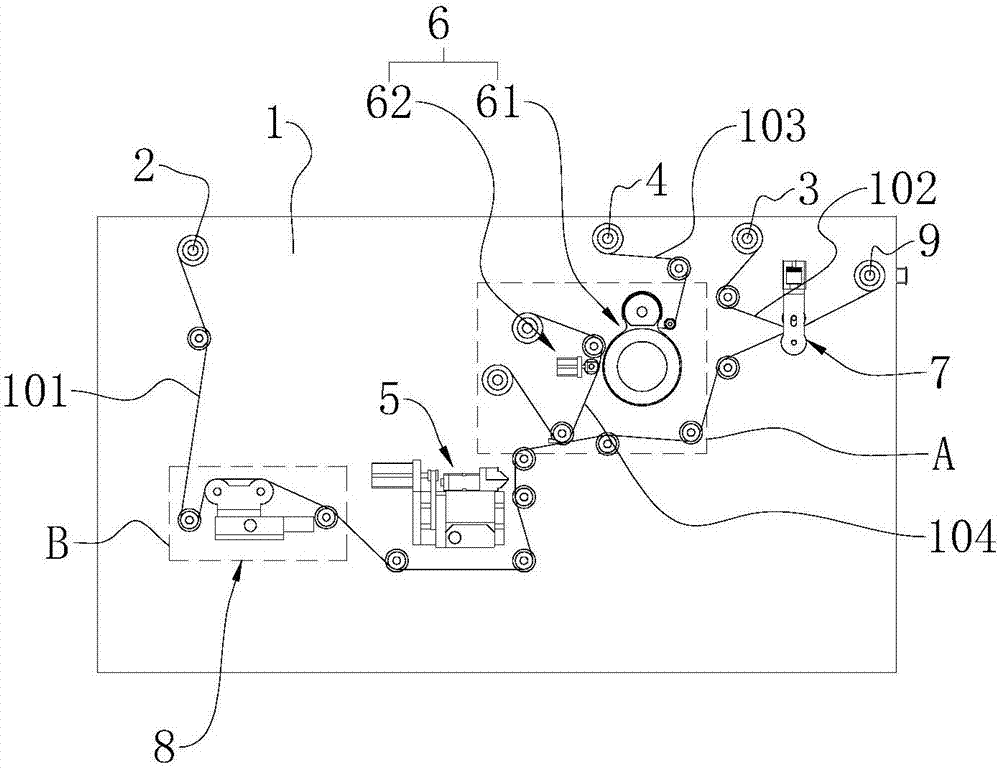

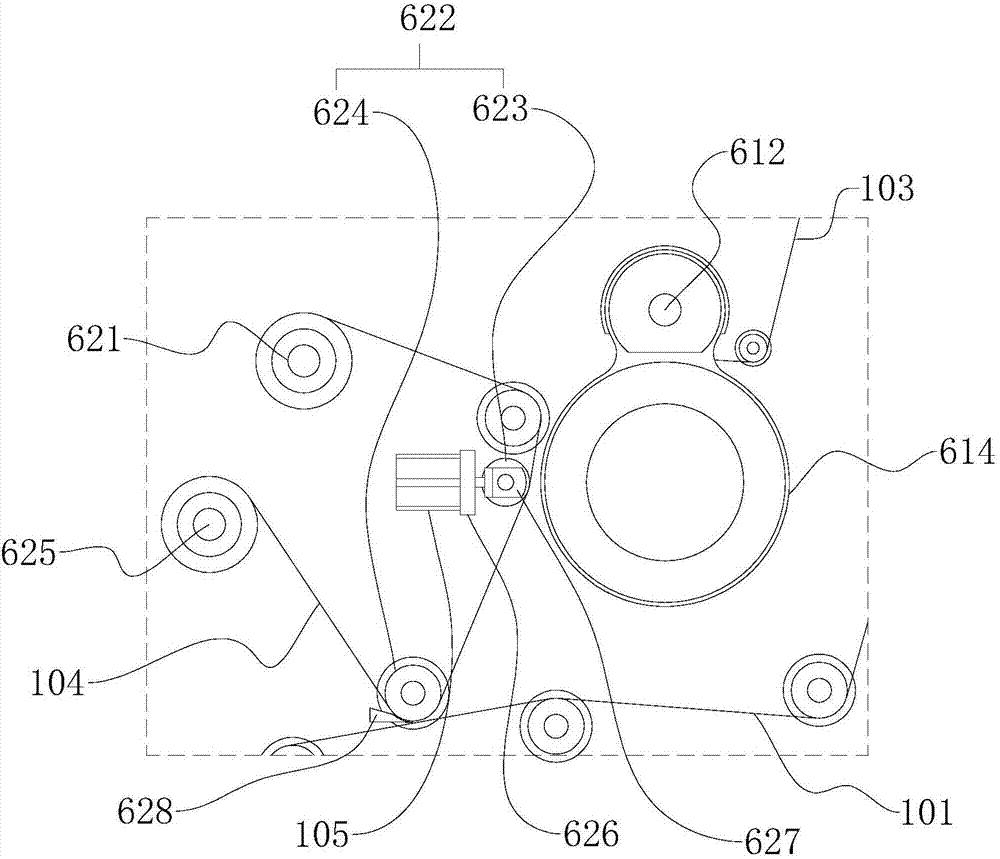

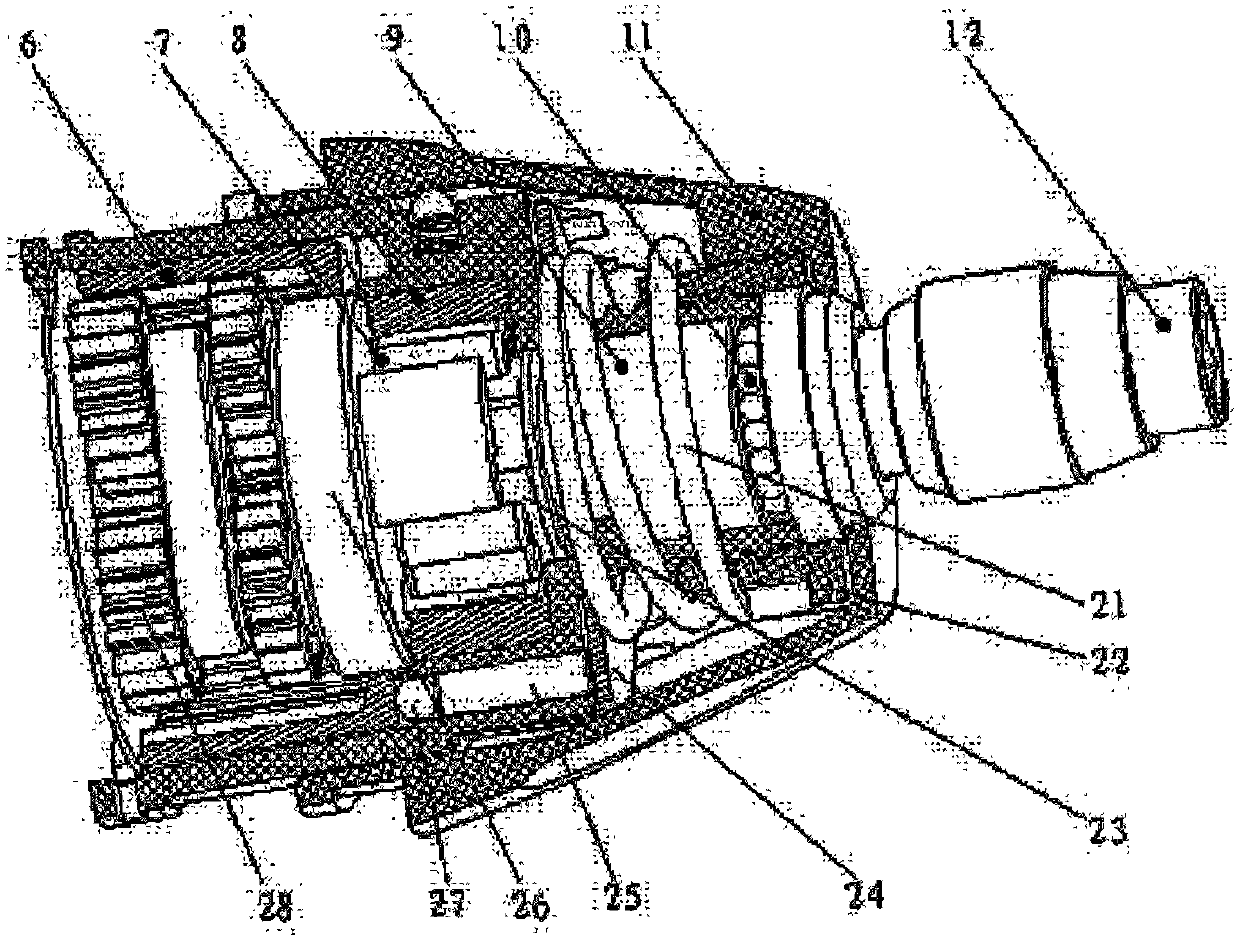

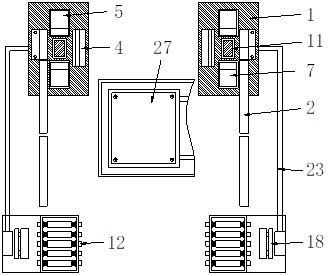

Label production equipment

ActiveCN107310202AEasy transferWon't fallPaper/cardboard articlesSurface layerPulp and paper industry

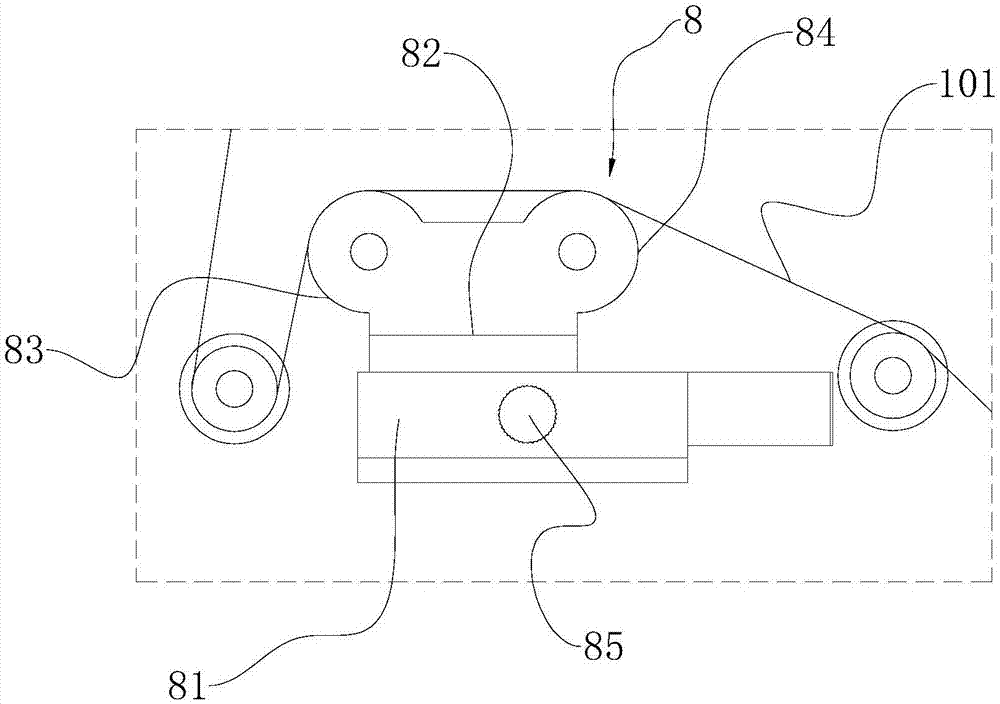

The invention discloses label production equipment. The label production equipment comprises a rack, a surface layer unwinding roller, a bottom layer unwinding roller, an anti-fake chip unwinding roller, a gluing device, an anti-fake chip cutting and transferring-storing device and a composite device, wherein the surface layer unwinding roller, the bottom layer unwinding roller, the anti-fake chip unwinding roller, the gluing device, the anti-fake chip cutting and transferring-storing device and the composite device are mounted on the rack. The bottom layer unwinding roller conveys a bottom layer paper layer into the anti-fake chip cutting and transferring-storing device; the gluing device is arranged between the bottom layer unwinding roller and the anti-fake chip cutting and transferring-storing device and glues the bottom layer paper layer; the anti-fake chip cutting and transferring-storing device cuts the anti-fake chip unwinding roller, transfers and stores the anti-fake chip unwinding roller and attaches a cut chip to the bottom layer paper layer; the bottom layer paper layer further enters the composite device; the surface layer unwinding roller conveys a surface layer paper layer to the composite device; and the bottom layer paper layer and the surface layer paper layer are composited through the composite device. Through the anti-fake chip cutting and transferring-storing device, the anti-fake chip can be cut, transferred and attached, so that a certain gap exists when the anti-fake chip is attached to the bottom layer paper layer, and transferring and attaching of the anti-fake chip are facilitated.

Owner:上海华哲印务有限公司

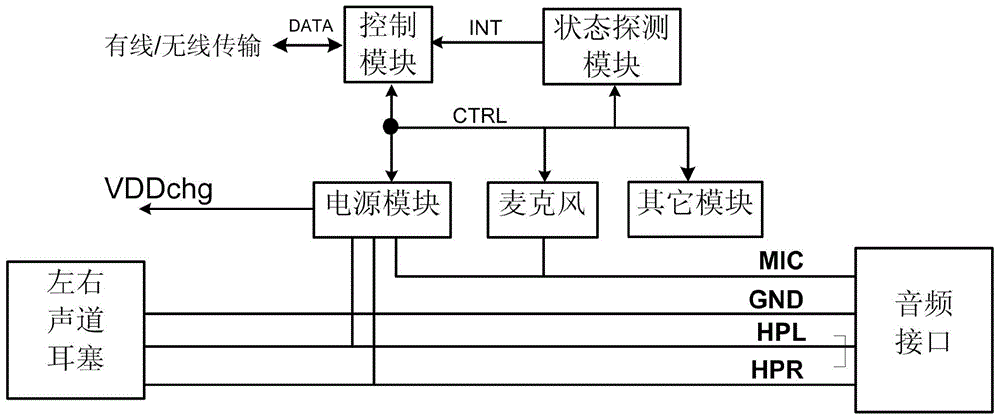

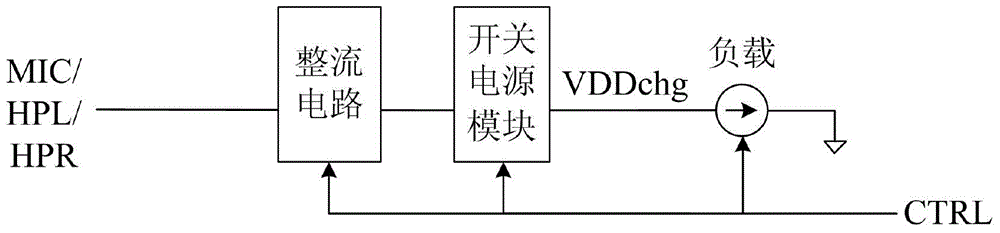

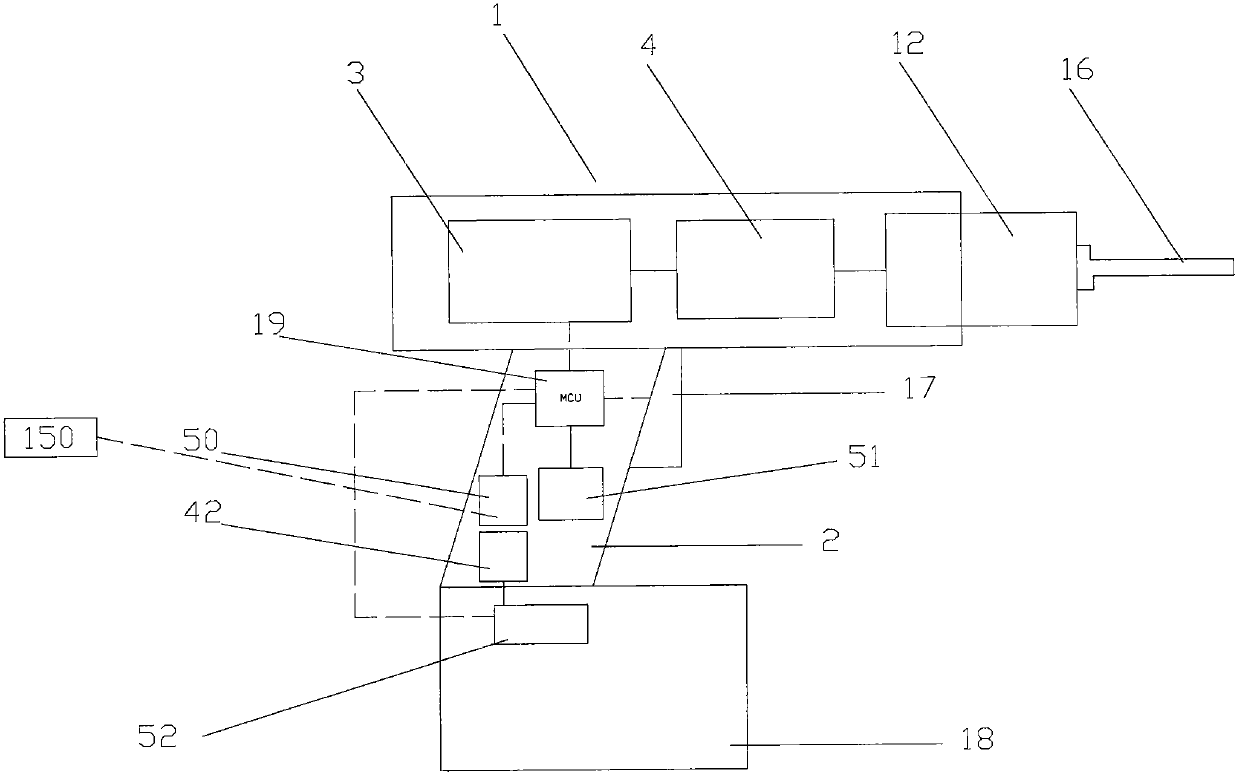

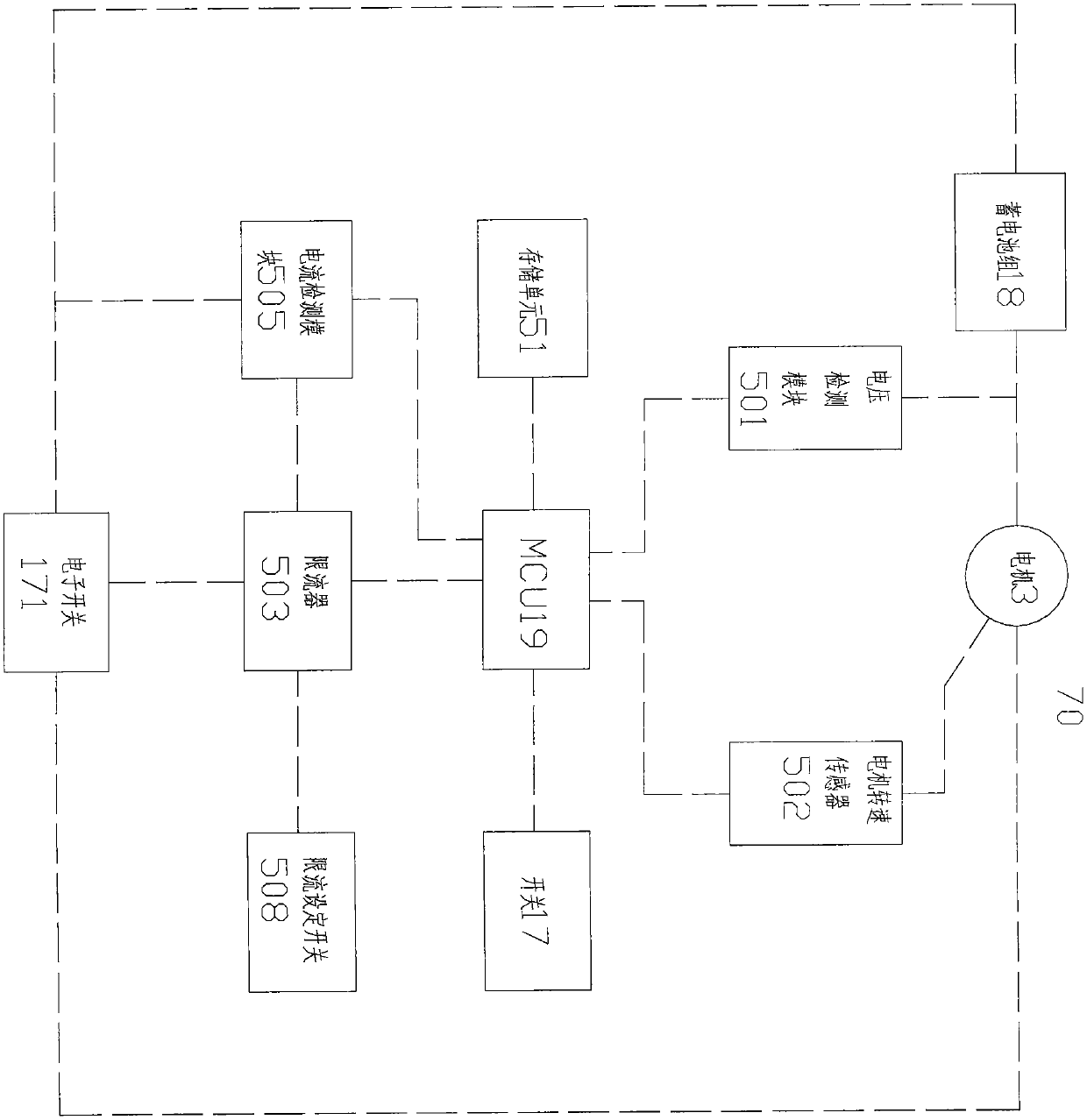

Earphone circuit, earphone control method, and using method of earphone

PendingCN106714018AAchieve the purpose of adjustmentEarpiece/earphone attachmentsTransducer circuitsEngineeringHeadphones

The invention provides an earphone circuit, an earphone control method, and a using method of an earphone. A state detection module is added and is used for detecting an attitude and a using state of an earphone and feeding back the attitude information to a control module; the control module determines the attitude of the earphone; and after analysis processing of the control module, other modules of the earphone are controlled, so that an objective of corresponding adjustment of the earphone can be achieved. And then the information is uploaded to a host.

