Barrel close mouth fixture

The technology of a clamp and a cylinder body is applied in the field of clamps for the cylinder body to be closed after being rolled by a plate rolling machine, which can solve the problems of poor cylinder body quality, low production efficiency, and difficulty in adjustment, so as to improve production efficiency and facilitate adjustment. , high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

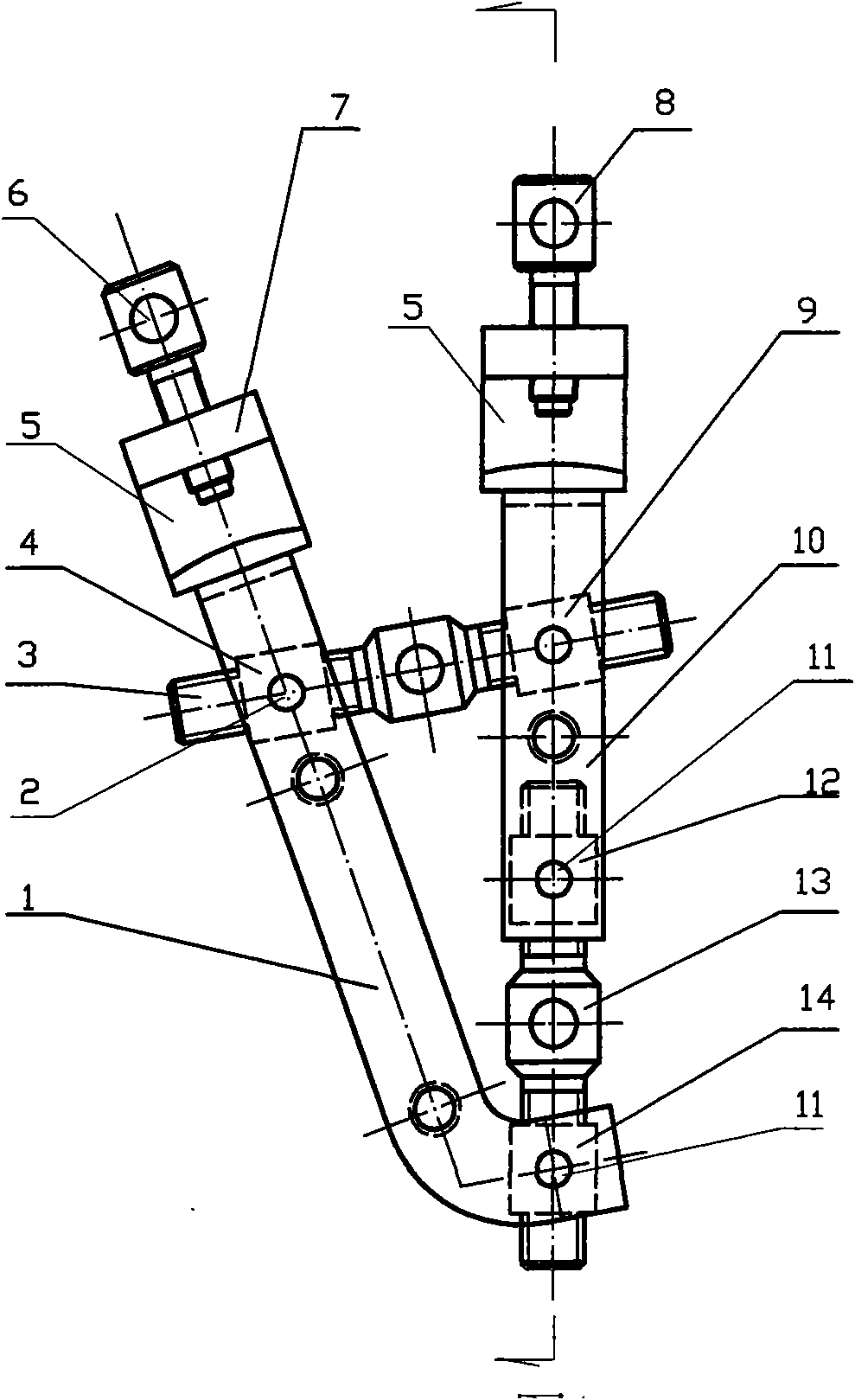

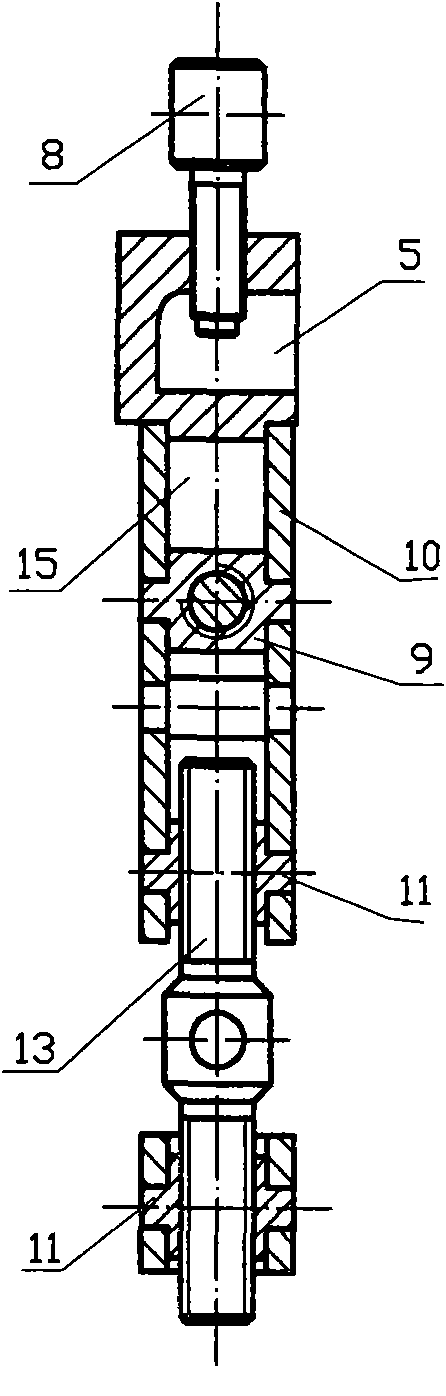

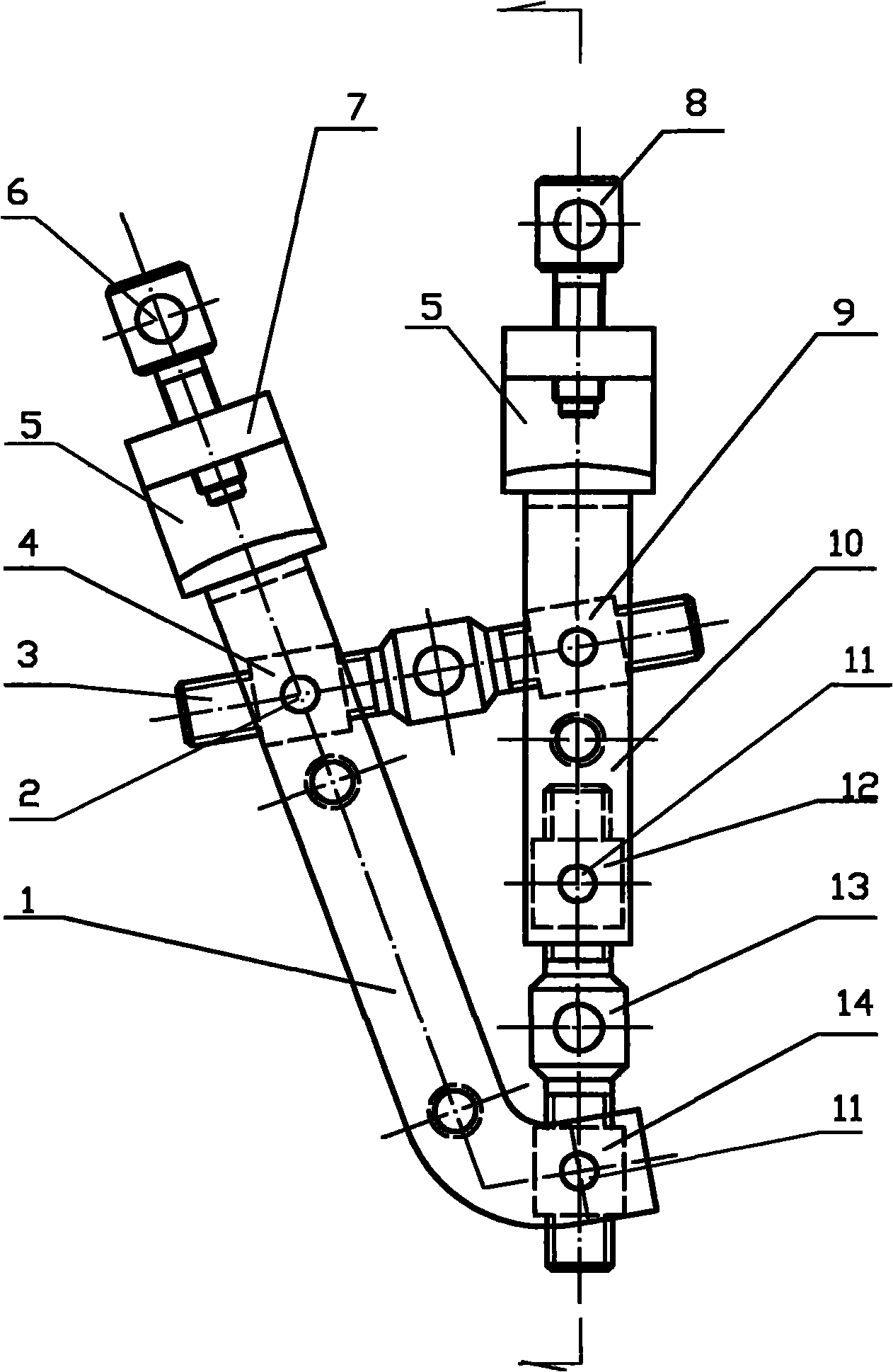

[0012] Cylinder closing fixture of the present invention, as figure 1 , figure 2 As shown, it includes an "L"-shaped left bracket 1, a right bracket 10 that is rotatably connected to one end of the left bracket 1, and a closing screw mechanism and a height adjusting screw mechanism that are connected between the two brackets to push the two brackets to open and close. The centers of the left bracket 1 and the right bracket 10 are axial holes.

[0013] The closing screw mechanism includes a closing screw 3 with opposite screw teeth at both ends and a left-handed nut 4 and a right-handed nut 9 which are adapted to form a screw mechanism with the two ends of the screw 3, and the left-handed nut 4 and the right-handed nut 9 are respectively located in the axial holes of the left bracket 1 and the right bracket 10, the corresponding positions of the left bracket 1 and the right bracket 10 are respectively provided with radial holes, and the left-handed nut 4 and the right-handed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com