Bottle cap sorting device

A technology of finishing device and bottle cap, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of insensitive changes in the center of gravity, unsatisfactory finishing effect, and high reverse cap rate, so as to achieve difficult stacking, avoid damage to bottle caps, and reverse low coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below through specific examples.

[0017] The conveying function side mentioned in the present invention refers to the side that the endless chain 3 carries the bottle cap 11 to convey;

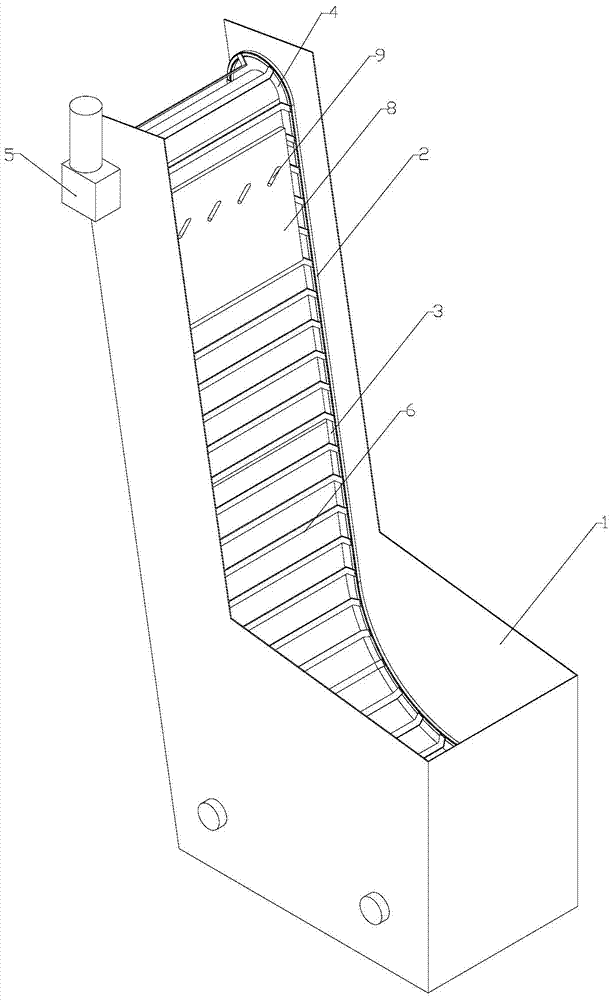

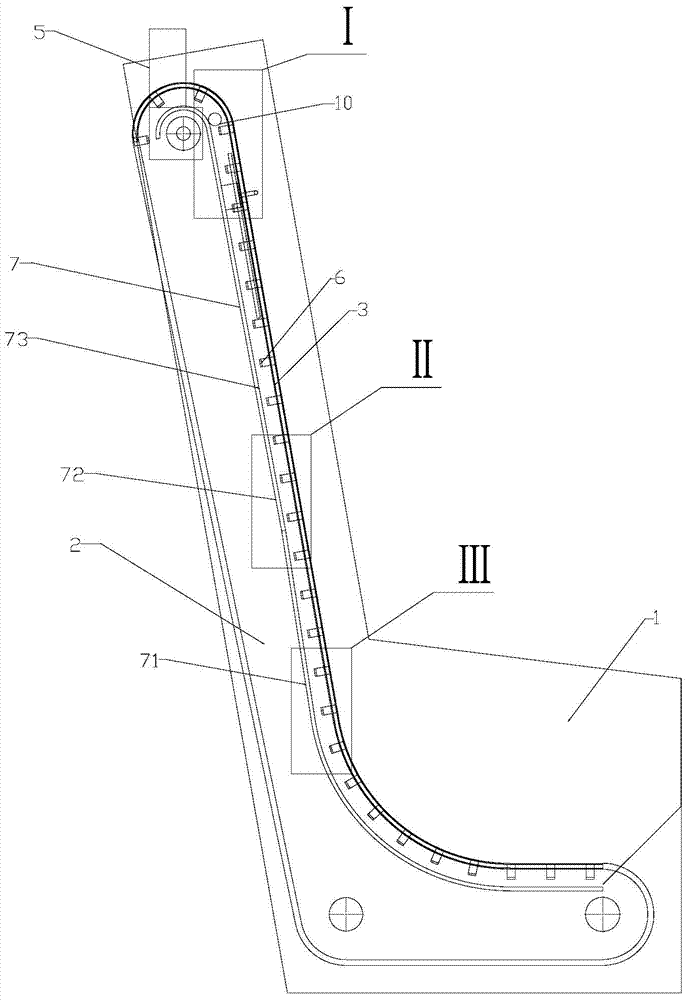

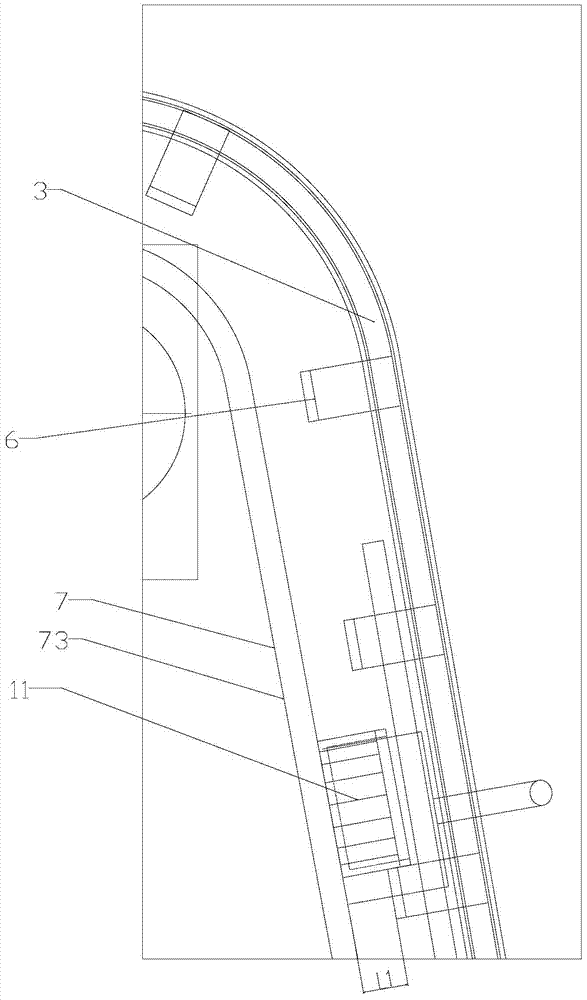

[0018] Such as Figures 1 to 5 As shown, a bottle cap sorting device includes a cap storage bucket 1 and a chain conveying device. The chain conveying device includes a support 2, an endless chain 3, a set of sprockets 4 and a driving device 5. The driving device is a motor. The output shaft of the motor is in drive connection with the sprocket 4 on the top of the bracket. The bracket 2 is obliquely fixed on the lid storage bucket 1. The set of sprocket 4 is rotatably installed on the bracket 2. The endless chain 3 is installed on a set of chain On the wheel 4, the driving device 5 is connected to any one of the set of sprockets 4; the endless chain 3 is fixed with a carrier cover plate 6 at intervals, and the carrier cover pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com