Owner:HANGZHOU NAXIONG TECH

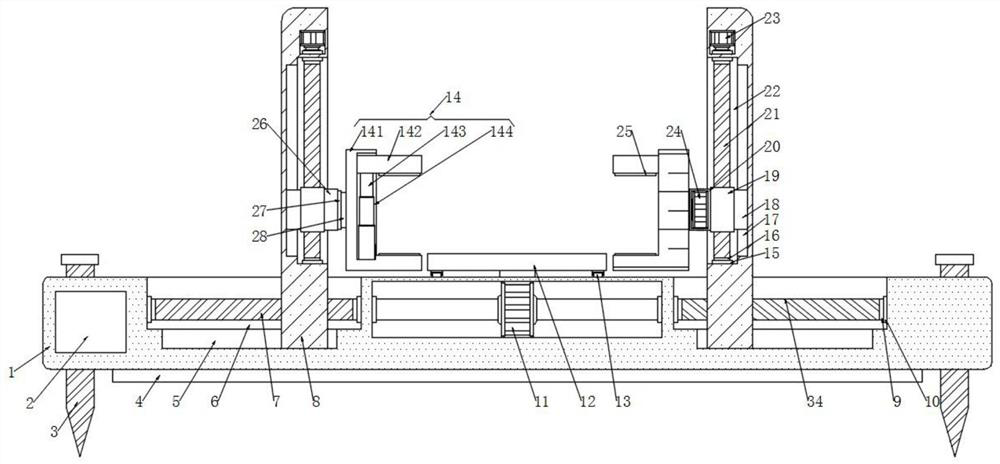

Machining equipment with turnover clamping mechanism

InactiveCN112809406ARealize the purpose of turning overAchieve the purpose of turningLarge fixed membersMetal working apparatusGear wheelElectric machinery

The invention belongs to the technical field of machining, and relates to machining equipment with a turnover clamping mechanism. The machining equipment comprises a bottom plate, a first groove is formed in the top of the bottom plate, a double-shaft motor is fixedly connected to the bottom of the inner wall of the first groove, and two output shafts of the double-shaft motor are fixedly connected with a first lead screw and a second lead screw correspondingly. The machining equipment with the turnover clamping mechanism has the beneficial effects that a third motor in a driving assembly works, a driving gear and a driven gear can be driven to rotate in a meshed mode, then a fourth rotating shaft can be driven to rotate, the purpose of driving a containing table to rotate is achieved, then the purpose of rotating a workpiece on the containing table is achieved, the purpose of adjusting the machining direction of the workpiece is achieved, a clamping assembly can be driven to rotate through work of a second motor, the workpiece clamped by the clamping assembly can be driven to rotate by means of running fit of a third bearing and a third rotating shaft, and the purpose of overturning machining of the workpiece is achieved.

Owner:苏州华擎广告服务有限公司

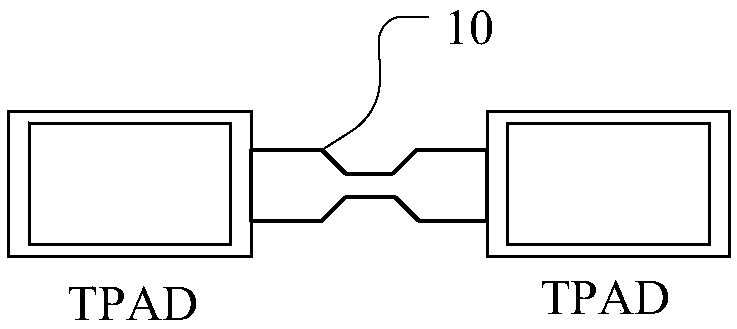

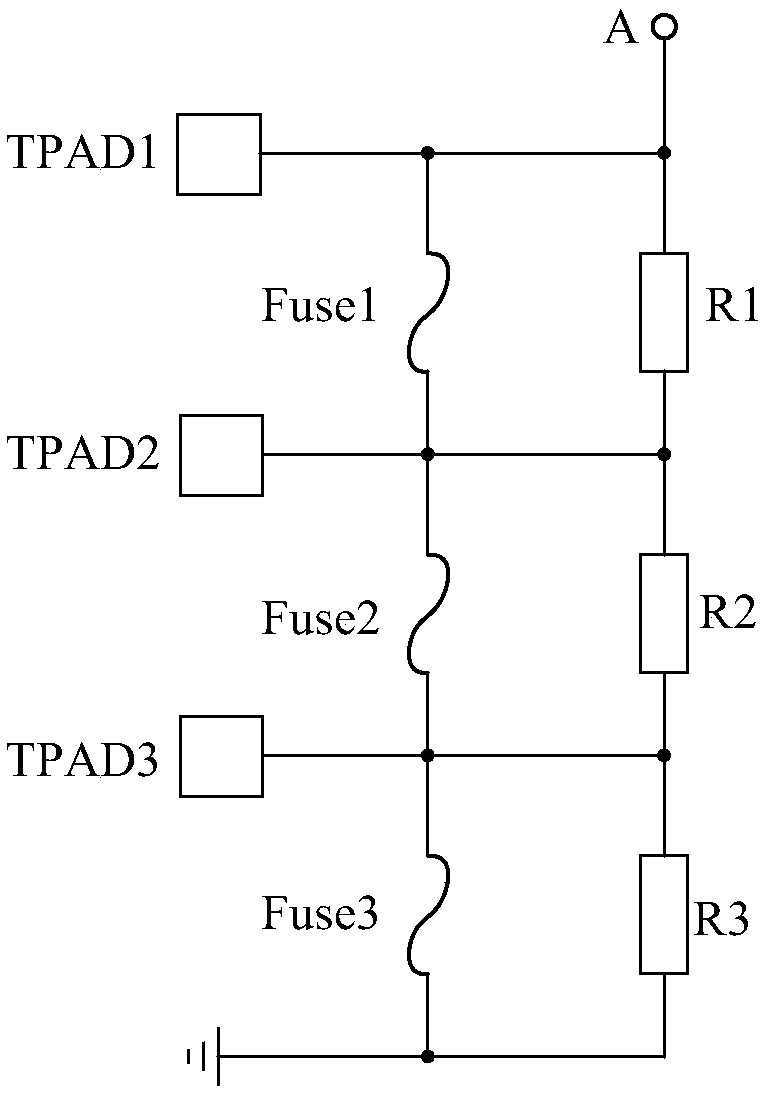

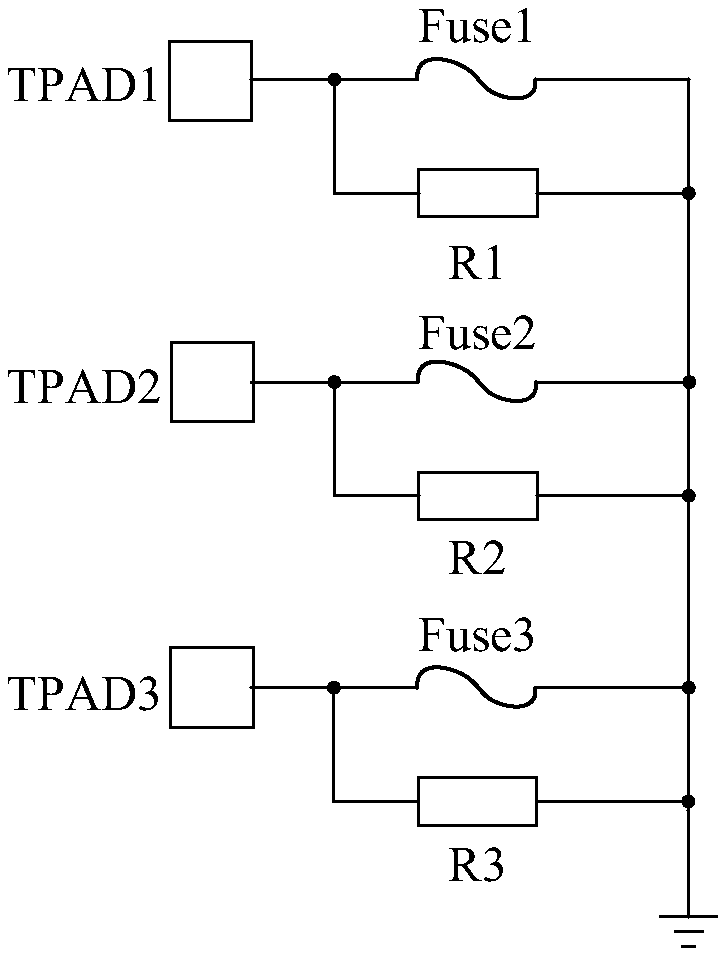

Trimming circuit and chip

ActiveCN110830022AAchieve the purpose of adjustmentIncrease productivityLogic circuit interface arrangementsComputer hardwareHemt circuits

The invention discloses a trimming circuit and a chip. The trimming circuit comprises a control module which is used for generating a fuse selection signal and a fuse signal according to a trimming signal and a reference voltage signal, a fuse unit which comprises a plurality of fuse structures, each of which comprises a fuse and a switching tube which are connected between the fuse signal input end and the ground, arranged in an array, a selection module which is used for scanning the switching tubes of the plurality of fuse structures according to a preset sequence and gating at least one switching tube according to the fuse selection signal, wherein the trimming signal at least comprises a first level and a second level, and when the trimming signal is the first level, the control module generates the fuse selection signal; and when the trimming signal is a second level, the control module generates the fuse wire signal and is used for applying the fuse wire signal to the fuse wirewhen the switching tube is switched on. The trimming precision can be improved, and a specific trimming pin does not need to be arranged on the chip.

Owner:SG MICRO

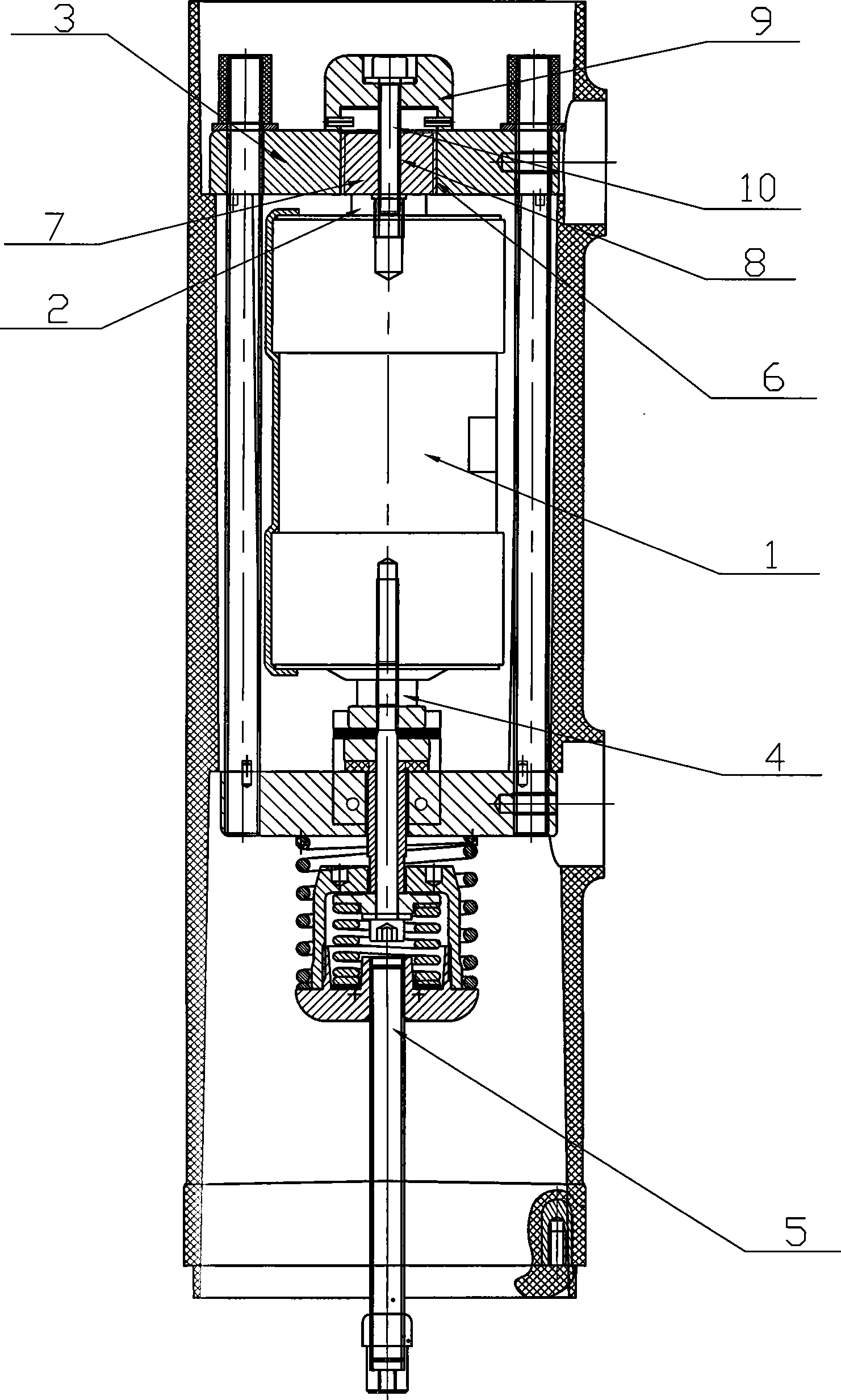

Vacuum circuit-breaker

InactiveCN101383244ASimple adjustment processChange final installation heightHigh-tension/heavy-dress switchesAir-break switchesFastenerHigh pressure

The invention belongs to a high-voltage transmission and distribution device which relates to a vacuum breaker. The vacuum breaker comprises a vacuum explosion chamber, the upper end of the vacuum explosion chamber is provided with a fixing electric conducting plate which is used for connecting a fixed contact in an electric conducting mode, the electric conducting plate is connected with an electric conducting bracket of the breaker, a moving contact which is arranged on the lower end of the vacuum explosion chamber is connected with a driving member through an insulation screw rod, the center of the electric conducting plate is provided with a threaded hole which is matched with a regulating block with external threads, and the regulating block and the upper end of the fixed contact of the vacuum explosion chamber are connected and fixed by a fastener. Because the regulating mode of the vacuum breaker is carried out on one end of the fixed contact, parts are relatively fewer in the position, and the operation space is larger, parts which need to be disassembled are fewer too, therefore, the regulating process is simple and convenient.

