Label production equipment

A technology for production equipment and labels, applied to cardboard items, etc., can solve problems such as difficulties and achieve the effect of convenient attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

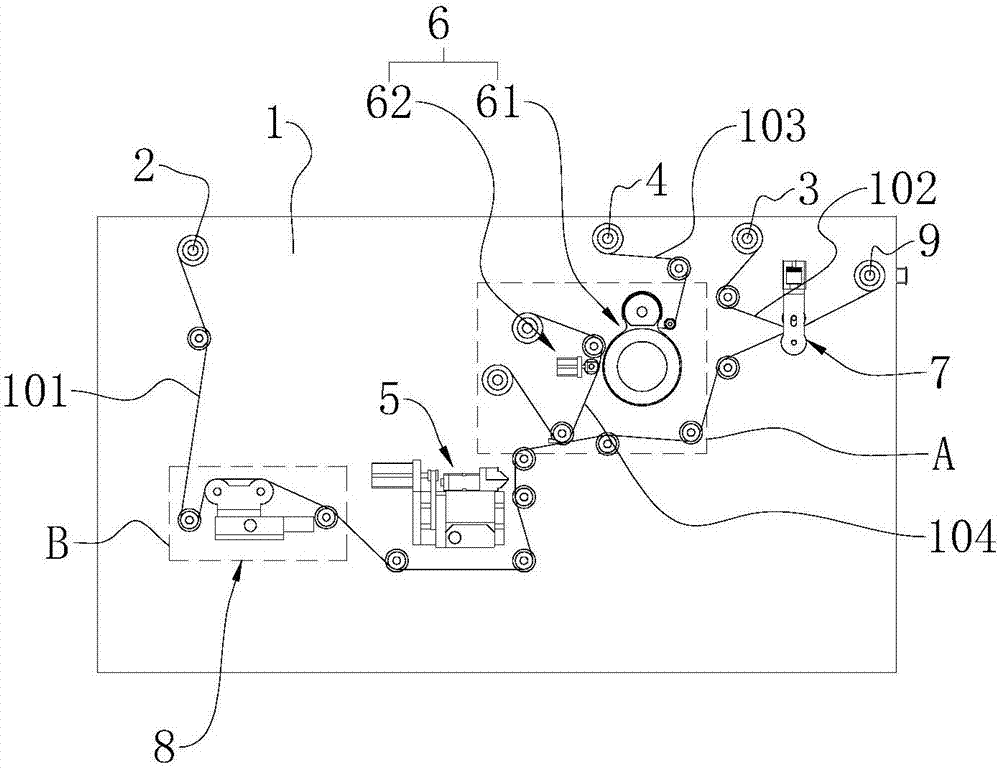

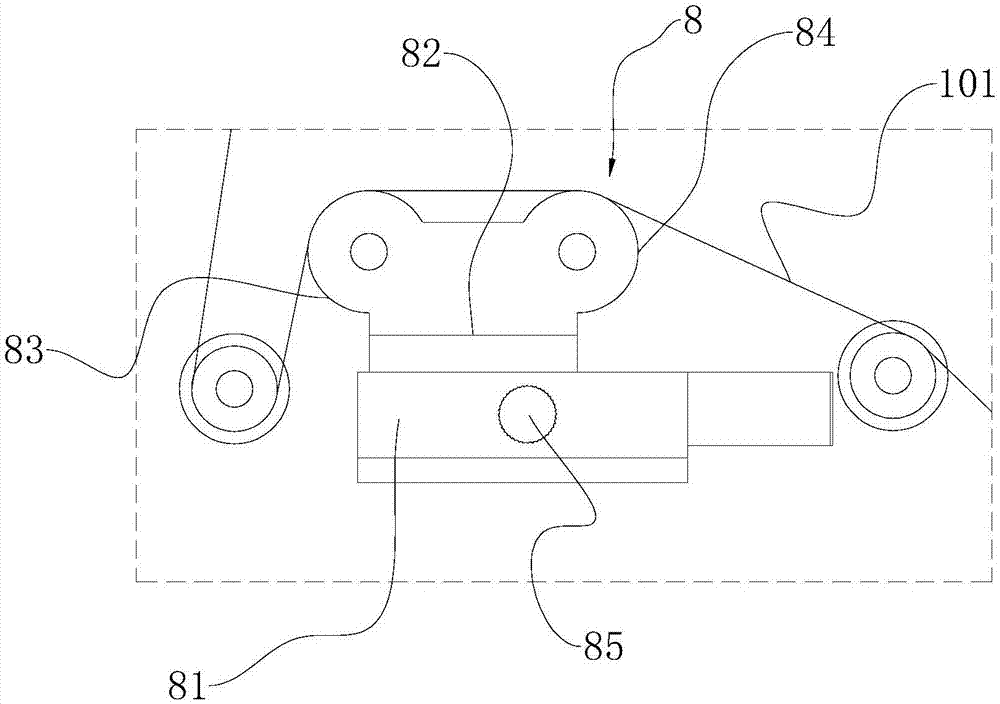

[0037] Embodiment 1: a kind of label production equipment, such as figure 1 As shown, it is used to place the anti-counterfeiting chip between two layers of paper and carry out pressure bonding, which includes a frame 1 and a surface layer unwinding roller 3 and a bottom layer unwinding roller 2 all installed on the frame 1 , anti-counterfeit chip unwinding roller 4, gluing device 5, anti-counterfeit chip cutting and transferring device 6 and composite device 7. The bottom unwinding roller 2 releases the bottom paper layer 101, and the bottom paper layer 101 passes through the glue coating device 5, the anti-counterfeit chip cutting and transfer device 6, and the composite device 7 in turn, and finally enters the winding device 9 for winding Work.

