Edge functionalized graphene, preparation method thereof, and applications of edge functionalized graphene in preparing anticorrosive paint

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, chemical instruments and methods, epoxy resin coatings, etc., can solve the problems that restrict the application of graphene and cannot be repaired, and achieve excellent anti-corrosion properties, complete sheet structure, The effect of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Graphene prepared by 300 mg turbulent flow method is added to 200ml H 2 SO 4 (98%), 1.8g NaClO 3 and 1mlH 2 o 2 (30%) in a mixed system, stirred at room temperature (25° C.) for 8 h, and then the product was repeatedly centrifuged and washed with water to obtain edge-functionalized graphene with carboxyl groups selectively modifying the edge of the sheet.

[0052] (2) Weigh 2.5mg of edge-functionalized graphene, 300mg of phenolic resin, 40mg of gypsum powder filler, 20mg of polyacrylic acid additive and 30mg of p-toluenesulfonic acid curing agent and disperse them in 100ml of water, and obtain edge-functionalized graphene after 5 hours of mechanical stirring Composite anti-corrosion coating.

[0053] It is applied to the surface of the substrate by spraying, and after drying, an edge-functionalized graphene composite anti-corrosion coating is obtained.

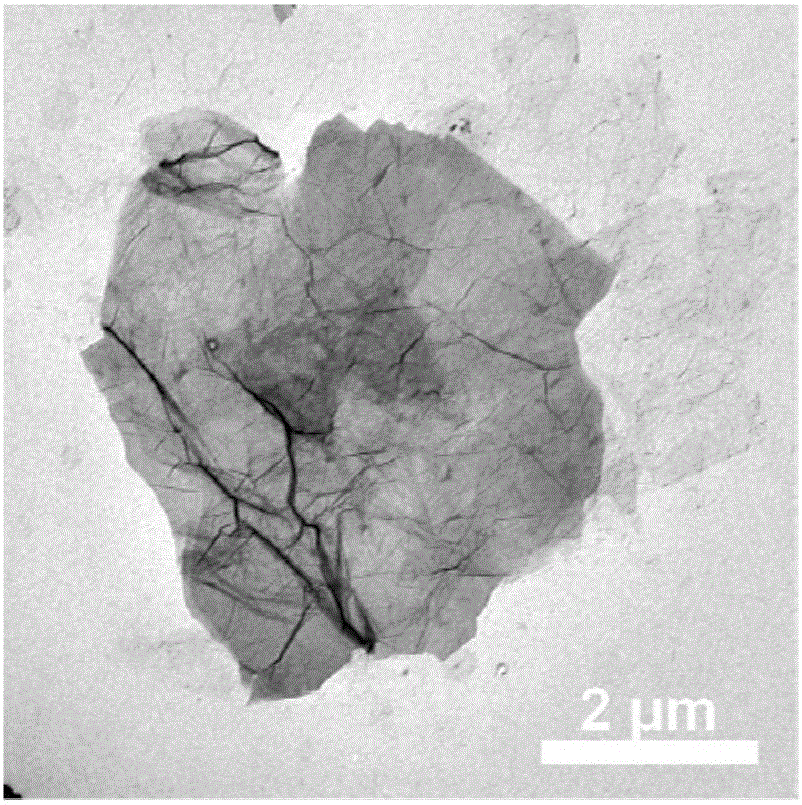

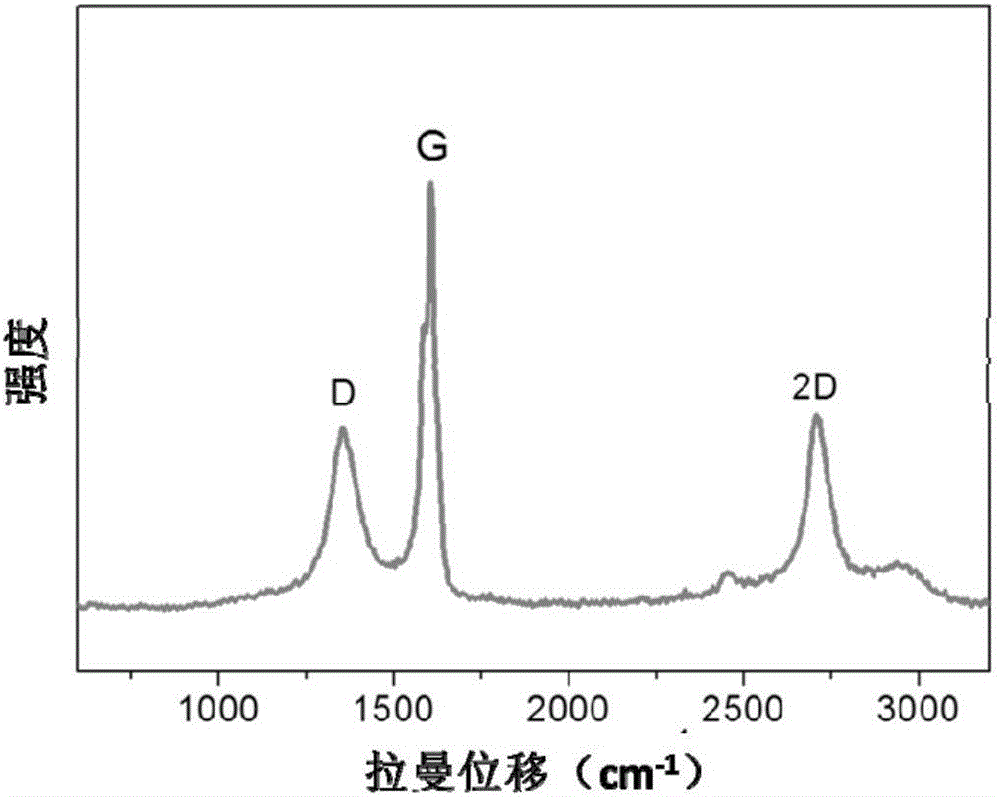

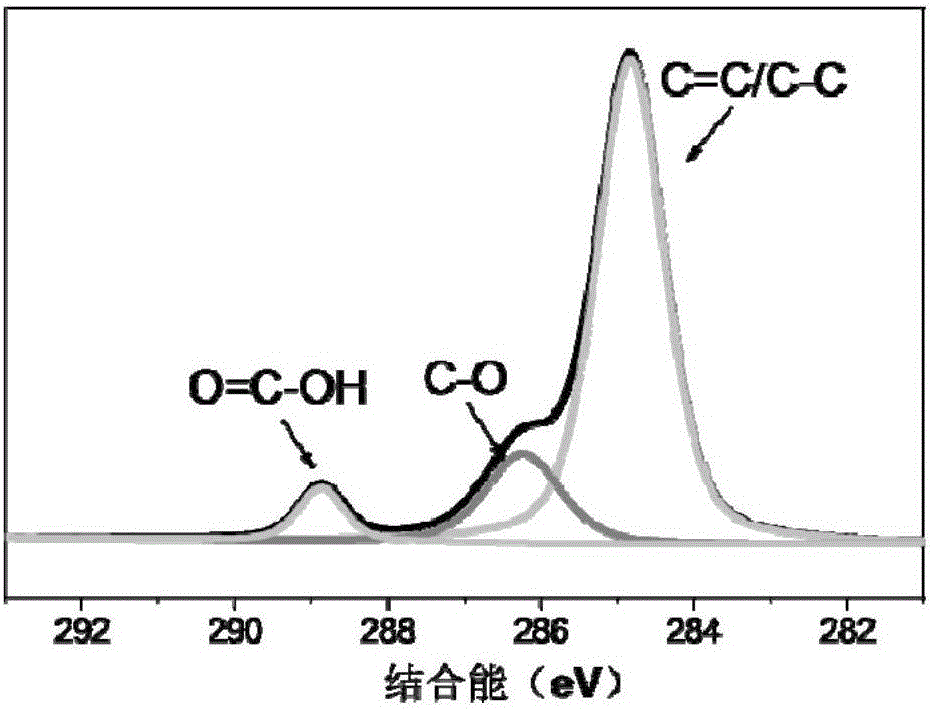

[0054] figure 1 and figure 2 Transmission electron micrograph and carbon Raman spectrum of edge-functiona...

Embodiment 2

