Full-automatic material preparing and car loading system and car loading method

A fully automatic and automatic technology, which is applied in the directions of loading/unloading, transportation and packaging, and unstacking of objects. It can solve the problems of labor costs, high labor intensity, and low production efficiency, and achieve the effect of realizing automation and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The content of the present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

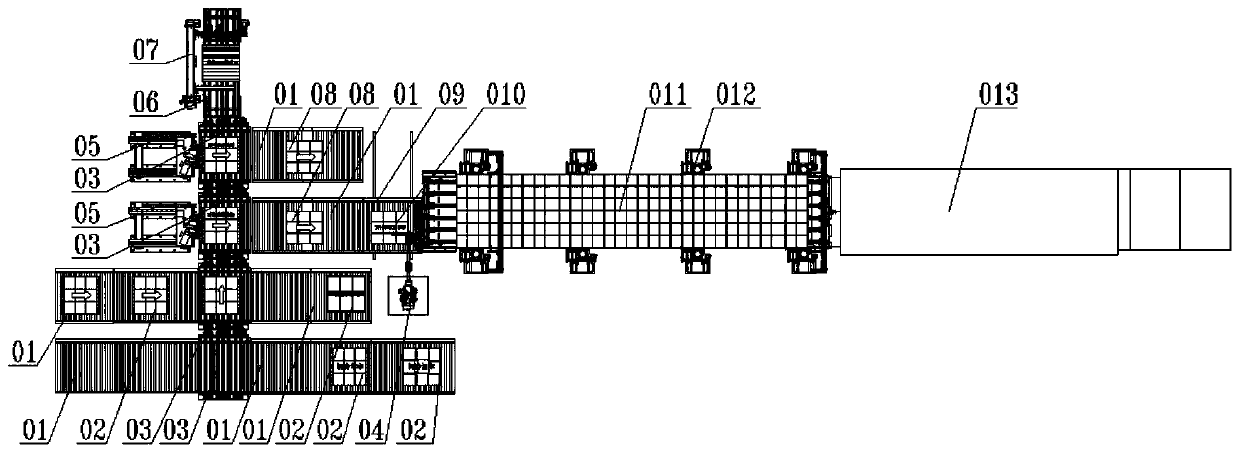

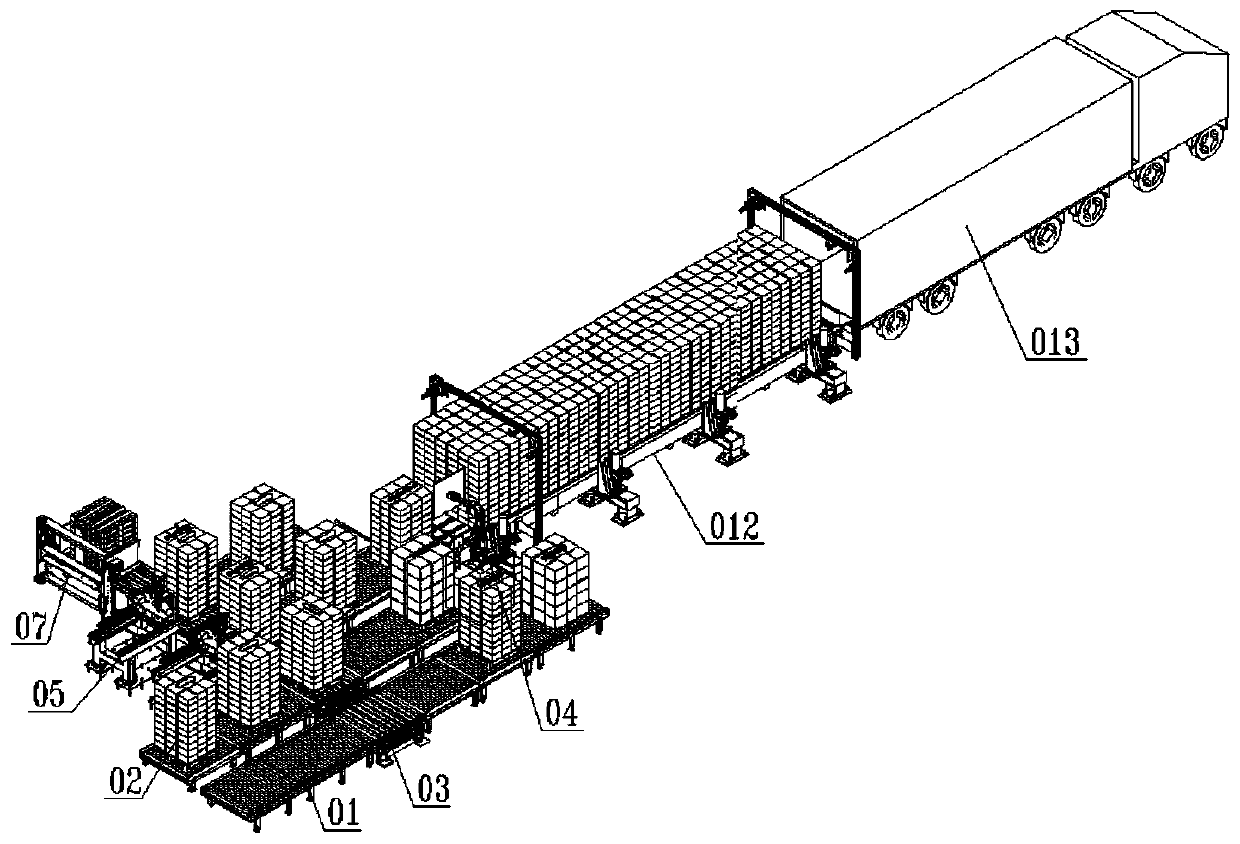

[0076] Such as figure 1 , figure 2 As shown, the fully automatic material preparation and loading system includes roller conveying device 01, material with pallet 