Three-dimensional structure multilevel-hole graphene electrode material and preparation method thereof

A technology of graphene electrode and three-dimensional structure, which is applied in the field of three-dimensional structure hierarchical porous graphene electrode material and its preparation, can solve problems such as poor performance, and achieve a simple and easy-to-operate method, excellent electrochemical stability, and high conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention relates to a three-dimensional structured hierarchical porous graphene material and a preparation method thereof, belonging to the field of energy materials. Through a simple treatment method of graphite oxide in an organic solvent, the morphology and surface properties of graphite oxide are changed, so that the reduced graphene presents a three-dimensional structure, and a hierarchical porous structure is realized after further activation. The method is environmentally friendly, simple and easy to operate, and is a material preparation process suitable for large-scale production.

[0027] The preparation method of the invention is to use an organic solvent to treat the graphite oxide to solvate the surface of the graphite oxide and make the structure wrinkle and bend. In this way, the exfoliated graphene sheets are wrinkled and bent, and are not easy to stack to form a three-dimensional structure. Then, the three-dimensional graphene is activated to incre...

Embodiment 1

[0050] Disperse 5 g of graphite oxide solids in 200 mL of ethanol, disperse ultrasonically for 2 hours to form a uniform dispersion, place the dispersion at room temperature to allow the solvent to evaporate naturally, and further vacuum-dry at 60 ° C to obtain ethanol-treated graphite oxide. Take 0.5 g of ethanol-treated graphite oxide, disperse it in 250 mL of deionized water, add 0.5 mL of hydrazine hydrate, react at 95° C. for 1 hour, filter and dry to obtain ethanol-treated graphene material. The ethanol-treated graphene material is directly mixed with KOH at a mass ratio of 1:1, activated in a nitrogen atmosphere at 800°C for 1 hour, and washed with deionized water until neutral to obtain graphene with a hierarchical porous structure;

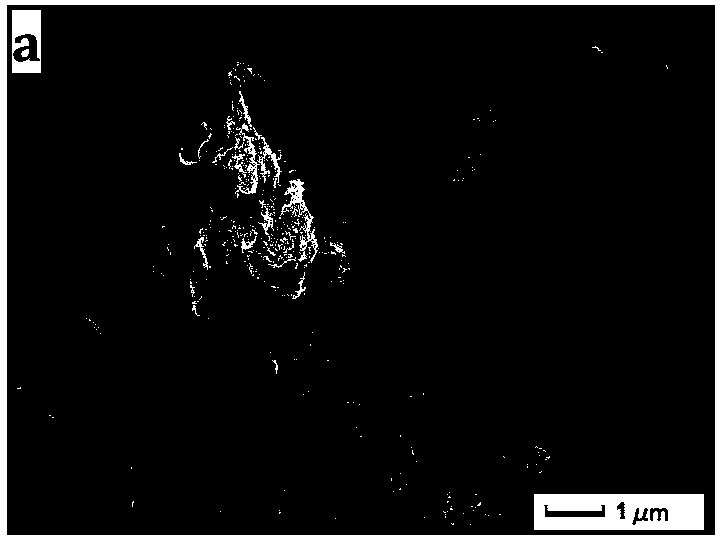

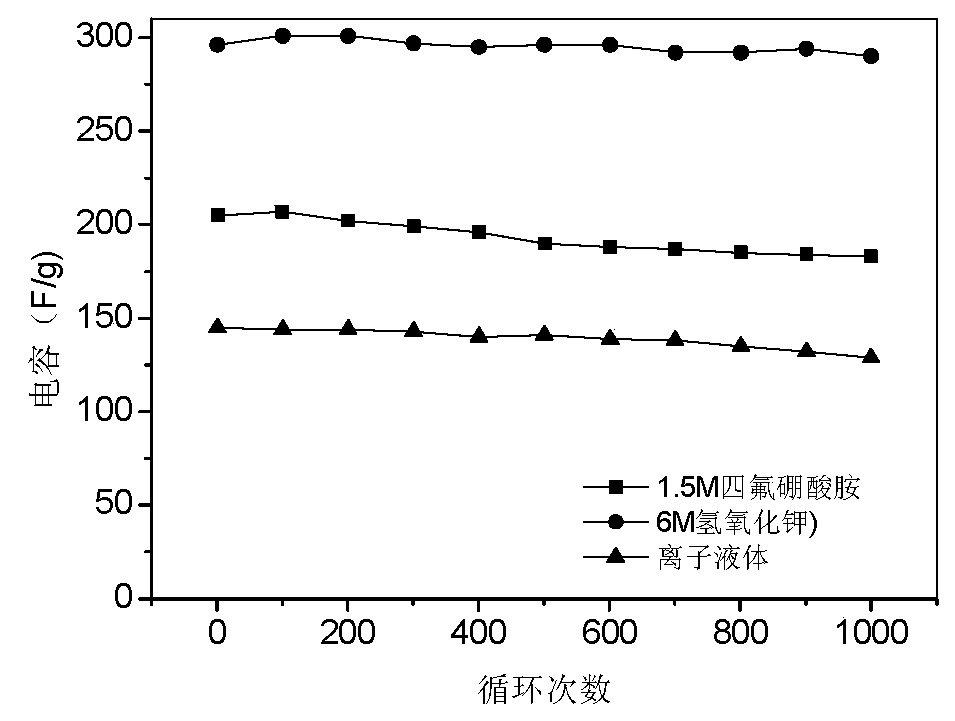

[0051] From Figure 1a and Figure 1b It can be seen that the graphene with hierarchical porous structure prepared by the present invention presents bending folds, so it is not easy to re-stack; and it can be used as an electrode material...

Embodiment 2

[0053] 5 g of graphite oxide solids were dispersed in 150 mL of methanol, and ultrasonically dispersed for 2 hours to form a uniform dispersion. The dispersion was placed at room temperature to allow the solvent to volatilize naturally to obtain methanol-treated graphite oxide. Take 0.5 g of methanol-treated graphite oxide, disperse it in 250 mL of deionized water, add 0.5 mL of hydrazine hydrate, react at 95° C. for 1 hour, filter and dry to obtain a methanol-treated graphene material. The methanol-treated graphene material was placed in an alumina boat and activated in a carbon dioxide atmosphere at 950°C for 1 hour to obtain graphene with a hierarchical porous structure, and the BET specific surface area reached 133m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com