A gluing positioning device for a packaging box gluing machine

A positioning device and box glue coating technology, which is applied to the surface coating liquid device, coating, etc., to achieve the effects of convenient use, reduced error rate, and accurate glue coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

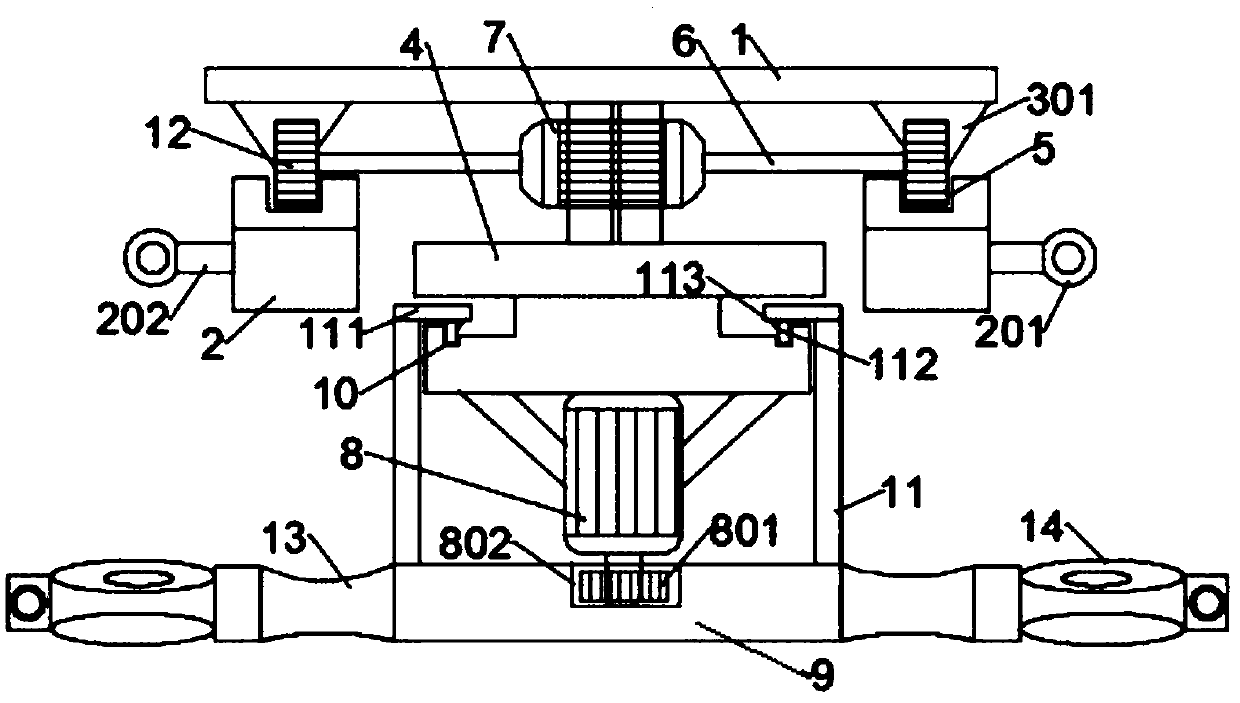

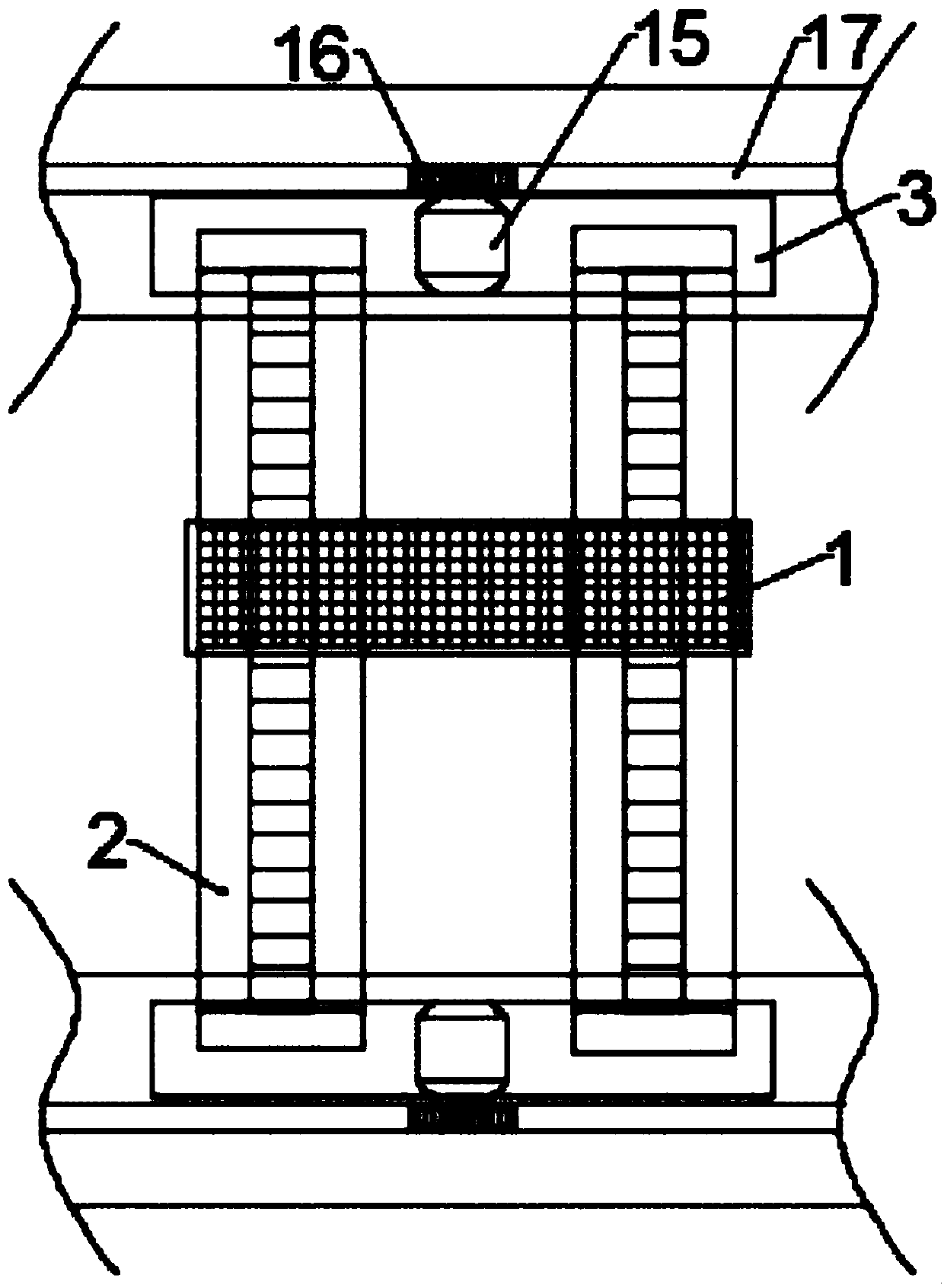

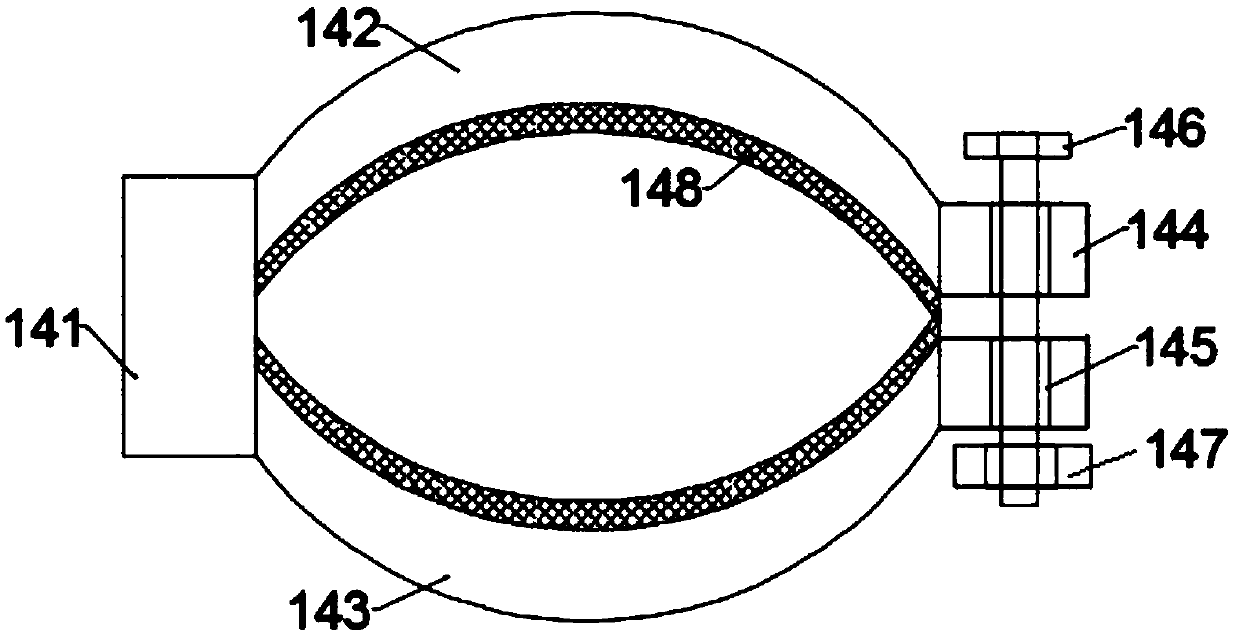

[0025] Such as figure 1 with figure 2 As shown, the present invention provides a gluing positioning device of a packaging box gluing machine, including a positioning plate 1, a positioning beam frame 2 and a positioning longitudinal beam frame 3, wherein the positioning beam frame 2 and the positioning longitudinal beam frame 3 The number is two, and the positioning plate 1 is arranged between two positioning beam frames 2, so that the positioning plate 1 is evenly stressed between the two positioning beam frames 2, and the two positioning longitudinal beam frames 3 can make positioning The beam frame 2 moves longitudinally in a balanced and orderly manner, and a limited tube ring 201 is arranged on one side of the positioning beam frame 2, and the tube limiting ring 201 is fixedly installed on the side surface of the positioning beam frame 2 through a limit rod 202, which can The rubber supply hose is effectively restricted to prevent the rubber supply hose from affecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com