TiB2 self-lubricating coating, preparation method thereof and abrasion-resistant component

A self-lubricating coating, VB2 technology, applied in coating, metal material coating process, ion implantation plating and other directions, can solve the problems of high friction coefficient of self-lubricating coating, low coating preparation efficiency and high friction coefficient, Achieve stable anti-friction effect, low friction coefficient and low environmental sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] On the other hand, the embodiment of the present invention also provides the TiB mentioned above 2 A preparation method of self-lubricating coating. Embodiment of the present invention TiB 2 The preparation method of self-lubricating coating comprises the steps:

[0028] TiB doped with vanadium 2 Ceramic as target or TiB 2 Ceramics and vanadium metal are used as targets respectively, and vanadium-doped TiB is deposited on the surface of the substrate to be deposited by magnetron sputtering. 2 Self-lubricating coating.

[0029] Among them, the selected target vanadium doped TiB 2 Ceramics can directly use conventional vanadium-doped TiB 2 Ceramic and vanadium metal targets are simple vanadium.

[0030] In one embodiment, by controlling the vanadium-doped TiB 2 The atomic percentage content of vanadium in the ceramic target or control the TiB 2 The molar ratio of ceramic and vanadium metal targets is such that the TiB 2 In the self-lubricating coating, the vanad...

Embodiment 1

[0042] This embodiment provides a TiB 2 A self-lubricating coating, a preparation method thereof, and a blade.

[0043] The TiB 2 Self-lubricating coating including hard phase TiB 2 and doped in the TiB 2 vanadium in the element.

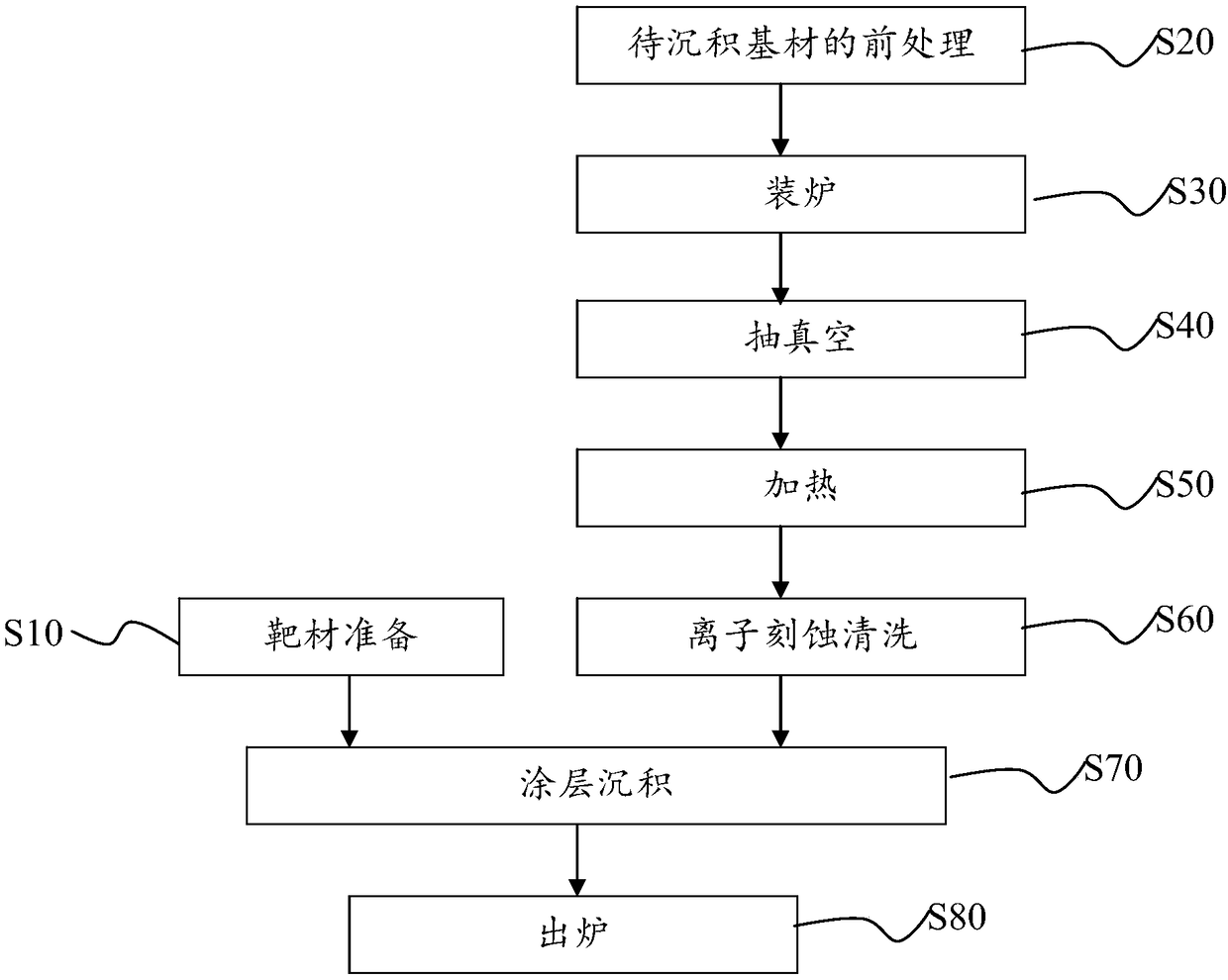

[0044] This embodiment TiB 2 The steps of the self-lubricating coating preparation method are as attached figure 2 shown, including the following steps:

