Automatic pallet unstacking and stacking roller conveying line and conveying method

A roller conveyor line and conveyor line technology, which is applied in the direction of object destacking, object stacking, transportation and packaging, etc., can solve the problems of limited number of rollers, large space occupation, poor practicability, etc., and achieve low production cost, Reasonable and compact structure, safe and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

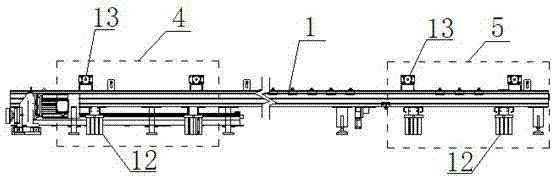

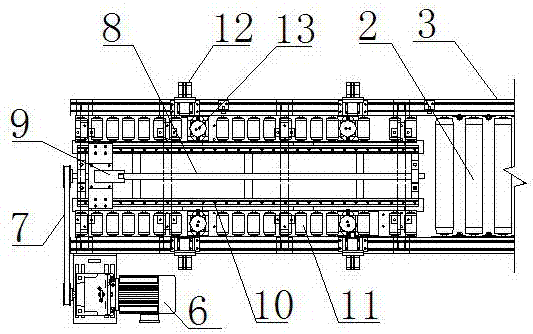

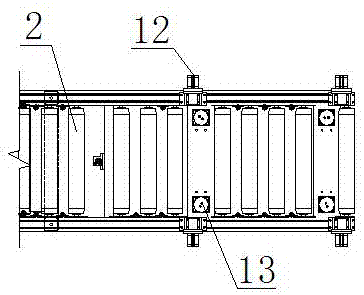

[0028] As shown in the accompanying drawing, a pallet automatic depalletizing roller conveying line includes a push mechanism and a non-powered conveying line 1. The non-powered conveying line includes a track composed of rollers 2 and a bracket 3. The upper plane formed by the roller 2 is a track On the surface, one end of the non-powered conveying line 1 is provided with a depalletizing mechanism 4, and the other end is provided with a palletizing mechanism 5,

[0029] Described pushing mechanism comprises decelerating motor 6, pulley 7, T-shaped screw leading screw 8, push plate 9, and decelerating motor 6 is fixedly arranged on the support 3, and T-shaped screw leading screw 8 ends are connected with belt pulley, and it is connected with belt pulley. The track surface is parallel and perpendicular to the cylinder 2. The reduction motor 6 rotates to drive the belt pulley 7 and the T-shaped screw lead screw 8 to rotate through the transmission belt, so that the push plate 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com