Owner:镇江大全智能电气有限公司

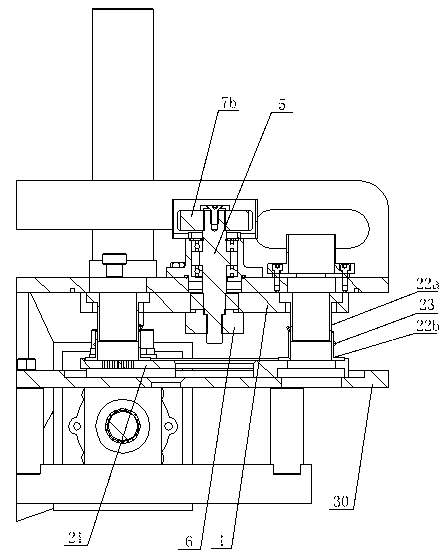

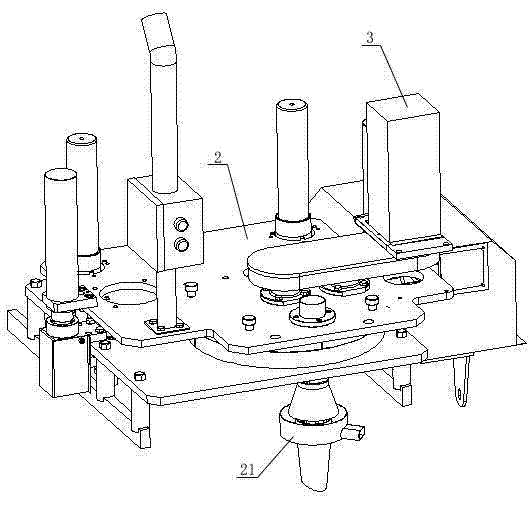

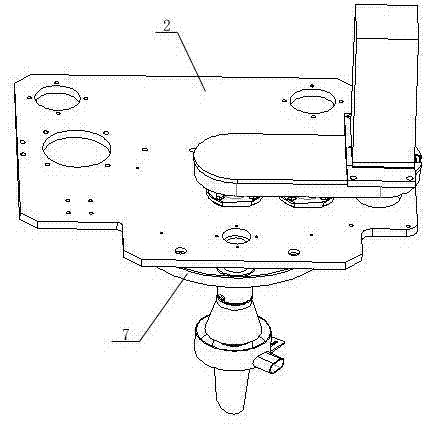

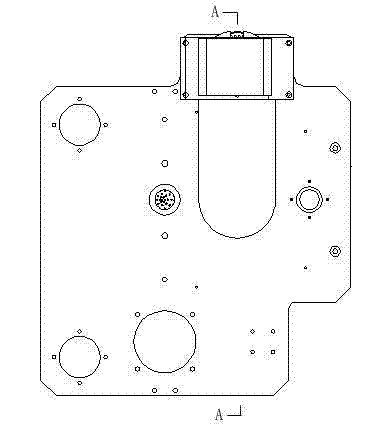

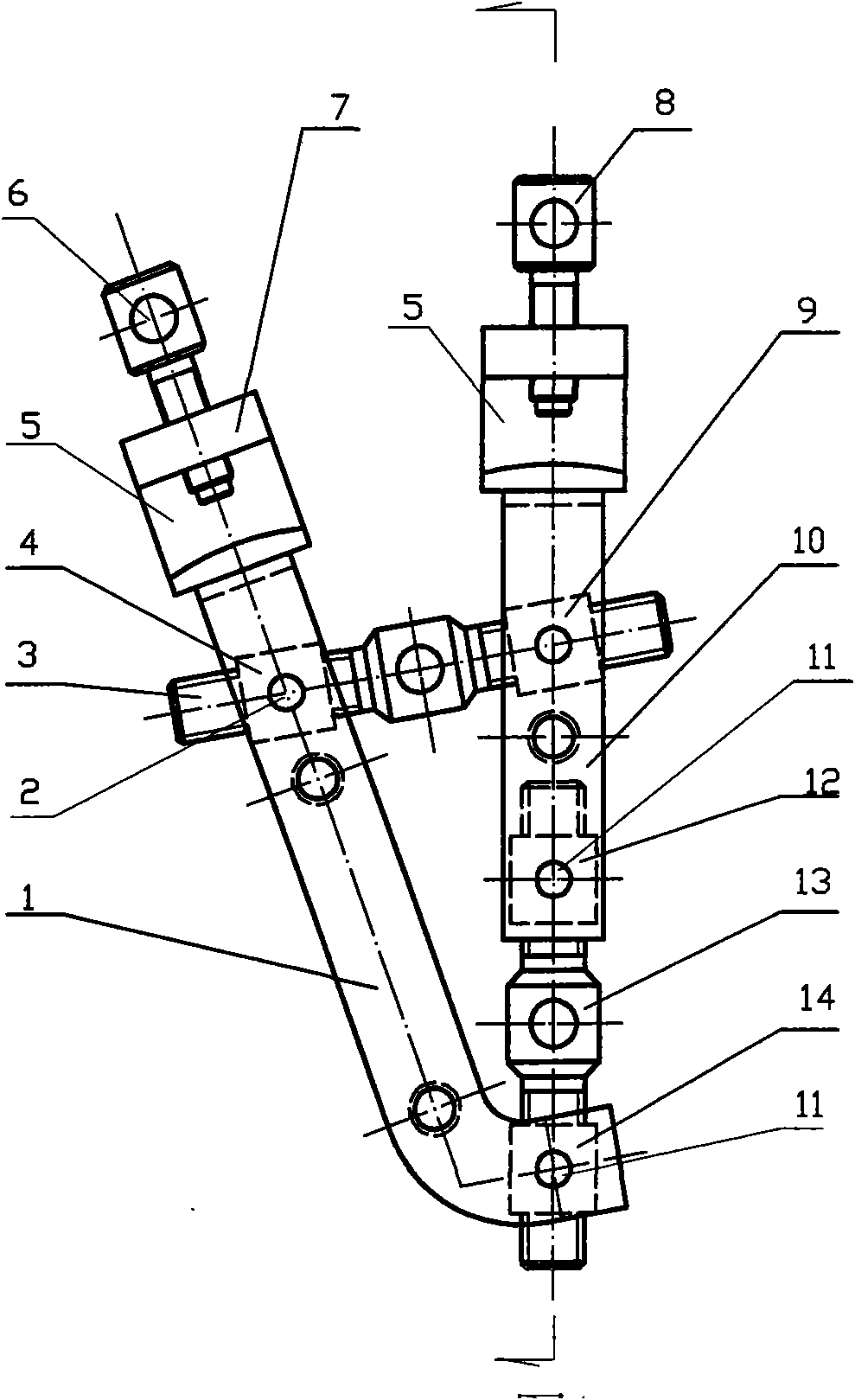

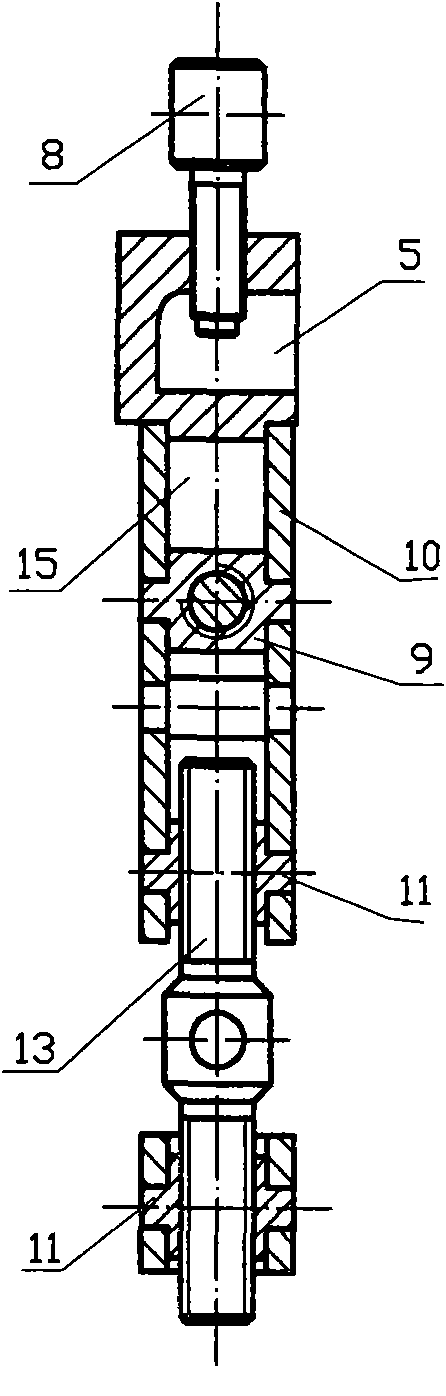

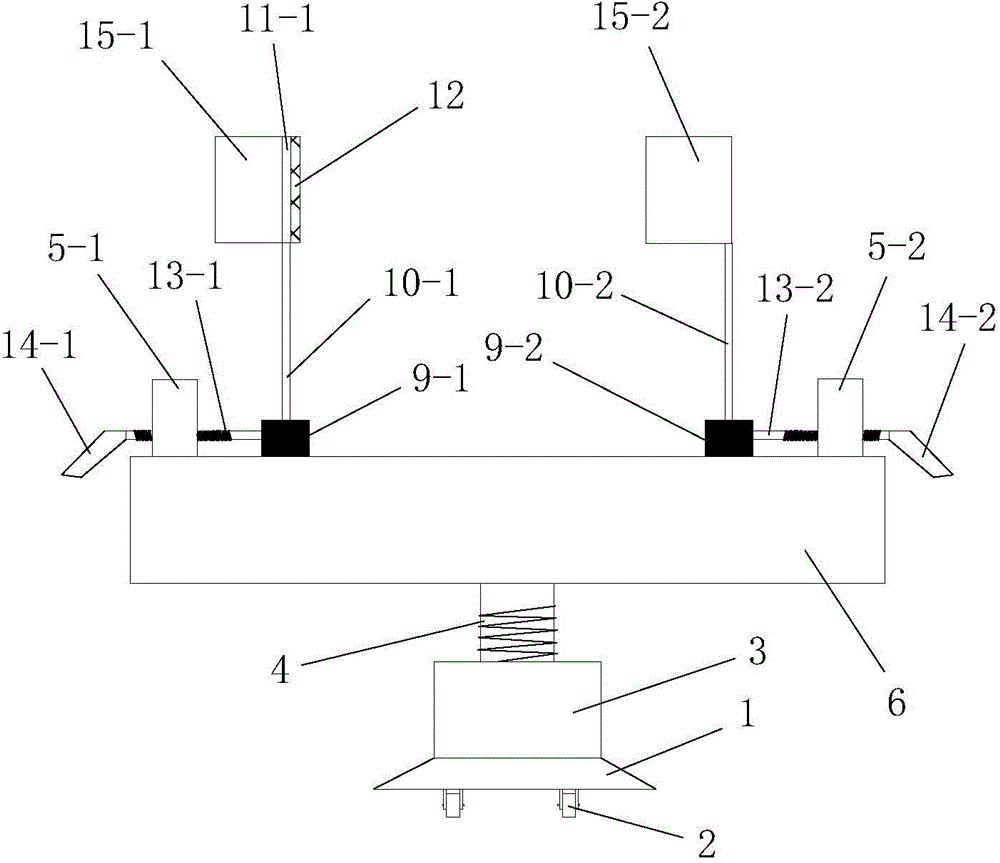

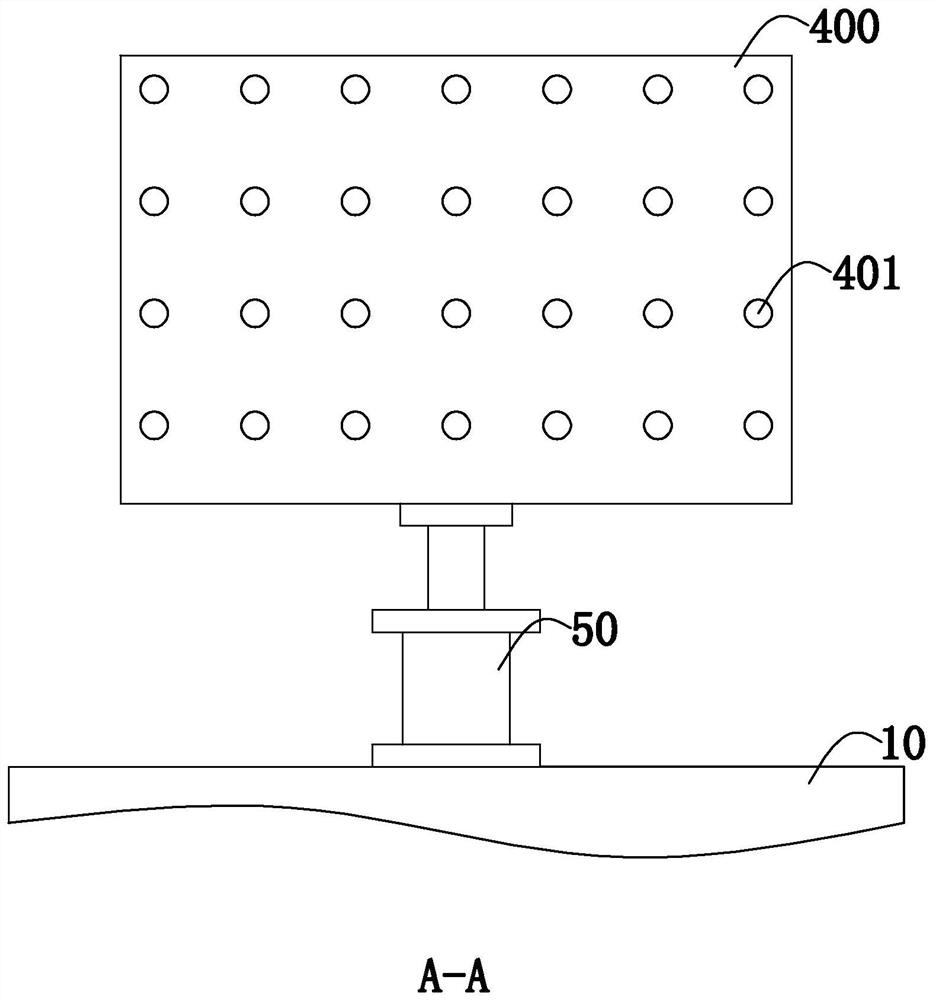

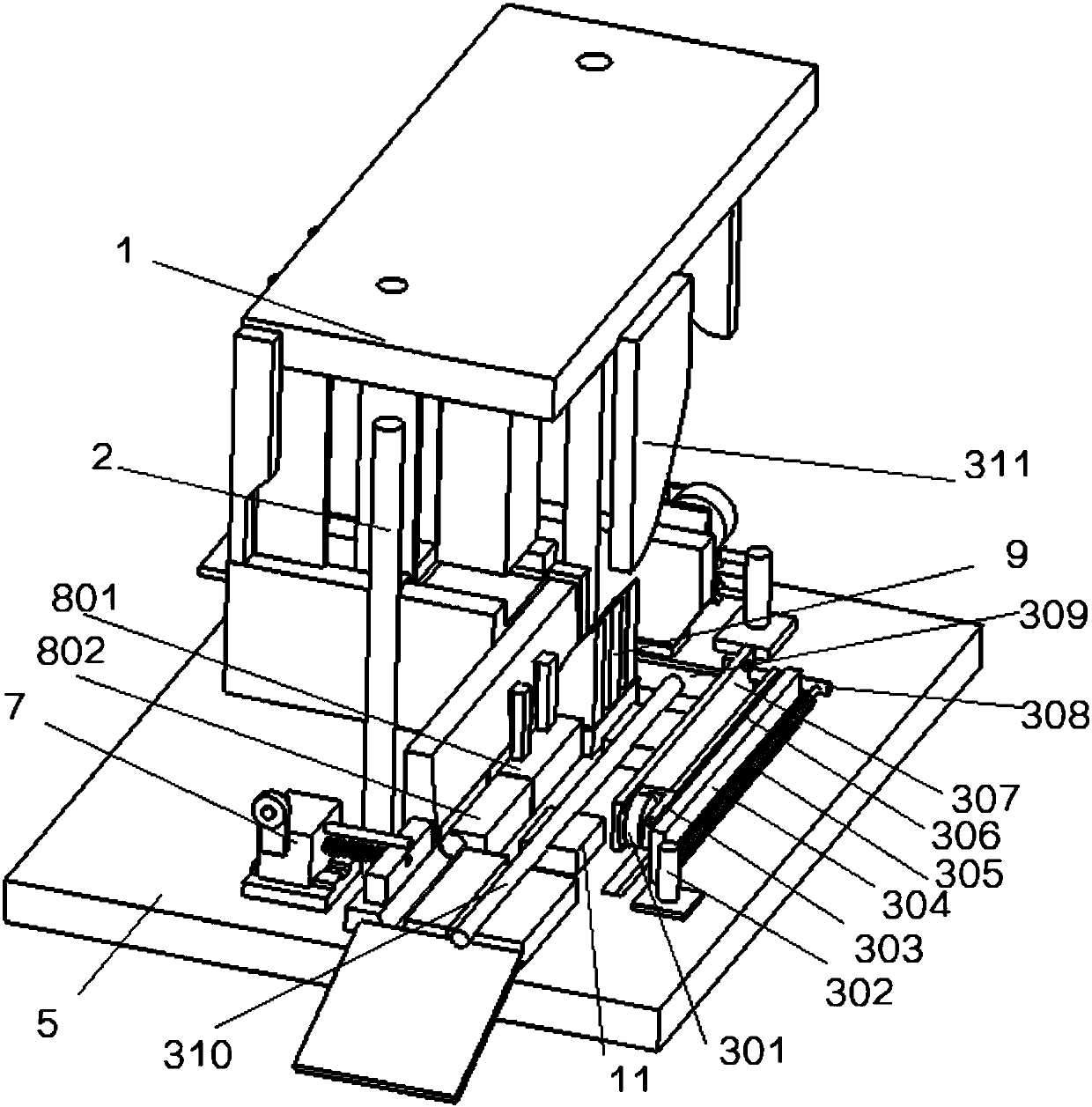

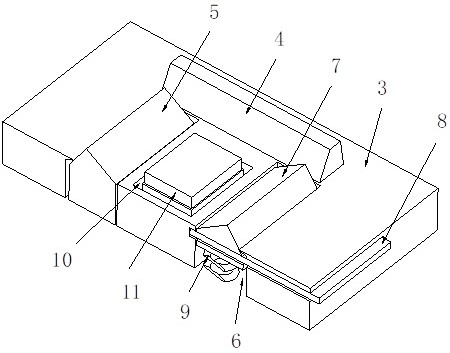

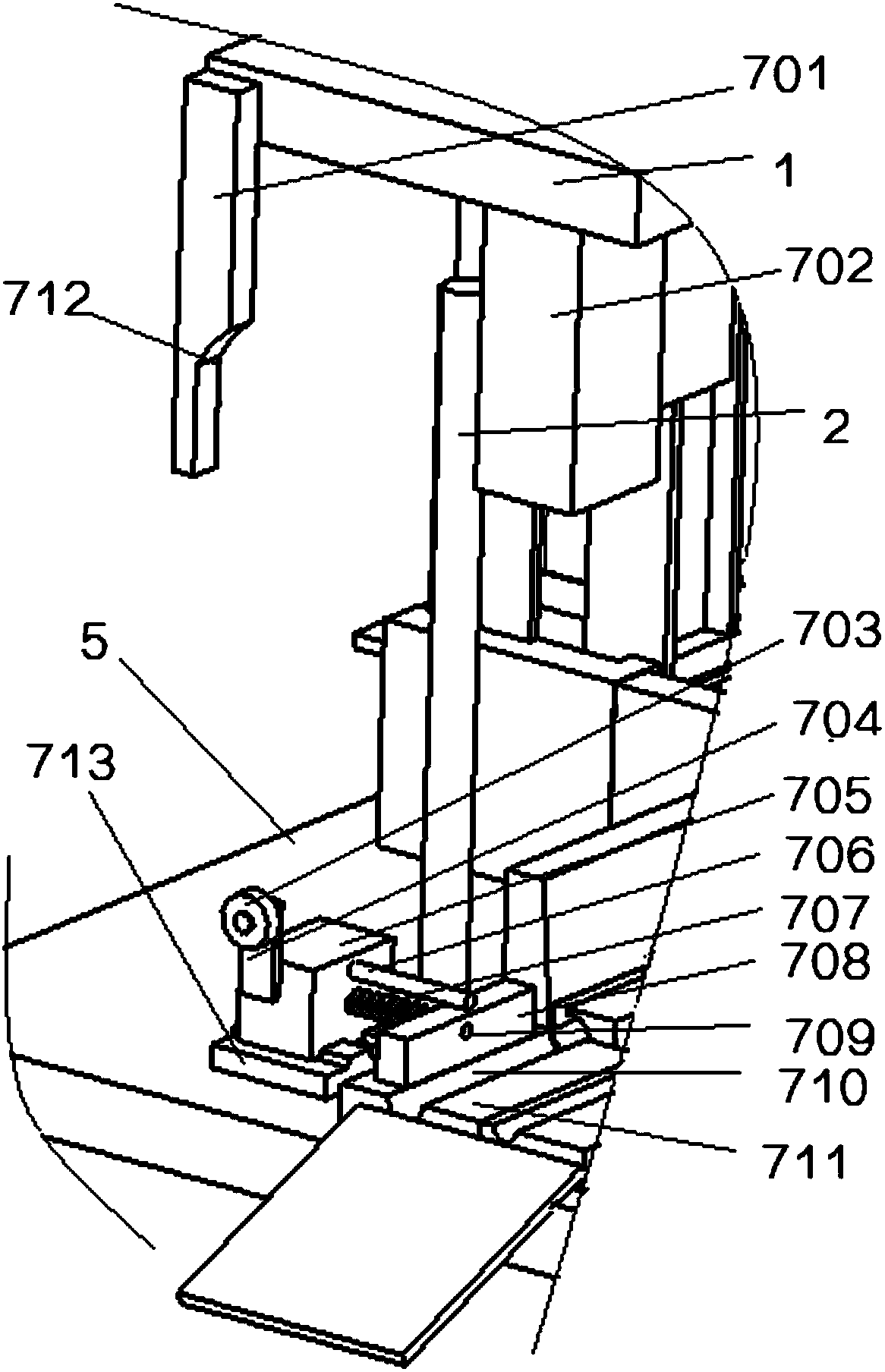

Rotating device with synchronous vertical moving effect

ActiveCN103204254AAchieve the purpose of adjustmentAchieve regulationSolid materialDrive shaftDrive motor

The invention discloses a rotating device with a synchronous vertical moving effect. The rotating device comprises a turntable and a driving device. The driving device is used for driving the turntable to rotate, and comprises a driving motor and a power transmission assembly, the driving motor is arranged on a moving plate, the power transmission assembly is in drive connection with a power output end of the driving motor, a transmission shaft is arranged on the power transmission assembly, the lower end of the transmission shaft sequentially penetrates through the axis of the moving plate and the axis of the turntable and is connected with the turntable by a locking screw, and the moving plate is connected with a synchronous vertical transmission mechanism. The rotating device has the advantages that the driving device is arranged on the moving plate, the moving plate is connected with the synchronous vertical transmission mechanism, and the turntable is connected with the power transmission assembly of the driving device by the transmission shaft, so that the driving device and the turntable can synchronously and integrally move vertically under the action of the synchronous vertical transmission mechanism, the distance from the turntable to a fixed plate can be adjusted, and the purpose of adjusting the storage capacity of a metering cup is achieved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

