Woodworking lathe capable of automatically adjusting position of turning tool tray

A woodworking lathe, automatic adjustment technology, applied to woodworking lathes, wood processing equipment, manufacturing tools, etc., can solve the problems of turning tool tray deflection, inconvenient use, lathe vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] as attached figure 2 To attach Image 6 Shown:

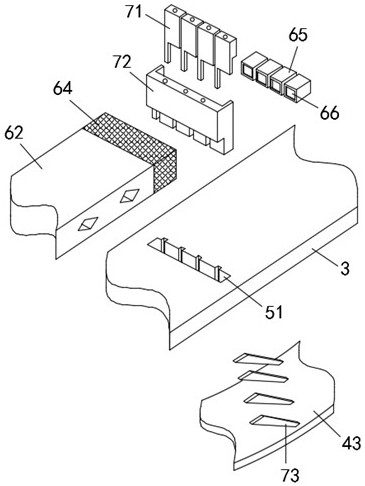

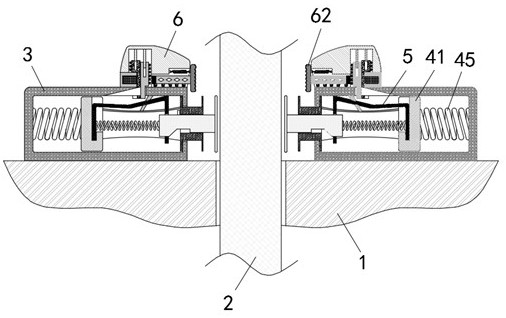

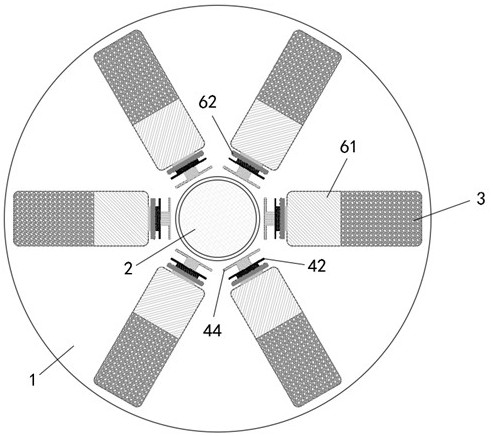

[0031] Including the lathe body 1 and the pallet part 2, the front of the lathe body 1 and the outer side of the pallet part 2 are fixedly installed with evenly distributed fixed seats 3, and the inner part of the fixed seat 3 is equipped with a detection assembly 4, and the detection assembly 4 is installed with elastic Sheet 5, the top of the fixed seat 3 is equipped with a correction assembly 6, the correction assembly 6 includes a support 61, a strike plate 62 and a metal box 65, the strike plate 62 is fixedly connected with a driven magnetic block 64, and the interior of the metal box 65 is fixedly installed There is a driving magnetic block 66, and a metal cover plate 7 is movably installed between the metal box 65 and the driven magnetic block 64.

[0032] Further, the detection assembly 4 includes a slider 41 slidably installed inside the fixed seat 3, and one end of the fixed seat 3 close to the tray part 2 is...

Embodiment 2

[0040] as attached figure 1 To attach Image 6 Shown:

[0041] The present invention provides a woodworking lathe capable of automatically adjusting the position of the turning tool tray, comprising a lathe main body 1 and a pallet part 2, the front of the lathe main body 1 and the outer side of the pallet part 2 are fixedly installed with evenly distributed fixing seats 3, the fixing seats 3 The internal activity of the detection assembly 4 is installed, and the elastic sheet 5 is installed on the detection assembly 4. The correction assembly 6 is installed on the top of the fixed seat 3. The correction assembly 6 includes a support 61, a strike plate 62 and a metal box 65. On the strike plate 62 A driven magnetic block 64 is fixedly connected, a driving magnetic block 66 is fixedly installed inside the metal box 65 , and a metal cover plate 7 is movably installed between the metal box 65 and the driven magnetic block 64 .

[0042] Further, the detection assembly 4 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com