[0058] (1) Graphene prepared by 1000 milligrams of turbulent flow method is added to 200ml H 2 SO 4 (98%), 1.8g NaClO 3 and 0.04ml H 2 o 2 (30%) in a mixed system, stirred at 15° C. for 4 h, and then the product was repeatedly centrifuged and washed with water, thereby obtaining edge-functionalized graphene with carboxyl groups selectively modifying the edge of the sheet.

[0059] (2) Weigh 5 mg of edge-functionalized graphene, 60 mg of epoxy resin, 8 mg of talc filler, 10 mg of tributyl phosphate additive and 5 mg of m-phenylenediamine curing agent and disperse them in 80 ml of N-methylpyrrolidone, and mechanically Stir to obtain edge functionalized graphene composite anticorrosion coating.

[0060] It is applied to the surface of the substrate by spraying, and after drying, an edge-functionalized graphene composite anti-corrosion coating is obtained.

[0061] Table 1 shows that the edge-functionalized graphene anticorrosion coating of the present embodiment has excellen...

Embodiment 3

[0063] (1) 200 milligrams of graphene prepared by mechanical exfoliation method are added to 10ml H 2 SO 4 (98%), 2g KClO 3 and 0.01ml H 2 o 2 (30%) in a mixed system, stirred at 0° C. for 10 h, and then the product was repeatedly centrifuged and washed with water to obtain edge-functionalized graphene with carboxyl groups selectively modifying the edge of the sheet.

[0064] (2) Weigh 70 mg of edge-functionalized graphene and disperse it in 30 ml of water, and mechanically stir for 1 hour to obtain a single-component anti-corrosion coating with edge-functionalized graphene.

[0065] It is applied to the surface of the substrate by brushing, and after drying, an edge-functionalized graphene single-component anti-corrosion coating is obtained.

[0066] Table 1 shows that the edge-functionalized graphene anticorrosion coating of the present embodiment has excellent corrosion resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com