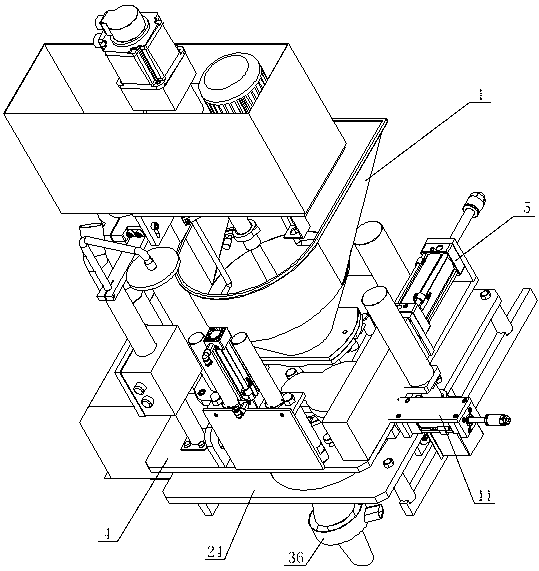

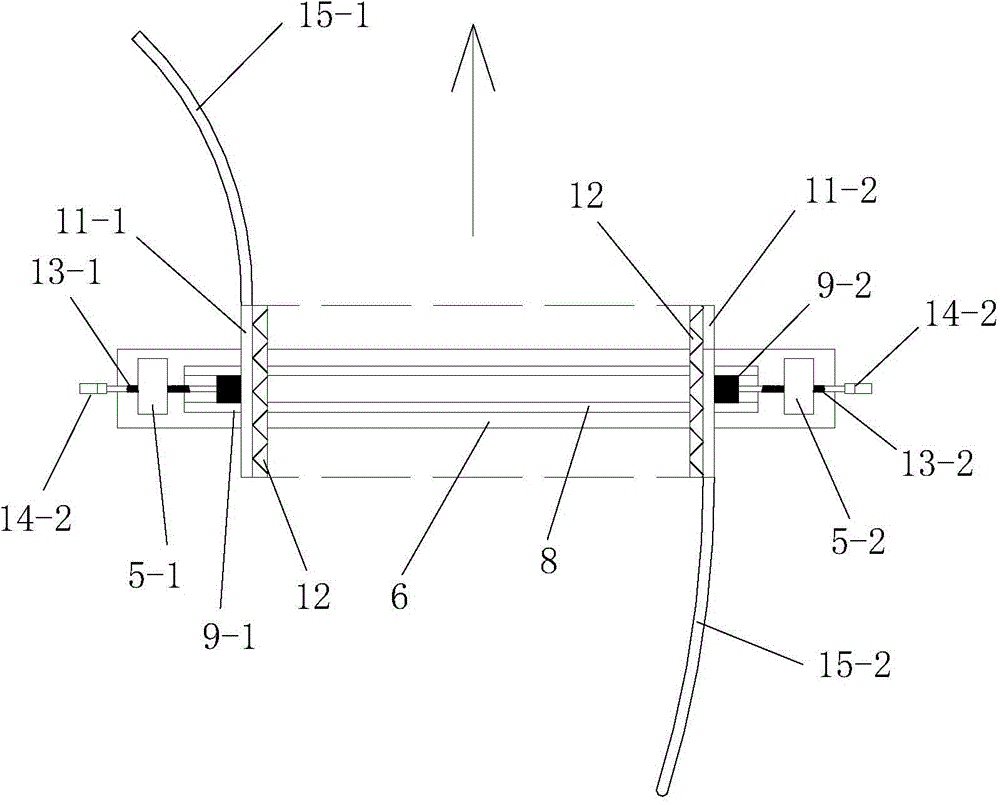

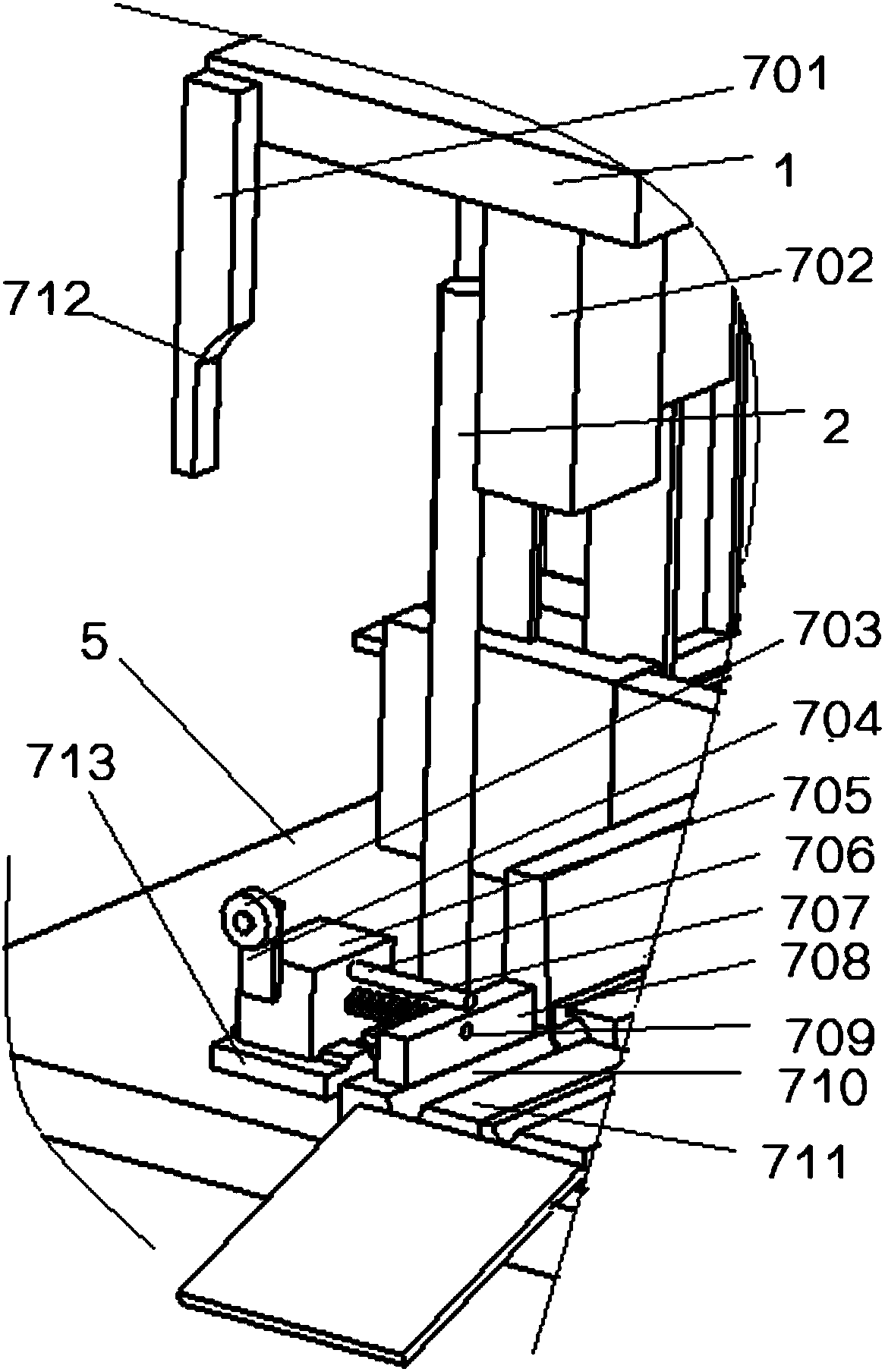

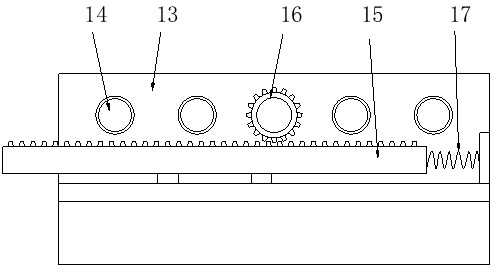

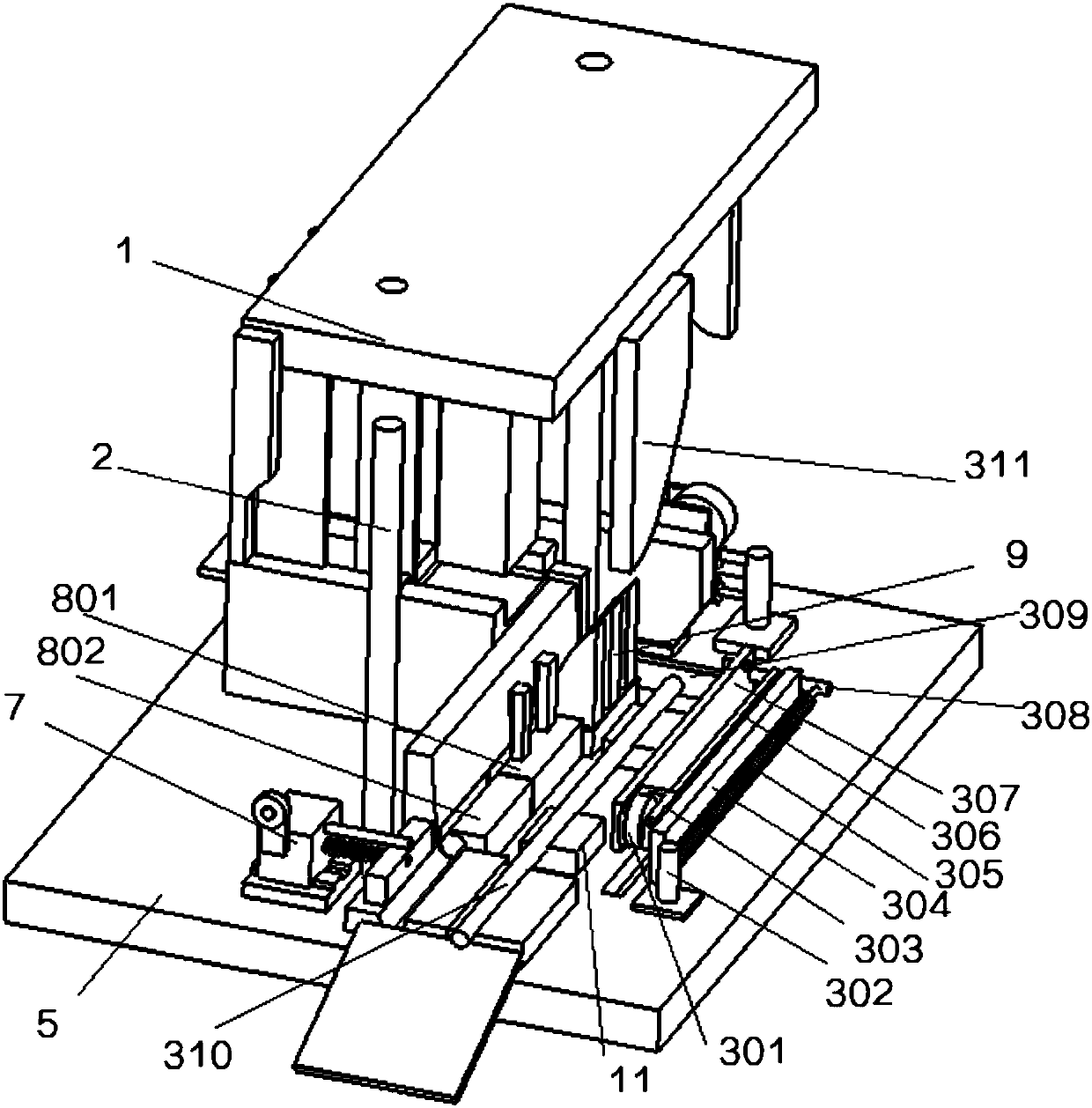

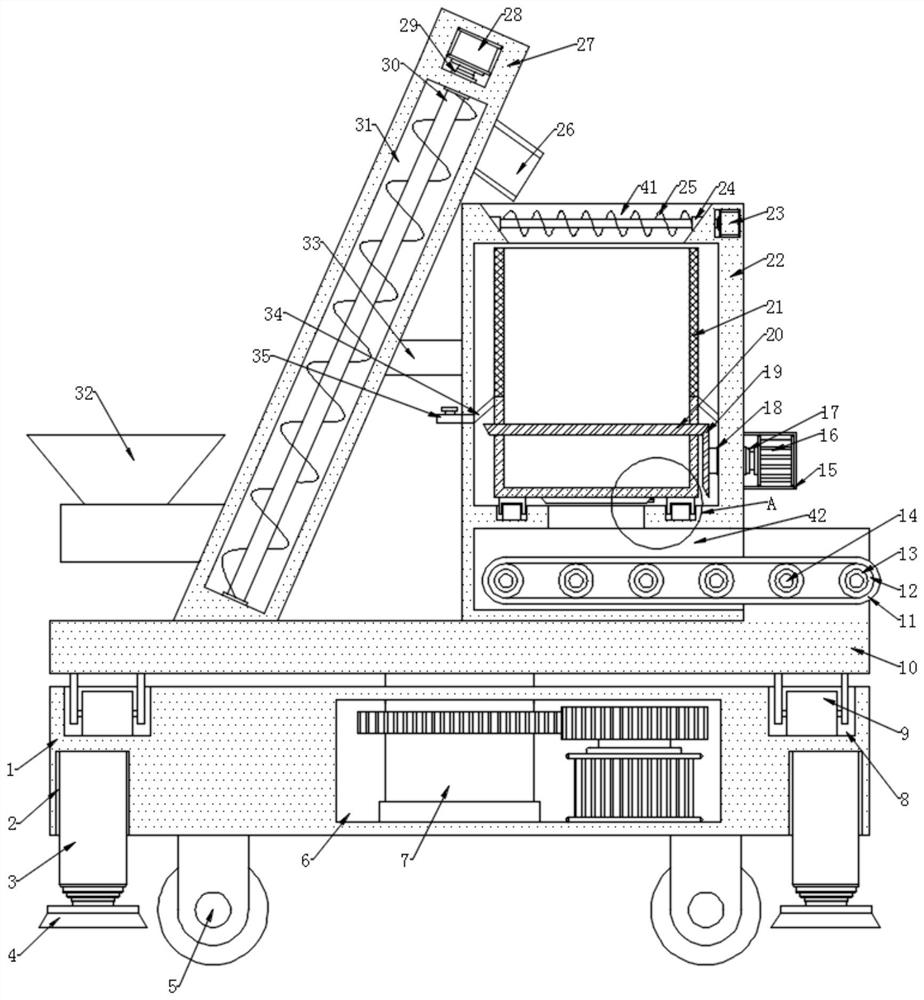

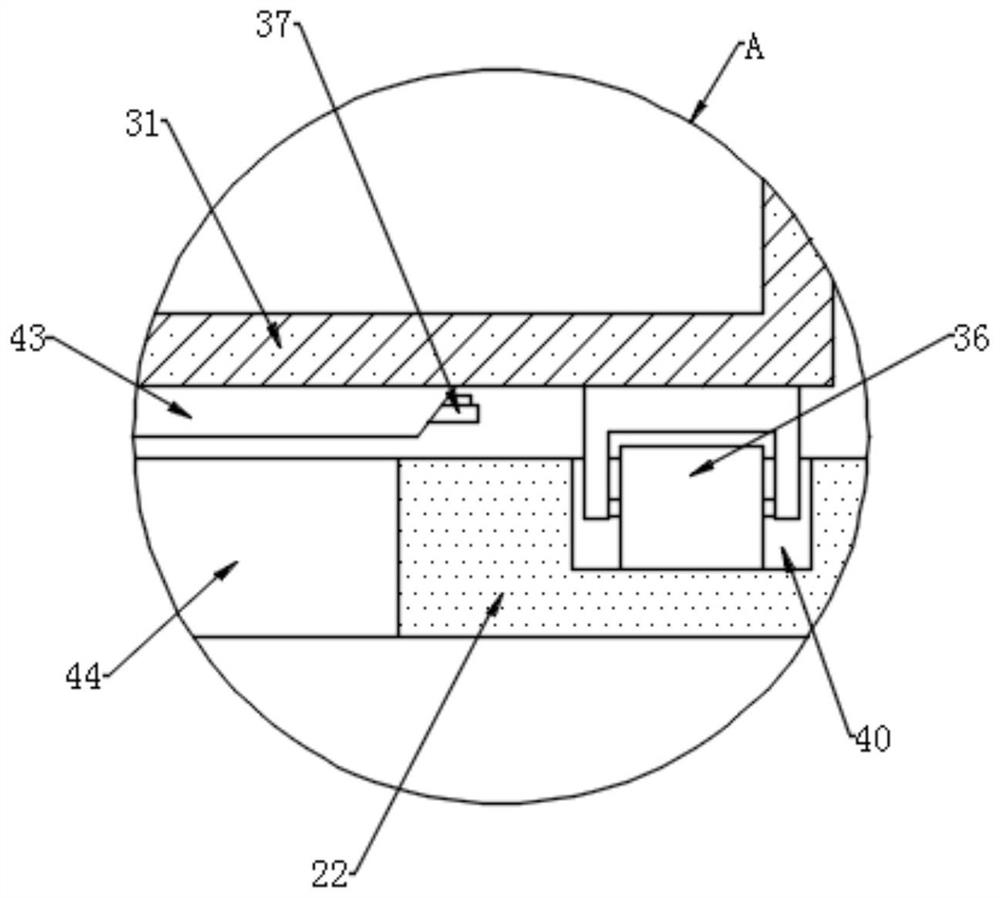

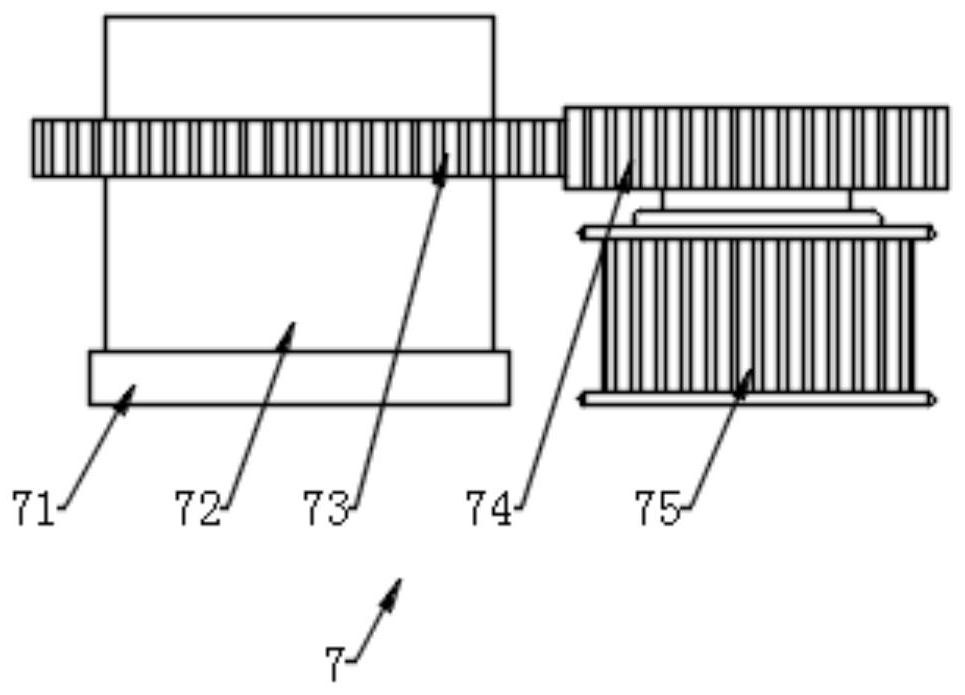

Reciprocating-type full-automatic filling machine

ActiveCN103264782AStock adjustmentAchieve the purpose of adjustmentLiquid materialGear transmissionEngineering

The invention discloses a reciprocating-type full-automatic filling machine. The reciprocating-type full-automatic filling machine comprises a storage hopper, a discharging mechanism, a rotating disc and a driving device used for driving the rotating disc to rotate. A moving plate is arranged above the rotating disc. The driving device comprises a reciprocating-type driving air cylinder and a rack, wherein the reciprocating-type driving air cylinder is arranged on the moving plate, and the rack is in driving connection with a piston rod of the reciprocating-type driving air cylinder. The rack is meshed with a gear transmission set. A transmission shaft is arranged on the gear transmission set. The lower end of the transmission shaft penetrates through the moving plate and the axis of the rotating disc sequentially and is connected with the rotating disc through a locking nut. The moving plate is connected with a synchronous vertical transmission mechanism. According to the reciprocating-type full-automatic filling machine, the driving device is arranged on the moving plate, the moving plate is connected with the synchronous vertical transmission mechanism, the rotating disc is connected with a power transmission assembly of the driving device through the transmission shaft, the driving device and the rotating disc can vertically move in a synchronous and integral mode under the effect of the synchronous vertical transmission mechanism, the distance between the rotating disc and a fixed disc can be adjusted, and the purpose of adjusting the storage volume of a jigger is achieved.

Owner:CHENGDU WENJIANG HAIKE INSTR FACTORY

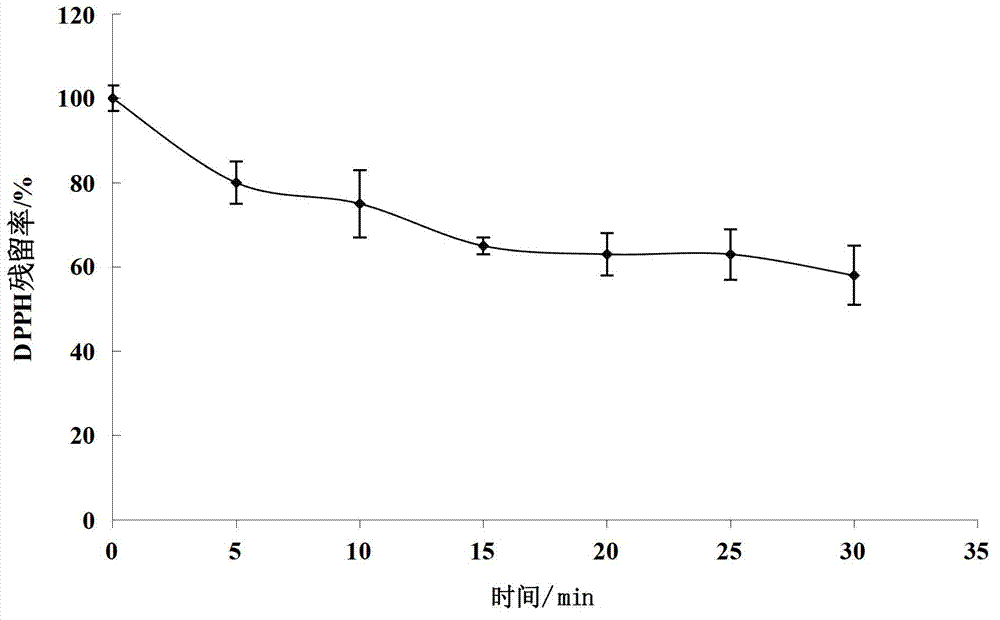

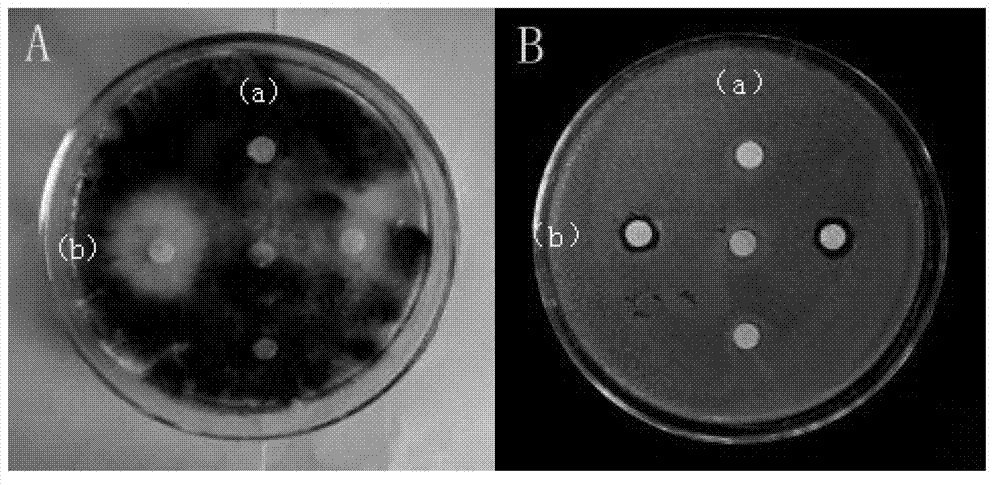

Chinese caterpillar fungus cyanine oral liquid and preparation method thereof

InactiveCN102813193AImprove the shortcomings of insufficient efficacy when used aloneFunction increaseFood preparationCyanineMedicine

The invention discloses Chinese caterpillar fungus cyanine oral liquid which comprises the following components expressed in weight parts: 10 to 20 parts of an extract solution of Chinese caterpillar fungus mycelia, 10 to 20 parts of an extract solution of anthocyanidin and 2 to 5 parts of a concentrated solution of cordyceps militaris. The invention also discloses a preparation method for the Chinese caterpillar fungus cyanine oral liquid. Based on the principle that the above mentioned medicines are compatible and mutually synergistic, the method improves the disadvantage of insufficient efficacy when Chinese caterpillar fungus or anthocyanidin is individually used. The prepared Chinese caterpillar fungus cyanine oral liquid has good taste and the effects of lung moistening, phlegm reducing, blood sugar adjusting and the like and can enhance immunity, refresh one's spirit, treat insomnia and allow people to glow when taken for a long time.

