Lubricating oil for vehicles and preparation method thereof

A lubricating oil and vehicle technology, applied in the field of lubricating oil, can solve the problems of loss of performance and degradation, and achieve the effect of outstanding synergistic effect, good anti-oxidation synergistic performance, and enhanced corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

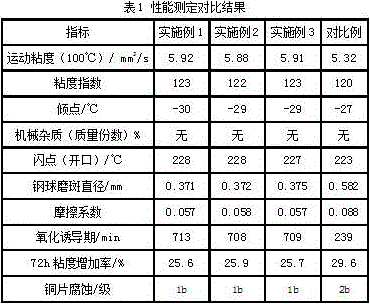

Examples

Embodiment 1

[0020] Embodiment 1: a, get 48 kilograms of 150SN base oils of Suzhou Saipahan Special Oil Co., Ltd., 7 kilograms of ricinoleic acid, 3.5 kilograms of ethylenediamine oleate, 2.5 kilograms of vinyl ether, sodium lauroyl sarcosinate ( LS-30) 3.5 kg, perfluorooctyl ethylene 1.8 kg, add to the high-speed mixer, stir at 1200-1400 rpm for 3-5 minutes at 50-55 °C;

[0021] b. Take 48 kg of 150SN base oil, 13 kg of 2-ethyldecanol, 2.5 kg of ethylene bisoleic acid amide, 4.5 kg of sodium ethylenediamine di-o-phenyl acetate, and 1.5 kg of nano bismuth oxide with a particle size of 40nm Put it into a high-speed mixer, stir at 1200-1400 rpm for 3-5 minutes at 65-70°C, and then stir for 60-80 minutes at 100-110°C with an ultrasonic stirrer;

[0022] c. Add the mixture in step b and the mixture in step a to a high-speed mixer, and stir at a speed of 1200 to 1400 rpm for 3 to 5 minutes at 45 to 50 ° C; Stir at 60°C for 60-80 minutes, then cool and serve.

Embodiment 2

[0023] Example 2: a. Take 46 kg of 150SN base oil, 6 kg of ricinoleic acid, 3 kg of ethylenediamine oleate, 2 kg of vinyl ether, 3 kg of sodium lauroyl sarcosinate (LS-30), 3 kg of perfluorinated Add 1.5 kg of octylethylene to a high-speed mixer, and stir at 1200-1400 rpm for 3-5 minutes at 50-55°C;

[0024] B, get 46 kilograms of 150SN base oil, 12 kilograms of 2-ethyl decanol, 2 kilograms of ethylene bisoleic acid amide, 4 kilograms of sodium ethylenediamine di-o-phenyl acetate, and 1.2 kilograms of nano bismuth oxide with an average particle diameter of 40nm Add it to a high-speed mixer, stir at 1200-1400 rpm for 3-5 minutes at 65-70°C, and then stir for 60-80 minutes at 100-110°C with an ultrasonic stirrer;

[0025] c. Add the mixture in step b and the mixture in step a to a high-speed mixer, and stir at a speed of 1200 to 1400 rpm for 3 to 5 minutes at 45 to 50 ° C; Stir at 60°C for 60-80 minutes, then cool and serve.

Embodiment 3

[0026] Example 3: a. Take 50 kg of 150SN base oil, 8 kg of ricinoleic acid, 4 kg of ethylenediamine oleate, 3 kg of vinyl ether, 4 kg of sodium lauroyl sarcosinate (LS-30), 4 kg of perfluorinated Add 2 kg of octylethylene to a high-speed mixer, and stir at 1200-1400 rpm for 3-5 minutes at 50-55°C;

[0027] B, get 50 kilograms of 150SN base oil, 15 kilograms of 2-ethyl decanol, 3 kilograms of ethylene bisoleic acid amide, 5 kilograms of sodium ethylenediamine di-o-phenyl acetate, and 1.8 kilograms of nano bismuth oxide with an average particle diameter of 40nm Add it to a high-speed mixer, stir at 1200-1400 rpm for 3-5 minutes at 65-70°C, and then stir for 60-80 minutes at 100-110°C with an ultrasonic stirrer;

[0028] c. Add the mixture in step b and the mixture in step a to a high-speed mixer, and stir at a speed of 1200 to 1400 rpm for 3 to 5 minutes at 45 to 50 ° C; Stir at 60°C for 60-80 minutes, then cool and serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com