Method for making plastic transparent and semitransparent business cards

A production method and translucent technology, applied in chemical instruments and methods, temperature recording method, lamination auxiliary operation, etc., can solve the problem of low light transmittance and refractive index of translucent plastic business cards, low transparency of translucent business cards, and poor transparency High problems, to achieve the effect of strong friction resistance, improved transparency, increased refractive index and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1 of the present invention: a method for making a transparent plastic business card, comprising a printing step, a lamination step and a die-cutting step, including a printing step, a lamination step and a die-cutting step, and the transparent plastic business card is arranged from top to bottom It includes an upper nanometer material layer, an upper PET layer, an ARM base layer, a lower PET layer and a lower nanometer material layer in sequence.

[0014] First design the pattern according to the actual needs, configure the wetting solution according to the ratio, and use the ultraviolet printer to print the pattern on the ARM substrate. The wetting solution required for printing includes distilled water, fountain solution and ethanol, and its weight ratio is 87.00: 1.70:11.30, the indoor temperature is 26°C and the humidity is 47% during the printing step.

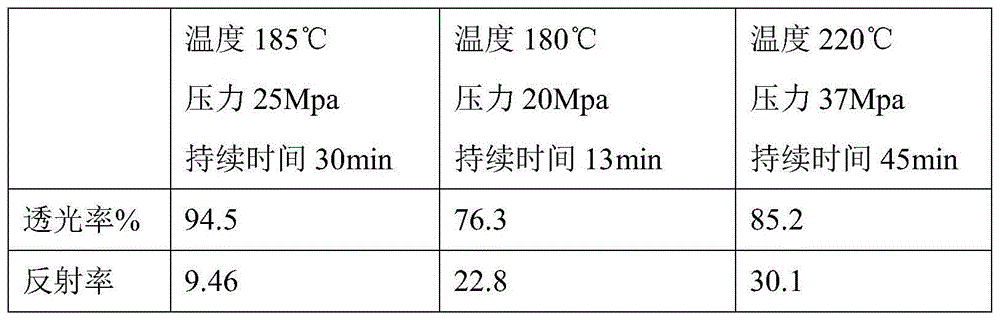

[0015] The laminating step includes stacking and arranging the upper nanomaterial layer, the upper PE...

specific Embodiment approach 2

[0017] Specific embodiment 2: A method for making a translucent plastic business card, including a printing step, a lamination step and a die-cutting step. The translucent plastic business card includes an upper nanomaterial layer, an upper PC material layer, and a PP material from top to bottom. The base layer, the lower PC material layer and the lower nanomaterial layer;

[0018] First design the pattern according to the actual needs, configure the wetting solution according to the ratio, and use the ultraviolet printer to print the pattern on the PP material substrate. The printing step uses the printing machine to print the PP material base layer, and print the required wetting solution Including distilled water, fountain solution and ethanol, the weight ratio of which is 87.90:1.67:10.53, the indoor temperature during the printing step is 25°C, and the humidity is 40%;

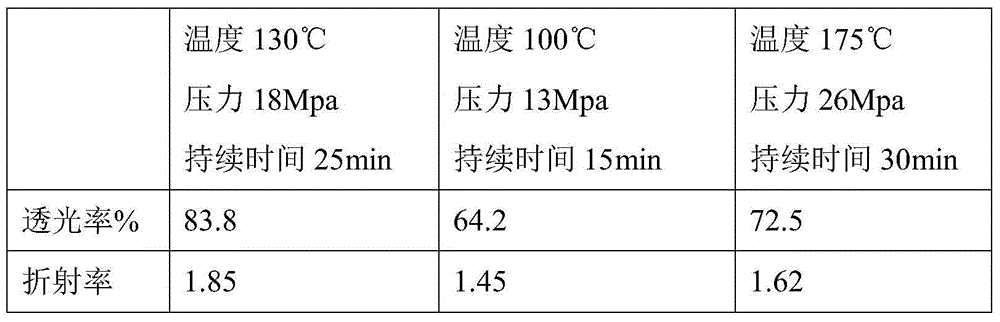

[0019] The lamination step includes stacking and arranging the upper nanomaterial layer, the upper PC ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com