Processing device for dip-coating waterproof rolls

A processing device and technology of waterproof membrane, applied in textiles and papermaking, etc., can solve the problems of stretching narrowing or breaking of the tire base fabric, easy longitudinal tearing of the tire base fabric, and large energy consumption, so as to reduce the accumulation , Avoid large area scratches, reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

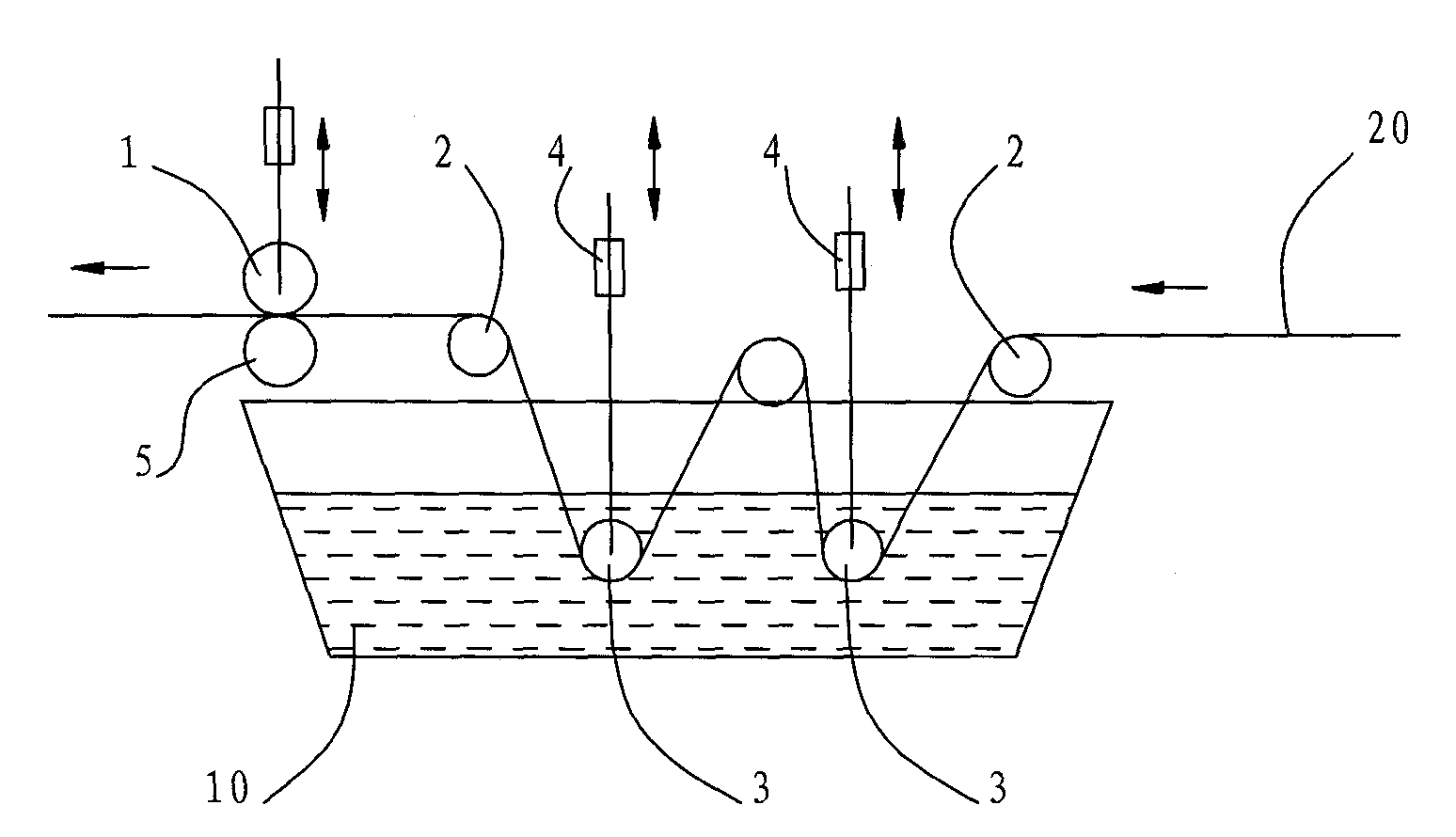