Owner:JIANGSU UNIV OF SCI & TECH

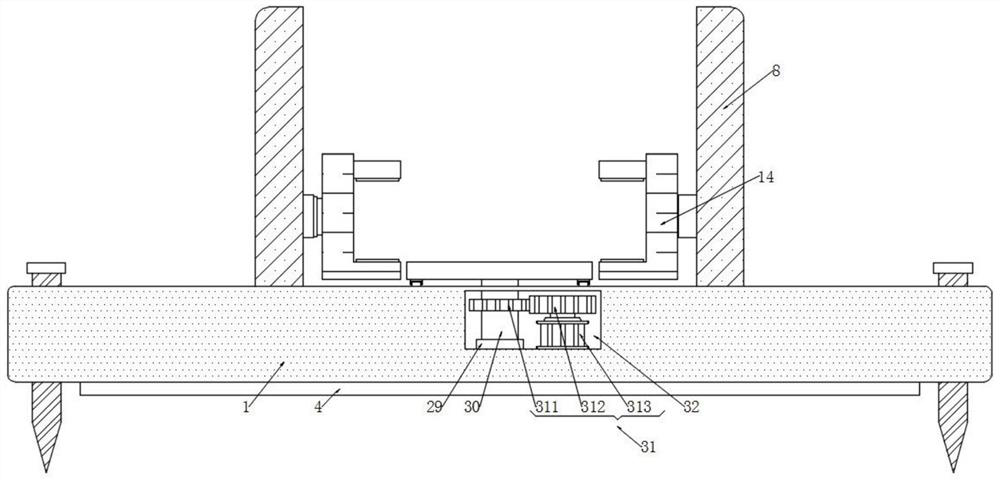

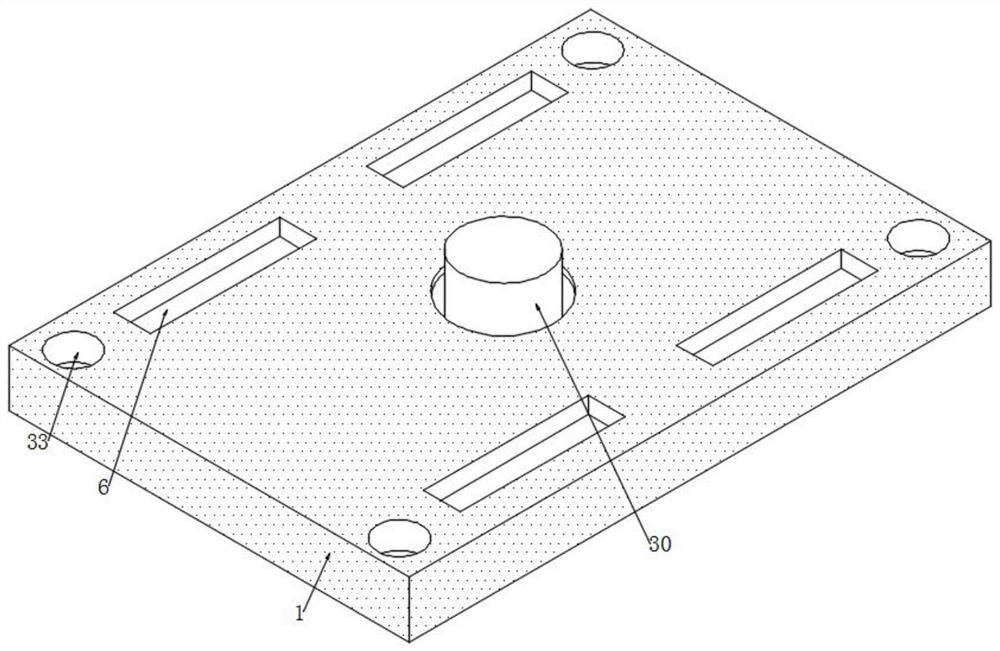

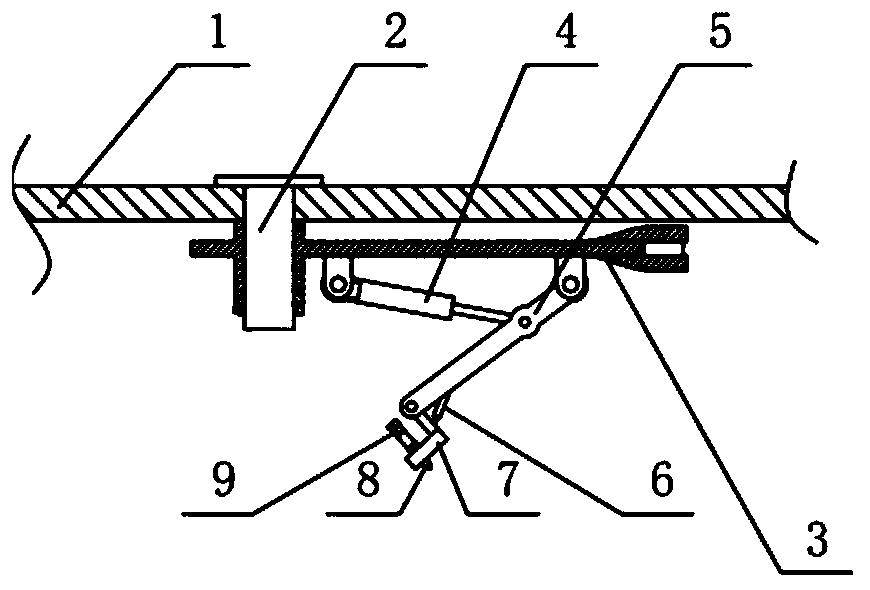

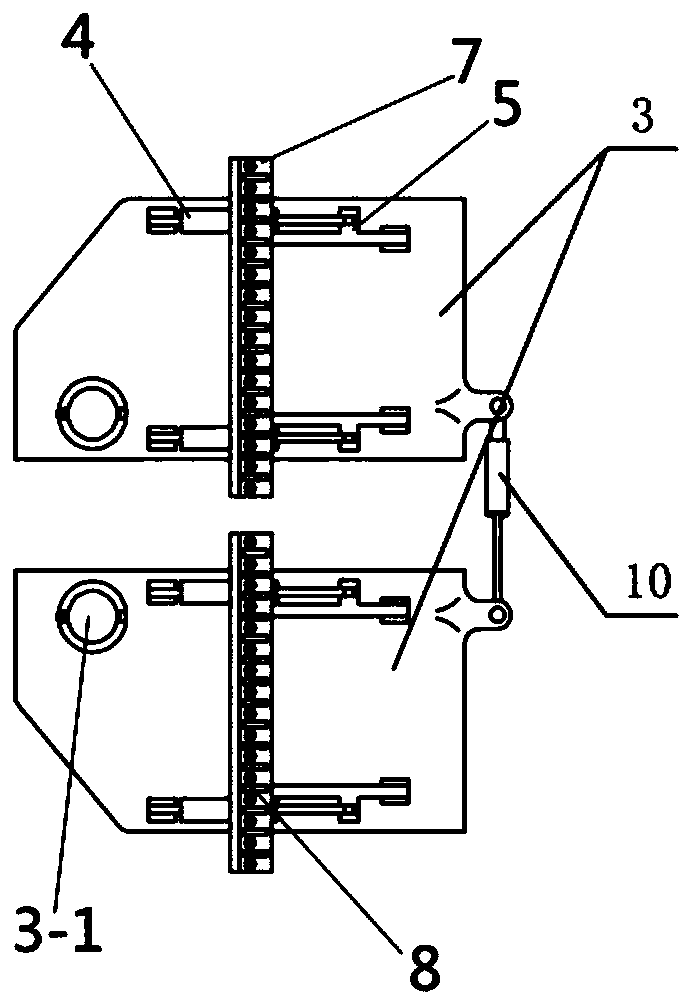

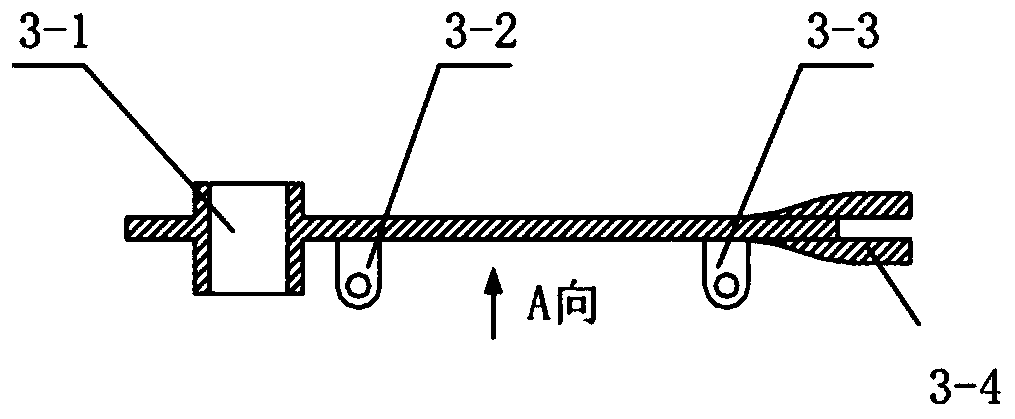

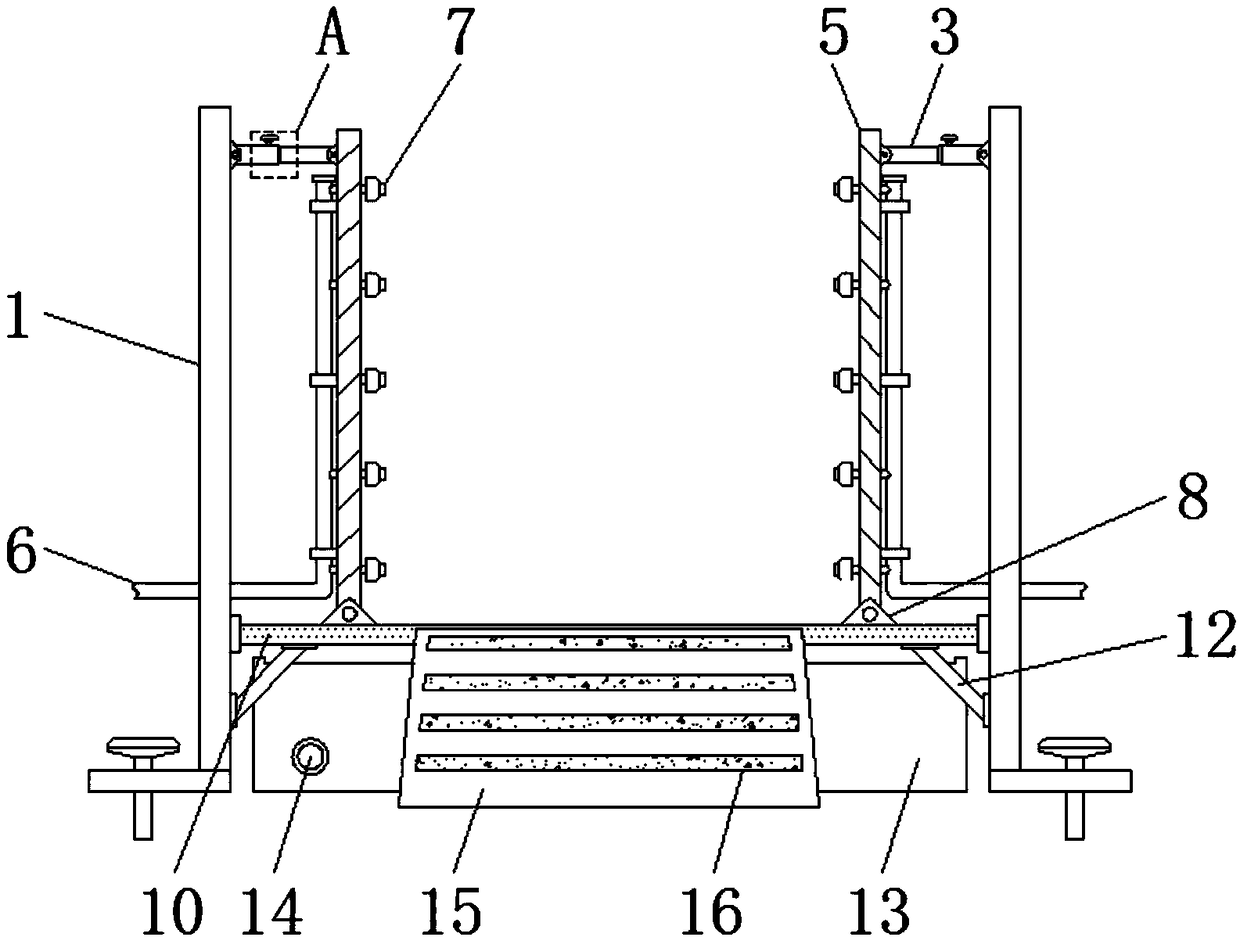

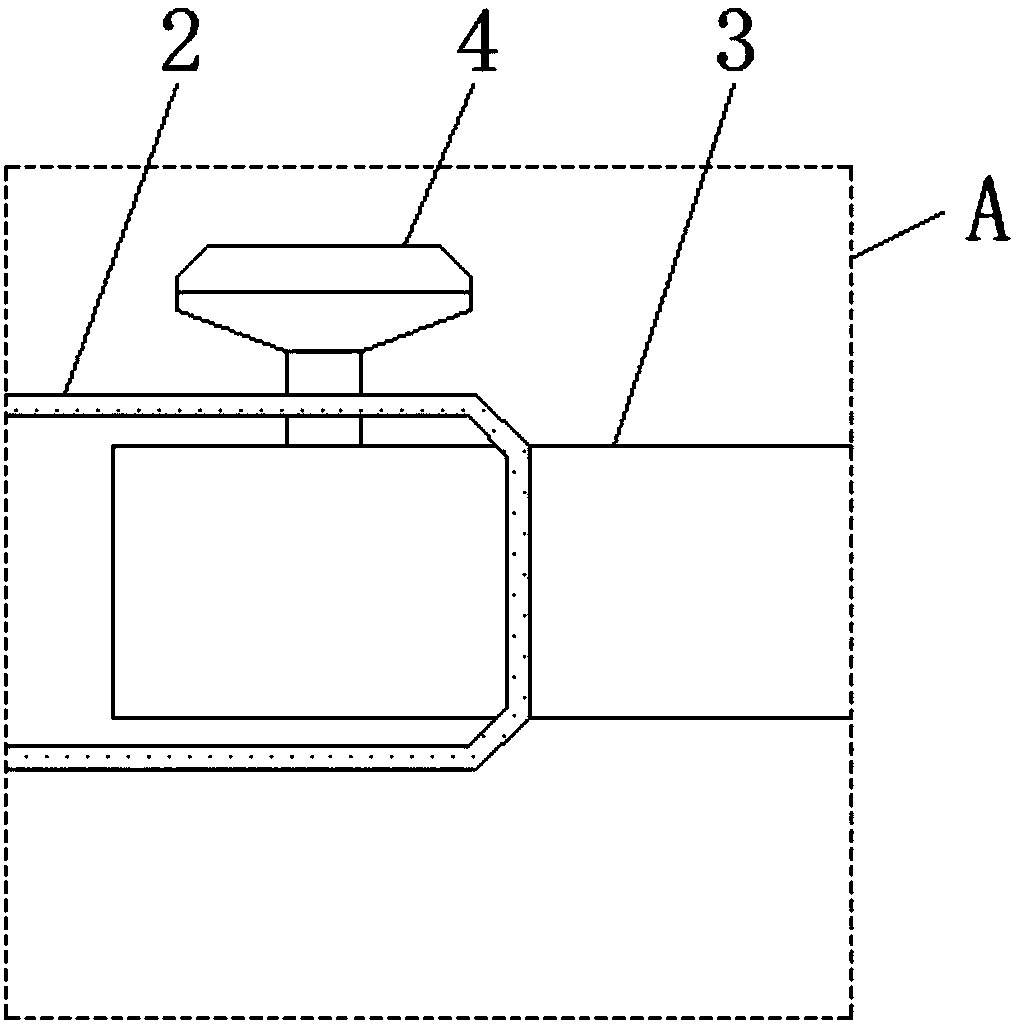

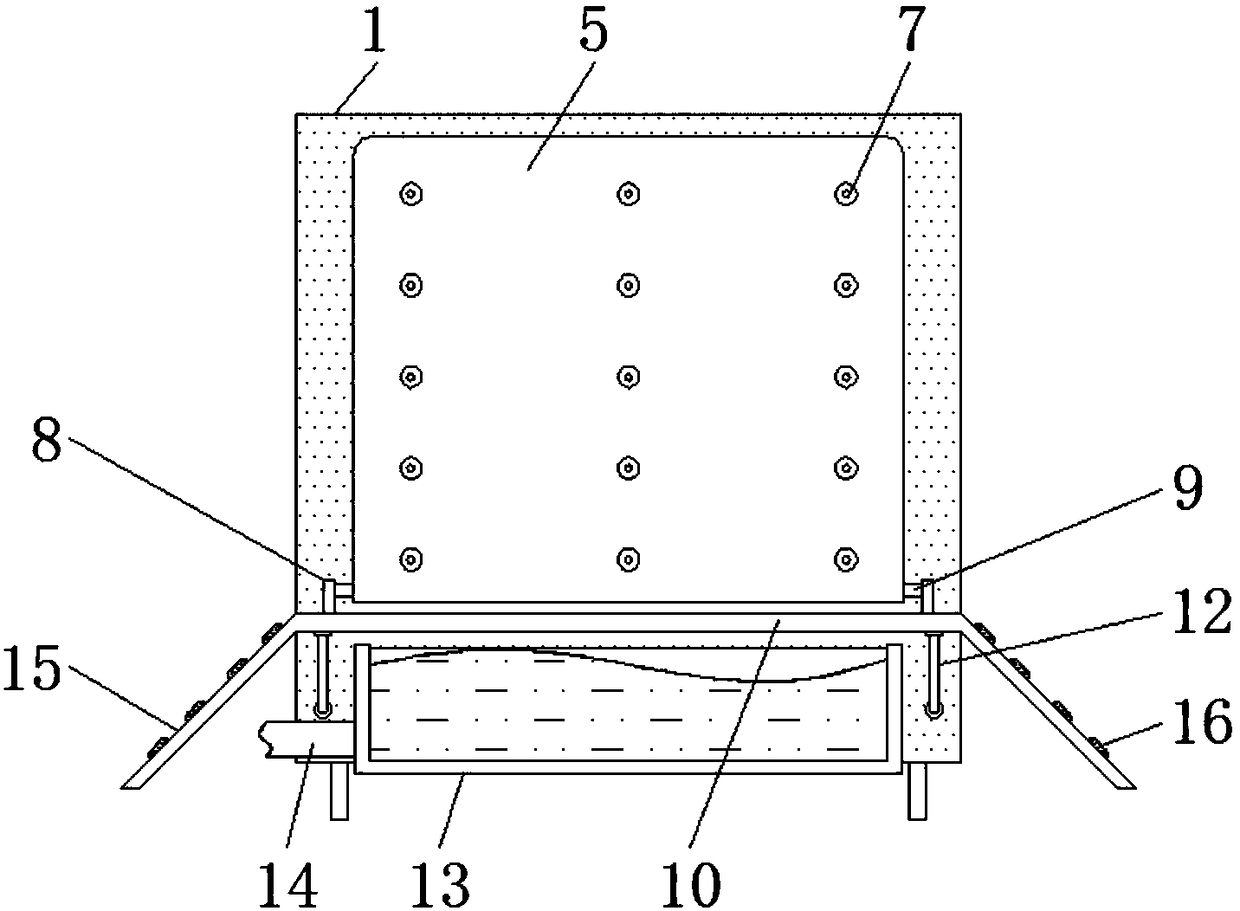

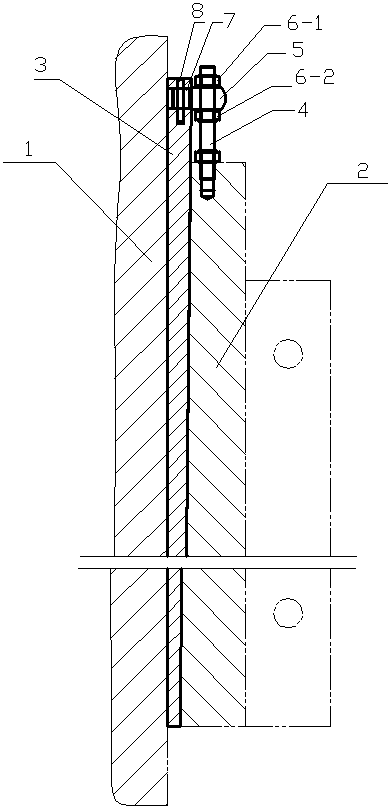

Barrel close mouth fixture

InactiveCN101804540AQuality improvementEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a barrel close mouth fixture, which comprises a left bracket [1], a right bracket [10] and a close mouth screw rod mechanism. The center of the left bracket [1] and the center of the right bracket [10] are provided with an axial hole [15] respectively; the close mouth screw rod mechanism comprises a close mouth screw rod [3], a left-hand nut [4] and a right-hand nut [9], and the turning directions of threads at both ends of the close mouth screw rod [3] are opposite; the left-hand nut [4] and the right-hand nut [9] are positioned in the axial holes [15] of the left bracket and the right bracket respectively; the corresponding positions on the left bracket [1] and the right bracket [10] are provided with radial holes respectively; the left-hand nut [4] and the right-hand nut [9] are provided with a rotating shaft [2] respectively; the rotating shafts [2] are positioned in the radial holes; the other end of the left bracket [1] and the other end of the right bracket [10] are provided with a jaw [5] respectively; the side walls of the jaws [5] are provided with screw holes; and fastening screws are arranged in the screw holes. The fixture has the advantages ofconvenient adjustment, improvement on production efficiency, and high quality during barrel welding.

Owner:铜陵皖江集团新高机电有限公司

Electric screw driver with adjustable output torque

InactiveCN105500263AIncrease or decrease in pressureAchieve the purpose of adjustmentSpannersWrenchesCoil spring

Owner:宁波中旺工具有限公司

Manual type air pipe air direction and air speed adjusting device

InactiveCN105626131ASimple structureReasonable designTunnel/mines ventillationTransverse grooveWind direction

The invention discloses a manual type air pipe air direction and air speed adjusting device which comprises a horizontal base, universal wheels, a vertical sleeve arranged on the horizontal base, an inner adjusting rod sleeved with the vertical sleeve in a threaded manner and a horizontal installation board installed on the inner adjusting rod. A transverse groove for installation of a horizontal sliding rail is formed in the upper portion of the horizontal installation board. A left installation seat and a right installation seat are installed on the horizontal installation board. Two laterally-moving sliding blocks are arranged on the horizontal sliding rail. A left push-pull rod is arranged on the left installation seat and a right push-pull rod is arranged on the right installation seat. A left strut is arranged on the left sliding block and provided with a left clamping board, and a left guide board is arranged on the front side of the left clamping board. A right strut is arranged on the right sliding block and provided with a right clamping board, and a right guide board is arranged on the rear side of the right clamping board. The manual type air pipe air direction and air speed adjusting device is simple in structure, reasonable in design, convenient to use and operate, good in use effect and capable of easily and conveniently adjusting the air supply direction and the air speed of any position of an air pipe.

Owner:XIAN YUEFU ELECTRICAL TECH

Water jet pavement crushing device

InactiveCN109837830AAchieve brokenMeet brokenRoad cleaningRoads maintainenceVehicle frameRoad surface

The invention discloses a water jet pavement crushing device which comprises a frame, connecting pins, a left supporting plate, a right supporting plate, a height adjusting oil cylinder, a swing rod,an angle oil cylinder, a nozzle support, a nozzle, a through pipe and a swing oil cylinder. The left and right supporting plates are hinged to the frame through the connecting pins; one of the heightadjusting oil cylinder and one end of the swing rod are hinged to the left and right supporting plates; the other end of the height adjusting oil cylinder is hinged to the swing rod, the other end ofthe swing rod is hinged to the nozzle support, the two ends of the angle oil cylinder are hinged to the swing rod and the nozzle support respectively, the nozzle and the through pipe are both installed on the nozzle support, and the two ends of the swing oil cylinder are hinged to the left supporting plate and the right supporting plate respectively. The height and the angle of a nozzle are adjusted through the height adjusting oil cylinder and the angle oil cylinder to be used for water jet crushing of a pavement, the angle of a jet device is adjusted through the swing oil cylinder to be usedfor cleaning and loading of the crushed pavement, the whole mechanism is simple and compact, the pavement crushing and cleaning requirements are met, and milling noise and dust pollution are reduced.

