Transfer device

A technology for transferring equipment and bonding glue, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., and can solve the problem that LEDs cannot be transferred to display backplanes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the present invention is not limited to the following specific embodiments.

[0033] At present, in the transfer process of LED chips, in order to facilitate the receiving of LED chips, the surface of the temporary substrate is usually provided with an adhesive layer with high adhesion. However, when transferring the LED chips from the temporary substrate to the display backplane, too high Adhesive force will cause some LED chips to be adhered to the adhesive layer, resulting in transfer failure.

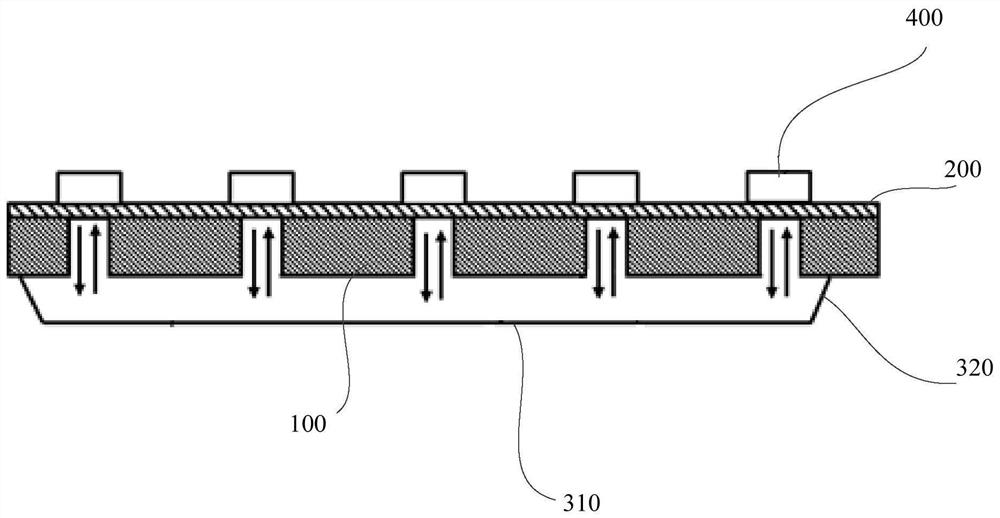

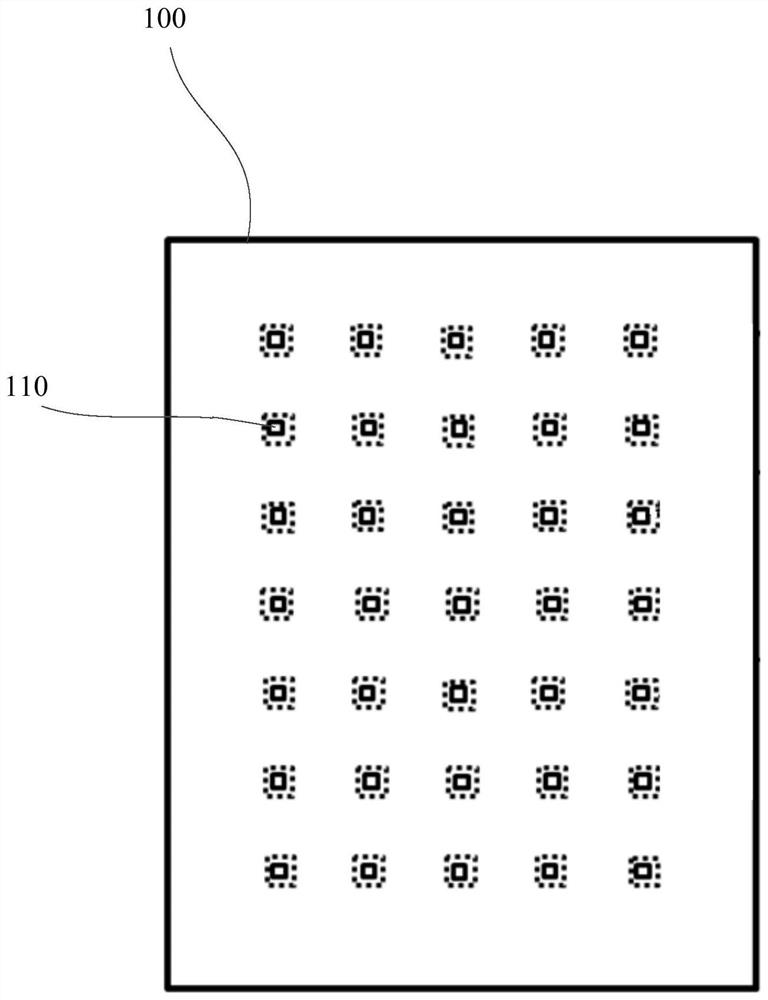

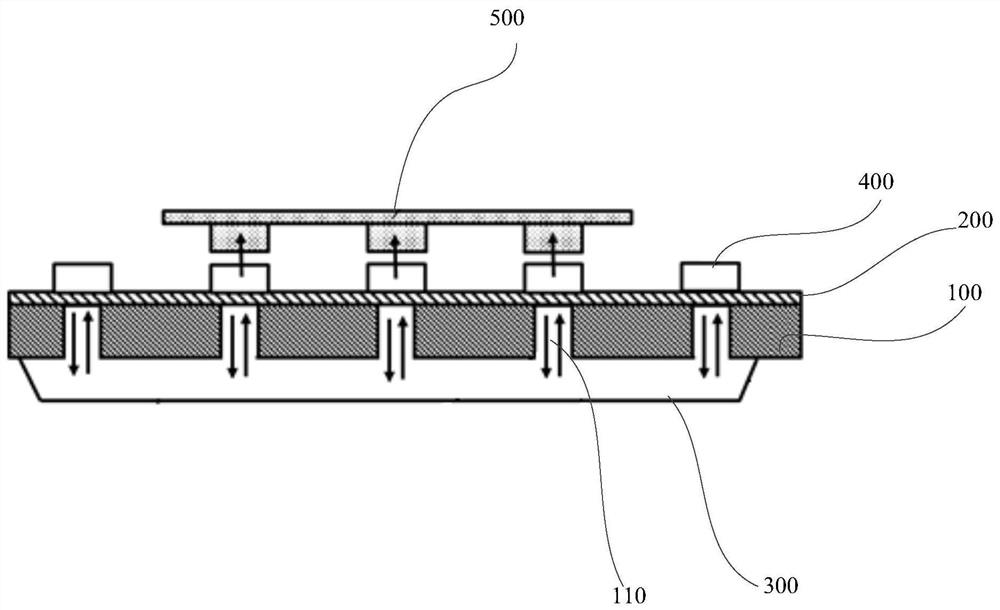

[0034] figure 1 It is a structural schematic diagram of the transfer device of the present invention; figure 2 for figure 1 Schematic diagram of the structure of the temporary substrate; image 3 It is a schem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com