Automatic pressure riveting mechanism for bus duct contact

A busway and contact technology, which is applied in the field of automatic riveting mechanism for busway contacts, can solve the problems of low safety, low production efficiency, complicated operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

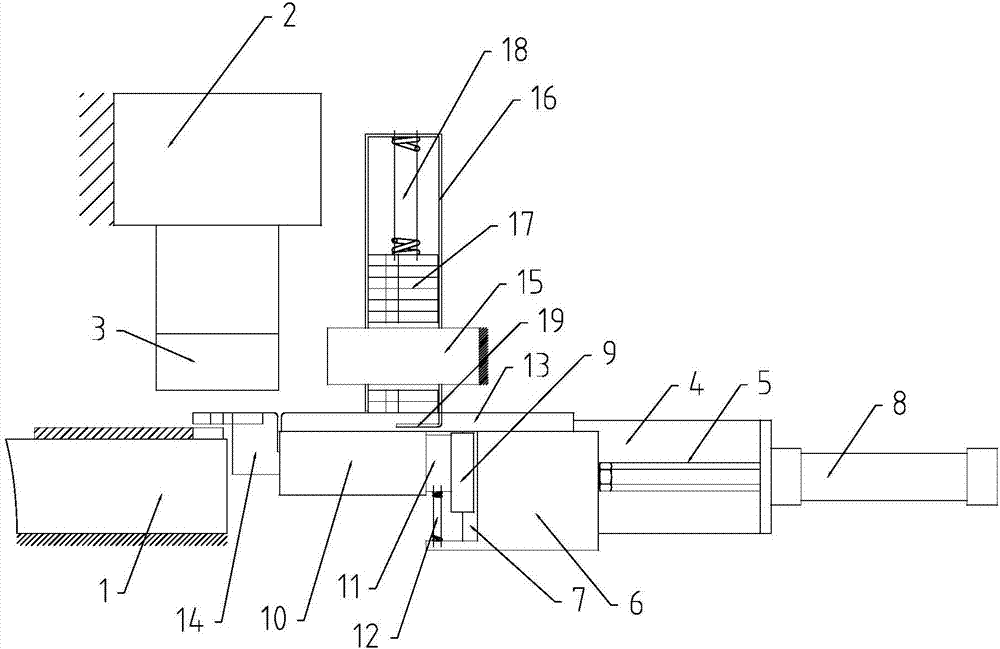

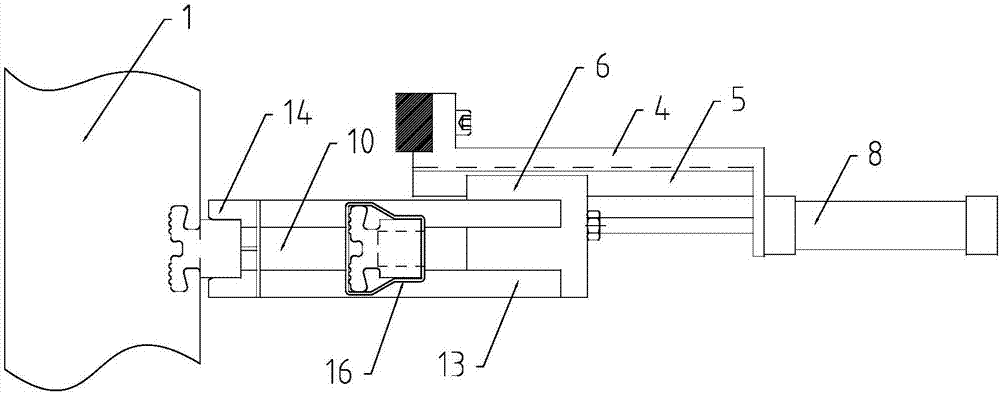

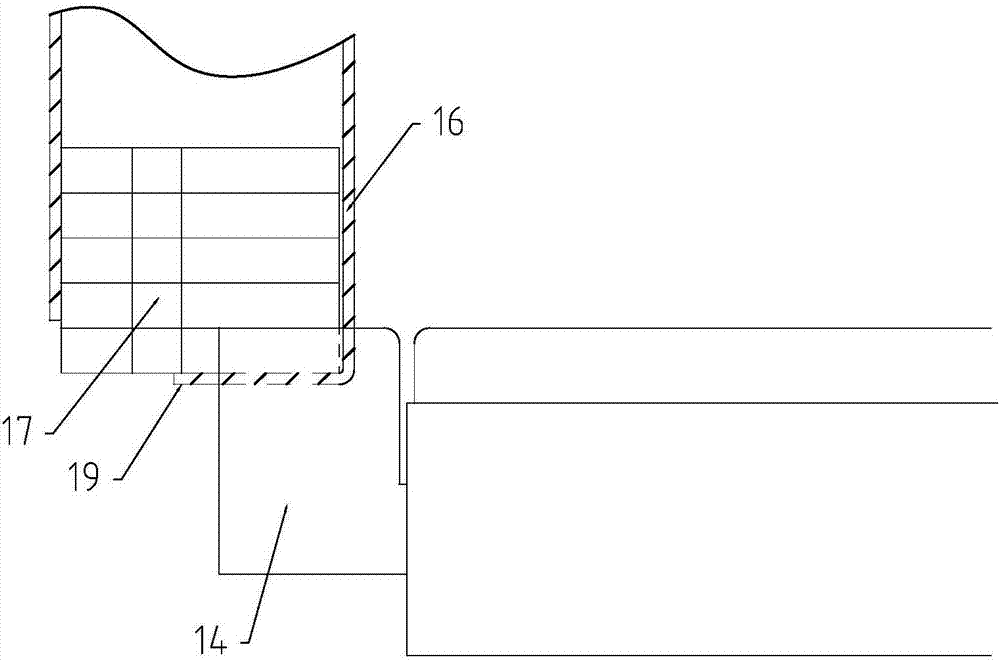

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0022] Such as Figure 1-6 As shown, an automatic pressure riveting mechanism for busway contacts, including a frame fixed on a mounting frame (omitted in the figure, is used to support and install the entire mechanism according to the required position of each component, and can also be a frame with The workpiece placement platform 1 on the fuselage of a device that this mechanism cooperates to produce), is provided with a pressure riveting hydraulic cylinder 2 that is connected on the installation frame on the top of the workpiece placement platform 1, and the piston rod of the pressure riveting hydraulic cylinder 2 A riveting head 3 is provided at the end of the workpiece, a guide rail seat 4 is provided on the mounting frame on the side of the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com