02, combined conveying device 03, robot palletizing device 04, pallet separating device 05, chain conveying device 06, pallet recycling device 07, and material without pallet 08, move the docking device 09, complete the palletizing material 010, complete the shaping material 011, the automatic loading device 012, and the carriage 013;

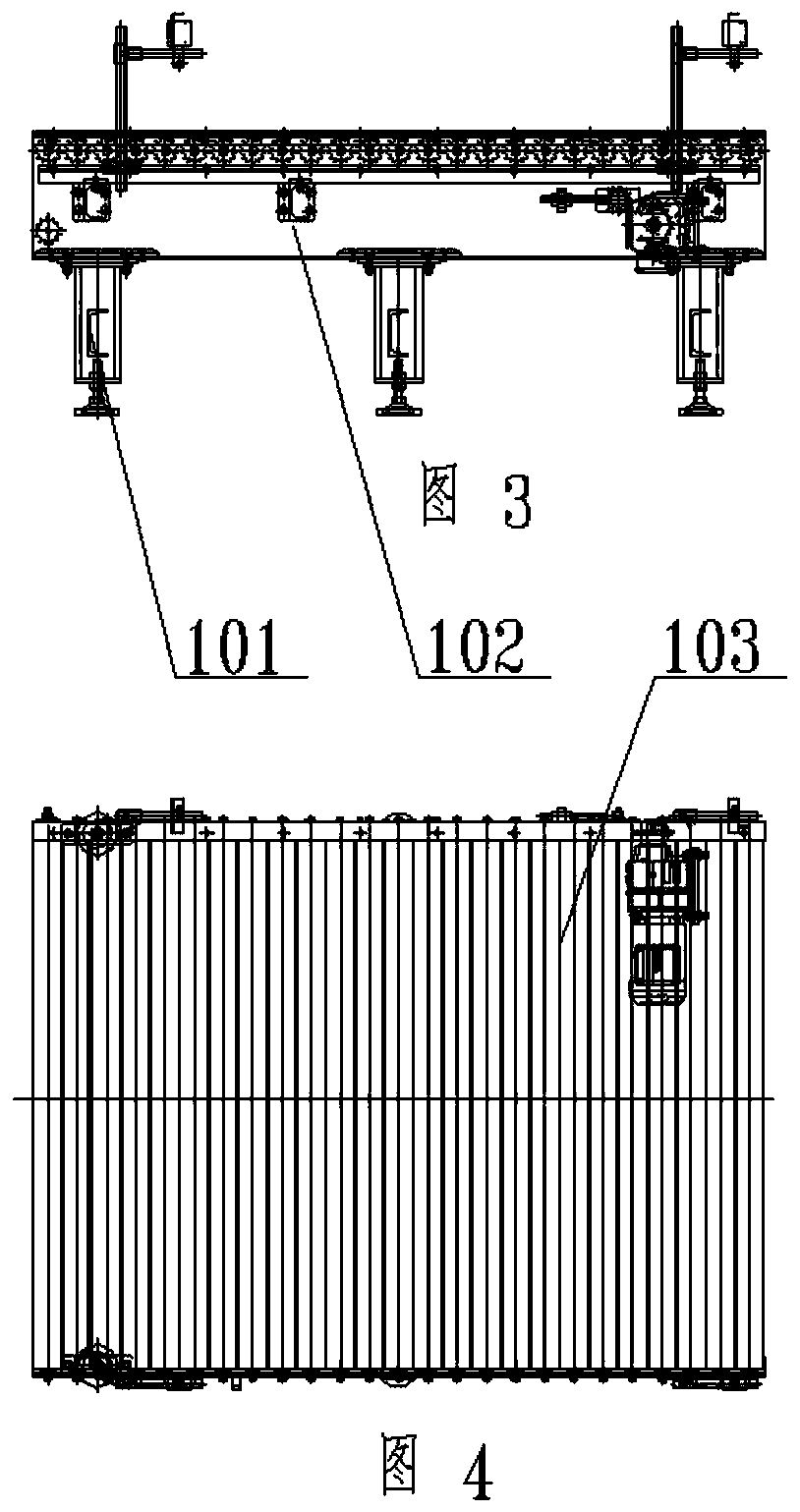

[0077] Such as image 3 , Figure 4 , Figure 5 As shown, the roller conveying device 01 includes a roller conveying device leg 101 , a roller conveying device frame 102 , a roller conveying device roller 103 and a roller conveying device driving device 104 . The roller conveyor roller 103 and the roller conveyor driver 104 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com