Wear-resistant aluminum silicate refractory fibers

A technology of refractory fiber and aluminum silicate, which is applied in the direction of fiber treatment, flame retardant fiber, fiber chemical characteristics, etc., can solve the problems of performance degradation and other problems, and achieve the improvement of environmental stress resistance, high temperature resistance, strong resistance grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

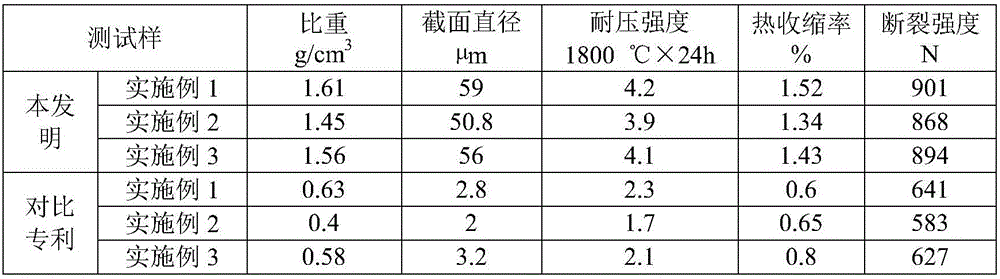

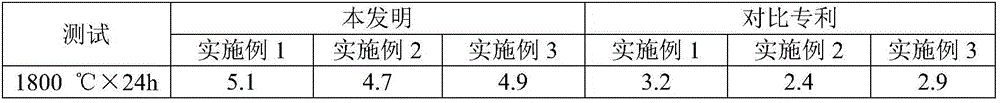

Examples

Embodiment 1

[0027] A wear-resistant aluminum silicate refractory fiber, prepared from the following components: 100g of coke powder, 55g of alumina, 30g of silicon dioxide, 32g of silicon nitride, 20g of ABS resin, 18g of polyurethane, 10g of natural rubber, carbon Black 1g, zirconate acid coupling agent 2g, dicumyl peroxide 0.6g, silica airgel 16g, dispersant 0.2g, borax 15g, refractory impregnating solution 20g, wherein the refractory impregnating solution is mixed by the following components Preparation: 50g of nano vermiculite powder, 10g of aluminum phosphate binder, 6g of titanium dioxide, 0.4g of liquid hardener, and 300g of water.

[0028] A preparation method of wear-resistant aluminum silicate refractory fiber, comprising the following steps:

[0029] (1) Calcining the burnt gemstone powder at 550°C for 1 hour, heating, melting and mixing with alumina, silicon dioxide, and silicon nitride to obtain a molten liquid, the melting temperature is 2300°C and the molten state is kept f...

Embodiment 2

[0036] A wear-resistant aluminum silicate refractory fiber, prepared from the following components: 110g of coke powder, 60g of alumina, 45g of silicon dioxide, 34g of silicon nitride, 22.5g of ABS resin, 20g of polyurethane, and 12.5g of natural rubber , carbon black 1.5g, zirconate acid coupling agent 2.5g, dicumyl peroxide 0.7g, silica airgel 18g, dispersant 0.4g, borax 20g, refractory impregnating solution 22.5g, wherein refractory impregnating solution It is made by mixing the following components: 55g of nano vermiculite powder, 12.5g of aluminum phosphate binder, 7g of titanium dioxide, 0.6g of liquid hardener, and 350g of water.

[0037] A preparation method of wear-resistant aluminum silicate refractory fiber, comprising the following steps:

[0038] (1) Calcining the burnt gemstone powder at 600°C for 1.5 hours, then heating, melting and mixing with alumina, silicon dioxide, and silicon nitride to obtain a molten liquid, the melting temperature is 2400°C and the molt...

Embodiment 3

[0045] A wear-resistant aluminum silicate refractory fiber, prepared from the following components: 120g of coke powder, 65g of alumina, 40g of silicon dioxide, 36g of silicon nitride, 25g of ABS resin, 22g of polyurethane, 15g of natural rubber, carbon Black 2g, zirconate acid coupling agent 3g, dicumyl peroxide 0.8g, silica airgel 20g, dispersant 0.6g, borax 25g, refractory dipping solution 25g, wherein the refractory dipping solution is mixed with the following components Preparation: 60g of nano vermiculite powder, 15g of aluminum phosphate binder, 8g of titanium dioxide, 0.8g of liquid hardener, and 400g of water.

[0046] A preparation method of wear-resistant aluminum silicate refractory fiber, comprising the following steps:

[0047] (1) Calcining the burnt gemstone powder at 650°C for 2 hours, heating, melting and mixing with alumina, silicon dioxide, and silicon nitride to obtain a molten liquid, the melting temperature is 2500°C and the molten state is maintained fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com