Cloth drying device used after printing processing

A cloth drying and drying box technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve the problems of inability to automate, color mixing, low efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

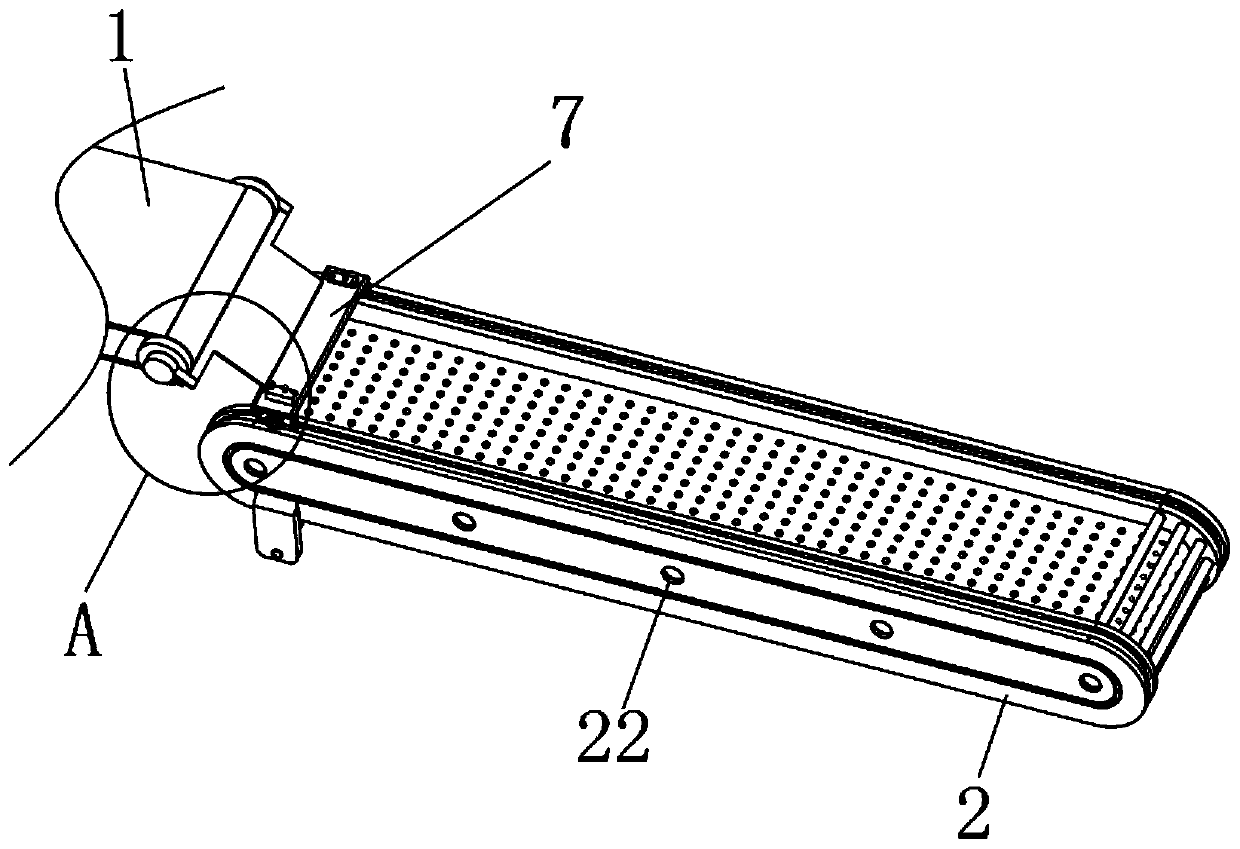

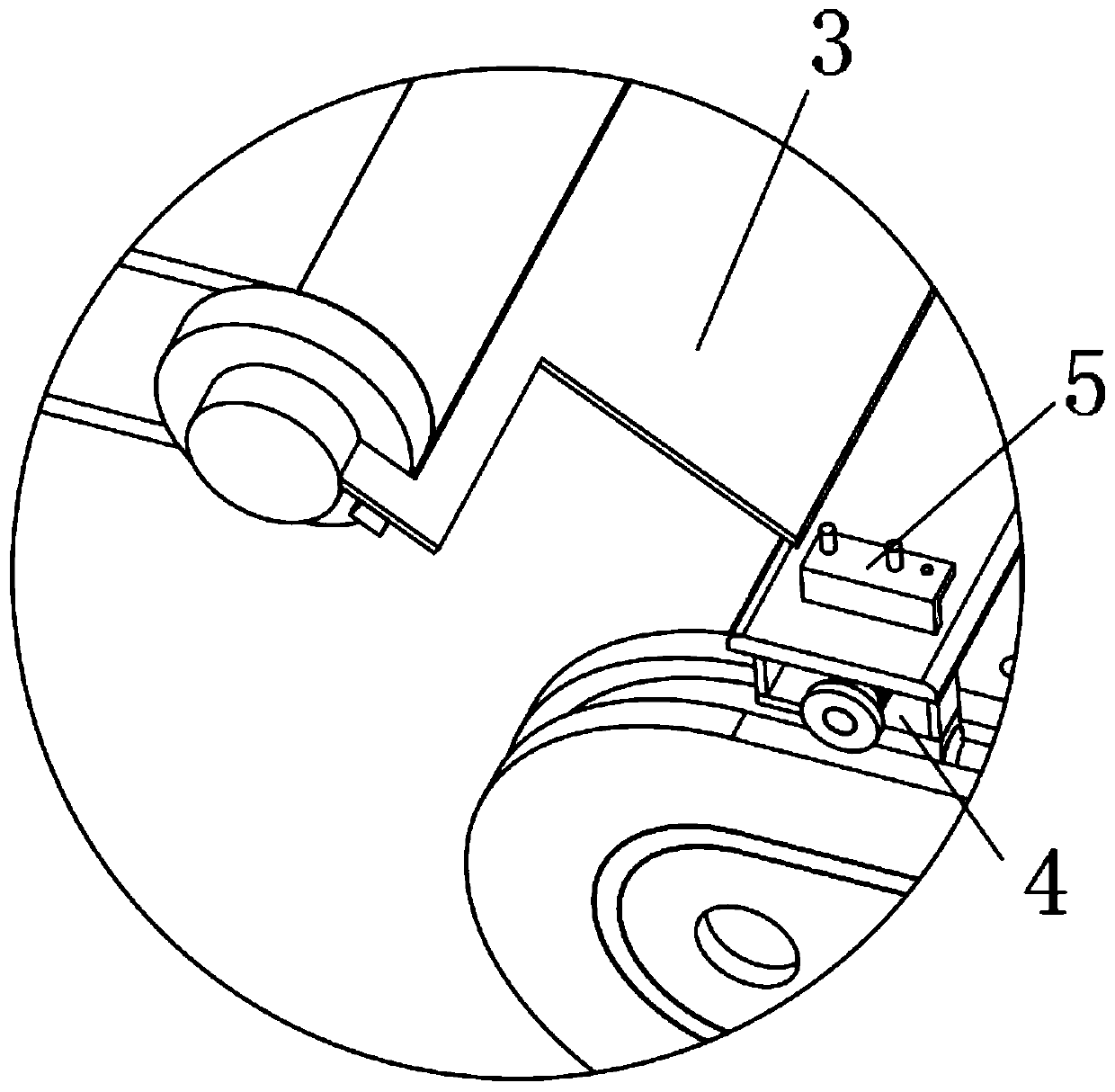

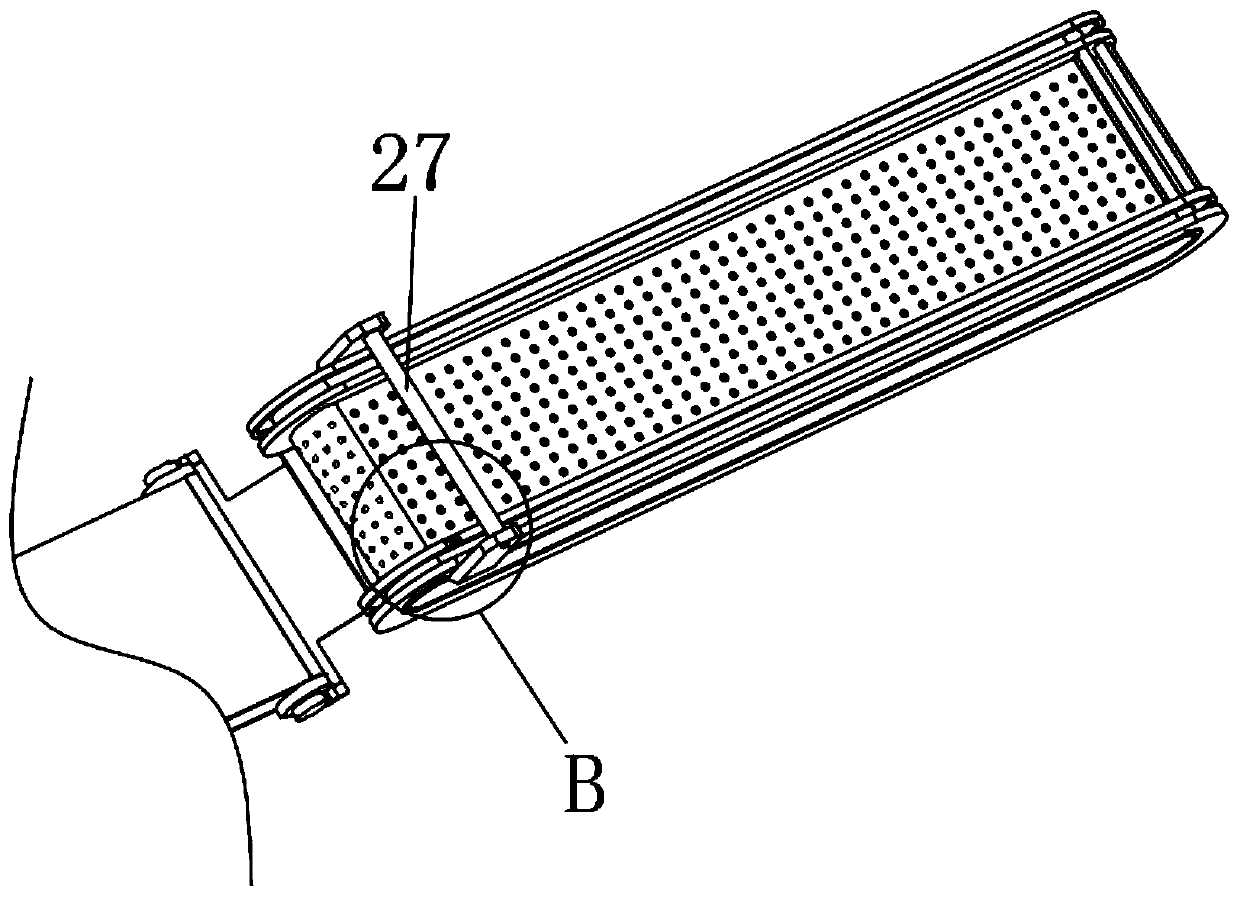

[0029] Specific implementation method: the cloth reaches the automatic cloth clamping device 4 from the conveyor belt 1 of the previous process via the material guide plate 3. Because the conveyor belt 1 continues to rotate, the cloth will continue to advance on the flat plate 7. When the cloth advances a certain distance, The infrared sensor 10 will detect the change of the distance of the object at its front end, because the cloth has a certain thickness, so after the cloth is detected, the electric telescopic rod 9 works to make the clamping plate 11 press down to press the cloth, and the real contact with the cloth is The backing plate 12, the backing plate 12 uses a material similar to polyurethane to increase the frictional force, making it more stable to clamp, the material guide plate 3 rotates around one end of the conveyor belt 1 at all times, and when the round of reciprocation is completed, move the supporting device 4 Can come up from the bottom of material guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com