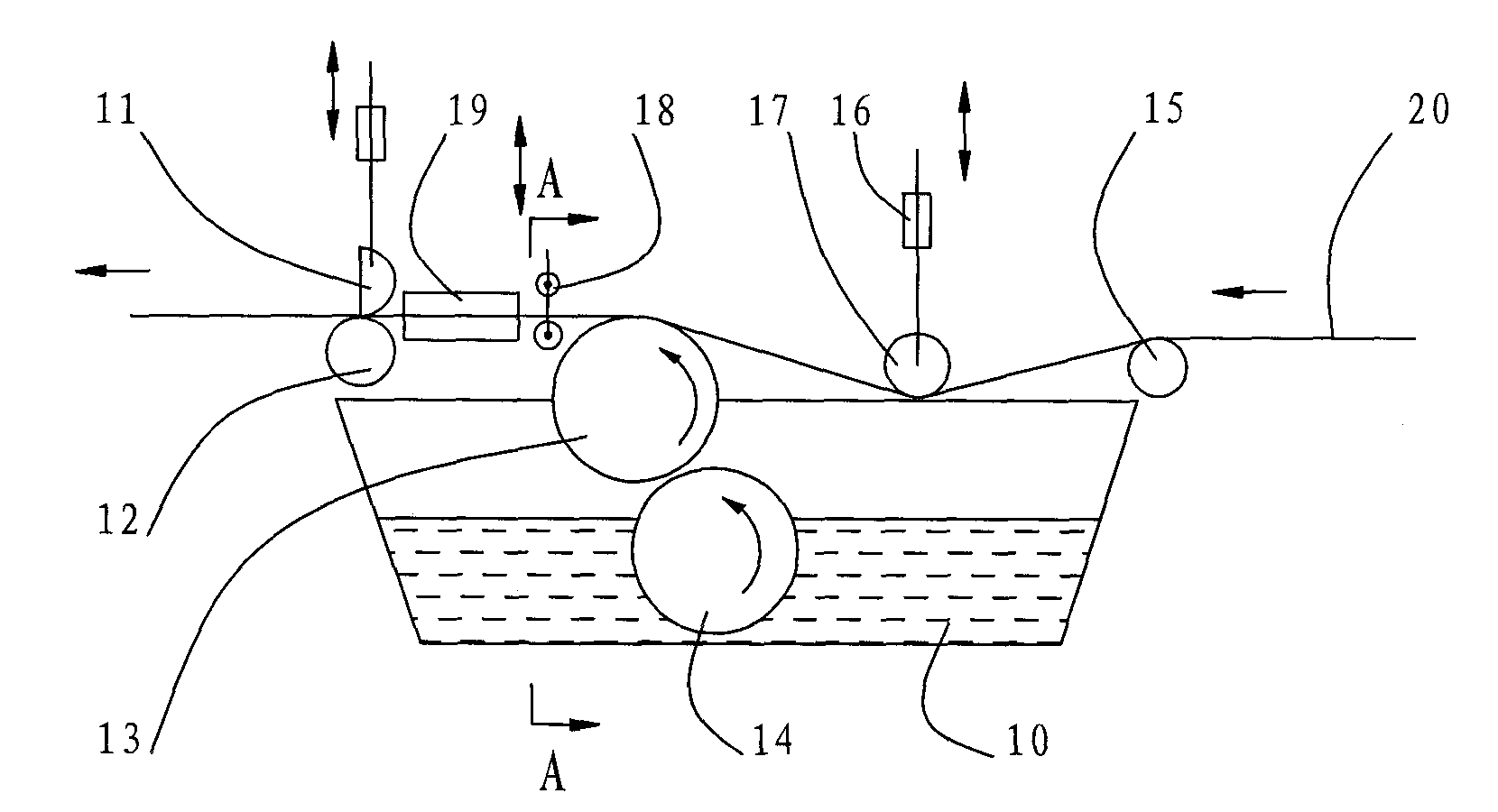

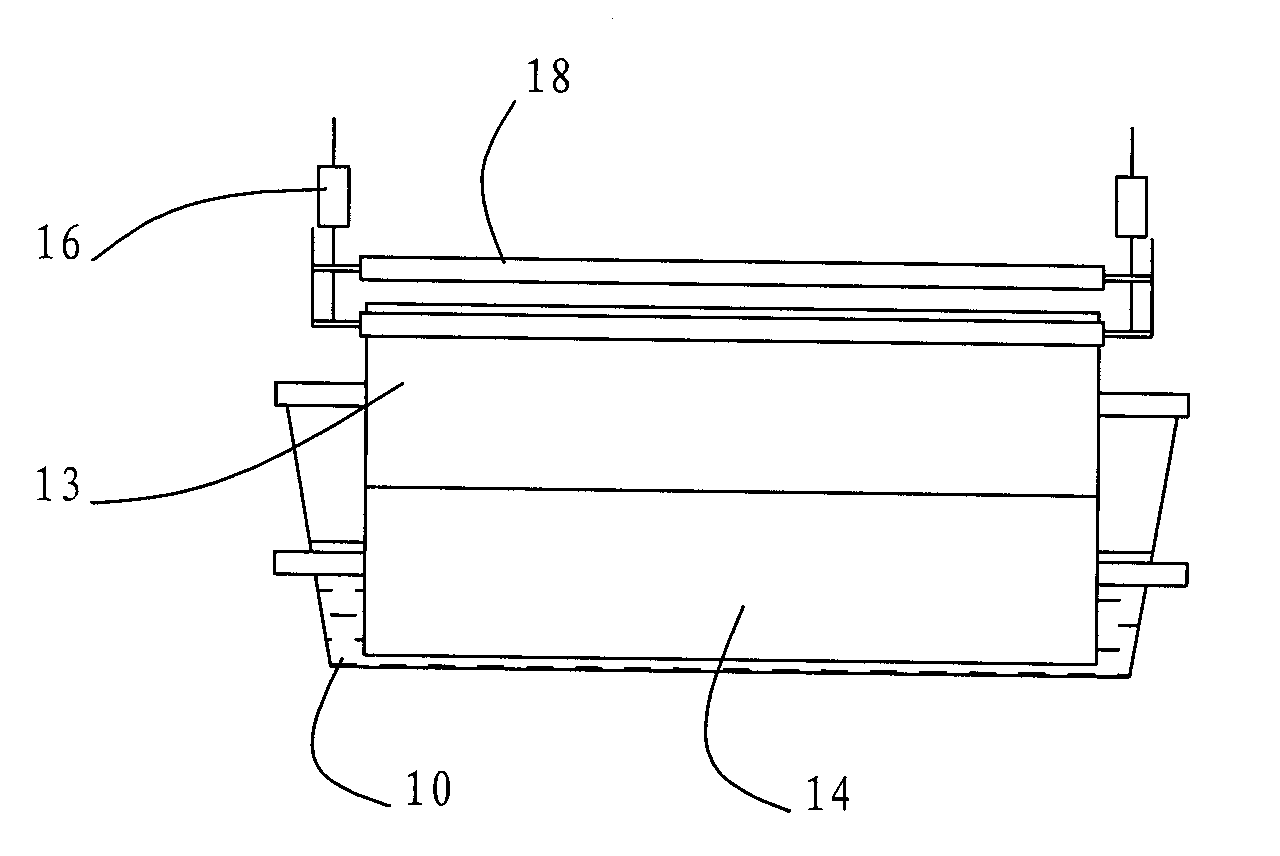

[0030] see Figure 1-Figure 5 , the waterproof coiled material dip coating processing device comprises a material pool 10 and a base cloth 20, the material pool 10 is filled with paint, the side wall of the material pool 10 and / or the bottom of the material pool 10 is provided with a heating mechanism, and the base cloth is Polyester base fabric, fiberglass base fabric, composite base fabric, PE base fabric, EVA base fabric or PVC base fabric.

[0031] The material tank 10 is provided with a pair of material transfer rollers composed of an upper belt material roller 13 and a lower belt material roller 14. The upper belt material roller 13 is positioned above the coating, and the lower belt material roller 14 is partly soaked in the coating. The roller 13 and the lower belt roller 14 rotate in the same direction or reversely, and the paint is transferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com