High-dispersibility de-valence electron modified graphene lubricant and preparation method thereof

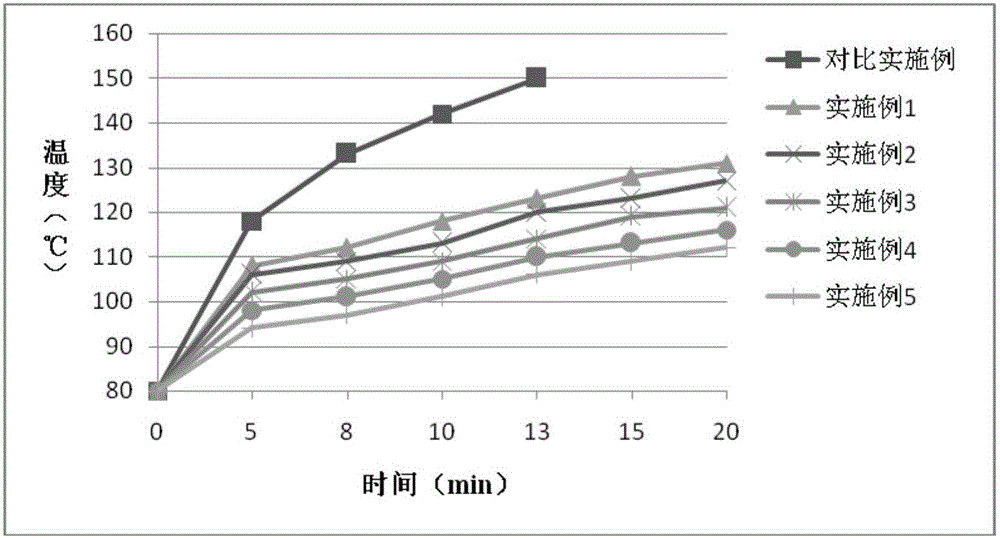

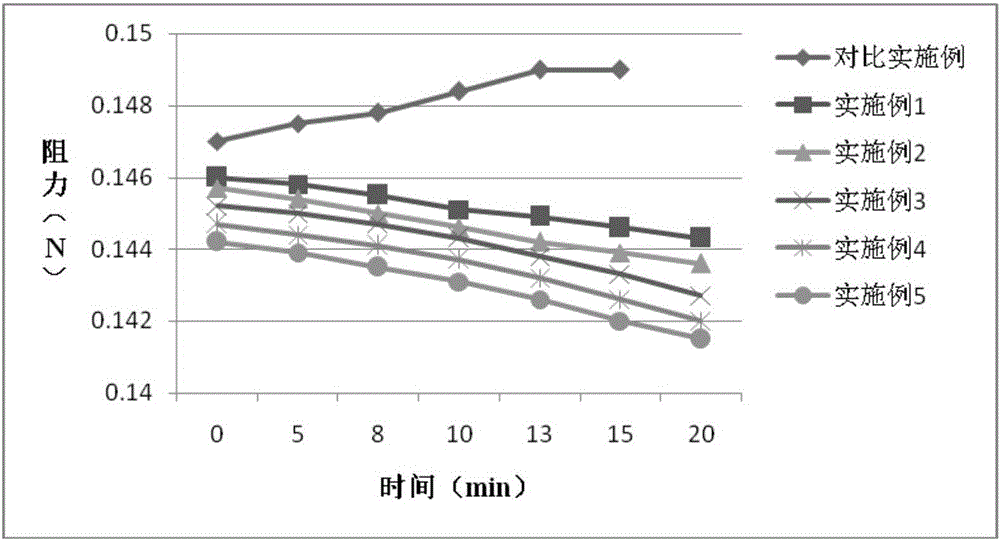

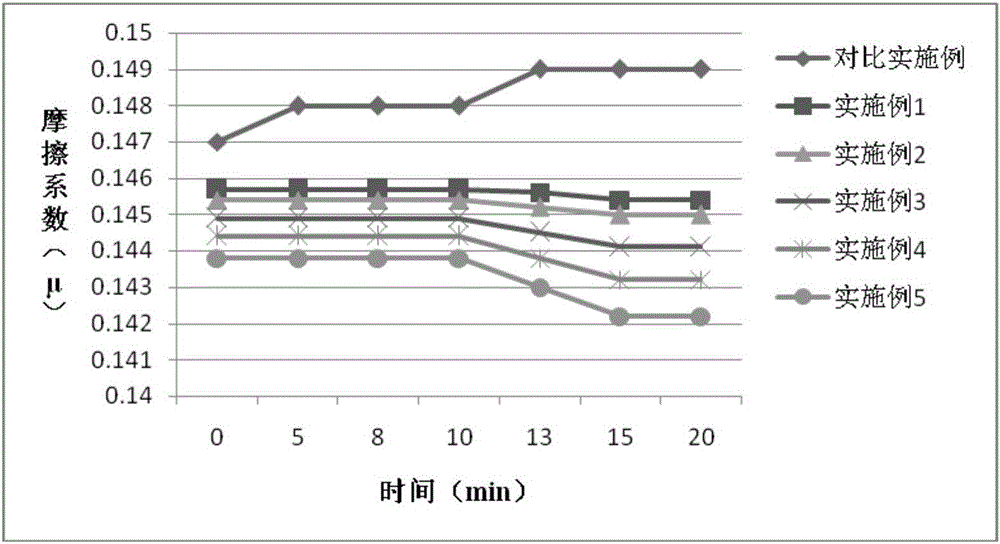

A technology of dispersion performance and graphene, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of lubricating oil dispersibility and stable point not being satisfactorily solved, easy stacking of lamellae, weak interaction, etc. Achieve the effect of improving the micro mixing rate, good heat dissipation, and improving anti-wear and anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 0.3 part of graphene oxide modified by polyoxypropylene group, 0.5 part of fatty acid glyceride, 0.2 part of acrylate-alkyl acrylate copolymer, 1 part of basic zinc salt of phosphobisoctyl, and gradually add to 100 parts of synthetic basis In the oil, stir at 1000r / min at a high speed for 0.5h, and then stir the resulting mixture at 250r / min while ultrasonically oscillating at an ultrasonic frequency of 20kHz and a power of 200W for 1h.

Embodiment 2

[0028] Take 1 part of graphene oxide modified by long-chain perfluoroalkyl, 0.6 part of fatty acid glyceride, 0.3 part of acrylate-alkyl acrylate copolymer, 3 parts of sulfur phosphorus bis-octyl basic zinc salt, and gradually add to 100 parts In the synthetic base oil, stir at a high speed of 1000r / min for 0.5h, and then stir the resulting mixture at 250r / min while ultrasonically oscillating at an ultrasonic frequency of 100kHz and a power of 300W for 1.5h.

Embodiment 3

[0030] Take 5 parts of graphene oxide modified by polysiloxane group, 0.7 part of fatty acid glyceride, 0.4 part of dimethyl silicone oil, 5 parts of sulfur phosphorus bis-octyl basic zinc salt, and gradually add them to 100 parts of synthetic base oil. Stirring at a high speed of 1000r / min for 0.5h, and then stirring the obtained mixture at 300r / min while ultrasonically oscillating at an ultrasonic frequency of 400kHz and a power of 400W for 1.5h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com