a stack method

A technology of stacking and pallets, applied in the field of automatic palletizing, can solve the problems of no need, waste of station space, no need to adjust the position and orientation of the material box, etc., to achieve the effect of convenience, difficulty, complexity and occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

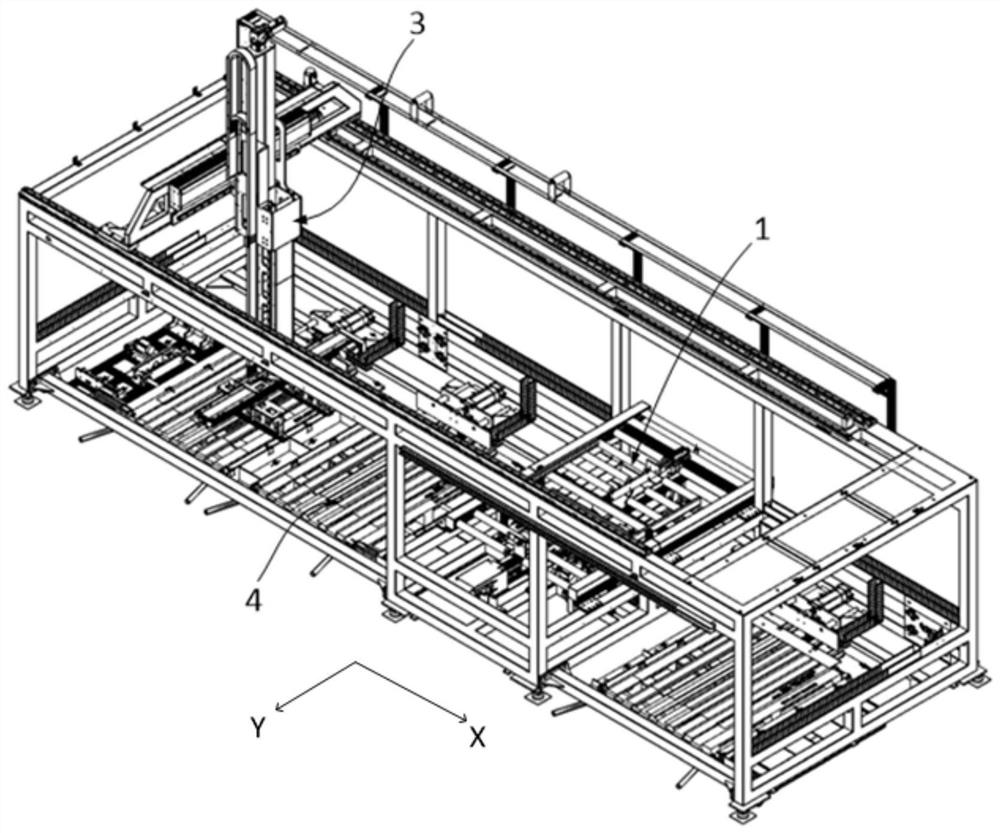

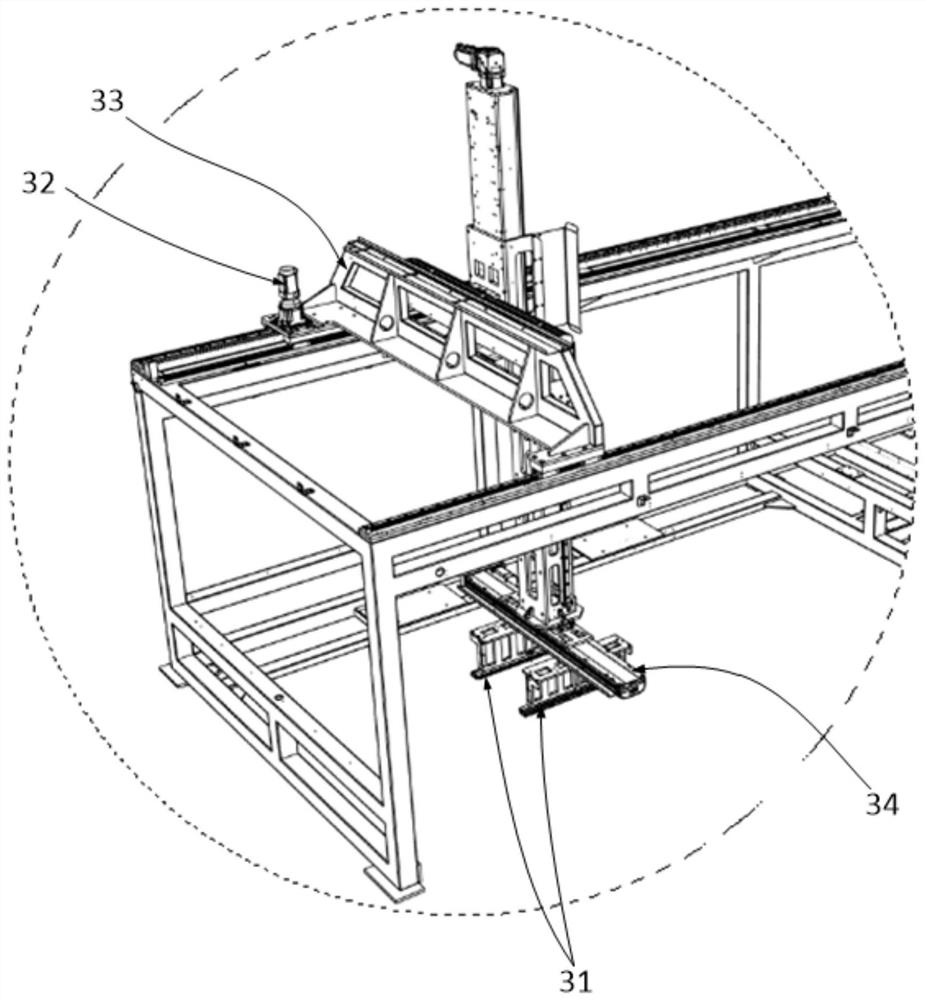

[0072] This embodiment provides an automatic stacking device, such as Figure 1-3 shown, including:

[0073] frame;

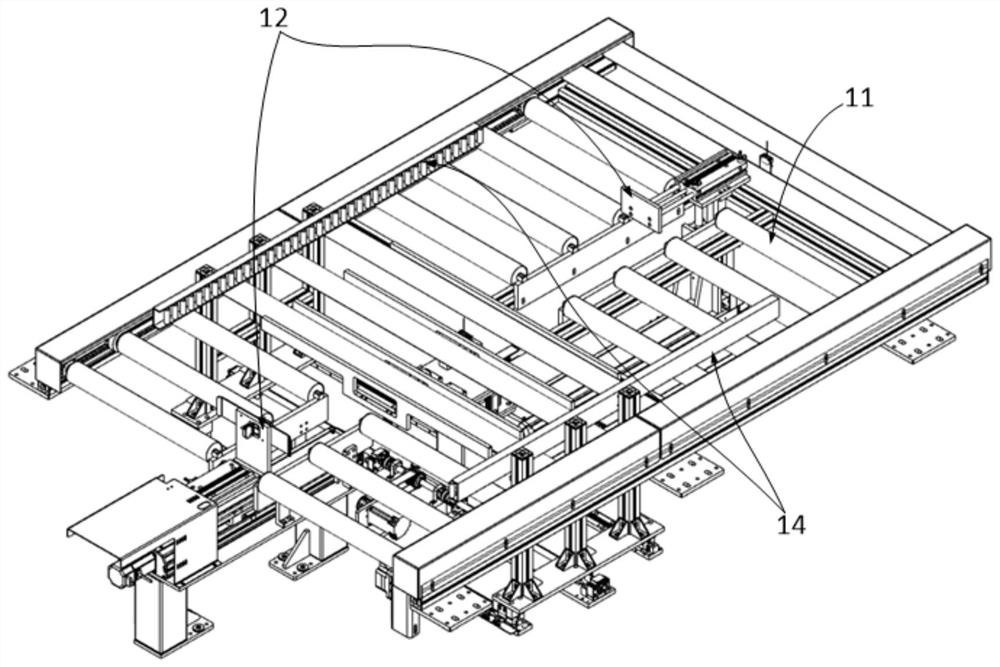

[0074] Incoming material drum line 1, used to transport the material box;

[0075] The pallet 4 is arranged on the side of the incoming material drum line 1;

[0076] Grab material conveying mechanism 3, used for grabbing material boxes from said incoming material drum line 1 and being able to stack at least 2 stacks of material boxes on said pallet 4;

[0077] The leaning mechanism is arranged at the pallet 4 and is used to push the stacked magazines so that two adjacent stacks of magazines are close to each other.

[0078] Preferably, the automatic stacking device of this embodiment, such as Figure 10 As shown, the positioning mechanism includes:

[0079] The stacking alignment plate 7 can push the stacked magazines on the pallet 4 to move under the drive of the driver.

[0080] Preferably, the automatic stacking device of the present embodiment also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com