Owner:CHANGAN UNIV

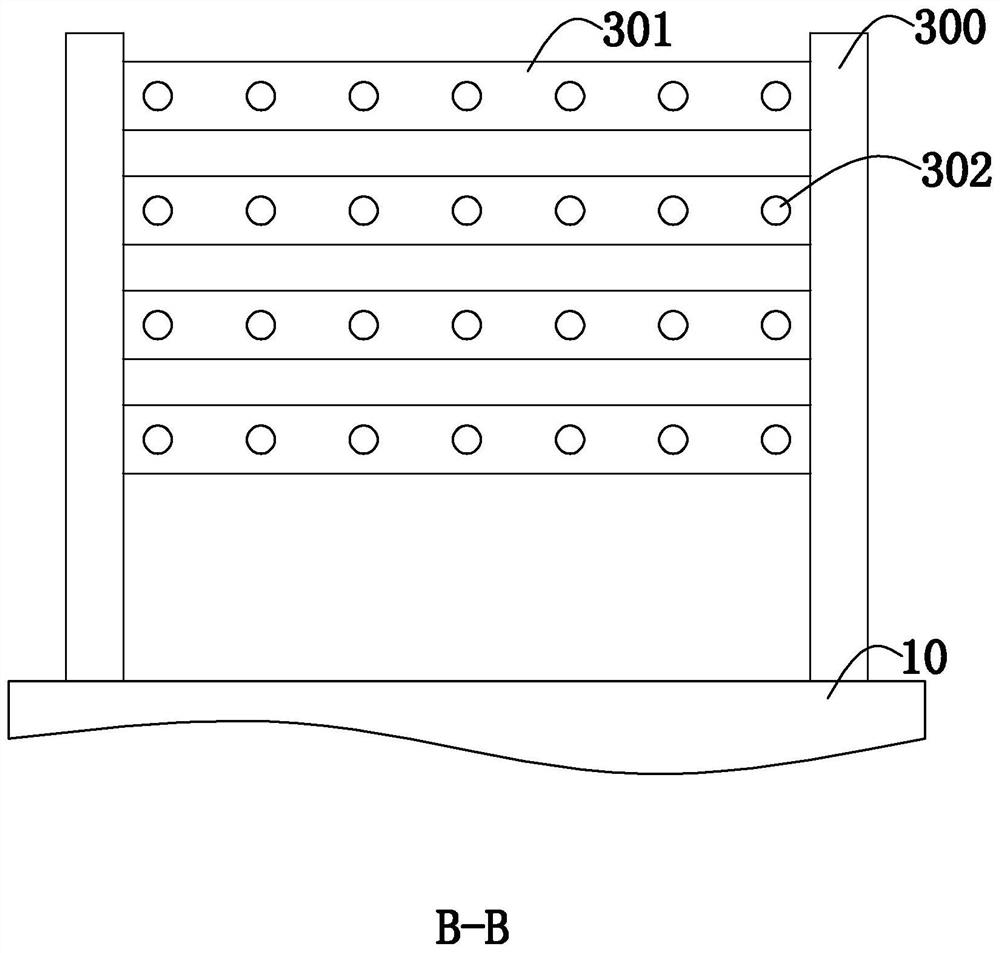

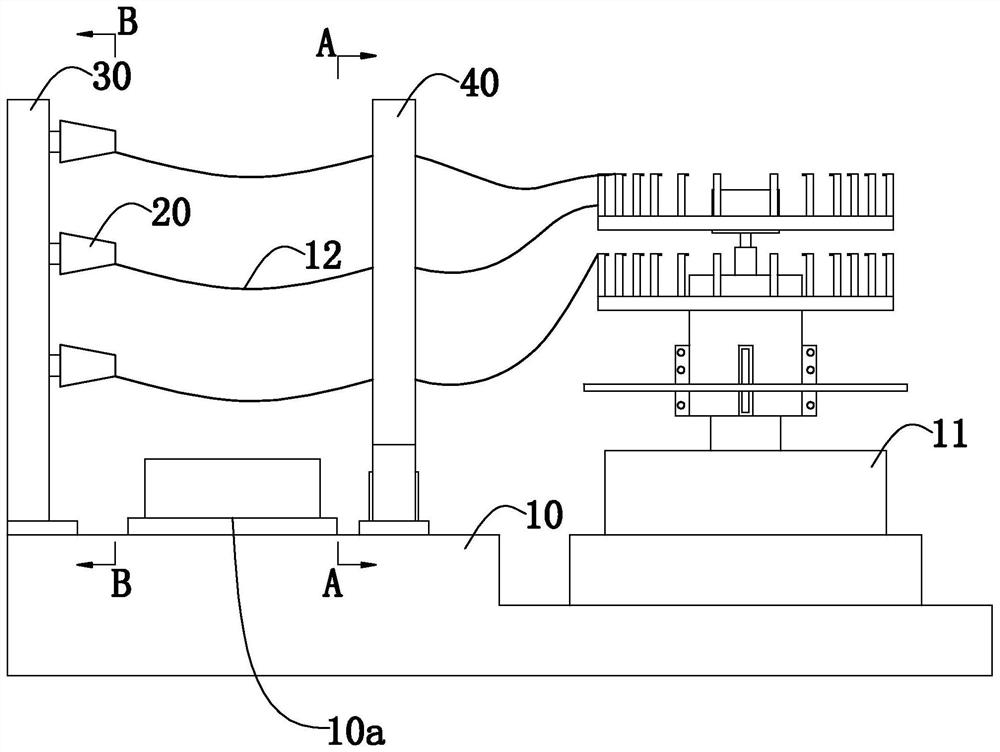

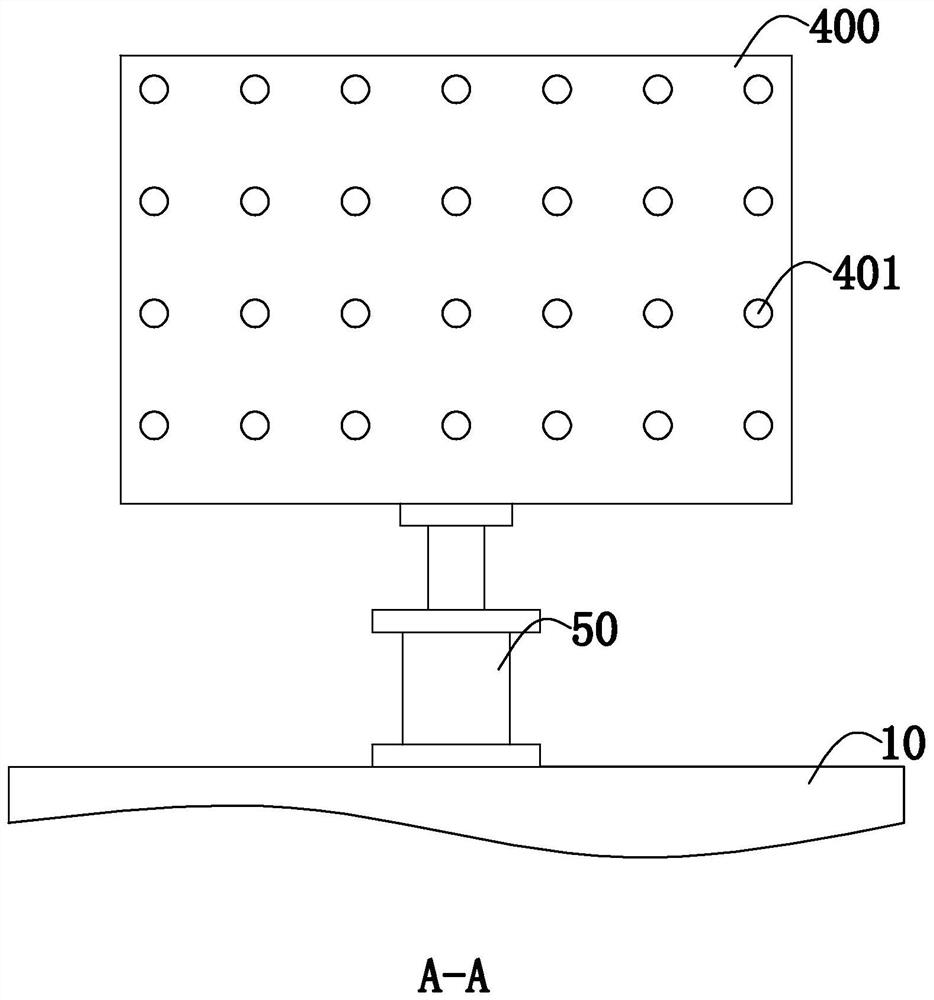

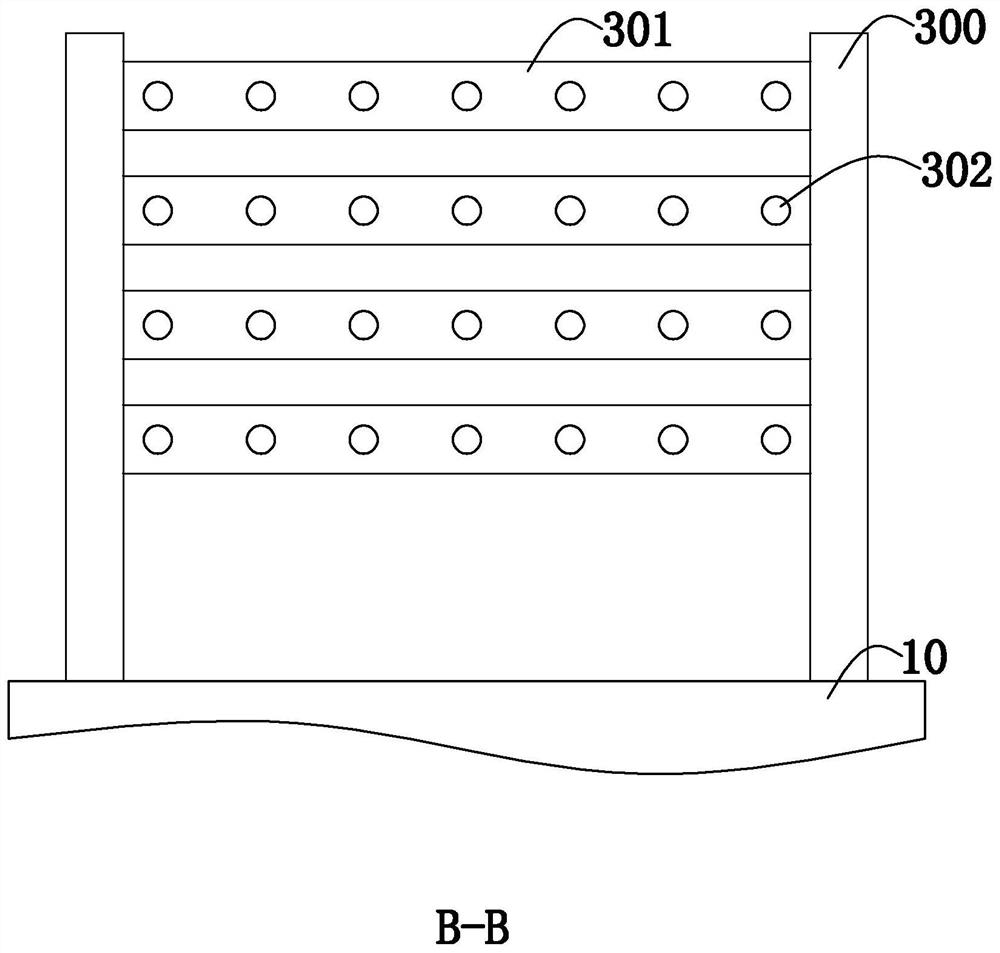

Production device and production method of ultra-high molecular weight polyethylene fiber socks

The invention relates to a production device and a production method of ultra-high molecular weight polyethylene fiber socks. The production device comprises a rack and a knitting module mounted on the rack, and the production device is characterized by comprising a yarn supply module mounted on the rack and used for mounting yarn bobbins, and a yarn arranging module mounted between the yarn supply module and the knitting module; wherein the yarn arranging module comprises a plate body mounted on the rack and located between the yarn supply module and the knitting module, and a plurality of yarn holes formed in the plate body and allowing yarn to penetrate through. The production device has the advantages of being high in production efficiency and good in sock knitting effect.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

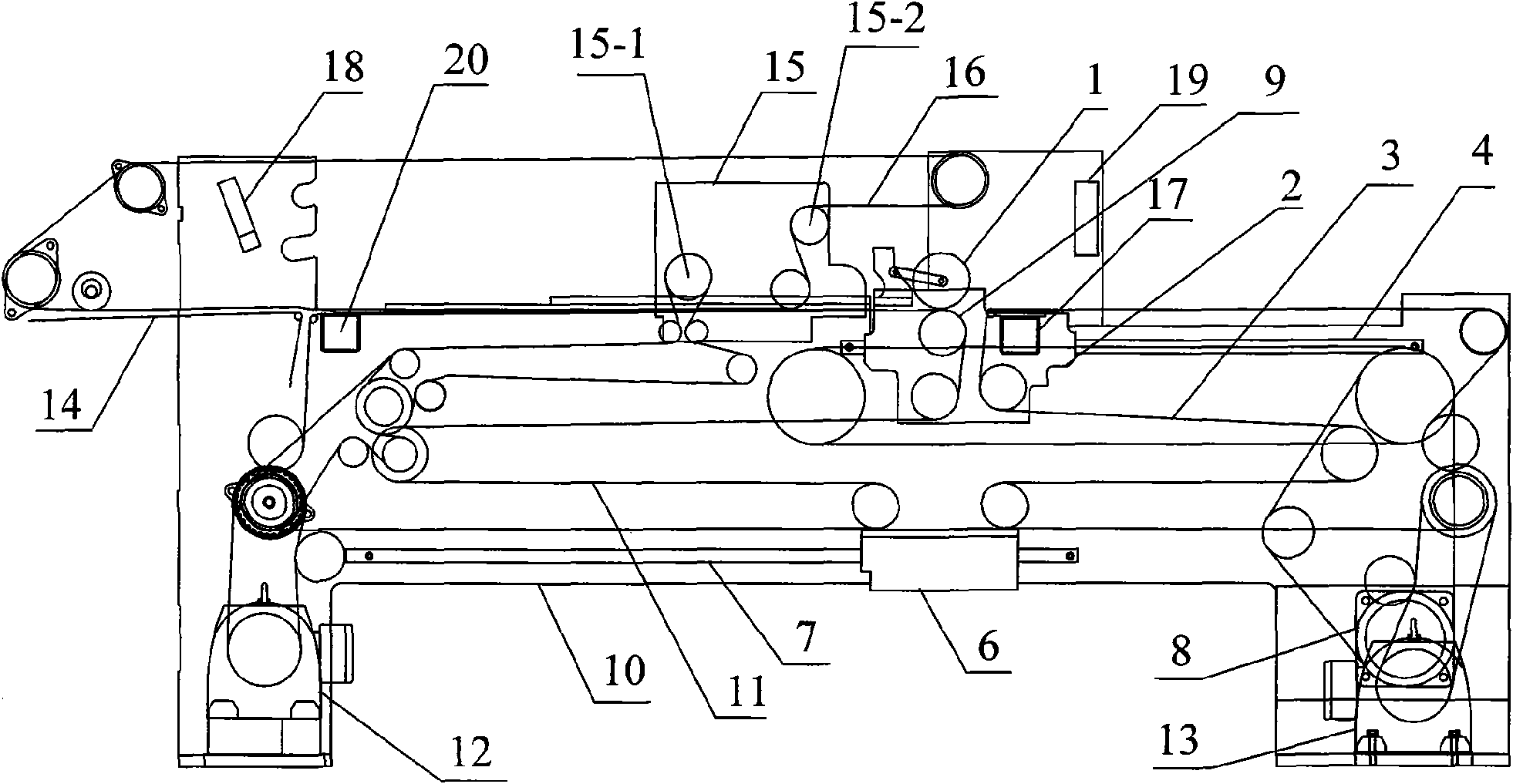

Blocked stack system for sheet positioning and paging and method thereof

ActiveCN101638192ARealize counting quantitative stackingRealize counting and quantitative stackingArticle deliveryLow speedElectric machinery

The invention discloses a blocked stack system for sheet positioning and paging and a method thereof. The system comprises a frame, a controller, a counter, an upper pressing belt arranged at the upper part of the frame, a low-speed conveying belt 1 and a low-speed conveying belt 2 respectively arranged at the left side and the right side of the frame, and power motors respectively providing powerfor the low-speed conveying belt 1 and the low-speed conveying belt 2; the height of a horizontal section at the upper part of the low-speed conveying belt 1 is lower than that of a high-speed conveying belt of a paper cutter at the left of the low-speed conveying belt 1, and a matched paging part is arranged between horizontal sections at the upper part of the low-speed conveying belt 1 and thelow-speed conveying belt 2. The blocked stack method comprises the following steps: conveying sheets from left to right by the low-speed conveying belt 1 and the low-speed conveying belt 2, paging after arriving sheet stack sizes, quickly conveying following sheets to a stacking part after paging, and conveying the preceding sheets at a low speed. The blocked stack system has the advantages of reasonable design, convenient use and operation and good use effect, and can achieve the functions of no waste discharge and automatic stack change without shutting down machines.

Owner:SHANGHAI ZIDAN FOOD PACKAGING & PRINTING CO LTD +1

Production system of ultra-high molecular weight polyethylene fiber socks

The invention relates to a production system of ultra-high molecular weight polyethylene fiber socks. The production system comprises a machine frame and a knitting module installed on the machine frame. The production system of the ultra-high molecular weight polyethylene fiber socks is characterized by comprising a yarn supply module installed on the machine frame and used for installing a yarnbobbin, a yarn arranging module installed between the yarn supply module and the knitting module and a cleaning module arranged between the yarn supply module and the yarn arranging module and / or between the yarn arranging module and the knitting module; the yarn arranging module comprises a plate body and a plurality of yarn holes, wherein the plate body is installed on the machine frame and located between the yarn supply module and the knitting module, and the yarn holes are formed in the plate body and allow yarns to penetrate through. The production system of the ultra-high molecular weight polyethylene fiber socks has the beneficial effect of stable production.

Owner:ZHEJIANG QIANXILONG SPECIAL FIBER

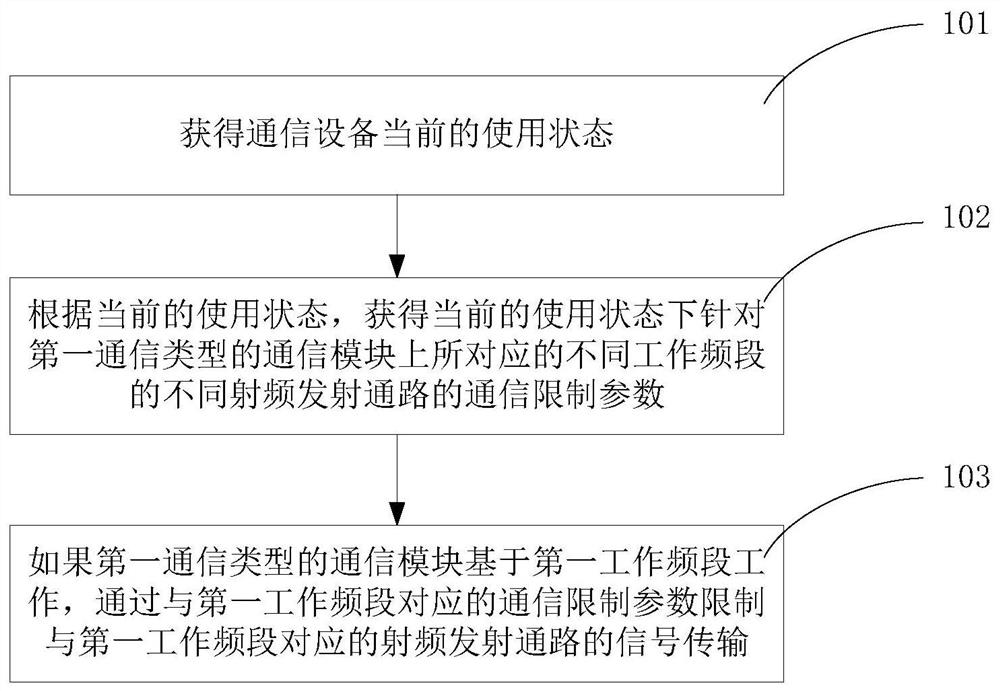

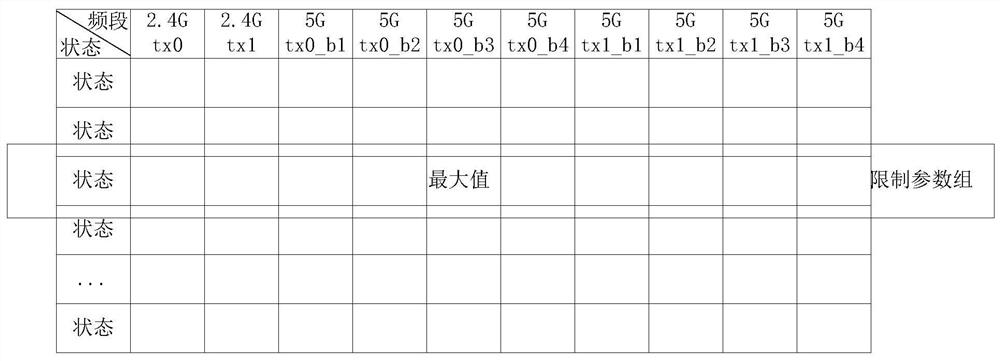

Communication control method and device and communication equipment

ActiveCN113067609AGuaranteed signal transmissionAchieve the purpose of adjustmentPower managementSubstation equipmentFrequency bandRadio frequency

The invention discloses a communication control method and device and communication equipment, wherein the method comprises the steps: obtaining a current use state of the communication equipment which comprises at least two first antennas needed by a first communication type and at least two second antennas needed by a second communication type, and the current use state at least comprises that the communication module of the first communication type is in a running state; according to the current use state, obtaining communication limitation parameters of different radio frequency emission paths corresponding to different working frequency bands on the communication module of the first communication type in the current use state; and in the current use state, if the communication module of the first communication type works based on a first working frequency band, limiting signal transmission of a radio frequency emission path corresponding to the first working frequency band through a communication limiting parameter corresponding to the first working frequency band.

