Insulation operating platform for isolation switch

A technology for operating platforms and isolating switches, applied to switchgear, electrical components, etc., can solve the problems of ineffective protection, time-consuming and labor-intensive, frequent movement of insulating operating platforms, etc., to save wasted time and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

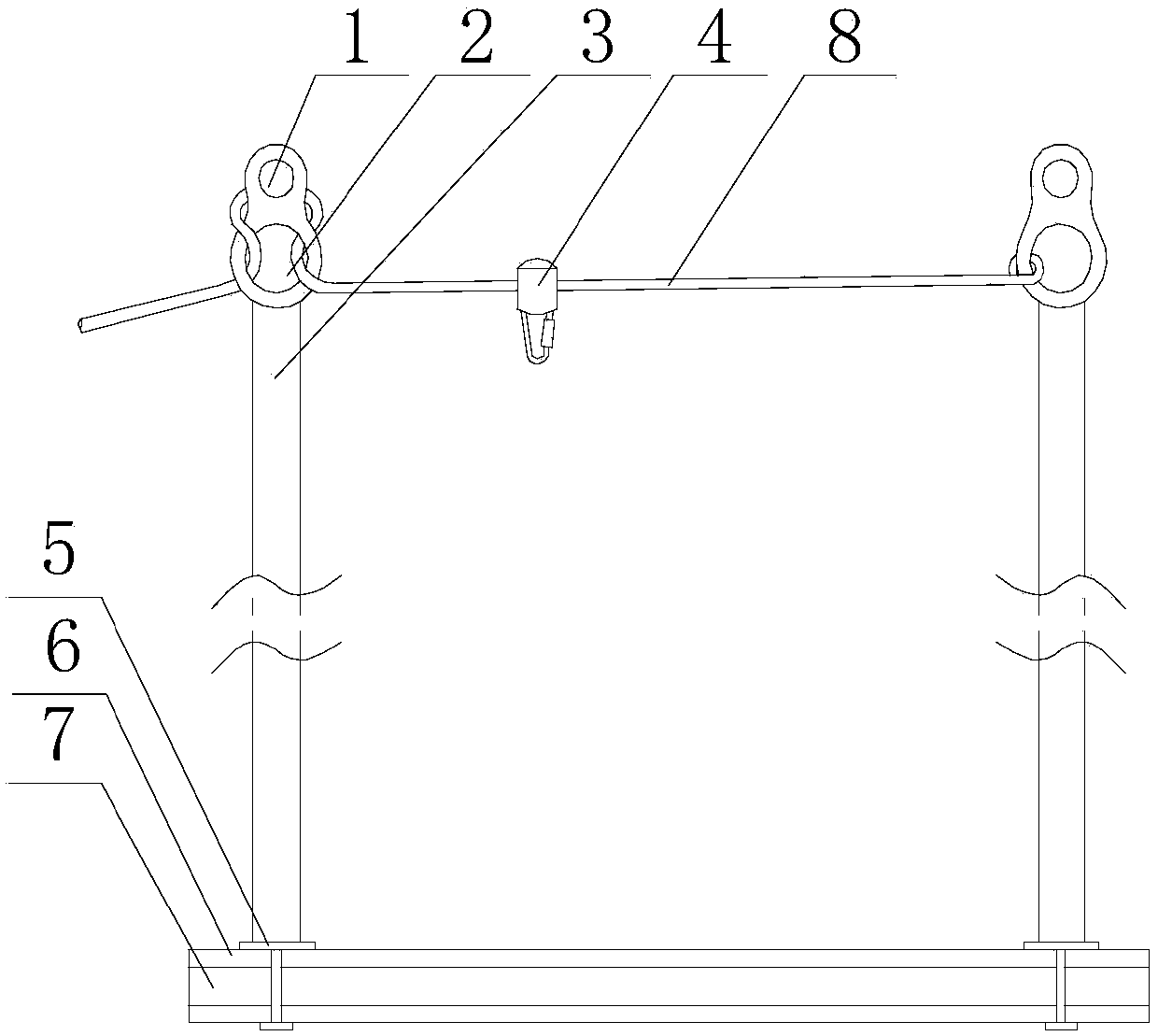

[0025] Such as figure 1As shown, the present embodiment includes two bases 5, an insulating support rod 3 is fixed on the upper end surface of each of the bases 5, and a fixed block is arranged on the upper end of the support rod 3, along the axis of the support rod 3 A small hole 1 and a large hole 2 are sequentially opened on the fixed block from top to bottom. The axis of the small hole 1 is parallel to the axis of the large hole 2, and a safety rope 8 is also included. The initial end of the safety rope 8 is connected to a The fixed block is connected, and after the end of the safety rope 8 passes through the inside of the large hole 2 on the other fixed block, it is wound on the outer wall of the small hole 1 for half a circle and then continues to extend outward after passing through the large hole 2 again, and A rope grab 4 is provided on the safety rope 8 , and the rope grab 4 is located between the two support rods 3 . In view of the defects in the protective measure...