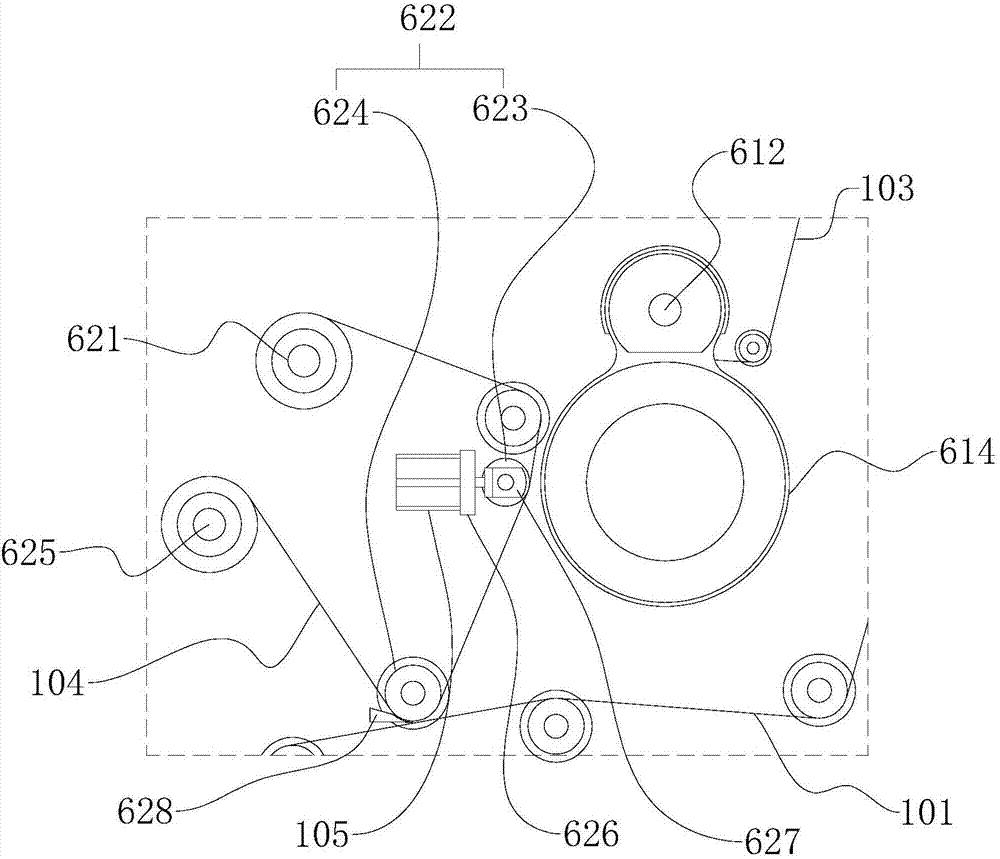

[0038] Wherein, the gluing device 5 performs gluing on the bottom paper layer 101 . The anti-counterfeit chip cutting and transfer device 6 cuts the anti-counterfeit chip tape 103 released by the anti-counterfeit chip unwinding r...

Embodiment 2

[0046] Embodiment 2: A label production equipment, its structure is basically the same as that of Embodiment 1, the difference lies in the setting of the transfer mechanism 62 . Such as Figure 9 As shown, the transfer mechanism 62 includes a transfer-in roller 630 and a transfer-out roller 631, the bottom paper layer 101 is directly entered by the transfer-in roller 630 and exported from the transfer-out roller 631, and the bottom paper layer 101 is directly connected to the adsorption The roller 614 is tangent, so that the bottom paper layer 101 can directly attach the single anti-counterfeit chip after cutting, and glue it through the glue on the bottom paper layer 101 to complete the transfer of the single anti-counterfeit chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com