Special grease composition for dual mass flywheel and preparation method thereof

A dual-mass flywheel and grease technology, which is applied in the field of grease, can solve problems such as no grease products, and achieve excellent lubrication, excellent anti-rust performance, and good high-temperature oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

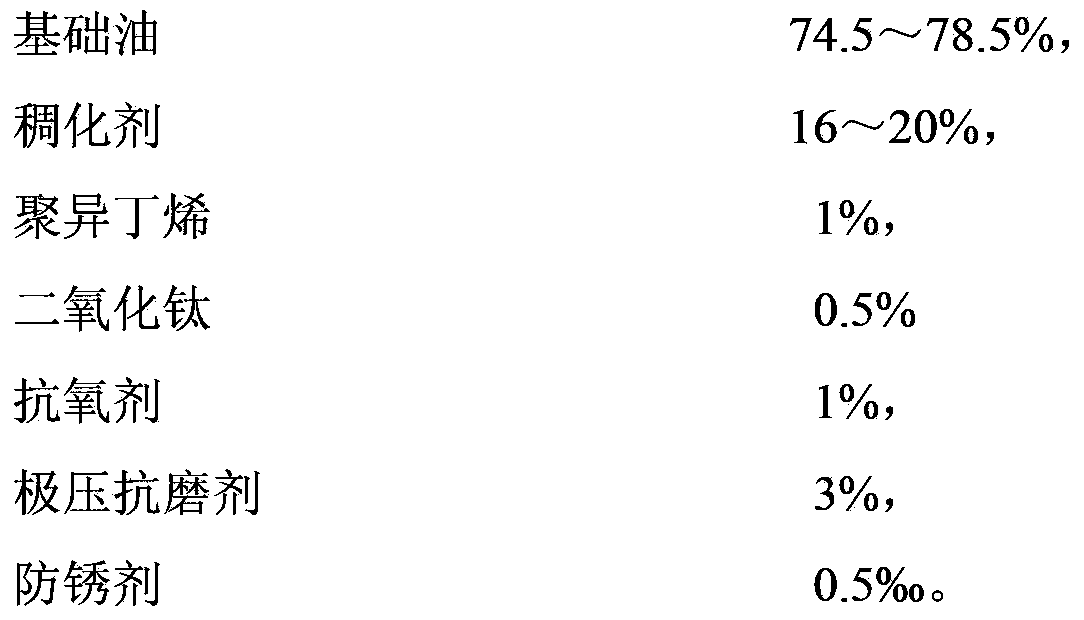

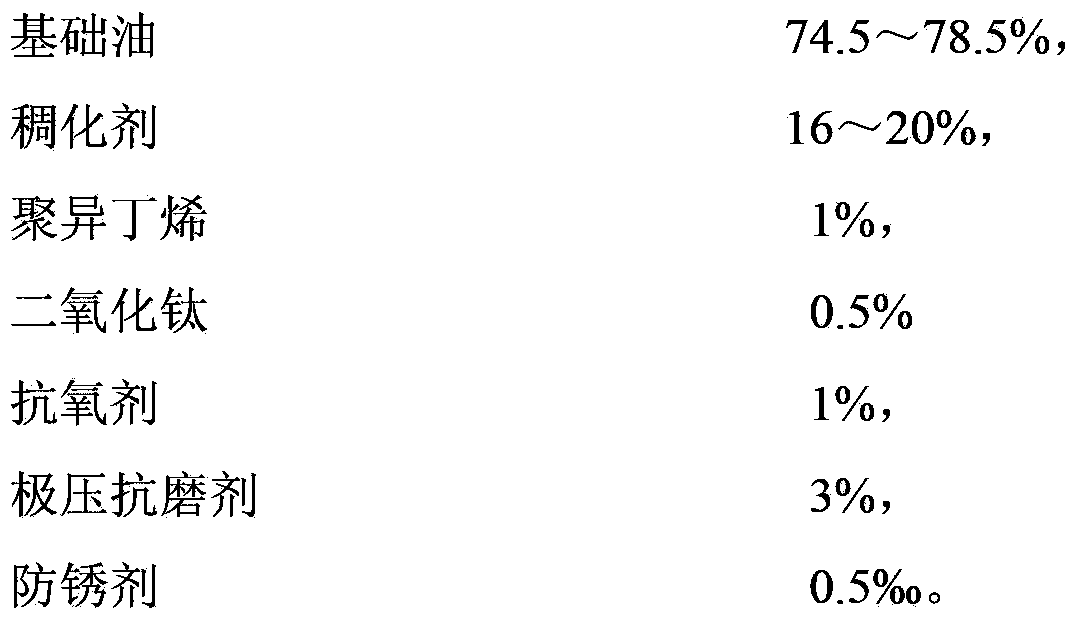

[0023]

[0024]

[0025] 400 grams of 12-hydroxystearic acid, 100 grams of azelaic acid and 700 grams of PAO (40°C viscosity 400mm 2 / s) into the reactor, heated to 90-100°C, and 102 grams of lithium hydroxide was dissolved in five times of water to prepare an alkaline solution. Add lye at 90°C of the reaction kettle, close all valves of the reaction kettle, increase the temperature and pressure, increase the pressure to 0.5-0.6MPa, heat up to 120-130°C and start constant temperature and constant pressure for 160-180 minutes. After the constant temperature is over, the temperature is increased and the pressure is released, and the pressure is released to normal pressure. At 130 to 140 ° C, 25 grams of polyisobutylene and 12.5 grams of titanium dioxide are added, and the temperature is kept constant for one hour to achieve the purpose of composite co-crystallization. After the constant temperature is over, continue to heat up, the material is heated to 200-210 °C, and the...

Embodiment 2

[0030]

[0031]

[0032] Mix 400 grams of 12-hydroxystearic acid, 100 grams of sebacic acid and 800 grams of PAO (40°C viscosity 400mm 2 / s) into the reaction kettle, heated to 90-100 °C, and 98 grams of lithium hydroxide was dissolved in five times of water to prepare an alkaline solution. Add lye at 90°C of the reaction kettle, close all valves of the reaction kettle, increase the temperature and pressure, increase the pressure to 0.5-0.6MPa, heat up to 120-130°C and start constant temperature and constant pressure for 160-180 minutes. After the constant temperature is over, the temperature is increased and the pressure is released, and the pressure is released to normal pressure. At 130-140 °C, 28 grams of polyisobutylene and 14 grams of titanium dioxide are added, and the temperature is kept constant for one hour to achieve the purpose of composite co-crystallization. After the constant temperature is over, continue to heat up, the material is heated to 200-210 °C, a...

Embodiment 3

[0037]

[0038]

[0039] Mix 400 g of 12-hydroxystearic acid, 100 g of azelaic acid and 750 g of ester oil (viscosity 380mm at 40°C) 2 / s) into the reactor, heated to 90-100°C, and 102 grams of lithium hydroxide was dissolved in five times of water to prepare an alkaline solution. Add lye at 90°C of the reaction kettle, close all valves of the reaction kettle, increase the temperature and pressure, increase the pressure to 0.5-0.6MPa, heat up to 120-130°C and start constant temperature and constant pressure for 160-180 minutes. After the constant temperature is over, the temperature is increased and the pressure is released, and the pressure is released to normal pressure. At 130-140 °C, 27 grams of polyisobutylene and 13.5 grams of titanium dioxide are added, and the temperature is kept constant for one hour to achieve the purpose of composite co-crystallization. After the constant temperature is over, continue to heat up, the material is heated to 200-210 ° C, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com