Preparation method of molybdenum sulfide/three-dimensional macroporous graphene and lithium ion battery negative electrode material

A three-dimensional macropore and graphene technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of poor rate performance of lithium-ion batteries, easy stacking of sheet structures, and attenuation of discharge capacity to achieve enhanced battery rates Performance, low cost, and the effect of improving poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of molybdenum glycerate spheres: Weigh 120 mg of molybdenum acetylacetonate into a 100 mL beaker, add 30 mL of isopropanol, 10 mL of water and 8 mL of glycerin, and then place the mixture under the condition of 55 kHz to make it Dissolved into a colorless and transparent solution, then transferred to a stainless steel autoclave lined with polytetrafluoroethylene with a capacity of 100 mL, set the temperature of the blast drying oven at 190 °C, and reacted for 3 h. After the reaction, it was naturally cooled to At room temperature, wash several times with ethanol centrifugation at 6000 rpm. Transfer to a blast drying oven, set the temperature at 60 °C, and dry for 12 h;

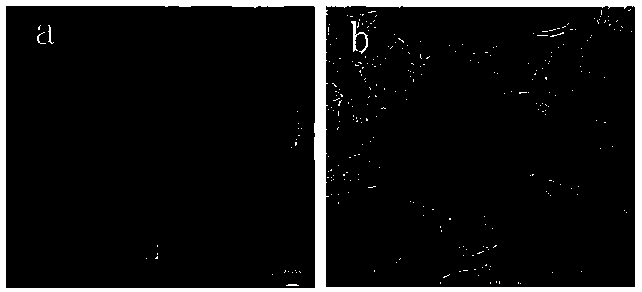

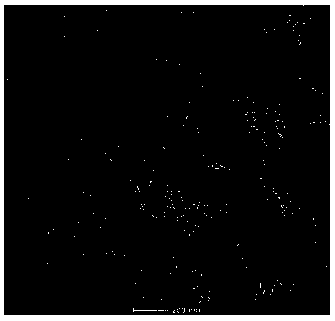

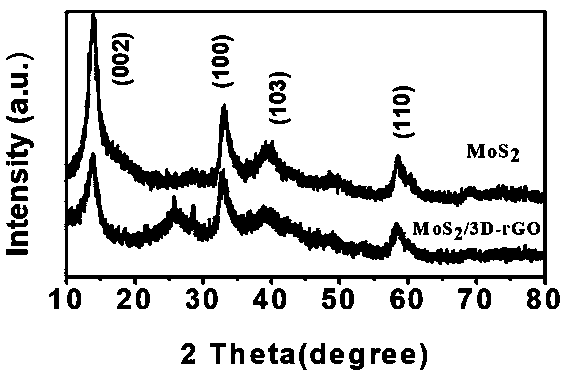

[0034] (2) Preparation of molybdenum glycerate spheres / three-dimensional macroporous graphene: Weigh 50 mg molybdenum glycerate spheres and 40 mg graphene oxide and disperse them in a beaker containing 40 mL deionized water, ultrasonically disperse for 1 h, then transfer to a 100 In a s...

Embodiment 2

[0044] In this example, the MoS prepared in Example 1 is used respectively 2 / 3D-rGO composites and MoS prepared by comparative examples 2 The electrode active material will be used to manufacture and assemble lithium-ion batteries and perform performance tests.

[0045] Use NMP as solvent to prepare MoS with prepared examples 2 / 3D-rGO composite material is used as the active material, acetylene black is used as the conductive agent, PVDF is used as the binder, the mass ratio of the three components is 8:1:1, the slurry is prepared by magnetic stirring for 8 hours, and the prepared slurry is prepared by a coating machine The good slurry is evenly coated on the copper foil and kept at 80°C for 10h. After drying, cut it into MoS with a microtome 2 / 3D-rGO electrode sheet, and then vacuum-dried at 120 °C for 12 h to remove a small amount of moisture. After the electrode piece is weighed, it is directly used as the negative electrode of the lithium-ion battery to assemble the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com