Blocked stack system for sheet positioning and paging and method thereof

A stacking system and paging technology, which is applied in the field of paper positioning and paging stacking system, can solve the problems of high, usually every 8-10 minutes, paper factory waste, etc., to achieve high degree of automation, easy to use and operate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

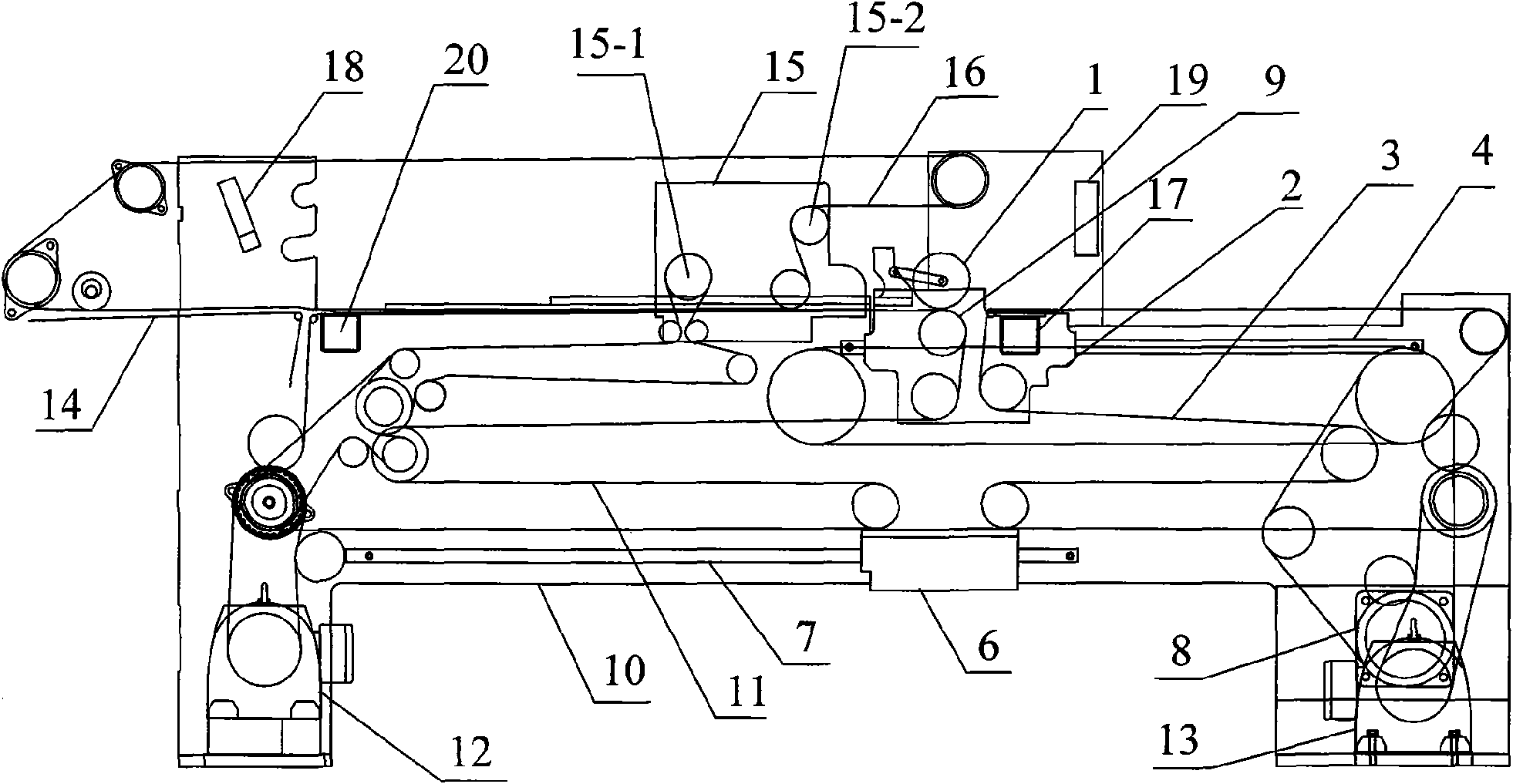

[0036] Such as figure 1 As shown, the paper positioning and paging stacking system of the present invention includes a frame 10, a controller 19, a counter 18 installed on the left upper part of the frame 10, an upper pressing belt 16 installed on the top of the frame 10, respectively Installed on the left and right sides of the frame 10 and all clockwise rotating low-speed conveyor belt one 11 and low-speed conveyor belt two 3 and power motor one 12 and power motor two 13 for the low-speed conveyor belt one 11 and low-speed conveyor belt two 3 to provide power respectively. The upper horizontal section of the low-speed conveyor belt 11 and the upper horizontal section of the low-speed conveyor belt 2 3 form a paper conveyor belt that is connected and conveyed from left to right. 3. The right end of the upper horizontal section is the paper output section. The right end of the upper horizontal section of the low-speed conveyor belt 11 and the left end of the upper horizontal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com