Owner:LENOVO (BEIJING) CO LTD

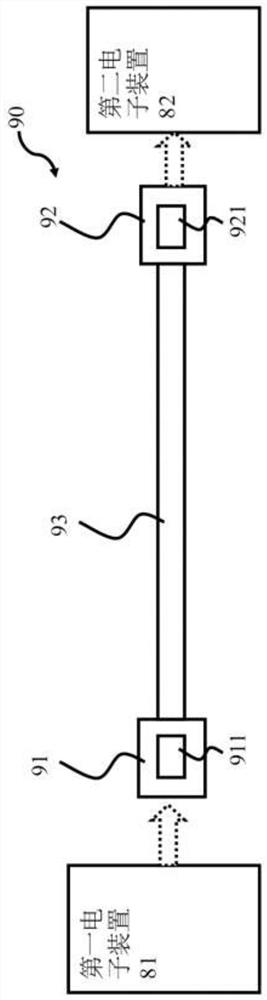

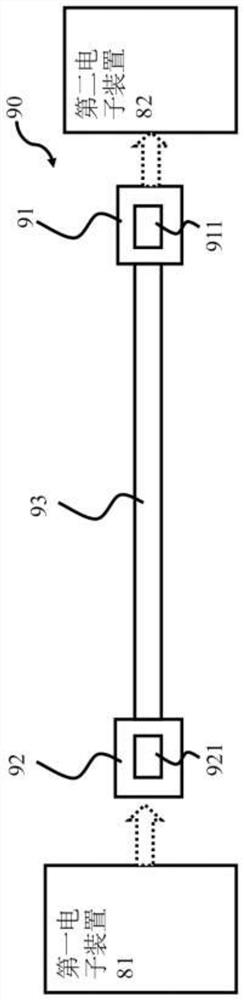

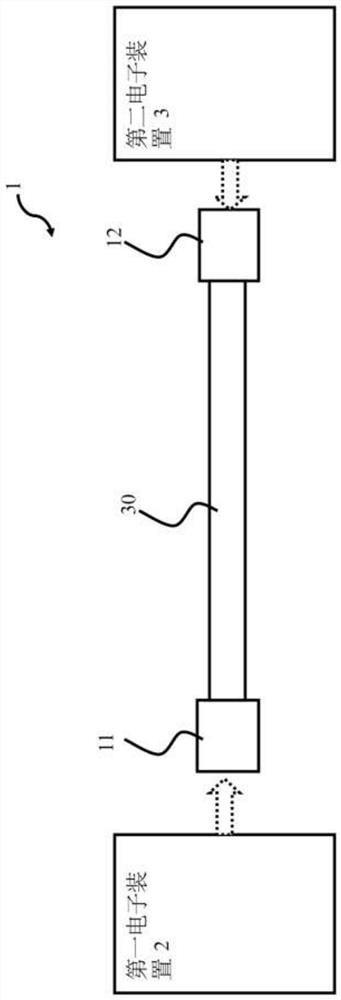

Bidirectional signal transmission connecting line

PendingCN114374124AAchieve the purpose of adjustmentCoupling device connectionsElectric digital data processingEngineeringComputer science

The invention relates to a bidirectional signal transmission connecting line. The bidirectional signal transmission connecting line is connected between the first electronic device and the second electronic device. The bidirectional signal transmission connecting line comprises a first connecting port, a second connecting port, a first adapter chip, a second adapter chip and a plurality of transmission wires. The first adapter chip and the second adapter chip are symmetrically arranged in the first connecting port and the second connecting port, the first adapter chip has a first set of adjusting parameters, and the second adapter chip has a second set of adjusting parameters. Therefore, when signals are transmitted between the first electronic device and the second electronic device through the first connecting port, the second connecting port and the plurality of transmission wires, the signals are adjusted by the first group of adjusting parameters and the second group of adjusting parameters.

Owner:LERAIN TECH CO LTD

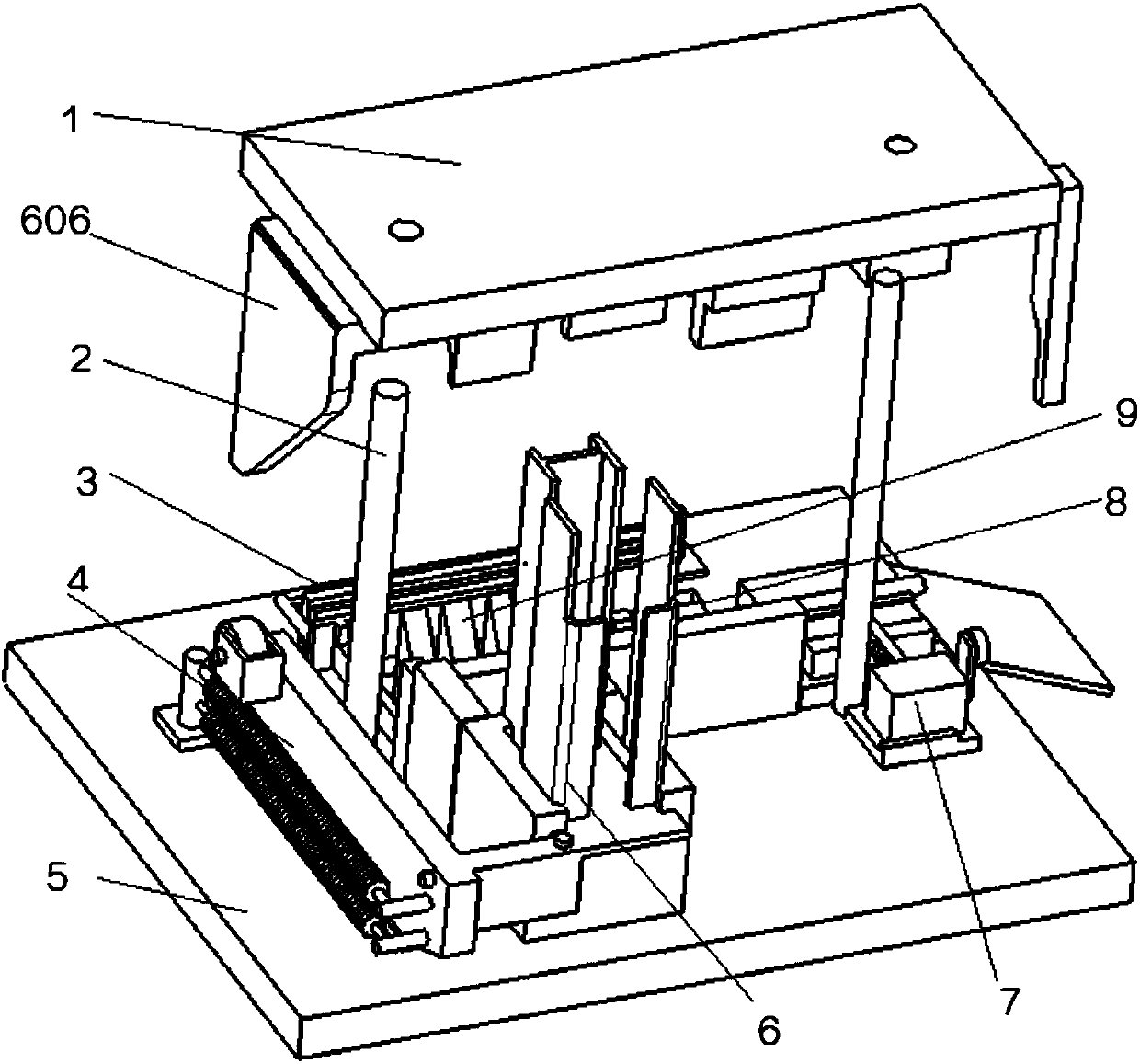

Novel efficient shutter forming die

ActiveCN107824685AImprove work efficiencyAchieve stereotypesShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention provides a novel efficient shutter forming die. The novel efficient shutter forming die comprises a lower die holder, and an upper template connected with the lower die holder in a sliding manner through symmetrically arranged guide rods, wherein a feeding device is arranged on the lower die holder; the feeding device is arranged at the outer part of the upper template; a reversing correction device is arranged in the position, close to the feeding device, between the lower die holder and the upper template; a circle winding device is arranged on one side of the reversing correction device; a pulling-down forming device is arranged at the side end of the circle winding device; the reversing correction device, the circle winding device and the pulling-down forming device are sequentially arranged between the lower die holder and the upper template, and are positioned on the same straight line; and an ejector mechanism is arranged at the end, away from the feeding device, of the lower die holder. According to the novel efficient shutter forming die, a traditional stamping design concept is changed through the precise die, circle winding and forming can be achieved in batches in one device, the die is relatively small, processing and manufacturing cost is obviously reduced, the circle winding effect is relatively good, and the forming requirement of shutters can be well met.

Owner:秦皇岛圣标门窗有限公司

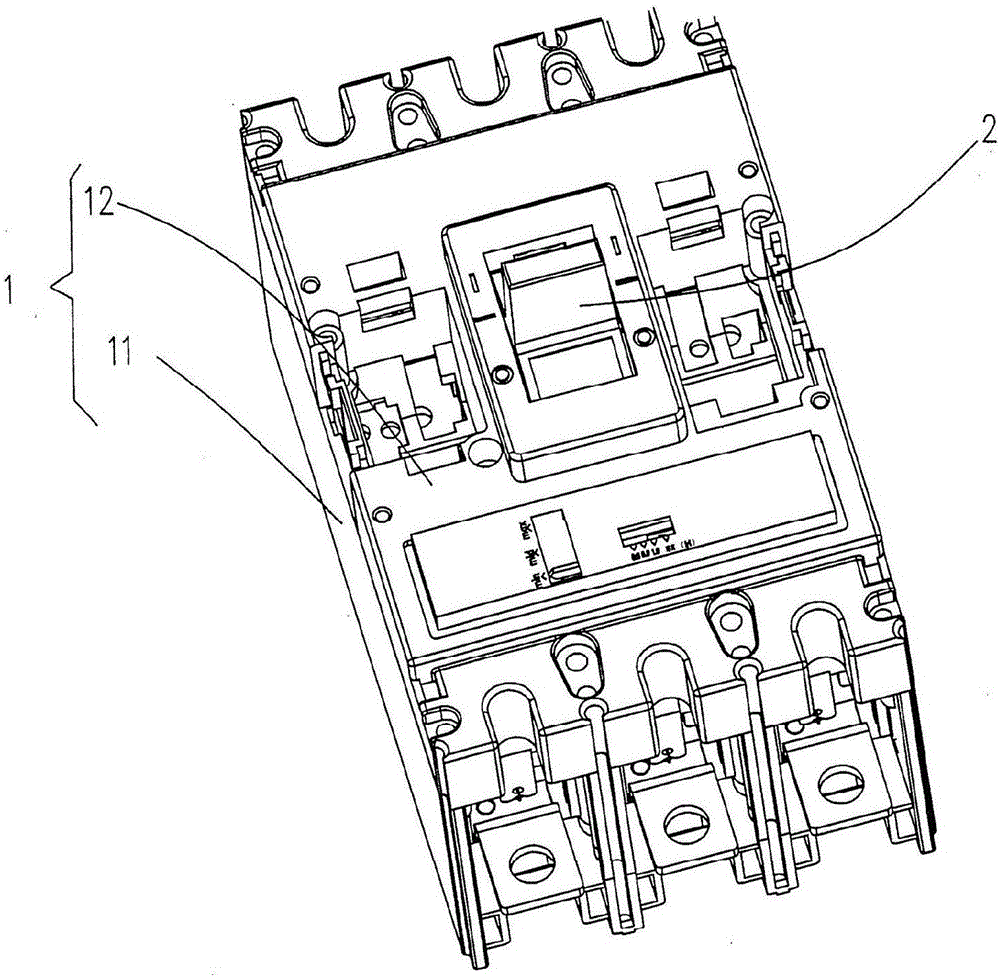

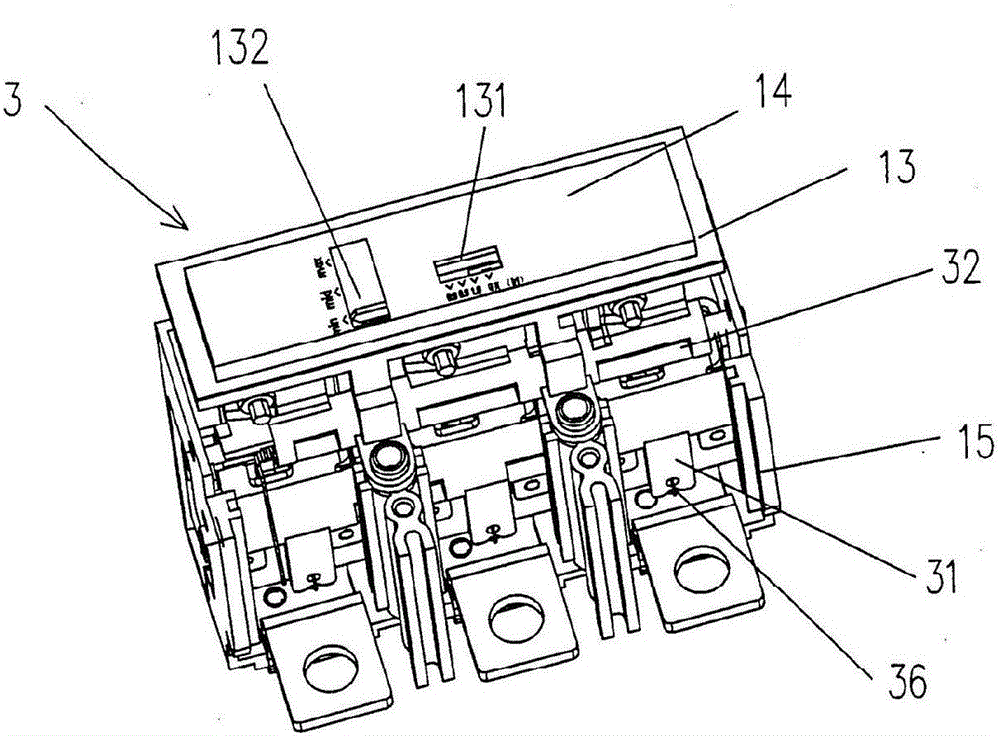

Molded case circuit breaker tripping device

ActiveCN106252177AAchieve regulationAchieve the purpose of adjustmentProtective switch operating/release mechanismsAdjustment of protective switch conditionsPower flowSpring force

The invention discloses a molded case circuit breaker tripping device, which comprises a shell, an operating mechanism and a tripping device. The tripping device comprises a short circuit instantaneous protection tripping device and a draw bar; the short circuit instantaneous protection tripping device comprises a keeper, an adjusting bar and a reaction spring; the adjusting bar is pivoted on the shell; and the reaction spring is connected with the adjusting bar and the keeper. When short circuit current flows through the tripping device, the keeper actuates the draw bar to be pivoted, and the draw bar unlocks the operating mechanism to actuate the circuit breaker to cut off the circuit. The shell is provided with an adjusting bar adjusting window, a sliding adjusting device is arranged at the adjusting bar adjusting window, the sliding adjusting device comprises a sliding piece and a sliding abutting bar arranged on the adjusting bar, and when the sliding piece slides and drives the sliding abutting bar arranged on the adjusting bar to enable the adjusting bar to rotate around an axial direction, the spring force of the reaction spring changes and an adjustable action current value of the short circuit instantaneous protection tripping device is realized. The reaction spring generates different tension forces, the reaction spring is adjusted, and the purpose of adjusting the short circuit current value is achieved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

Electric vehicle chassis charging and battery replacing station and battery replacing method

ActiveCN112977152APrecise positioningEasy to moveCharging stationsVehicular energy storageBattery chargeAutomotive battery

The invention relates to the technical field of battery replacing stations, and discloses an electric automobile chassis battery charging and replacing station and a battery replacing method. The electric automobile chassis battery charging and replacing station comprises a lifting frame used for conveying automobile batteries and two positioning assemblies, and the electric automobile chassis battery charging and replacing station comprises the two positioning assemblies; the positioning assembly is composed of a guide rod and a fixed base, the fixed base is located at one end of the guide rod, a limiting baffle is arranged on one side of the fixed base, and the limiting baffle and the guide rod are arranged in parallel. According to the technical scheme, the two positioning assemblies are arranged to position the wheels, the good positioning effect is achieved. Meanwhile, the movable second guide seat is arranged on the fixing base, when a vehicle needs to move from a battery replacing station, the second guide seat can be pressed into the fixing groove by the wheels, and therefore the vehicle can be conveniently replaced. In this way, the wheels cannot be limited by the second guide seats, and the wheels can move more conveniently.

