Automatic paper sorting and recycling device for glass stacks

A recovery device and automatic sorting technology, which is applied in stacking receiving devices, thin material processing, object destacking, etc., can solve the problems of messy stacking, polluting the environment, affecting civilized production, etc., and achieve the effect of automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

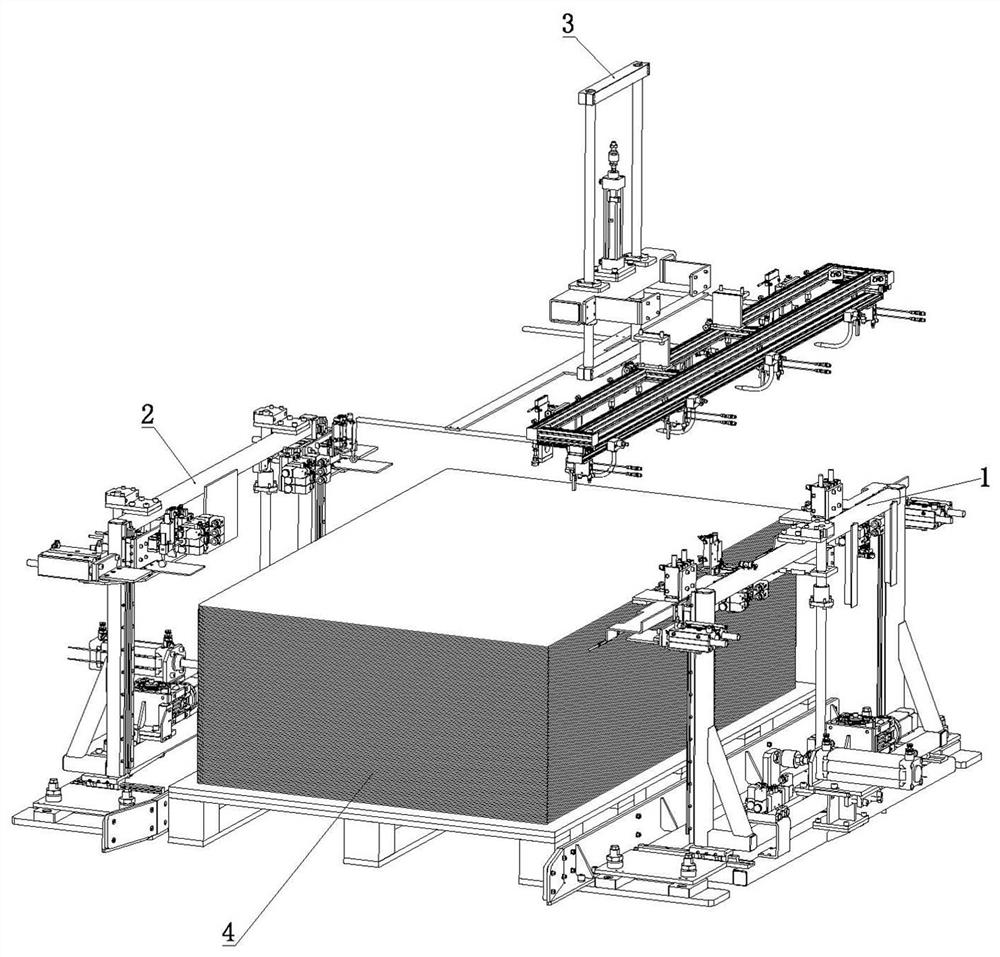

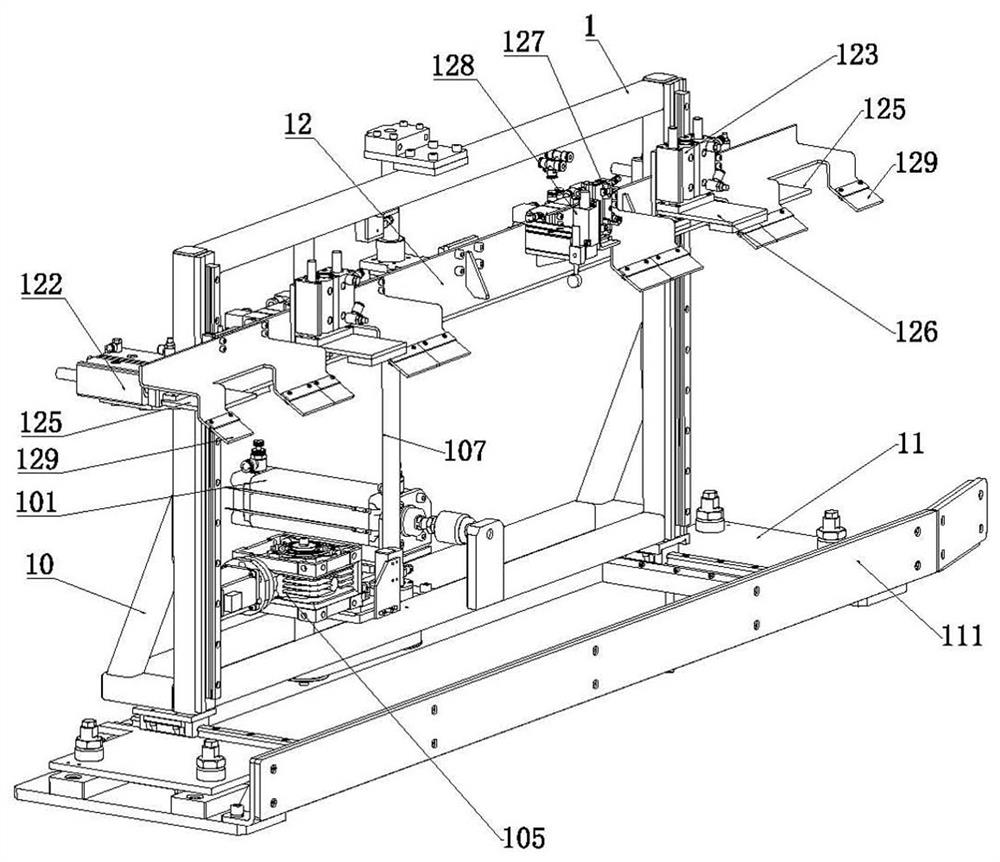

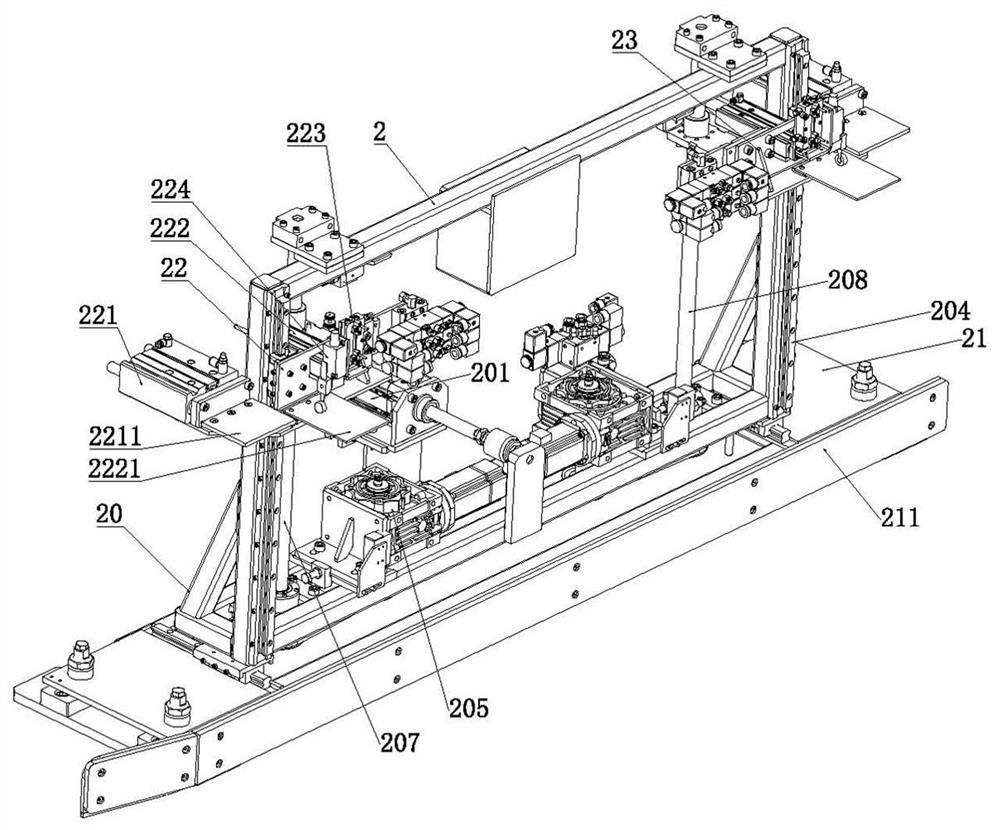

[0026] The present invention includes a paper-separating and stabilizing mechanism 1 on the right side, a paper-clamping and separating mechanism 2 on the left and a paper pick-up clamp device 3, and is characterized in that the paper-separating and stabilizing mechanism 1 includes a right fixed frame , the right translation frame 10 is provided with the right translation frame 10 through the right translation cylinder 101 on the right fixed frame, the right lifting frame 12 is provided with the right lifting mechanism 105 on the right translation frame 10, and the right lifting frame 12 is passed through the right down-moving cylinder and a right stroke switch 128 connected; the two ends of the right lifting frame 12 are provided with a right normalizing plate 125 through a right-returning cylinder 122; Also be provided with the cardboard brush 129 of inclination; Described paper clamping and splitting mechanism 2 comprises left fixed frame, is provided with left translation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com