Polyricinoleate phosphate and preparation method thereof, and application of polyricinoleate phosphate in preparing biodegradable trace cutting oil

A technology of ester phosphate and ricinoleic acid, applied in the field of polyricinoleic acid phosphate and its preparation, biodegradable micro-cutting oil, to achieve good lubricity and extreme pressure anti-wear properties, good biodegradability, and low pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

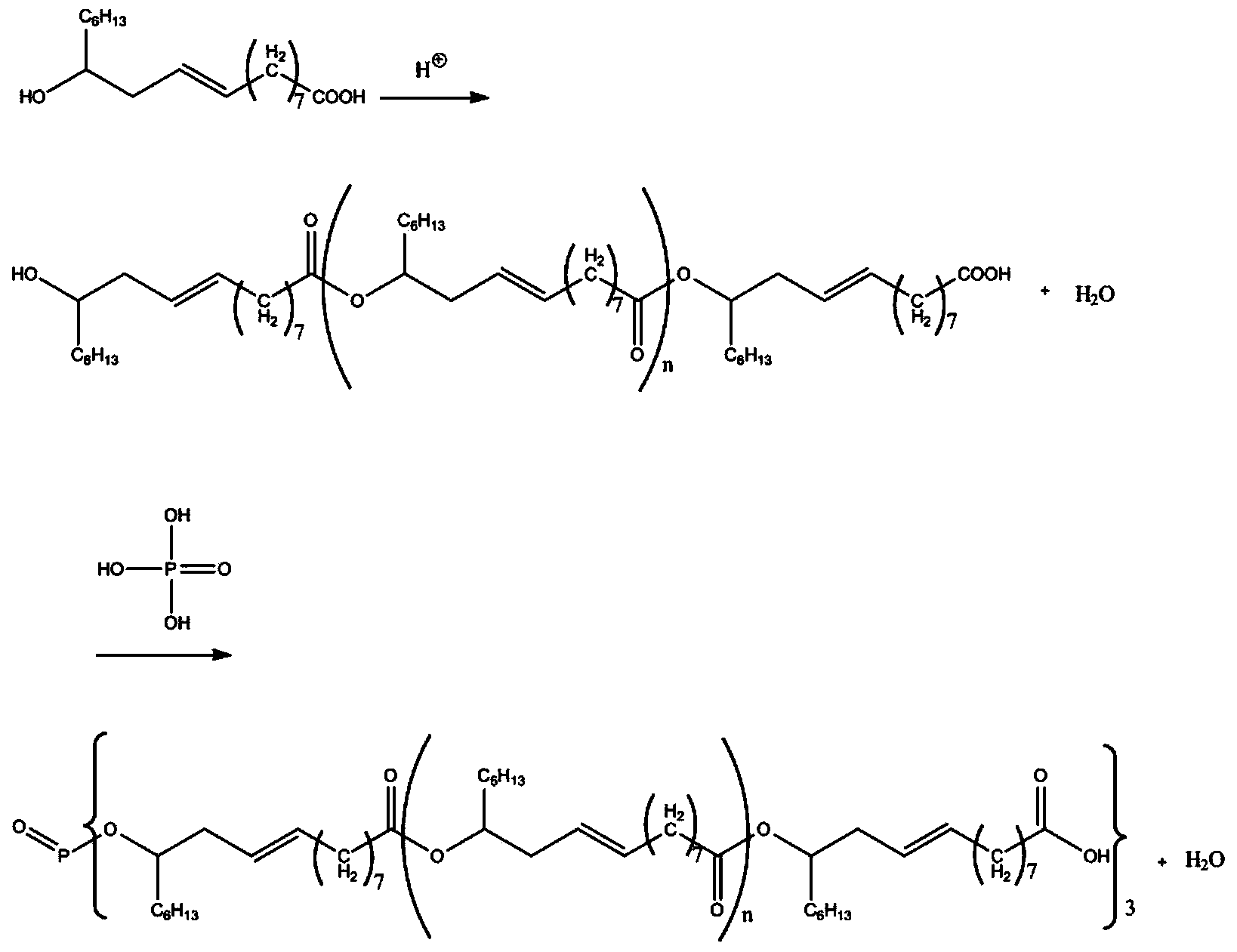

Method used

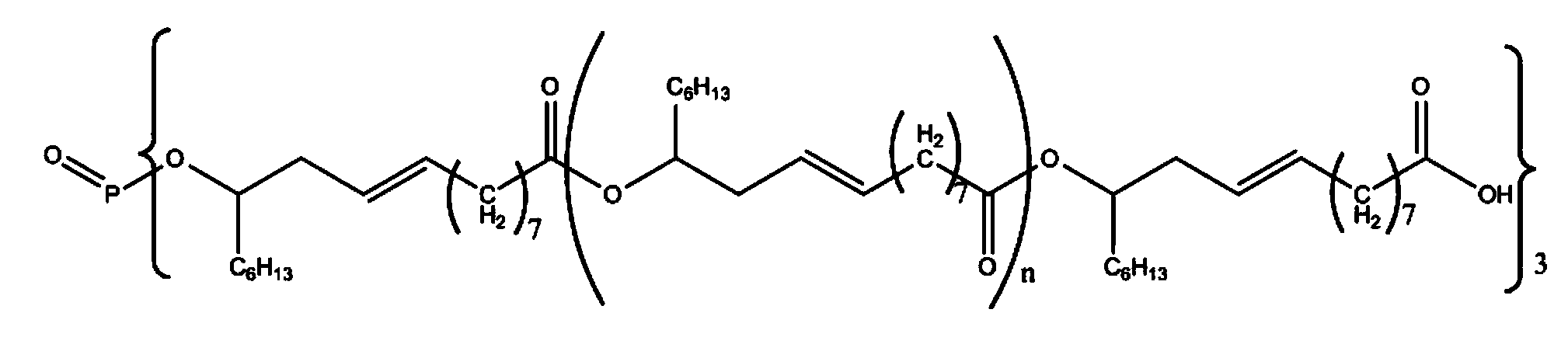

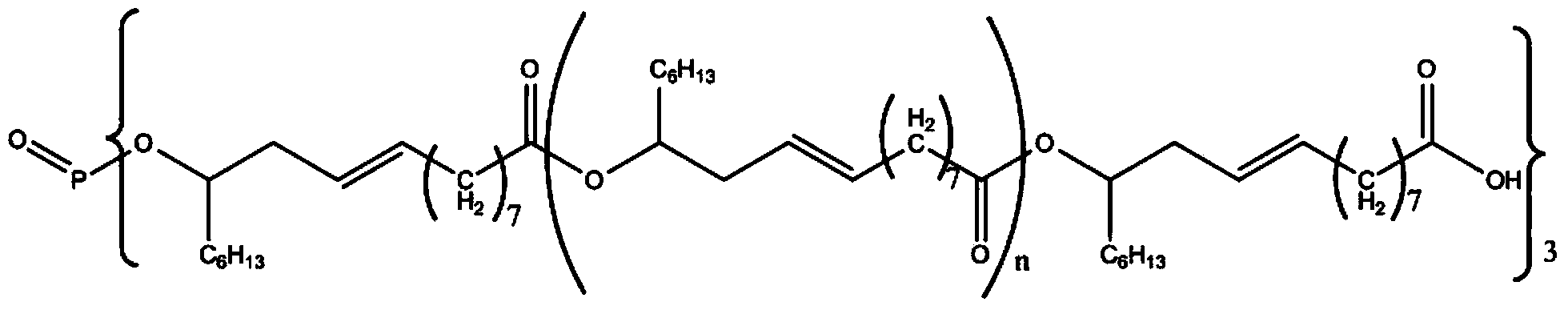

Image

Examples

Embodiment 1

[0032] 1# biodegradable micro cutting oil

[0033] Weigh 90kg of ricinoleic acid and 10kg of phosphoric acid into the polymerization kettle, fill with nitrogen to replace the air in the kettle, stir and heat up to 200°C for 4 hours, remove water under reduced pressure, and obtain a viscosity of 1800mm at 40°C 2 / s polyricinoleate phosphate;

[0034] The above-mentioned polyricinoleic acid ester phosphate 50kg and 40 ℃ viscosity 5mm 2 / s50kg of methyl oleate was mixed and stirred for 30 minutes to obtain 1# biodegradable micro cutting oil with a viscosity of 87mm at 40°C 2 / s.

Embodiment 2

