Tubular thermal treatment furnace capable of continuously conveying materials

A heat treatment furnace and tube-type technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of heat treatment furnace temperature and ambient atmosphere that are difficult to control, and affect the quality of heat-treated products of workpieces. Guaranteed quality and consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

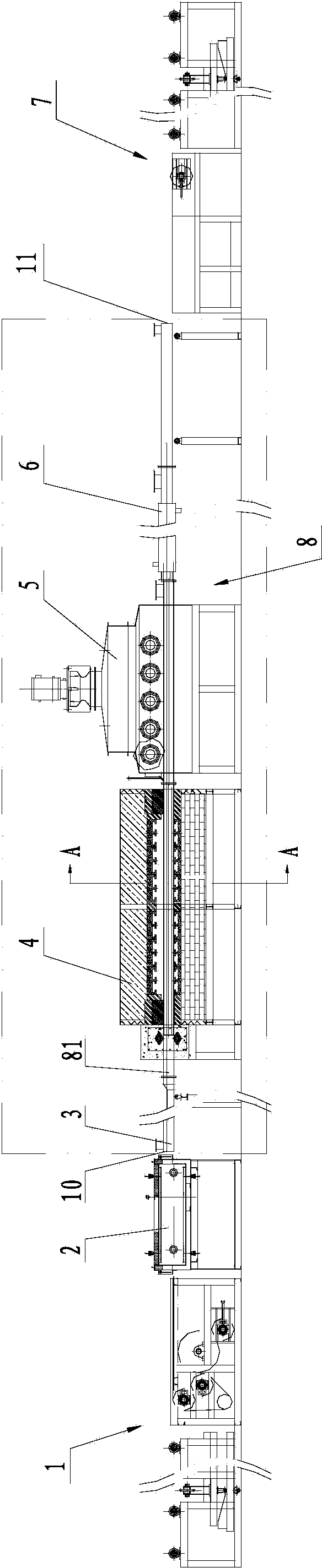

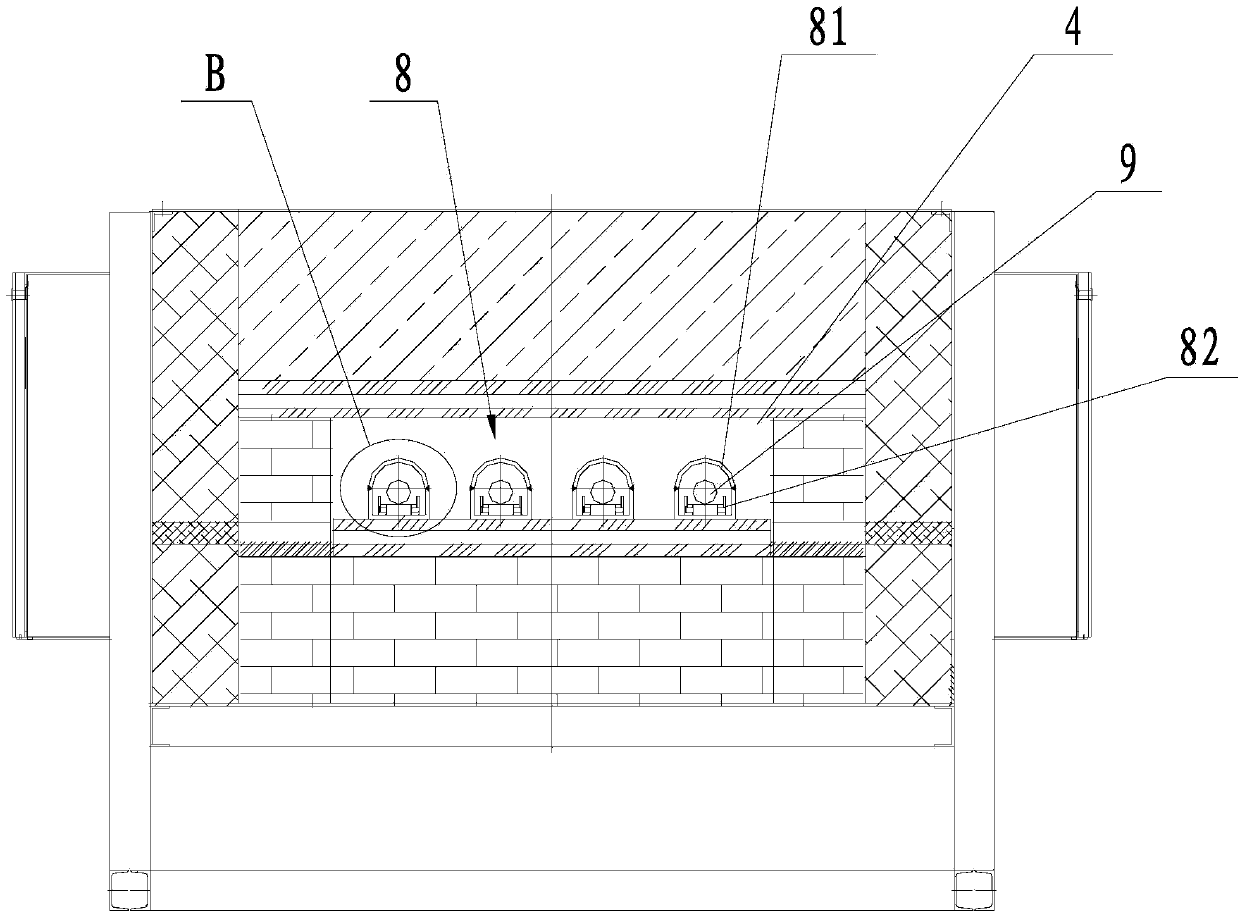

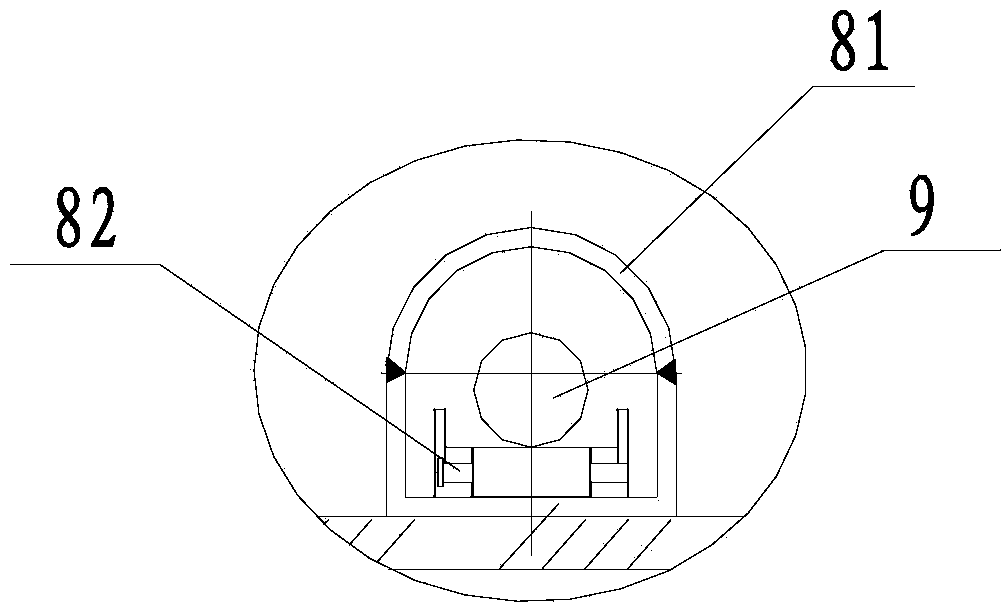

[0022] see Figure 1~3 As shown, the tubular heat treatment furnace capable of continuous feeding includes a furnace body with a feed inlet and a discharge port, a feeding mechanism for conveying the workpiece 9 to be heat treated, and a gas supply device for supplying protective gas to the furnace body ( not shown in the figure). A drying chamber 2 for drying the workpiece 9 and a feed end roller table 1 for transporting the workpiece 9 to the drying chamber 2 are arranged in sequence in front of the feed port of the furnace body. The feed port of the furnace body enters the furnace body, and the discharge end roller table 7 for transmitting the workpiece 9 is provided behind the discharge port of the furnace body.

[0023] The furnace body has a preheating passage 3, a heating chamber 4, an air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com