Non-woven fabric melt-blowing forming method

A technology of melt-blown molding and non-woven fabrics, applied in the direction of separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as difficult operation, pipeline blockage, and reduced factory quality, so as to ensure the quality of reception and ensure The effect of the filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

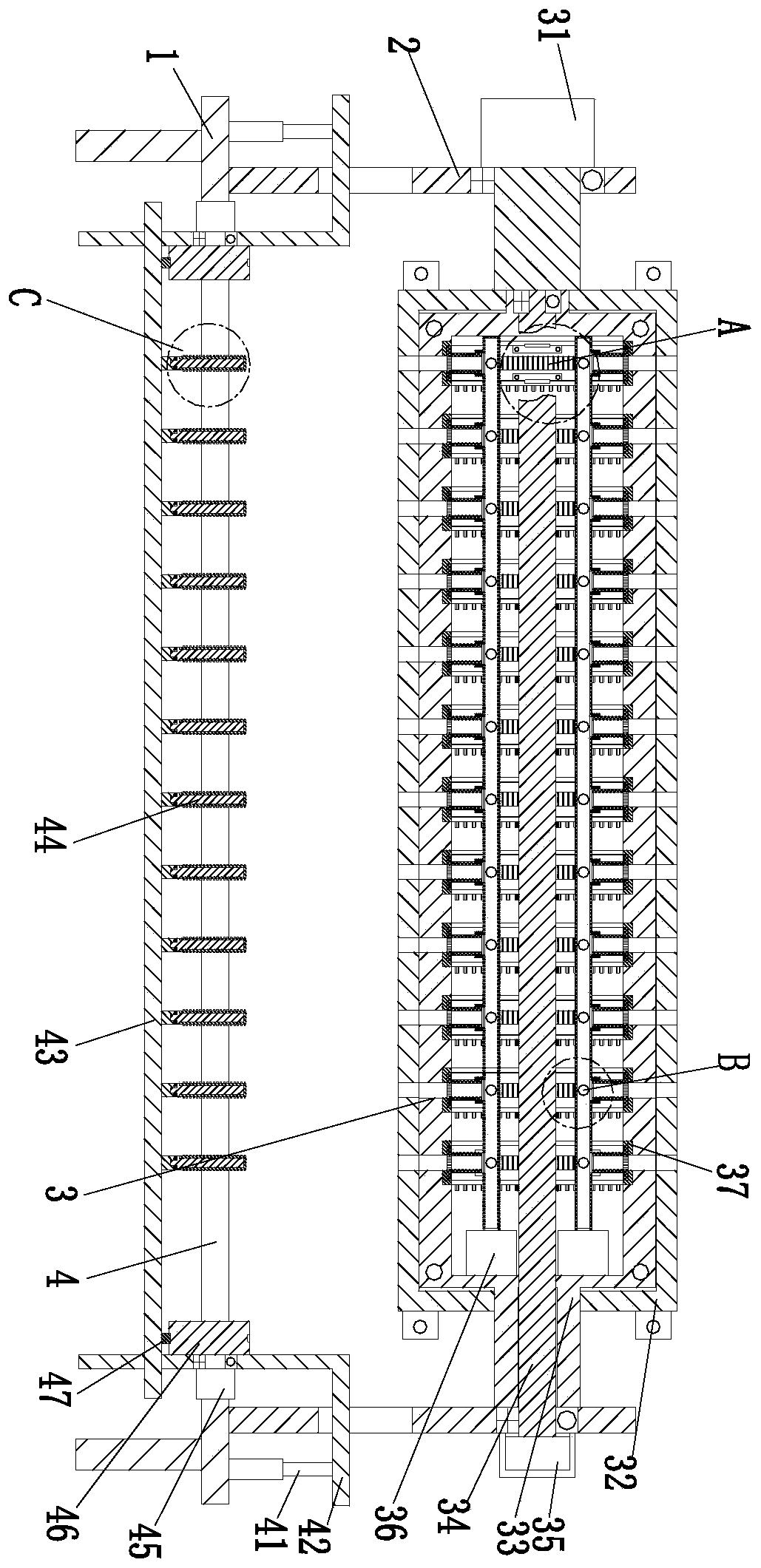

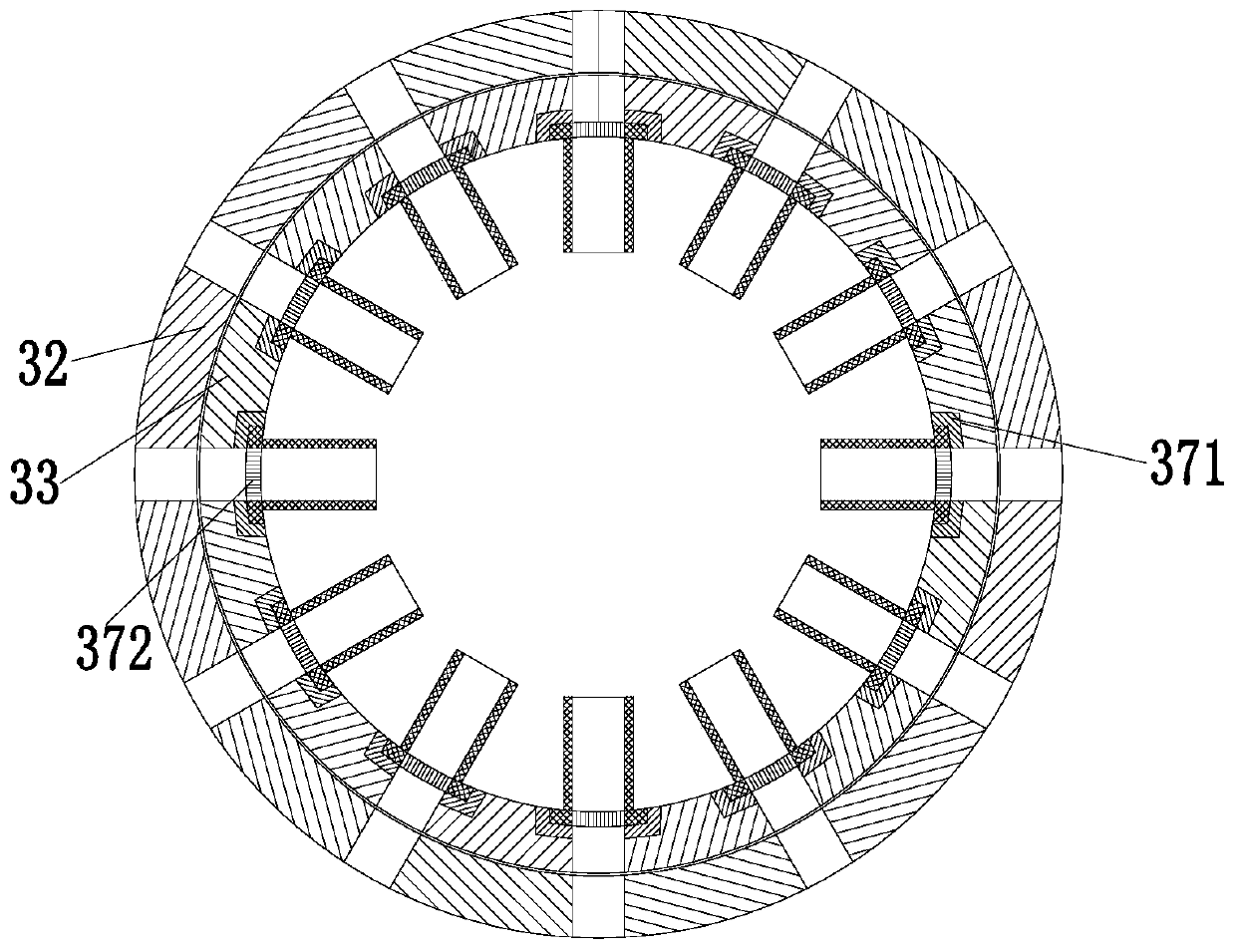

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

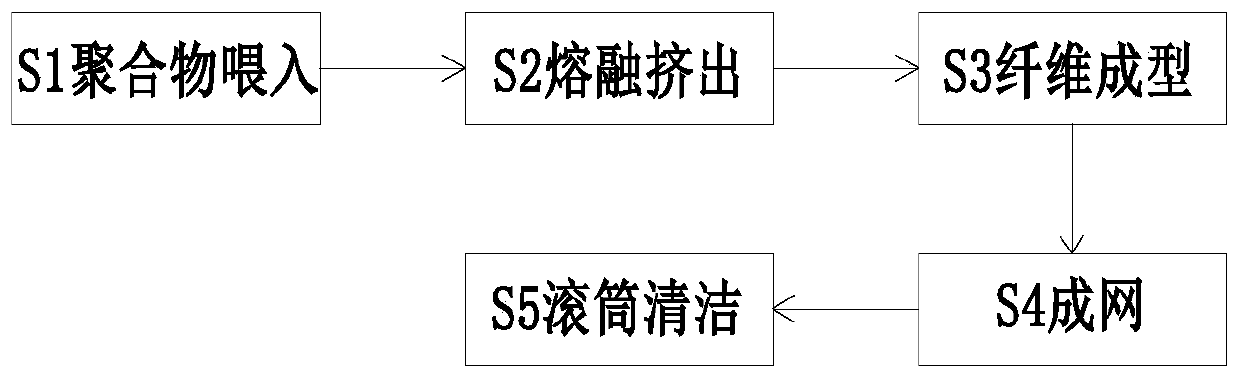

[0036] Such as Figure 1 to Figure 6 As shown, a non-woven fabric melt-blown forming method uses a roller receiving device, which includes a bottom plate 1, a mounting frame 2, a receiving roller 3 and a cleaning mechanism 4, and adopts the above-mentioned roller receiving device to clean the melt-blown The specific method of non-woven fabric processing is as follows:

[0037] S1. Polymer feeding: the polymer chips are fed into the existing screw extruder hopper by the existing feeder;

[0038] S2. Melt extrusion: heat and shear the polymer slices through the existing screw extruder, and extrude the molten polymer;

[0039] S3. fiber molding: make the melt-blown non-woven fabric limit by the existing melt-blown die head assembly;

[0040] S4. net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com