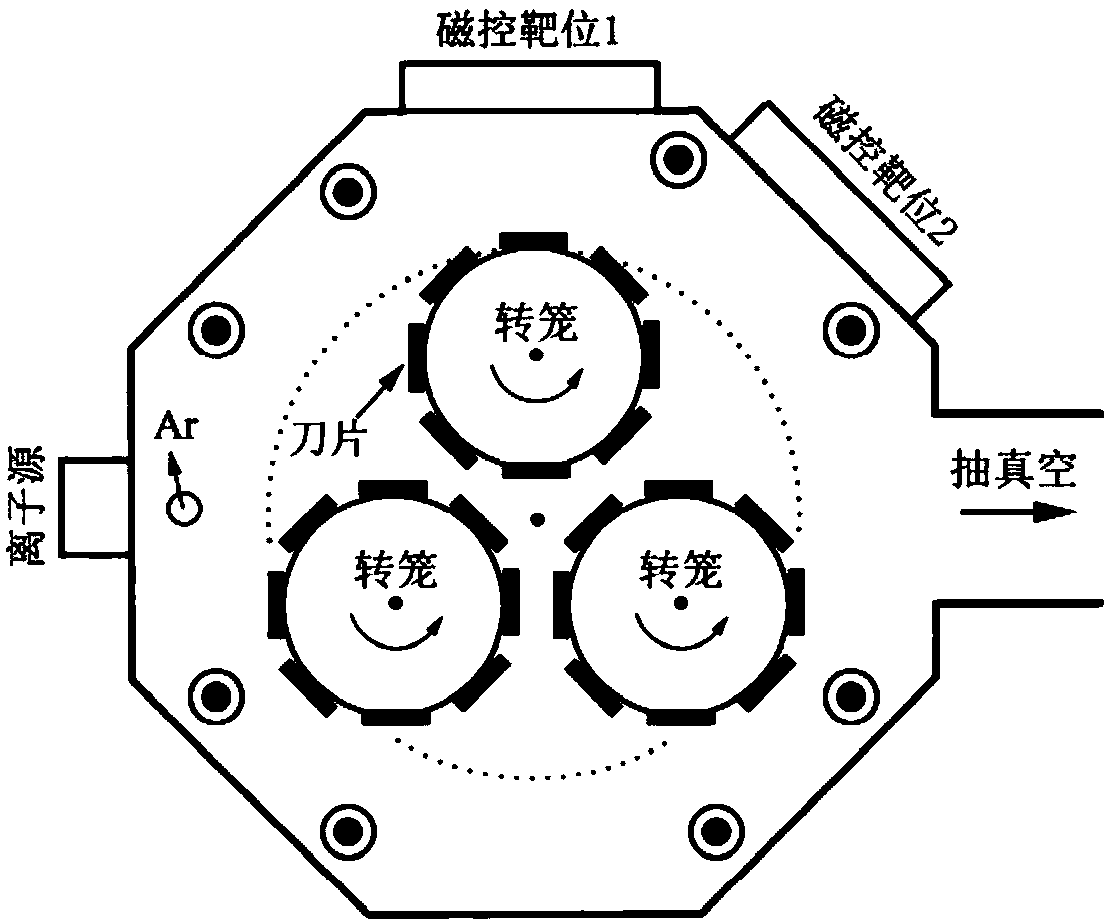

[0045] S10. Target preparation: select vanadium-doped TiB 2 The ceramic target is a sputtering target, and the vanadium-doped TiB 2 TiB with vanadium doping content of 5 at.% in ceramic target 2 ceramic targets, and mounted on such image 3 Magnetron target position 1 of the magnetron sputtering coating equipment shown;

[0046] S20. Pre-treatment: put the hard alloy blade to be deposited into an acetone solution for ultrasonic cleaning for 10-20 minutes, then put the blade into an alcohol solution for ultrasonic cleaning for 10-20 minutes, then dry the surface with dry nitrogen, and th...

Embodiment 2

[0056] This embodiment provides a TiB 2 A self-lubricating coating, a preparation method thereof and a cemented carbide end mill.

[0057] The TiB 2 Self-lubricating coating including hard phase TiB 2 and doped in the TiB 2 vanadium in the element.

[0058] This embodiment TiB 2 The steps of the self-lubricating coating preparation method are as attached figure 2 shown, including the following steps:

[0059] S10. Target preparation: choose TiB 2 A ceramic target and a vanadium metal target are used as sputtering targets, and the TiB 2 The ceramic target and the vanadium metal target are respectively installed in such as image 3 Magnetron target position 1 and magnetron target position 2 of the magnetron sputtering coating equipment shown;

[0060] S20. Pretreatment: first put the cemented carbide end mill in acetone solution for ultrasonic cleaning for 10-20 minutes, then put the end mill in alcohol solution for ultrasonic cleaning for 10-20 minutes, and then blow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com