Printable waterborne polyurethane 3D golden oil or 3D ink

A water-based polyurethane, 3D technology, applied in the field of printing ink, can solve the problems of poor heat resistance, friction, and different production processes, and achieve the effects of easy industrial production, simple preparation method, and obvious synergy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

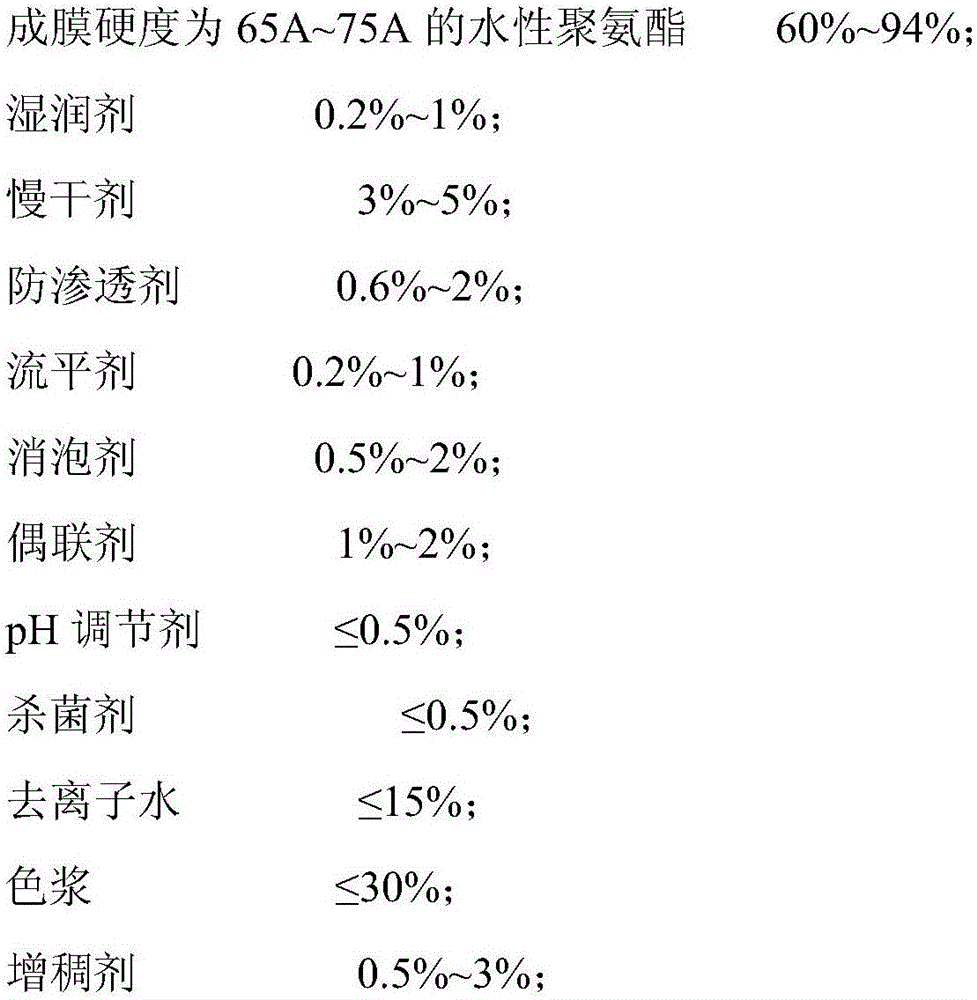

Method used

Image

Examples

Embodiment 1

[0028] Formulation 1: Bayer DLS 45% and Wanhua 7396 40%; Dow AMP95 0.2%; Deionized water 3.5%; Tego 825 0.3% and Gas Chemical DF-37 0.5%; Cytec OT75 0.2% and Tego WET500 0.5 Dow PEG6005%; OMGLA50 0.3%; Dow Corning 6040 1%; Tokuyama Chemical DM-10 1.5%; Korea SK PG521 0.3%;

[0029] 1. After filtering the water-based polyurethane resin Bayer DLS and Wanhua 7396, put it in a high-speed stirring disperser for stirring at a speed of 300r / min, and disperse and stir for 5 minutes;

[0030] 2. Keep the stirring and dispersing machine stirring at a rate of 300r / min, add Dow AMP95, deionized water, Tego 825 and Gas Chemical DF-37, increase the speed of the high-speed stirring and dispersing machine to 600r / min, and disperse and stir for 5 minutes;

[0031] 3. Keep the rotation speed constant, add Cytec OT75, Tego WET500, Dow PEG600, OMGLA50 and Dow Corning 6040 in turn, after dispersing and stirring for 5 minutes, slowly add Japan Tokuyama Chemical DM-10;

[0032] 4. After adding, inc...

Embodiment 2

[0036] Formulation 2: Bayer DLU 50% and Opeldi 4101 38%; Dow AMP95 0.2%; Deionized water 1.5%; Tego 825 0.5% and Gas Chemical DF-37 0.5%; BYK346 0.6%; Propylene glycol 3.5%; OMGLA50 0.3 %; Japan Shin-Etsu A187 1.5%; DE Degussa A200 2%; Korea SK PG52 10.3%; Haichuan 3800 0.6% and Huntsman PTF 0.5%.

[0037] The preparation steps are as in Example 1.

Embodiment 3

[0039]Formulation 3: Bayer DLU 41% and Kawamoto A539 45%; Dow AMP95 0.2%; Deionized water 2.5%; Tego 825 0.2% and Gas Chemical DF-37 0.8%; Cytec OT75 0.2% and Tego WT500 0.5% Dow PEG600 3% and diethylene glycol 1%; BYKETOL-AQ 0.5%; Dow Corning 6040 2%; Tokuyama Chemical DM-10 1%; Korea SKPG521 0.3%; .

[0040] The preparation steps are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com