Embodiment 2

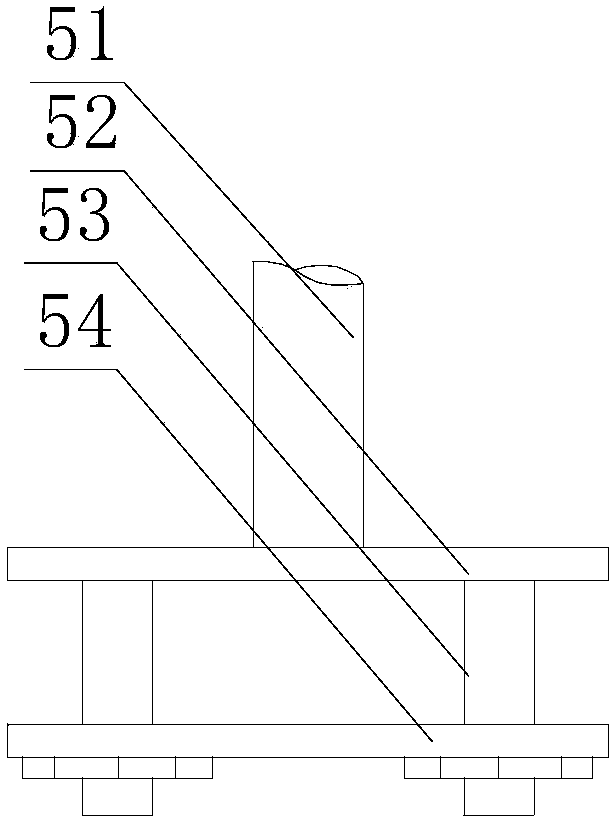

[0028] Such as Figure 1~2 As shown, the base 5 in this embodiment includes a sleeve 51 and an upper plate 52 and a lower plate 54 parallel to each other, the sleeve 51 is fixed on the upper surface of the upper plate 52, and the lower end of the support rod 3 is placed on the In the sleeve 51, the upper plate 52 and the lower plate 54 are connected by bolts 53. Further, since the load-bearing part of the base 5 is an I-shaped channel steel 6, and utilizing the particularity of the shape of the channel steel 6, the upper plate 52 and the lower plate 54 are respectively placed on the upper surface and the lower surface of the channel steel 6, Then the upper plate 52 and the lower plate 54 are connected and fixed by bolts 53 , and the sleeve 51 is fixed on the upper surface of the upper plate 52 to provide effective support for the support rod 3 .

[0029] Preferably, three screw holes in a triangular distribution are provided on the upper plate 52 and the lower plate 54, and t...

Embodiment 3

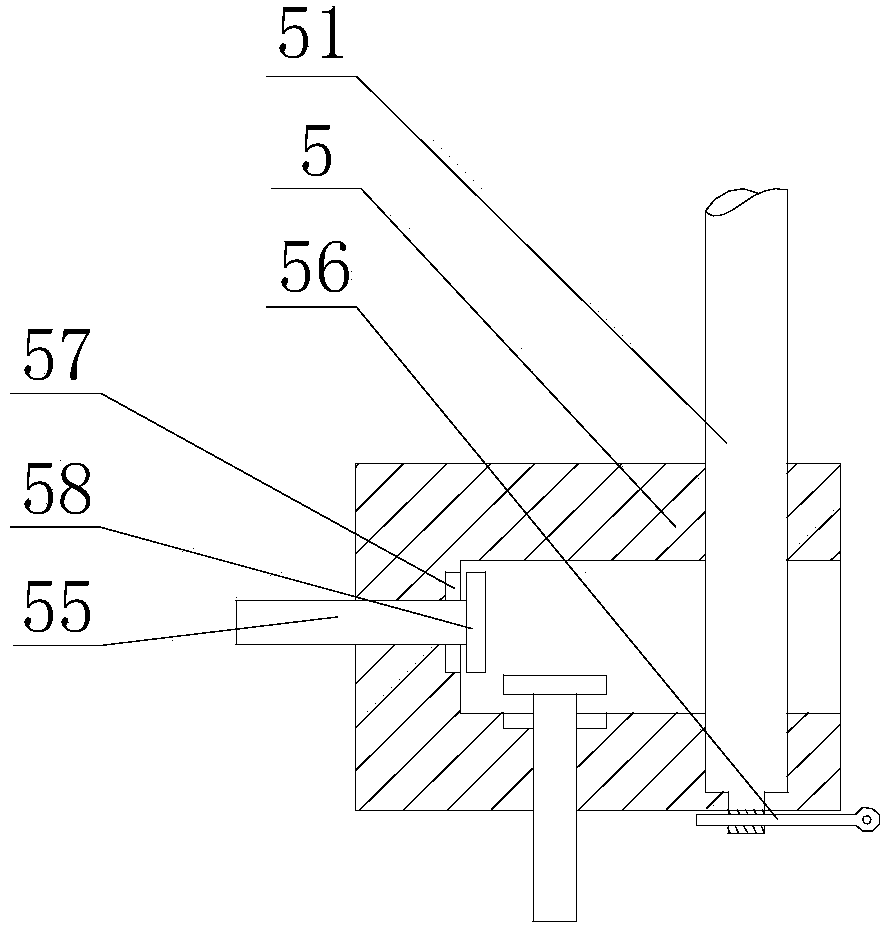

[0031] Such as figure 1 , 3 As shown, the base 5 in this embodiment includes a U-shaped body and a sleeve 51, the opening direction of the body is parallel to the horizontal direction, through holes and blind holes are respectively provided on the two horizontal sections of the body, and the sleeve The lower end of 51 enters the blind hole after passing through the through hole, and the lower end of the support rod 3 is placed in the sleeve 51 . Further, the base 5 includes a body and a sleeve 51, wherein the body is U-shaped, and its opening direction is parallel to the horizontal direction, so that the body can pass through the channel steel 6 transversely, ensuring that the upper and lower surfaces of the channel steel 6 are aligned with the U-shaped area of the body. contact, and the through holes and blind holes provided on the horizontal section of the body can facilitate the rapid insertion of the sleeve 51 and ensure that the sleeve 51 is integrated with the base 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com