Sorting robot applied to machining industry

A technology of mechanical processing and robotics, applied in sorting, manipulators, program-controlled manipulators, etc., can solve the problems of manpower and time-consuming, high labor costs, and the inability to realize the sorting and transportation of workpieces of different shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with specific embodiments.

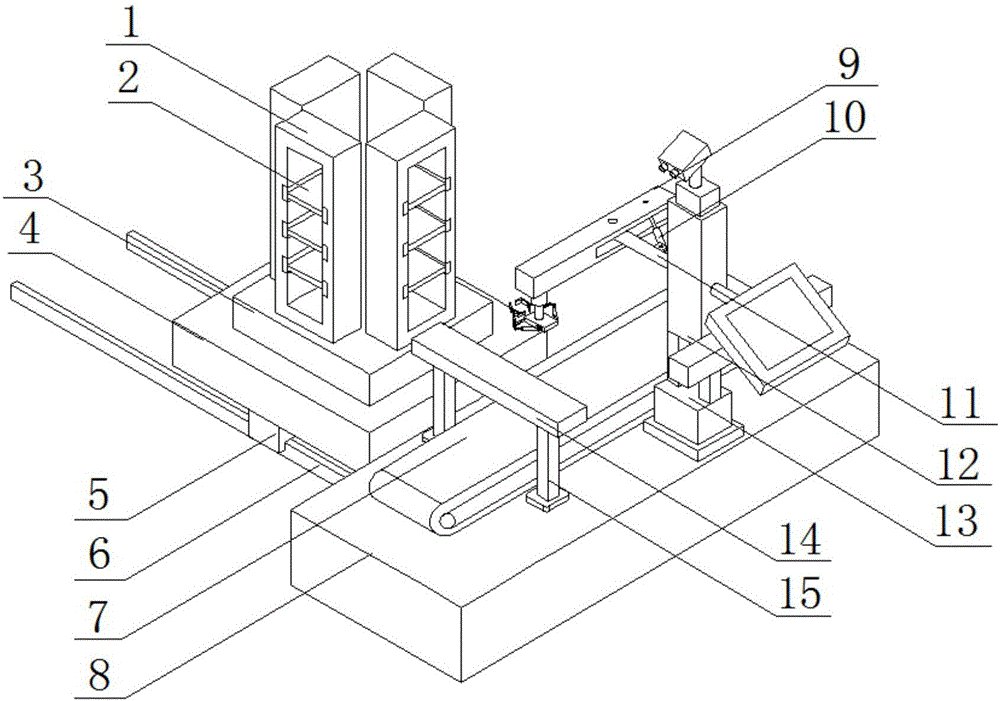

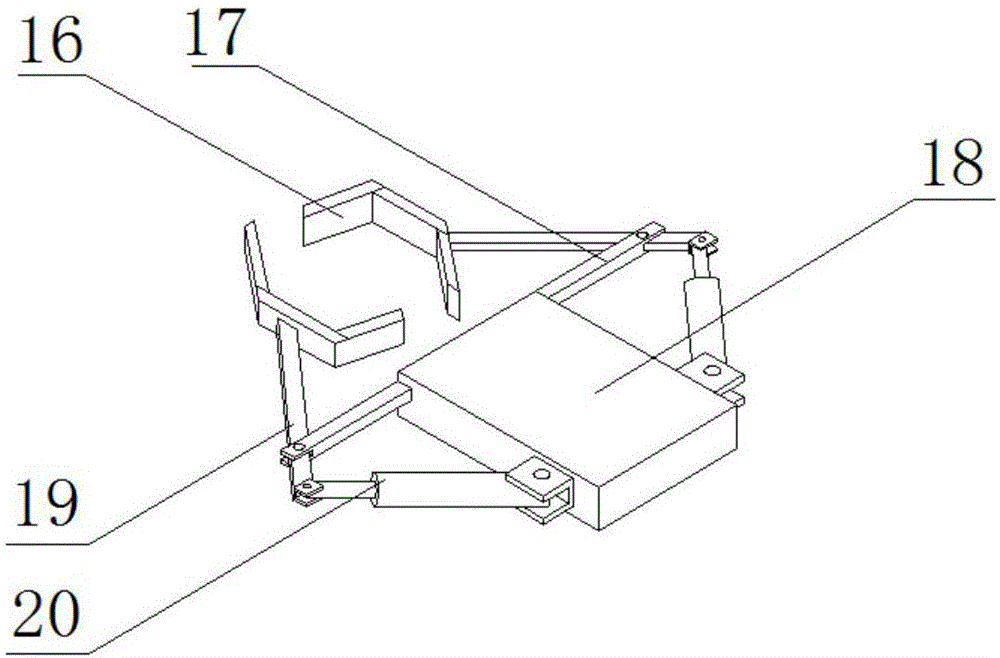

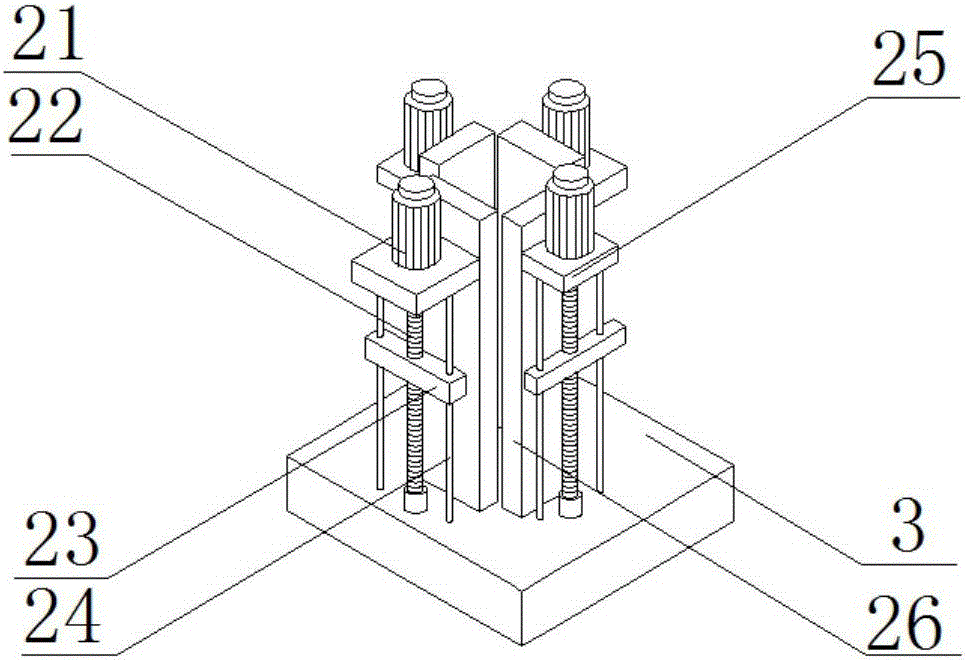

[0018] refer to Figure 1-3 , a sorting robot used in the mechanical processing industry, including an operating table 8, a visual recognition device, a gripping device and a transfer device, the upper end of the operating table 8 is provided with a conveyor belt 7 for conveying parts, and the two ends of the conveyor belt 7 are provided There are support rods 15, the upper ends of the two support rods 15 are fixed with support plates 14, the support rods 15 support the support plates 14, the lower end of the support plates 14 is provided with a visual recognition device, the visual recognition device is composed of a high-definition camera and a flashlight, Parts on the conveyor belt 7 can be identified, one side of the conveyor belt 7 is provided with a fixed block 13, the upper end of the fixed block 13 is provided with a robot body 12, and one side upper end of the robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com