[0036] 2# biodegradable micro cutting oil

[0037] Weigh 95kg of ricinoleic acid and 5kg of phosphoric acid into the polymerization kettle, fill with nitrogen to replace the air in the kettle, stir and heat up to 180°C for 3 hours, remove water under reduced pressure, and obtain a viscosity of 650mm at 40°C 2 / s polyricinoleate phosphate;

[0038] The above-mentioned polyricinoleic acid ester phosphate 60kg and 40 ℃ viscosity 8mm 2 / s40kg of dioctyl sebacate was mixed and stirred for 30 minutes to obtain 40°C viscosity of 2# biodegradable trace cutting oil 78mm 2 / s.

Embodiment 3

[0040] 3# biodegradable micro cutting oil

[0041] Weigh 94kg of ricinoleic acid and 6kg of phosphoric acid into the polymerization kettle, fill with nitrogen to replace the air in the kettle, stir and heat up to 190°C for 3.5 hours, remove water under reduced pressure, and obtain a viscosity of 950mm at 40°C 2 / s polyricinoleate phosphate;

[0042] The above-mentioned polyricinoleic acid ester phosphate 55kg and 40 ℃ viscosity 4mm 2 / s45kg of ethyl caprate was mixed and stirred for 30 minutes to obtain 3# biodegradable micro cutting oil with a viscosity of 75mm at 40°C 2 / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com