Adjustable centrifugal coal washing mechanism with automatic conveying mechanism

An adjustable and automatic technology, applied to the frame of the engine, the conveyor, the supporting machine, etc., can solve the problems of low flexibility, low efficiency, and single function, and achieve high flexibility, reasonable device structure, and realization of Effects Using Altitude and Azimuth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

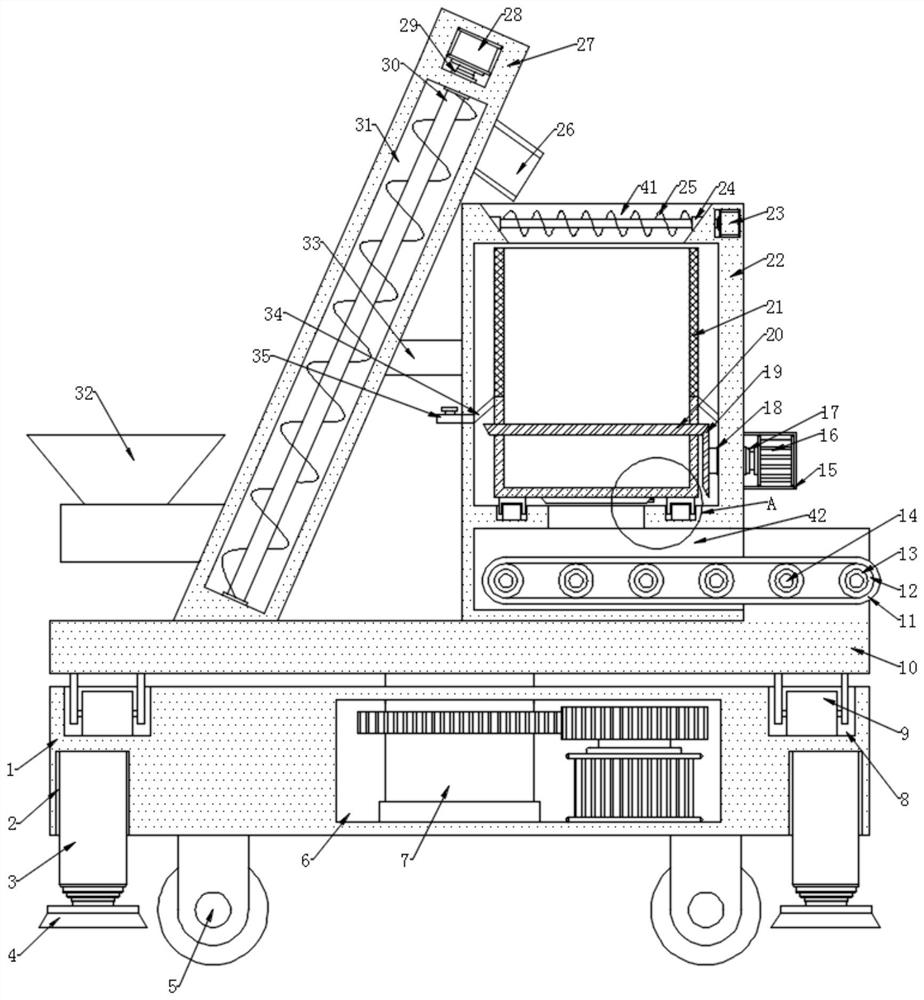

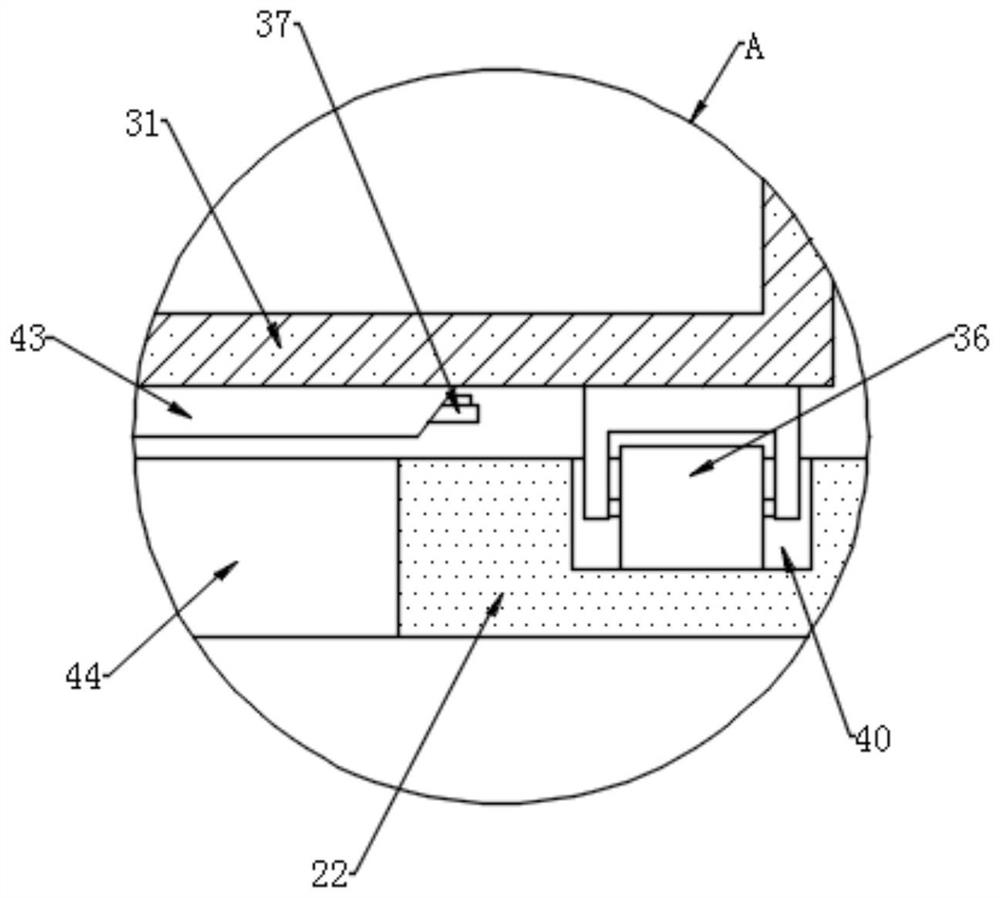

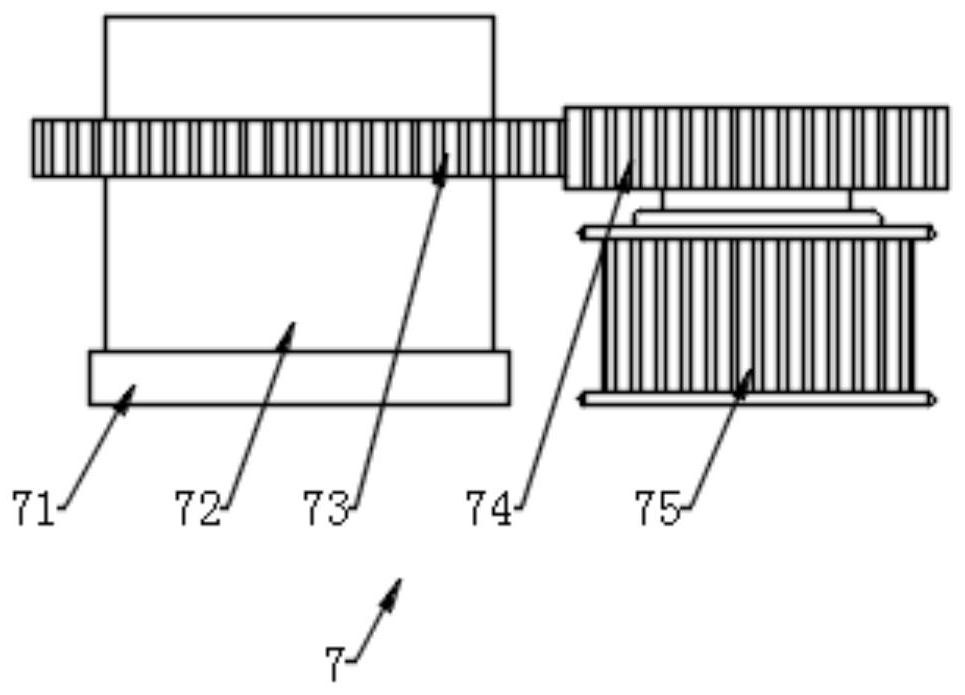

[0030] see Figure 1-6 , the present invention provides the following technical solutions: an adjustable centrifugal coal washing mechanism with an automatic feeding mechanism, including a base 1, a cavity 6 is opened inside the base 1, a drive assembly 7 is fixedly connected to the inside of the cavity 6, and the drive assembly 7 The top passes through the cavity 6 and is fixedly connected with the rotating plate 10. The driving assembly 7 includes a driving motor 75, a first bearing 71, a first rotating shaft 72, a driving gear 74 and a driven gear 73. Both the driving motor 75 and the first bearing 71 Fixedly connected to the bottom of the inner wall of the cavity 6, the output shaft of the driving motor 75 is fixedly connected with the driving gear 74, the first bearing 71 is pierced with the first rotating shaft 72, and the surface of the first rotating shaft 72 is fixedly connected with the driven gear 73 , the surfaces of the driving gear 74 and the driven gear 73 are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com