Owner:HEMEI (ZHEJIANG) AUTOMOBILE CO LTD

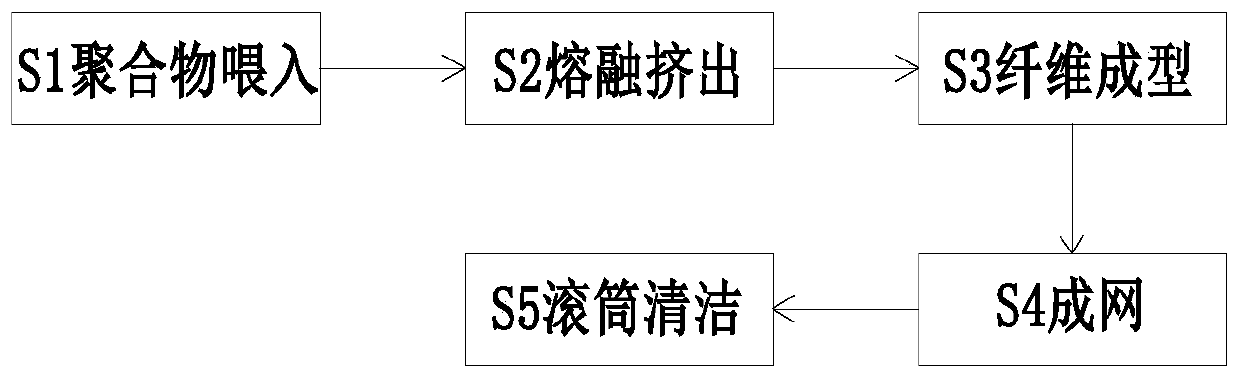

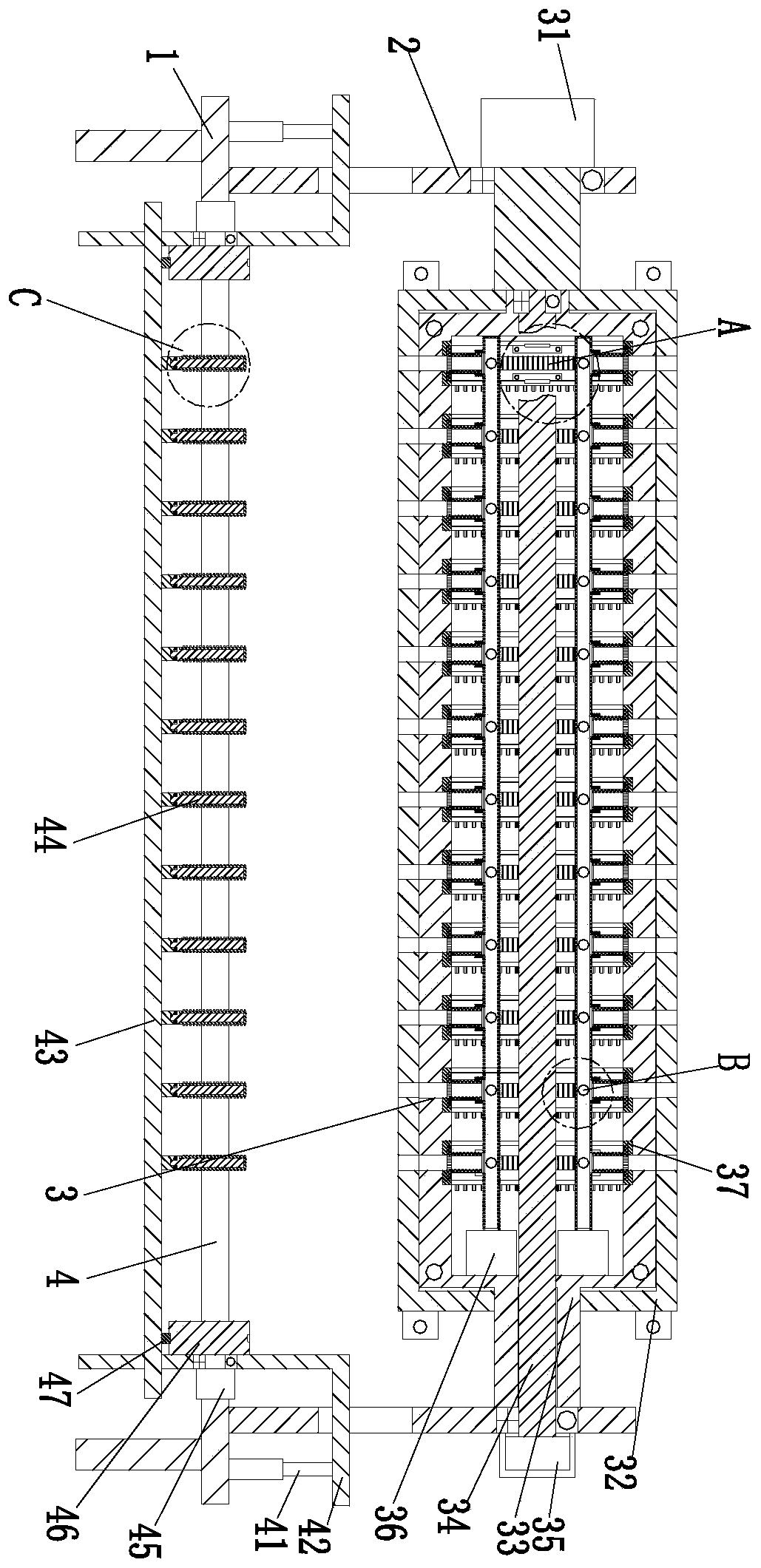

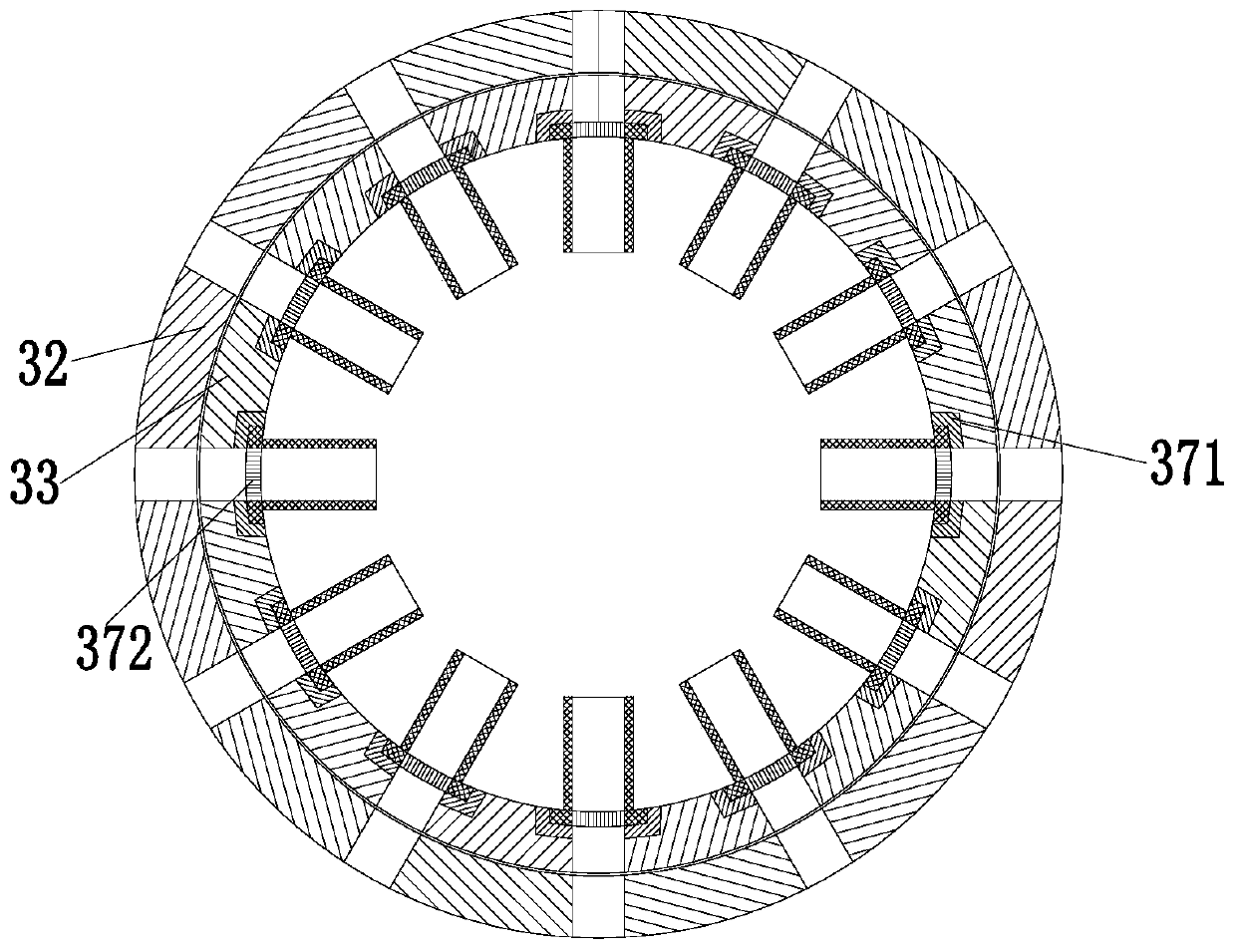

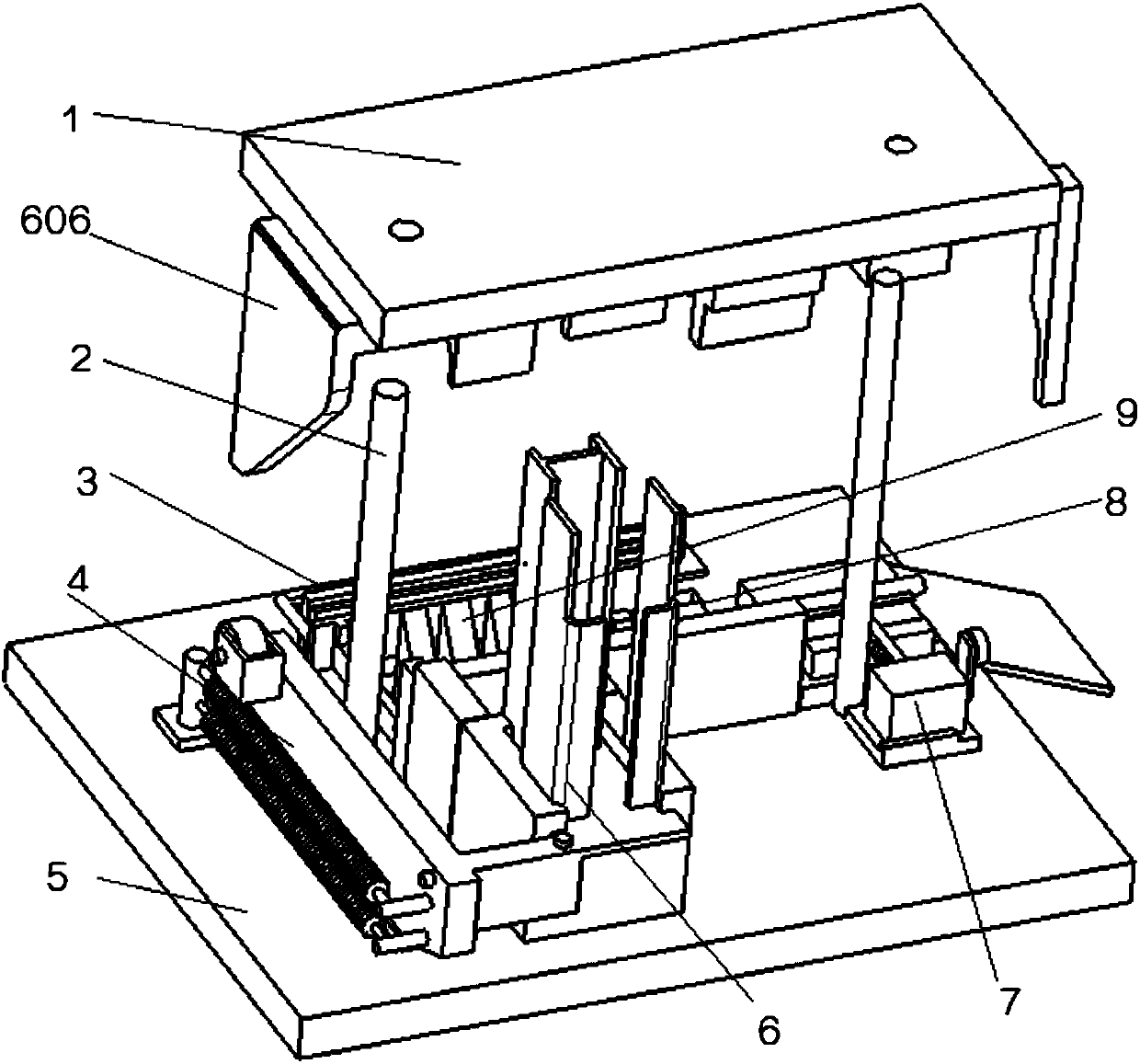

Non-woven fabric melt-blowing forming method

ActiveCN111468488ACircumstances affecting normal workGuaranteed filtering effectGas treatmentDispersed particle filtrationAir pumpElectric machinery

The invention relates to a non-woven fabric melt-blowing forming method. A roller receiving device is adopted. The roller receiving device comprises a base plate, an installing frame, a receiving roller and a cleaning mechanism. The specific method for treating a melt-blowing non-woven fabric by adopting the roller receiving device comprises the steps of polymer feeding, melt extrusion, fiber forming, net forming and roller cleaning. The receiving roller comprises a rotating motor, a rotating cylinder, an inner cylinder, a rotating rod, a driving motor, an air pump and a filter module. The filter module comprises a rotating ring, a filter cloth, a driven gear ring and a driving gear ring. The cleaning mechanism comprises a lifting air cylinder, a lifting plate, a bearing plate, a cleaningbrush, a rotating motor, a rotating cam and a connecting sliding block. The air pump and the external environment are isolated through the filter module, the phenomenon that normal work of the air pump is affected due to the fact that external impurities enter a pipeline, and the pipeline is blocked can be effectively avoided, and the surface of the receiving roller can be cleaned through the cleaning mechanism so as to ensure the receiving quality.

Owner:山东莱芬无纺布有限公司

Novel efficient circle curling device for shutter die

PendingCN107824684AImprove work efficiencyReduce processShaping toolsMetal-working feeding devicesStructural engineeringMechanical engineering

The invention provides a novel efficient circle curling device for a shutter die. The device comprises a first circle curling device body and a second circle curling device body which are placed sideby side; the first circle curling device body is a first square block, a groove is formed in the first square block, a round through hole is internally formed along the groove, a limiting block is arranged at the position, located on the edge of the groove, above the first square block, a circle curling compressing male die is arranged at the position, corresponding to the groove, of an upper dieplate, a groove is also formed in the second square block of the second circle curling device body, a round through hole is also formed inside along the groove, the upper die plate is provided with acompressing male die, and the compressing male die is provided with a folding type groove. According to the novel efficient circle curling device for the shutter die, the design forming manner of two-time circle curling forming further ensures the circle curling effect, the circle curling manner is simple in structure, forming is facilitated, cost is saved, production efficiency is improved, and product quality is improved.

Owner:TIANJIN BOLIXIN HARDWARE PROD

Water-saving cleaning platform for oversize vehicle in construction site

PendingCN108216137AEfficient collectionQuick washCleaning apparatus for vehicle exteriorsDevice PlateWater saving

The invention discloses a water-saving cleaning platform for an oversize vehicle in a construction site. The platform comprises a fixing plate, a device plate, a bearing plate and a buffer plate, wherein the top end of the fixing plate is connected to an adjusting sleeve, the device plate is connected to the other end of the adjusting rod, the bottom end of the device board is connected to a horizontal shaft, the two ends of the horizontal shaft are connected to a vertical plate, the upper end surface of the bearing plate is provided with the vertical plate, the bearing plate is provided witha water leakage port, the bearing plate is connected to the fixing plate through an reinforcing diagonal rod, a water receiving box is arranged below the bearing plate, the water receiving box is connected to a water outlet pipe, the buffer plate is arranged on an edge side of the bearing plate, and the surface of the buffer plate is provided with a non-slip strip. The water-saving cleaning platform for the oversize vehicle in the construction site has the advantages that the water after being used for cleaning the vehicle can be effectively collected, the water-saving function is better, thewashing angle can be conveniently adjusted, and the vehicle can be quickly and comprehensively flushed.

Owner:GUIZHOU UNIV

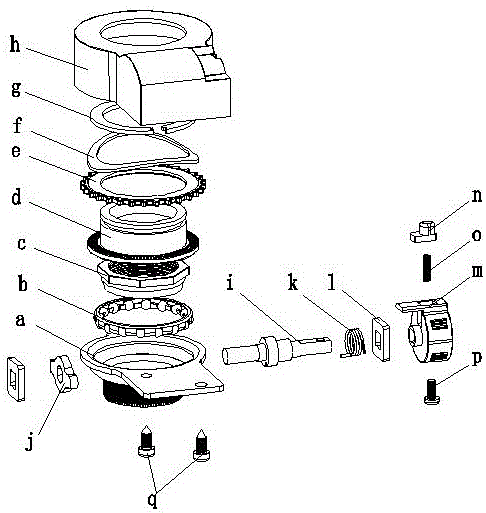

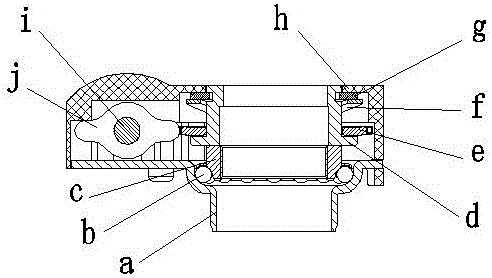

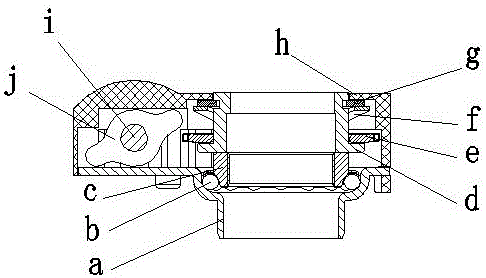

Faucet lock capable of achieving bicycle faucet direction positioning

ActiveCN106394781AAchieve positioningReasonable structureSteering deviceMechanical engineeringProtruding tooth

The invention discloses a faucet lock capable of achieving bicycle faucet direction positioning. The faucet lock comprises a shell. A tooth piece and a locking block are assembled in the shell; protruding teeth are uniformly arranged on the periphery of the tooth piece; the locking block is sleeved with the tooth piece; the lower surface of the tooth piece is provided with a tooth piece tooth face; the upper surface of an annular protrusion of the locking block is provided with a locking block tooth face matched with the tooth piece tooth face; the shell is covered with a fixing upper bowl which is internally provided with a tooth eight-corner upper plug; a ball nest is arranged between the tooth eight-corner upper plug and the fixing upper bowl; a rotary shaft placed on two supporting pieces is transversely assembled in the shell and sleeved with a torsional spring; the inner end of the rotary shaft is provided with a locking piece with the two ends provided with positioning ends; the locking piece is placed in a locking piece positioning groove of the shell; and the outer end of the rotary shaft is connected with a rotary knob. The faucet lock is reasonable in structure, convenient to assemble, safe, stable and wide in adaptable vehicle model; and by cooperation of the locking piece and the tooth piece, faucet positioning can be achieved, and the phenomenon that a bicycle body is overturned due to the fact that objects loaded on a faucet are too heavy can be effective prevented.

Owner:NINGBO JULONG MACHINERY CO LTD

Adjustable centrifugal coal washing mechanism with automatic conveying mechanism

PendingCN112676241AHigh flexibilityRealize the use of altitude and azimuthPortable framesConveyorsPhysicsElectric machinery

The invention belongs to the technical field of centrifugal coal washing, and relates to an adjustable centrifugal coal washing mechanism with an automatic conveying mechanism. The coal washing mechanism comprises a base, a cavity is formed in the base, a driving assembly is fixedly connected to the interior of the cavity, and the top of the driving assembly penetrates through the cavity and is fixedly connected with a rotating plate. The adjustable centrifugal coal washing mechanism with the automatic conveying mechanism has the beneficial effects that a driving motor in the driving assembly works to drive a driving gear and a driven gear to rotate in a meshing mode, then the rotating plate can be driven to rotate through a first rotating shaft, the purpose of adjusting the use directions of a box body and a barrel body can be achieved, and the use flexibility is high; through cooperation of all structures of the mechanism, the purposes of automatic material conveying and material transferring are achieved while the purpose of coal washing is achieved, and the use height and direction of the mechanism can be flexibly adjusted; and the whole mechanism is reasonable in structure, convenient to use and high in practicability.

Owner:杨建南

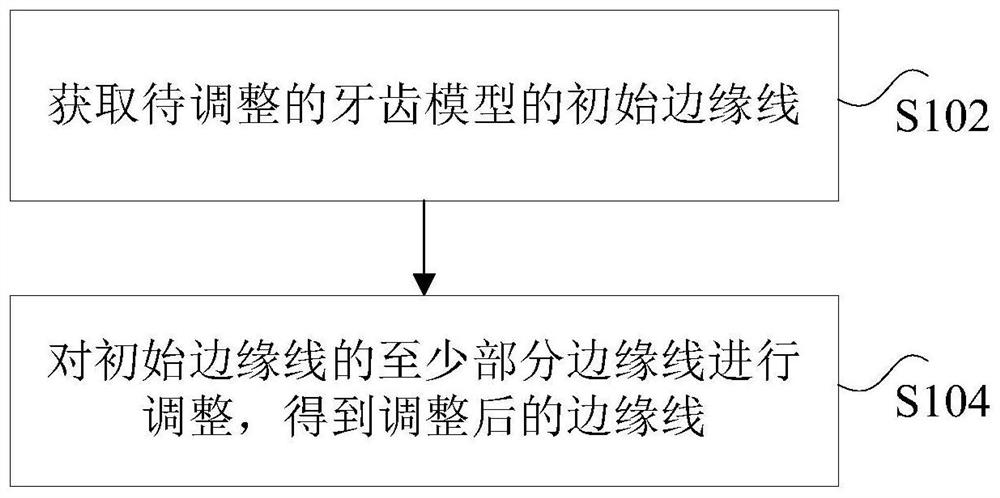

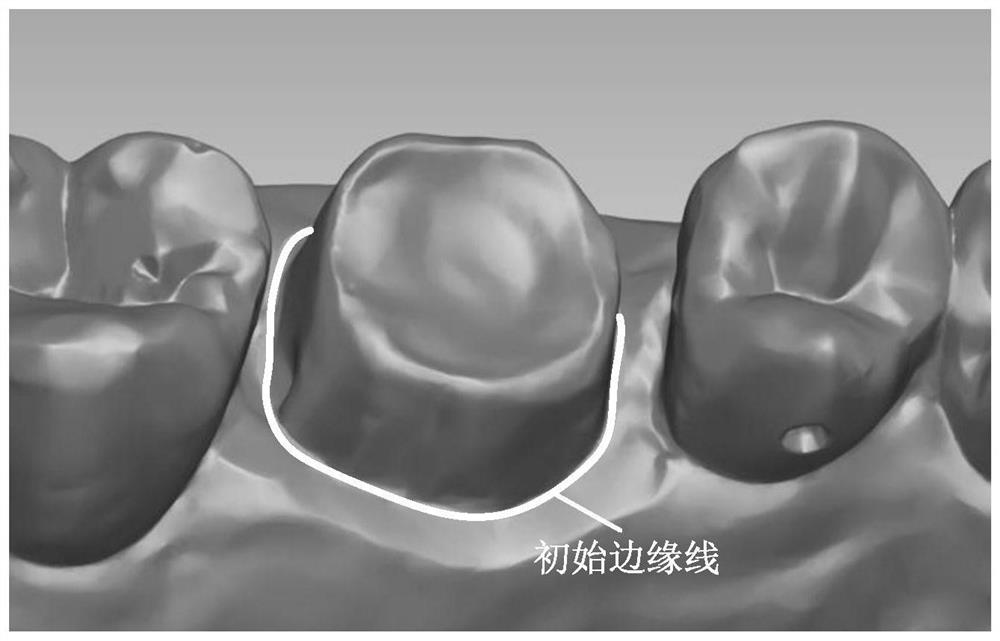

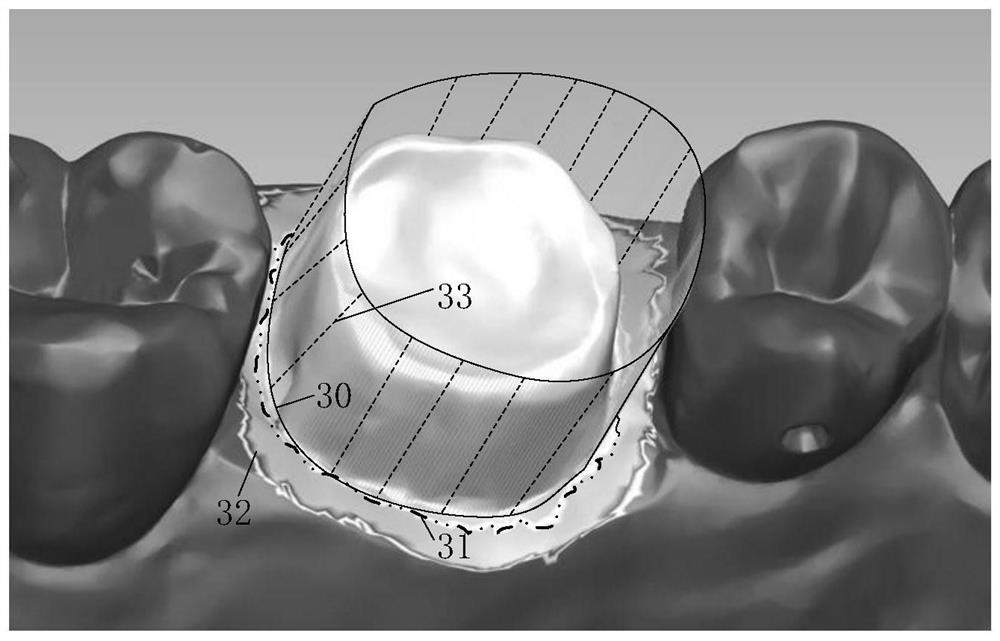

Method and device for adjusting tooth model

PendingCN112734948AImprove correction efficiencyStrong software operation abilityMedical simulationGeometric CADOral problemsBiomedical engineering

Owner:SHINING 3D TECH CO LTD

Tilting iron adjusting device in vertical lathe rotation sliding seat

The invention belongs to the technical field of lathe machining and aims at providing a tilting iron adjusting device in a vertical lathe rotation sliding seat. The tilting iron adjusting device comprises a rotation sliding seat body, a ram and a piece of tilting iron located between the rotation sliding seat body and the ram, and is characterized in that an adjusting bolt is fixed to the top of the rotation sliding seat body, a supporting sleeve is arranged on the adjusting bolt, an upper adjusting nut and a lower adjusting nut are arranged on the adjusting bolt bodies at the top and the bottom of the supporting sleeve respectively, and the supporting sleeve is clamped by the upper adjusting nut and the lower adjusting nut and fixedly connected with the tilting iron. The tilting iron adjusting device is simple in structure, convenient to operate and capable of effectively improving the machining accuracy of a lathe.

Owner:RONGCHENG METAL FORMING MACHINE GROUP

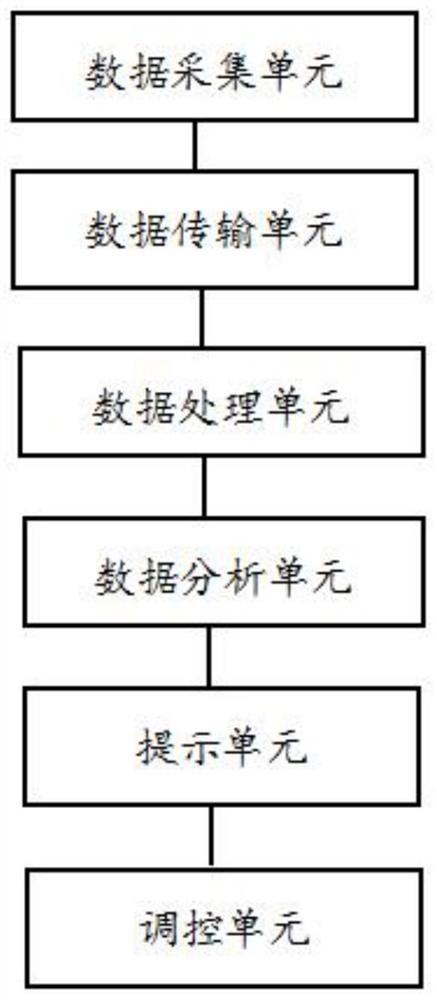

Poultry breeding management system

InactiveCN112506985AImprove environmental conditionsAchieve the purpose of adjustmentRelational databasesResourcesBiotechnologyFarming environment

The invention discloses a poultry farming management system, which utilizes a data acquisition unit to acquire growth information and farming environment information of poultry, and utilizes a data processing unit to receive and process the growth information and the environment information to obtain growth processing information and environment processing information. The growth migration value and the environment adaptation value in the data processing information are analyzed by using a data analysis unit to obtain growth analysis data and environment analysis data, and growth analysis dataand the environment analysis data are received and processed by using a prompt unit to generate growth prompt data and environment prompt data; a regulation and control unit is used for managing thegrowth of the poultry and managing the breeding environment; various aspects disclosed by the invention are used for solving the problems that in an existing scheme, different poultry breeding cannotbe adjusted according to the growth conditions of poultry, the breeding environment cannot be monitored and analyzed, and the breeding conditions cannot be adjusted.

Owner:淮南天陈农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com